|

市场调查报告书

商品编码

1907238

木质素产品:市场占有率分析、产业趋势与统计、成长预测(2026-2031)Lignin Products - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

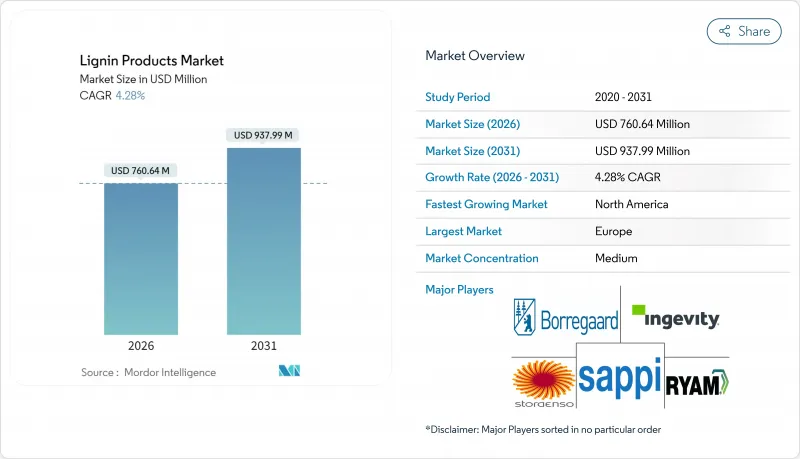

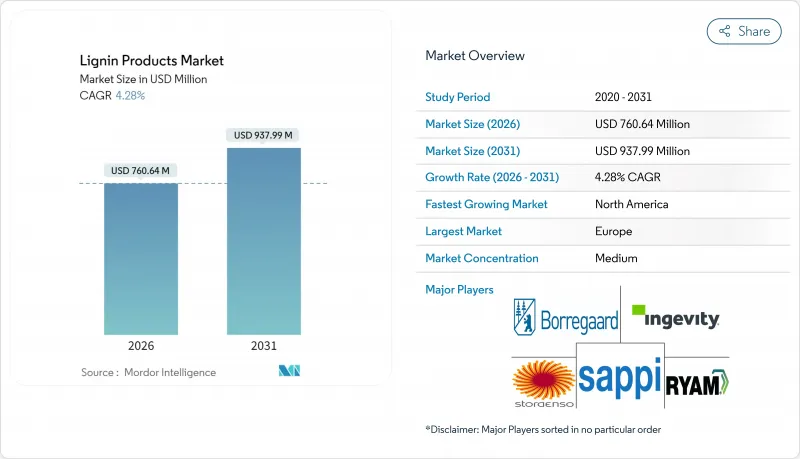

预计木质素产品市场将从 2025 年的 7.2942 亿美元成长到 2026 年的 7.6064 亿美元,到 2031 年将达到 9.3799 亿美元,2026 年至 2031 年的复合年增长率为 4.28%。

这一增长主要受以下因素驱动:对低碳建设化学品的需求不断增长、成熟经济体可持续永续性法规的日益严格,以及生物转化途径的持续创新,这些创新为木质素基芳烃的高价值应用开闢了道路。从废弃物处理向一体化高附加价值生物炼製厂的转变,增强了企业的定价权,尤其是对医药和电子价值链所需的高纯度等级产品而言。欧洲凭藉其长期累积的纸浆厂基础设施,保持着先发优势;而北美则受益于纤维素乙醇强制掺混政策和汽车轻量化计划,实现了最快成长。市场竞争强度仍然适中,一体化纸浆生产商利用规模经济优势来保护其利润,抵御小规模特种加工商的竞争。

全球木质素产品市场趋势及洞察

对高性能混凝土外加剂的需求不断增长

亚太和拉丁美洲的基础设施扩张推动了对高效减水剂的需求,这种减水剂能够提高混凝土的流动性并减少水泥消费量。木质素基外加剂可降低水灰比,使混凝土抗压强度提高15-20%,水泥用量减少8-12%。致力于获得LEED认证的建设公司倾向于采用这些生物基解决方案,以减少高层建筑和交通运输计划的碳蕴藏量。中国和印度的绿建筑标准现已推荐使用天然外加剂,这项监管措施将加速其商业化进程。製造商正在扩大产能,以满足大规模城市和公路项目对高性能混凝土的要求。预计智慧城市投资的稳定成长将在中期内持续推动对木质素高效减水剂的需求。

在动物营养学中引入木质素基饲料粘合剂

欧洲限制抗生素生长促进剂的法规正促使饲料生产商转向磺酸盐粘合剂。研究表明,与糖蜜基系统相比,木质素磺酸盐黏合剂可将颗粒饲料的耐久性提高25%至30%,从而减少饲料粉尘和运输损失。某些木质素成分具有益生元活性,能够改善反刍动物的肠道微生物群,使饲料生产商能够以更高的价格出售产品。丹麦和荷兰的生产商报告称,透过从当地纸浆厂在地采购木质素衍生物,物流成本降低了12%至15%。随着大型综合企业寻求建构无抗生素价值链,北美生产商也正在采取类似的策略。随着亚太地区畜牧业生产商转向高价值蛋白质并寻求更高的复合饲料效率,长期前景仍然强劲。

萃取过程导致品质差异

硫酸盐木质素、亚硫酸盐木质素和碱木质素在硫含量和分子量上的差异,使得对规格要求一致的用户采购产品变得复杂。亚硫酸盐木质素的硫含量比其他木质素高出20-30%,这会影响树脂固化速度,并需要特殊的加工通讯协定。下游企业需要维护平行库存和双重认证程序,导致供应链成本增加8-12%。小规模工厂很少有分析实验室来认证每一批产品,这限制了其市场进入。在建立通用测试标准和云端追溯平台成熟之前,不确定性在短期内仍将存在。因此,品质协调统一对于其在特种应用领域的广泛应用至关重要。

细分市场分析

到2025年,与硫酸盐纸浆生产相关的木质素产品市场规模将占据全球市场总规模的绝大部分,达到76.62%,这主要得益于其充足的供应和作为分散剂的成熟性能。纤维素乙醇工厂虽然规模不大,但利润丰厚,是成长最快的来源类别,预计2031年将以4.95%的复合年增长率成长。美国可再生燃料标准(RFS)和欧盟可再生能源指令II(RED-II)的生产奖励鼓励生物炼製厂整合木质素分离装置,这将带来相当于乙醇销售额12-15%的额外收入。主要位于欧洲和中国的硫酸盐纸浆生产商正透过优化回收率和推出用于混凝土和饲料的客製化等级产品来巩固其市场地位。苏打纸浆在印度和东南亚地区仍保持着重要的地位,这些地区将农业废弃物加工成低灰分木质素,为该地区的纺织化学品提供原料。

与硫酸盐原料相比,纤维素乙醇衍生的木质素通常具有较低的灰分含量和较窄的分子量分布,因此在特殊聚合物应用领域具有溢价优势。汽车复合材料的先导用户对其可预测的流变性能讚赏有加,这有助于连续纤维纺丝。随着乙醇生产商扩大产能,这种高品质木质素的供应量也在增加,进一步加强了其与生质燃料和特殊化学品产业链的整合。虽然亚硫酸盐衍生的生产方式在其他来源中占据主导地位,但竞争优势取决于每吨价值,而不仅仅是产量,尤其是在碳排放收入影响盈利的情况下。

区域分析

到2025年,欧洲将占全球木质素价值的33.55%,这得益于综合林业和严格的气候政策促进了木质素的早期增值利用。芬兰和瑞典的纸浆厂正在维修提取生产线以开拓新的收入来源,而德国混凝土和汽车产业的需求则保持稳定。 REACH化学品法规鼓励复合材料生产商转向生物基原料,从而改善了市场需求前景。欧盟「地平线欧洲」研究津贴计画正在加速香草醛和碳纤维的试点计画部署,巩固了该地区的创新主导。

预计到2031年,北美将以5.08%的复合年增长率实现最快增长,这主要得益于联邦纤维素燃料强制令将扩大木质素供应,以及汽车轻量化倡议将推动对永续复合材料的需求。美国混凝土外加剂用木质素产品市场将受益于两党共同推动的桥樑和交通现代化基础设施立法而扩大。加拿大林业公司正利用丰富的北方森林资源,在各州碳定价计画的支持下,将业务从纸浆生产拓展到特种木质素领域,这些计画有利于低排放材料的开发。墨西哥的建筑热潮也将为外加剂进口创造空间,从而补充整个北美大陆的需求。

亚太地区在应用木质素超塑化剂方面尚处于起步阶段,但成长潜力巨大。中国快速的都市化推动了混凝土消费,国家标准也开始认可木质素超塑化剂。印度正扩大利用农业废弃物生产苏打浆的规模,以生产具有成本竞争力的木质素,用于当地的饲料和染料分散剂。日本正在利用木质素的芳香骨架生产电子树脂,韩国已将木质素基化学品纳入其绿色采购清单。东南亚国协的基础设施发展计画和不断扩大的肉类生产正在推动多元化的需求,但统一的标准对于跨境贸易至关重要。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 对高性能混凝土外加剂的需求不断增长

- 木质素基饲料粘合剂在动物营养上的应用现状

- 透过为每个纸浆厂产品增加价值来产生收入

- 一种从木质素到香草醛的创新生物转化路线

- 促进木质素衍生生物碳纤维在汽车产业的应用

- 市场限制

- 萃取工艺之间的品质差异

- 对醣类衍生生物芳香化合物的竞争

- 缺乏国际木质素产品标准

- 价值链分析

- 波特五力模型

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模与成长预测

- 按来源

- 亚硫酸盐纸浆

- 纤维素乙醇

- 牛皮纸浆生产

- 苏打浆法

- 依产品类型

- 磺酸盐

- 硫酸盐木质素

- 高纯度木质素

- 苏打木质素

- 其他产品类型

- 透过使用

- 分散剂

- 混凝土添加剂

- 饲料

- 树脂

- 其他用途

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 东南亚国协

- 亚太其他地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 俄罗斯

- 北欧国家

- 其他欧洲地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率/排名分析

- 公司简介

- Borregaard AS

- Burgo Group SpA

- Domsjo Fabriker AB

- Ingevity

- Lignin Industries AB

- MetGen

- Metsa Group

- NIPPON PAPER INDUSTRIES CO., LTD.

- RYAM

- Sappi Ltd

- Stora Enso

- Suzano S/A

- UPM Biochemicals

- Valmet

第七章 市场机会与未来展望

The Lignin Products market is expected to grow from USD 729.42 million in 2025 to USD 760.64 million in 2026 and is forecast to reach USD 937.99 million by 2031 at 4.28% CAGR over 2026-2031.

Performance gains stem from rising demand for low-carbon construction chemicals, stricter sustainability regulations across mature economies, and continuing breakthroughs in bioconversion pathways that open high-value outlets for lignin-based aromatics. The shift from waste-stream disposal toward value-added biorefinery integration reinforces pricing power, especially for high-purity grades supplied to the pharmaceutical and electronics value chains. Europe preserves first-mover advantage thanks to long-standing pulp-mill infrastructure, while North America records the fastest growth on the back of cellulosic ethanol mandates and automotive lightweighting programs. Competitive intensity remains moderate, with integrated pulp producers leveraging scale to protect margins against smaller specialty processors

Global Lignin Products Market Trends and Insights

Rising Demand for High-Performance Concrete Admixtures

Infrastructure expansion across Asia-Pacific and Latin America raises the need for superplasticizers that improve flow while lowering cement consumption. Lignin-based admixtures reduce water-cement ratios, boosting compressive strength by 15-20% and cutting cement use by 8-12%. Construction firms pursuing LEED certification favor these bio-based solutions because they lower embodied carbon in high-rise and transportation projects. Green-building codes in China and India now endorse natural admixtures, providing a regulatory pull that accelerates commercialization. Producers scale up capacity to keep pace with large metro and highway contracts that specify performance concrete. Steady gains in smart-city investments anticipate durable demand for lignin superplasticizers through the medium term.

Uptake of Lignin-Based Feed Binders in Animal Nutrition

European regulations that restrict antibiotic growth promoters have moved feed formulators toward lignosulfonate binders. Studies show 25-30% better pellet durability versus molasses systems, translating into lower feed dust and reduced transport losses. Specific lignin fractions exhibit prebiotic activity that enhances ruminant gut microbiota, allowing feed companies to price at a premium. Danish and Dutch manufacturers report 12-15% logistics cost savings after sourcing local lignin derivatives from regional pulp mills. North American producers adopt similar strategies as large integrators target antibiotic-free supply chains. The long-term outlook remains strong as Asia-Pacific livestock operators shift toward higher-value protein and require efficiency gains in compound feed.

Quality Variability Across Extraction Processes

Differences in sulfur content and molecular weight between kraft, sulfite, and soda lignin complicate procurement for users that require consistent specifications. Sulfite variants carry 20-30% higher sulfur, impacting resin cure kinetics and demanding tailored processing protocols. Downstream firms maintain parallel inventories and dual qualification programs, inflating supply-chain spending by 8-12%. Smaller mills rarely possess analytical labs to certify each batch, restricting market access to low-margin outlets. Near-term uncertainty remains until shared testing standards emerge and cloud-based traceability platforms mature. Quality harmonization is therefore pivotal for broader adoption in specialty segments.

Other drivers and restraints analyzed in the detailed report include:

- Valorisation of Pulp-Mill Side-Streams for Circular Revenue

- Breakthrough Lignin-to-Vanillin Bioconversion Routes

- Competition from Sugar-Derived Bio-Aromatics

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

The lignin products market size linked to sulfite pulping totaled the bulk of global value, securing 76.62% in 2025 on the back of abundant volumes and well-known performance in dispersants. Cellulosic ethanol plants offer much smaller but higher-margin flows, and their 4.95% CAGR makes them the most dynamic source category to 2031. Production incentives under the U.S. Renewable Fuel Standard and EU RED-II encourage biorefineries to integrate lignin separation units, adding revenue equal to 12-15% of ethanol sales. Sulfite operators, chiefly in Europe and China, defend position by optimizing recovery yields and launching tailor-made grades for concrete and feed. Soda pulping keeps niche importance in India and Southeast Asia, processing agricultural residues into low-ash lignin for regional textile chemicals.

Cellulosic ethanol lignin typically displays lower ash and narrower molecular-weight distribution than kraft material, granting it a premium in specialty polymers. Pilot users in automotive composites value the predictable rheology that aids continuous fiber spinning. As ethanol producers scale capacity, supply of this high-quality lignin grows, tightening integration between biofuel and specialty chemical chains. Although sulfite volumes dwarf other sources, competitive dynamics hinge on value per ton rather than tonnage alone, especially as carbon revenue streams influence profitability.

The Lignin Products Market Report is Segmented by Source (Sulfite Pulping, Cellulosic Ethanol, Kraft Pulping, and Soda Pulping), Product Type (Lignosulfonate, Kraft Lignin, and Other Product Types), Application (Dispersant, Concrete Additive, and Other Applications), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Europe held 33.55% of global value in 2025 because integrated forest industries and strict climate policies foster early lignin valorization. Pulp mills in Finland and Sweden retrofit extraction lines to capture new revenue, while German concrete and automotive sectors absorb steady volumes. REACH chemicals regulation nudges formulators toward bio-derived inputs, improving demand visibility. Horizon Europe research grants accelerate pilot deployments in vanillin and carbon-fibre, solidifying the region's innovation leadership.

North America posts the fastest 5.08% CAGR through 2031 as federal cellulosic fuel mandates widen lignin supply and automotive lightweighting efforts raise the bar on sustainable composites. The lignin products market size for concrete admixtures climbs in the United States on the back of the Bipartisan Infrastructure Law, which modernizes bridges and transit. Canadian forestry companies leverage abundant boreal resources to diversify beyond pulp into specialty lignin, supported by provincial carbon-pricing mechanisms that favor low-emission materials. Mexico's construction boom also creates room for admixture imports, rounding out continental demand.

Asia-Pacific stands at an earlier adoption curve yet offers vast upside. China's rapid urbanization elevates concrete consumption, and state standards begin to recognize lignin superplasticizers. India scales soda pulping for agri-residue, producing cost-competitive lignin for local feed and dye dispersants. Japan exploits lignin's aromatic backbone in electronics resins, while South Korea includes lignin-based chemicals in green-procurement lists. Ongoing ASEAN infrastructure initiatives and growing meat production foster multipronged demand, though standards harmonization will be critical for cross-border trade.

- Borregaard AS

- Burgo Group S.p.A.

- Domsjo Fabriker AB

- Ingevity

- Lignin Industries AB

- MetGen

- Metsa Group

- NIPPON PAPER INDUSTRIES CO., LTD.

- RYAM

- Sappi Ltd

- Stora Enso

- Suzano S/A

- UPM Biochemicals

- Valmet

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rising Demand for High-Performance Concrete Admixtures

- 4.2.2 Uptake of Lignin-Based Feed Binders in Animal Nutrition

- 4.2.3 Valorisation of Pulp-Mill Side-Streams for Circular Revenue

- 4.2.4 Breakthrough Lignin-To-Vanillin Bioconversion Routes

- 4.2.5 Automotive Push for Lignin-Derived Bio-Carbon Fibre

- 4.3 Market Restraints

- 4.3.1 Quality Variability Across Extraction Processes

- 4.3.2 Competition from Sugar-Derived Bio-Aromatics

- 4.3.3 Lack of International Lignin Product Standards

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitute Products

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Source

- 5.1.1 Sulfite Pulping

- 5.1.2 Cellulosic Ethanol

- 5.1.3 Kraft Pulping

- 5.1.4 Soda Pulping

- 5.2 By Product Type

- 5.2.1 Lignosulfonate

- 5.2.2 Kraft Lignin

- 5.2.3 High-Purity Lignin

- 5.2.4 Soda Lignin

- 5.2.5 Other Product Types

- 5.3 By Application

- 5.3.1 Dispersant

- 5.3.2 Concrete Additive

- 5.3.3 Animal Feed

- 5.3.4 Resins

- 5.3.5 Other Applications

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 ASEAN Countries

- 5.4.1.6 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Russia

- 5.4.3.6 NORDIC Countries

- 5.4.3.7 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share/Ranking Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Borregaard AS

- 6.4.2 Burgo Group S.p.A.

- 6.4.3 Domsjo Fabriker AB

- 6.4.4 Ingevity

- 6.4.5 Lignin Industries AB

- 6.4.6 MetGen

- 6.4.7 Metsa Group

- 6.4.8 NIPPON PAPER INDUSTRIES CO., LTD.

- 6.4.9 RYAM

- 6.4.10 Sappi Ltd

- 6.4.11 Stora Enso

- 6.4.12 Suzano S/A

- 6.4.13 UPM Biochemicals

- 6.4.14 Valmet

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment