|

市场调查报告书

商品编码

1906999

绝缘包装:市场份额分析、行业趋势和统计数据、成长预测(2026-2031)Insulated Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

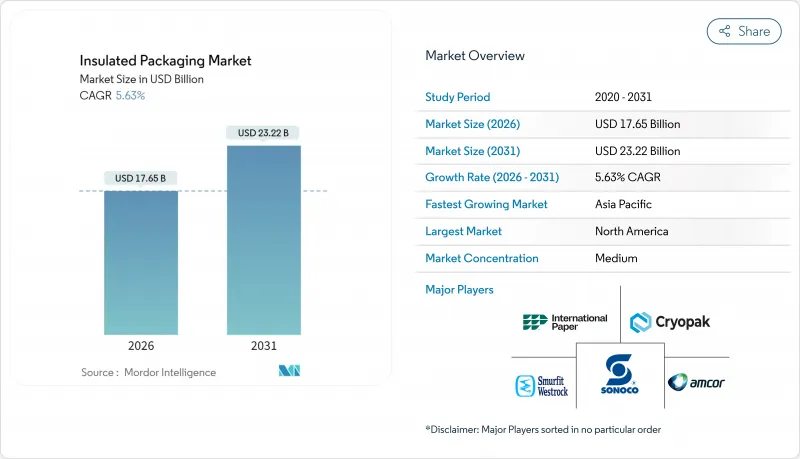

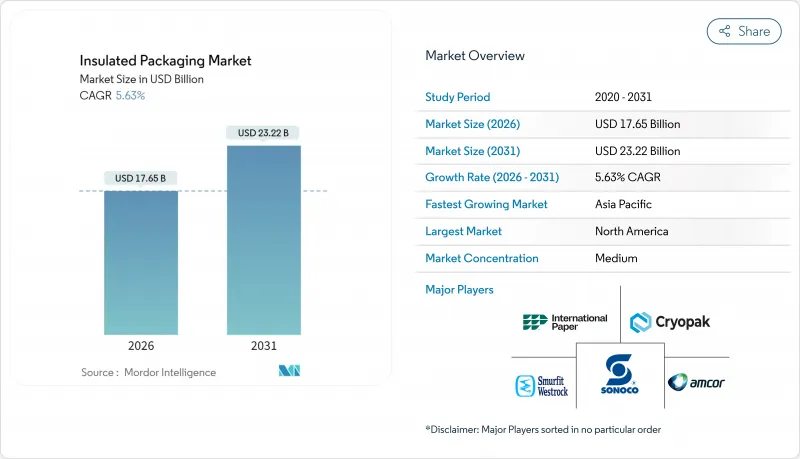

预计隔热包装市场将从 2025 年的 167.1 亿美元成长到 2026 年的 176.5 亿美元,到 2031 年将达到 232.2 亿美元,2026 年至 2031 年的复合年增长率为 5.63%。

低温运输现代化、电子商务履约需求以及监管机构对永续材料的关注正在推动这一扩张。先进的相变材料 (PCM) 和真空绝热板 (VIP) 延长了温度敏感货物的可接受运输时间,降低了货物变质风险,并为全球医疗物流提供支援。区域差异仍然存在:亚太地区的製药业持续成长,并大力投资低温运输枢纽;而北美凭藉其成熟的电子商务网络,保持着 40.1% 的收入领先优势。虽然塑胶仍然是最受欢迎的基材,但生物基气凝胶的成长速度超过了所有竞争对手,这表明终端用户除了关注性能指标外,也越来越关注处置成本和合规风险。在聚合物成本持续波动的情况下,保温包装製造商正在实现原料多元化,并采用闭合迴路模式来稳定利润率。

全球保温包装市场趋势与洞察

电子商务的扩张推动了对高效隔热运输货柜的需求

直接面向消费者的配送模式正在改变物流格局,要求供应商设计能够应对多通路配送、送货上门以及气候变迁等挑战的包装,从而确保产品品质。亚马逊投资建置温控履约中心就是一个平台自建低温运输能力的典范,旨在保护品牌价值并减少变质索赔。食材自煮包品牌每週出货量的成长意味着对保温包装的需求将更加稳定和频繁。因此,保温包装市场正朝着轻量化、模组化的方向发展,以支援自动化分类并降低运费附加费。需求分析也促使生产商采用QR码感测器,以便在包裹温度异常时提醒承运商,并仅对超过设定阈值的包裹进行退款。展望2025年,各大电商零售商正越来越多地发布将供应商合约与已验证的配送路线数据挂钩的绩效指标,从而巩固对高性能隔热材料的持续投资。

全球低温运输投资增加,涵盖生物製药和食材自煮包

细胞和基因疗法、疫苗以及单株抗体需要低至-80°C的温度控制,这迫使製药公司投资建造包含冗余电源、现场相变材料填充设备和检验的包装材料的配送中心。同时,食材自煮包服务商也在扩展菜单,纳入更多冷藏蛋白质和生鲜食品。这些趋势推动了冷藏仓库全年运转率的提高,并持续刺激了对能够填补週末服务空白的物流公司的需求。一些成功的包装供应商现在提供通用系统,只需更换相变材料模组,即可同时满足-20°C生物製药和0-4°C生鲜食品的储存需求,从而减少物流合作伙伴的库存单位(SKU)数量。美国食品药物管理局(FDA)和欧洲监管机构的审核进一步强化了合规性溢价,并加速了对可追踪保温生产线的投资。

聚合物价格波动对加工商的利润率带来压力。

发泡聚苯乙烯和聚氨酯的生产依赖苯乙烯和异氰酸酯这两种原料,而它们的价格与基准原油价格同步波动。这使得加工商面临成本突然上涨的风险,而客户合约通常会锁定价格6到12个月。避险策略可以部分缓解此风险,但对于中型企业而言,这需要大量的流动资金投入。利润率的压缩阻碍了新模具和验证研究的资本预算,从而延缓了保温包装产品的更新换代週期。一些加工商正在用回收材料取代原生聚合物以降低成本,但供应的波动限制了其在医药级包装中的应用。持续的价格波动促使终端用户尝试使用纤维和生物聚合物替代品,抑制了保温包装市场对传统发泡材解决方案的需求。

细分市场分析

到2025年,塑胶材料将占据保温包装市场41.85%的份额,这得益于其成熟的供应链和优异的机械性能。然而,生物基气凝胶的复合年增长率将达到7.74%,这将显着蚕食发泡材在医药产业的市占率。随着可堆肥和可回收内衬的出现,采购负责人在计算废弃物处理税和用户费用时,整体合规成本将降低,保温包装市场也将从中受益。木纤维复合材料製造商正在添加水性阻隔涂层以防止冷凝,扩大其在冷冻食品产业的应用。同时,对上游工程机械回收的投资正在生产可转化为模塑块的再生PET颗粒,这些模塑块适用于堆迭。采用PET表层和纤维芯材的混合复合复合材料在较低的纸张重量下即可达到相同的保温性能(R值),在保持隔热性能的同时,包装重量最多可减轻18%。因此,材料的选择需要在保温效率、与生产线自动化的兼容性以及不断变化的掩埋税之间取得平衡。

下游原料买家正透过拓展树脂合约,将生物聚合物纳入其中,以对冲苯乙烯价格波动风险。拥有垂直整合聚合製程的供应商保持着定价权,而第三方混配商则竞相争取快速固化化学品的认证,以缩短成型週期。生命週期评估(LCA)将于2025年到期,如今已成为竞标文件中的标准内容,鼓励生产商揭露其生产过程(从摇篮到大门)的碳足迹。在保温包装产业,大型零售商也日益要求提供认证,以验证生物气凝胶原料的农业残余物来源,这对森林管理计画产生了影响。

预计到2025年,箱式容器仍将占据保温包装市场37.95%的份额,这主要得益于其与多个行业的手动和自动化拣货线的兼容性。然而,托盘式运输正以7.62%的复合年增长率快速成长,反映出市场正转向可重复使用的散装包装,以减少缓衝废弃物和搬运次数。区域配送中心集中库存并依赖包裹整合运输,因此更倾向于使用预先检验储存期限为48小时的托盘式容器。在保温包装市场,航空公司正在核准可装载于较低层甲板的全托盘VIP货箱,从而在严格的时限限制下扩大细胞疗法出口的运力。此外,电子产品製造商正在采用内建相变材料(PCM)隔热板的托盘式运输容器,以确保锂离子电池保持在国际航空运输协会(IATA)核准的温度范围内。

虽然内衬包装和缓衝材料对于小众电商小包裹仍然重要,但快速零售的食品杂货零售商正越来越多地用可直接与保温柜配合使用的模组化手提袋内衬来取代它们。轻质包装袋麵临可回收性的检验,促使製造商试用气体阻隔涂层整体聚乙烯结构。未来的成长取决于能否将尺寸规格与部署在履约中心的自主移动机器人相匹配。能够将模拟资料回馈给设计团队的公司正在优化包装形状,以在保护有效载荷的同时降低运输成本。

区域分析

到2025年,北美将占总收入的39.60%,并将继续保持最大的区域中心地位,这得益于其成熟的电子商务流程、庞大的药品生产规模和统一的配送准则。履约中心正日益与微型配送中心连接,以缩短最后一公里配送距离,这迫使包装设计师优化解决方案,以适应6-12小时的都会区环线配送。随着连锁药局推出生物製药当日送达服务,低温运输资本投资依然强劲,进一步支撑了国内保温包装的采购。

亚太地区以8.85%的复合年增长率成为全球保温包装市场成长最快的地区,这主要得益于疫苗生产群集的快速扩张、中阶对餐饮服务需求的不断增长以及政府对现代化冷藏基础设施的补贴。跨国加工企业正在化工原料供应中心附近建立合资企业,以确保树脂供应并规避进口关税。韩国和新加坡等区域出口国正在采用VIP-PCM混合技术,以确保长途飞往欧洲和北美航班的运输性能稳定。

欧洲在平衡永续性法规与先进医疗需求的同时,维持着稳定的个位数成长。随着循环经济指令提高了不可可再生发泡材的处置成本,大型食品零售商正转向使用符合回收标准的纤维基衬。东欧成员国正利用欧盟区域基金扩大冷藏能力,确保从农场到药局的温度控制统一。同时,南美洲正在扩大鱼贝类和水果出口,需要价格适中且经久耐用的EPS包装箱用于空运。此外,中东和非洲正着力于基础疫苗分发,随着收入成长和供应链现代化,这两个地区都拥有巨大的成长空间。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 电子商务的扩张带动了对保温运输货柜的需求成长。

- 全球生物製药和食材自煮包低温运输投资不断成长

- PCM和VIP技术在最后一公里配送的快速应用

- 永续性加速了向纤维基隔热材料的转变

- 拓展生鲜速卖(Q commerce)网络

- 亚太地区温度敏感型特用化学品出口

- 市场限制

- 聚合物价格波动对加工商的利润率带来压力。

- 多层包装袋挨家挨户回收的局限性

- 不同地区的热测试标准并不统一。

- 扩大生物基气凝胶生产规模的资本投资障碍

- 产业价值链分析

- 监管环境

- 技术展望

- 宏观经济因素的影响

- 波特五力分析

- 新进入者的威胁

- 买方的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模与成长预测

- 材料

- 塑胶

- 纸张和木纤维

- 玻璃

- 金属箔

- 生物基气凝胶

- 依产品类型

- 小袋和包装袋

- 盒子和容器

- 托盘运输公司

- 包装材料和衬垫

- 透过绝缘技术

- 发泡聚苯乙烯(EPS)

- 真空绝热板(VIP)

- 相变材料(PCM)系统

- 反光箔层压板

- 按最终用户行业划分

- 食品/饮料

- 製药和生物技术

- 工业化学品

- 美容及个人护理

- 其他终端用户产业

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 欧洲

- 英国

- 德国

- 法国

- 西班牙

- 义大利

- 其他欧洲地区

- 亚太地区

- 中国

- 印度

- 日本

- 澳洲

- 韩国

- 亚太其他地区

- 中东和非洲

- 中东

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 土耳其

- 其他中东地区

- 非洲

- 南非

- 肯亚

- 其他非洲地区

- 中东

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Amcor plc

- International Paper Company

- Sonoco Products Company

- Sealed Air Corporation

- Smurfit WestRock

- Cryopak Industries Inc.

- Innovative Energy Inc.

- Providence Packaging Corporation

- The Wool Packaging Company Ltd

- Thermal Packaging Solutions Ltd

- Insulated Products Corporation

- Cold Chain Technologies LLC

- Pelican BioThermal LLC

- Mondi plc

- Packaging Corporation of America

- Tetra Pak International SA

- Clondalkin Group

- Huhtamaki Oyj

- Storopack Hans Reichenecker GmbH

- Ecovative Design LLC

第七章 市场机会与未来展望

The insulated packaging market is expected to grow from USD 16.71 billion in 2025 to USD 17.65 billion in 2026 and is forecast to reach USD 23.22 billion by 2031 at 5.63% CAGR over 2026-2031.

Cold-chain modern-ization, e-commerce fulfillment demands, and regulatory attention on sustainable materials jointly steer this expansion. Advanced phase-change materials (PCM) and vacuum insulated panels (VIP) lengthen allowable transit windows for temperature-sensitive goods, lowering spoilage risk and supporting global health logistics. Regional disparities persist: Asia-Pacific experiences sustained pharmaceutical manufacturing growth and invests heavily in cold-chain nodes, whereas North America leverages mature e-commerce networks to protect a 40.1% revenue lead. Plastic remains the most common substrate, yet bio-based aerogels outpace all rivals, showing that end-users now weigh disposal costs and compliance risks alongside performance metrics. As polymer cost volatility lingers, insulated packaging producers diversify feedstocks and adopt closed-loop models to stabilize margins.

Global Insulated Packaging Market Trends and Insights

Growing E-Commerce Driven Demand for Thermal-Efficient Shippers

Direct-to-consumer delivery has re-shaped logistics, forcing suppliers to design packaging that safeguards product integrity through multi-stop carrier networks, porch dwell times, and variable climates. Amazon's investment in temperature-controlled fulfillment centers illustrates how platforms internalize cold-chain functions to protect brand equity and reduce spoilage claims. Meal-kit brands further amplify weekly volume, translating to predictable, high-frequency orders for insulated shippers. As a result, the insulated packaging market pivots toward lighter, modular formats that fit sorting automation while cutting freight surcharges. Demand analytics also prompt producers to embed QR-coded sensors that warn shippers if thermal abuse occurs, supporting refunds only when packages breach set thresholds. Across 2025, large e-commerce retailers increasingly issue performance scorecards that link supplier contracts to proven lane data, anchoring sustained investment in higher-performing insulators.

Rising Global Cold-Chain Investments in Biologics and Meal-Kits

Cell and gene therapies, vaccines, and monoclonal antibodies require temperature windows down to -80 °C, compelling drug sponsors to fund distribution nodes that include redundant power, on-site PCM charging, and validated packaging fleets. Concurrently, meal-kit operators broaden menu offerings that rely on chilled proteins and fresh produce. Together these sectors elevate year-round utilization rates of cold-room space, which in turn sustains recurring demand for shippers that can endure weekend service gaps. Successful packaging suppliers now market universal systems adaptable to both -20 °C biologics and 0-4 °C perishables by swapping PCM bricks, reducing SKU proliferation for logistics partners. Regulatory audits by the FDA and European agencies further cement a compliance premium, accelerating spend on track-and-trace enabled insulation lines

Volatile Polymer Prices Squeezing Converter Margins

Expanded polystyrene and polyurethane rely on styrene and isocyanate feedstocks whose prices swing with crude benchmarks, exposing converters to sudden cost spikes while customer contracts often lock prices for six to twelve months. Hedging strategies offer partial relief but require liquidity outlays that strain mid-tier firms. Margin compression hinders capital budgets for new tooling or validation studies, slowing the refresh cycle of insulated formats. Some converters replace virgin polymer with recycled content to buffer costs, yet inconsistent supply streams limit usage in pharmaceutical-grade packs. Persistent volatility encourages end-users to test fiber or bio-polymer substitutes, moderating demand for conventional foam-based solutions within the insulated packaging market.

Other drivers and restraints analyzed in the detailed report include:

- Rapid Adoption of PCM and VIP Technologies for Last-Mile Delivery

- Sustainability Mandates Accelerating Shift to Fiber-Based Insulators

- Limited Curbside Recyclability of Multi-Layer Pouches

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Plastic materials commanded 41.85% of the insulated packaging market size in 2025 owing to entrenched supply chains and robust mechanical properties. Yet, bio-based aerogels post an 7.74% CAGR that visibly erodes foam share in pharmaceutical corridors. The insulated packaging market benefits when procurement officers calculate disposal levies and user fees, because compostable and recyclable liners cut overall compliance spend. Manufacturers of wood-fiber composites add water-borne barrier coats to repel condensation, expanding addressable segments in frozen meals. Parallel investment in mechanical recycling upstream yields r-PET pellets that convert into molded bricks suited for pallet shippers. Hybrid composites combining PET skin with fiber core reach equivalent R-values at lower grammage, preserving thermal performance while dropping pack weight by up to 18%. Material choice therefore reflects a balancing act among insulation efficiency, line automation compatibility, and evolving landfill taxes.

Downstream, raw material buyers diversify resin contracts to include biopolymers, thus hedging against styrene volatility. Suppliers that vertically integrate polymerization steps maintain pricing power, while third-party compounders race to qualify rapid-cure chemistries enabling shorter molding cycles. Lifecycle assessments carried out in 2025 commonly form part of bid documents, nudging producers to publish cradle-to-gate carbon footprints. The insulated packaging industry also sees major retailers demand certificates verifying agricultural residue sourcing for bio-aerogels, influencing forest stewardship programs.

Boxes and containers preserved 37.95% of the insulated packaging market share in 2025 because they fit manual and automated picking lines across multiple sectors. Nonetheless, pallet shippers accelerate at 7.62% CAGR, reflecting a shift toward reusable macro-packs that cut dunnage waste and labor touches. Regional distribution centers pool inventory and rely on consolidated LTL moves, which favor pallet-level containers pre-validated for 48-hour hold times. The insulated packaging market sees airlines approve full-pallet VIP crates that ride in lower-deck positions, expanding capacity for cell therapy exports under stringent time windows. Furthermore, electronics manufacturers employ pallet shippers with PCM tiles to keep lithium-ion batteries within IATA approved temperature limits.

Liner wraps and cushions still serve niche e-commerce parcels, yet quick-commerce grocers substitute modular tote inserts that integrate directly with insulated lockers. Pouch formats, while lightweight, face recyclability scrutiny, pushing producers to trial mono-PE structures with gas-barrier coatings. Future growth hinges on harmonizing size matrices with autonomous mobile robots deployed in fulfillment hubs. Firms able to feed simulation data back to design teams optimize form factors that reduce outbound freight spend while safeguarding payloads.

The Insulated Packaging Market Report is Segmented by Material (Plastic, Paper and Wood-Fiber, Glass, Metal Foils, and More), Product Type (Pouches and Bags, Boxes and Containers, and More), Insulation Technology (Expanded Polystyrene, Vacuum Insulated Panels, and More), End-User Industry (Food and Beverage, Pharmaceutical and Biotechnology, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America represented 39.60% revenue in 2025 and remains the largest regional node thanks to mature e-commerce workflows, broad pharmaceutical manufacturing, and harmonized distribution guidelines. Fulfillment centers increasingly pair with micro-hubs to trim last-mile distance, thereby pushing pack designers to tailor solutions for six to 12-hour urban loops. Cold-chain capital spending remains robust as pharmacy chains roll out same-day biologics delivery, further sustaining domestic procurement of insulated packaging.

Asia-Pacific records a 8.85% CAGR, the fastest in the global insulated packaging market, driven by rapid expansion of vaccine production clusters, growing middle-class demand for meal services, and government subsidies for modern cold storage infrastructure. Multinational converters open joint-ventures near chemical feedstock hubs to secure resin supply while avoiding import tariffs. Regional exporters, especially in South Korea and Singapore, adopt VIP-PCM hybrids to achieve consistent lane performance on long-haul flights to Europe and North America.

Europe balances sustainability regulation with advanced healthcare needs, registering steady single-digit growth. The circular economy directive raises disposal fees on non-recyclable foams, spurring large grocers to adopt fiber-based liners that pass curbside collection tests. Eastern member states upgrade cold-room capacity via EU regional funds, ensuring harmonized temperature control from farm to pharmacy. Elsewhere, South America scales fish and fruit exports that necessitate affordable yet robust EPS boxes for airfreight, while Middle East and Africa focus on baseline vaccine distributionboth offering upside as incomes rise and supply chains modernize.

- Amcor plc

- International Paper Company

- Sonoco Products Company

- Sealed Air Corporation

- Smurfit WestRock

- Cryopak Industries Inc.

- Innovative Energy Inc.

- Providence Packaging Corporation

- The Wool Packaging Company Ltd

- Thermal Packaging Solutions Ltd

- Insulated Products Corporation

- Cold Chain Technologies LLC

- Pelican BioThermal LLC

- Mondi plc

- Packaging Corporation of America

- Tetra Pak International SA

- Clondalkin Group

- Huhtamaki Oyj

- Storopack Hans Reichenecker GmbH

- Ecovative Design LLC

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing e-commerce driven demand for thermal-efficient shippers

- 4.2.2 Rising global cold-chain investments in biologics and meal-kits

- 4.2.3 Rapid adoption of PCM and VIP technologies for last-mile delivery

- 4.2.4 Sustainability mandates accelerating shift to fiber-based insulators

- 4.2.5 Expansion of grocery quick-commerce (q-commerce) networks

- 4.2.6 Temperature-sensitive speciality chemicals exports from Asia Pacific

- 4.3 Market Restraints

- 4.3.1 Volatile polymer prices squeezing converter margins

- 4.3.2 Limited curb-side recyclability of multi-layer pouches

- 4.3.3 Inconsistent thermal-test standards across regions

- 4.3.4 Capex hurdles for scaling bio-based aerogel production

- 4.4 Industry Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Impact of Macroeconomic Factors

- 4.8 Porter's Five Forces Analysis

- 4.8.1 Threat of New Entrants

- 4.8.2 Bargaining Power of Buyers

- 4.8.3 Bargaining Power of Suppliers

- 4.8.4 Threat of Substitute Products

- 4.8.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Material

- 5.1.1 Plastic

- 5.1.2 Paper and Wood-fiber

- 5.1.3 Glass

- 5.1.4 Metal Foils

- 5.1.5 Bio-based Aerogels

- 5.2 By Product Type

- 5.2.1 Pouches and Bags

- 5.2.2 Boxes and Containers

- 5.2.3 Pallet Shippers

- 5.2.4 Wraps and Liners

- 5.3 By Insulation Technology

- 5.3.1 Expanded Polystyrene (EPS)

- 5.3.2 Vacuum Insulated Panels (VIP)

- 5.3.3 Phase-Change Material (PCM) Systems

- 5.3.4 Reflective Foil Laminate

- 5.4 By End-user Industry

- 5.4.1 Food and Beverage

- 5.4.2 Pharmaceutical and Biotechnology

- 5.4.3 Industrial Chemicals

- 5.4.4 Beauty and Personal Care

- 5.4.5 Other End-user Industries

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 United Kingdom

- 5.5.3.2 Germany

- 5.5.3.3 France

- 5.5.3.4 Spain

- 5.5.3.5 Italy

- 5.5.3.6 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 India

- 5.5.4.3 Japan

- 5.5.4.4 Australia

- 5.5.4.5 South Korea

- 5.5.4.6 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 Saudi Arabia

- 5.5.5.1.2 United Arab Emirates

- 5.5.5.1.3 Turkey

- 5.5.5.1.4 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Kenya

- 5.5.5.2.3 Rest of Africa

- 5.5.5.1 Middle East

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Amcor plc

- 6.4.2 International Paper Company

- 6.4.3 Sonoco Products Company

- 6.4.4 Sealed Air Corporation

- 6.4.5 Smurfit WestRock

- 6.4.6 Cryopak Industries Inc.

- 6.4.7 Innovative Energy Inc.

- 6.4.8 Providence Packaging Corporation

- 6.4.9 The Wool Packaging Company Ltd

- 6.4.10 Thermal Packaging Solutions Ltd

- 6.4.11 Insulated Products Corporation

- 6.4.12 Cold Chain Technologies LLC

- 6.4.13 Pelican BioThermal LLC

- 6.4.14 Mondi plc

- 6.4.15 Packaging Corporation of America

- 6.4.16 Tetra Pak International SA

- 6.4.17 Clondalkin Group

- 6.4.18 Huhtamaki Oyj

- 6.4.19 Storopack Hans Reichenecker GmbH

- 6.4.20 Ecovative Design LLC

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment