|

市场调查报告书

商品编码

1907241

积层製造与材料:市场占有率分析、产业趋势与统计、成长预测(2026-2031)Additive Manufacturing And Materials - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

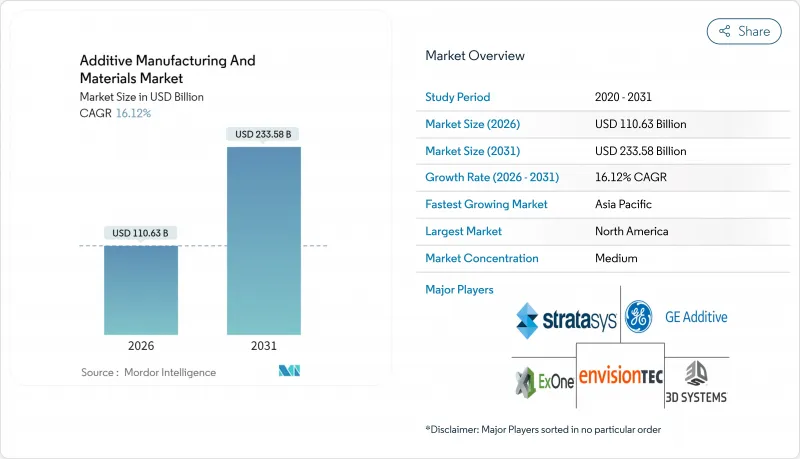

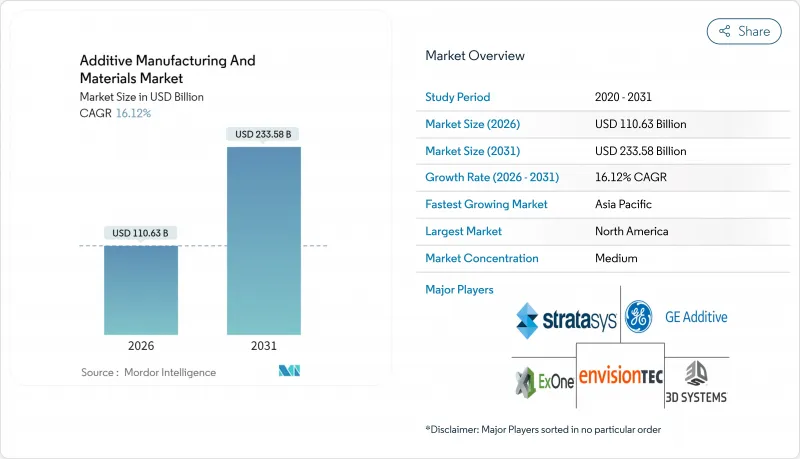

预计积层製造和材料市场将从 2025 年的 952.7 亿美元成长到 2026 年的 1,106.3 亿美元,预计到 2031 年将达到 2,335.8 亿美元,2026 年至 2031 年的复合年增长率为 16.12%。

受材料价格下降、轻量化航太零件需求以及医疗领域快速应用等因素的推动,积层製造和材料市场正从原型製作阶段迈向大规模生产阶段。美国美国标准与技术研究院 (NIST) 和美国材料与试验协会 (ASTM) 的标准化项目提供了一套统一的认证流程,降低了认证成本;北美、欧洲和亚太地区的政府激励措施也加速了工厂层面的采用。随着供应商将软体、印表机和认证粉末整合到产品中,提供满足工业运转率要求的承包生产线,市场竞争日益激烈。同时,循环经济政策正促使生产商对回收聚合物和金属原料进行认证,这在拥有成熟废弃物处理能力的地区带来了成本和永续性优势。航太机构对在轨金属列印技术的检验,开启了原位微型生产的长期发展前景,从而减少了高成本的发射品质。

全球积层製造及材料市场趋势及洞察

汽车和航太领域对轻量化零件的需求

航太原始设备製造商 (OEM) 正在将多部件组装整合为单一列印件,以减轻飞机重量并降低维护成本。通用电气航空集团的列印燃油喷嘴可取代 20 个零件,为航空公司每架飞机节省 160 万美元的生命週期营运成本。波音公司将钛合金格栅支架整合到 787 飞机中,在满足结构标准的前提下,降低了 200 万至 300 万美元的零件成本。汽车製造商正在将类似的整合技术应用于电池外壳和煞车系统,从而延长电动车的续航里程。拓朴优化软体能够实现机械加工无法实现的有机形状,使早期采用者获得性能优势。 ASTM F2792 标准中的标准化定义统一了术语和测试方法,有助于认证机构加快飞行关键零件的核准。

患者客製化医疗植入的快速普及

粉末层熔融技术能够製造出与个体解剖结构相符的多孔钛植入,从而改善骨整合并降低失败率。史赛克公司已生产超过200万个均质植入物,证明了医院级积层製造工作流程的扩充性。美国FDA的即时护理指南允许认证医院在院内列印手术导板,从而缩短前置作业时间并降低库存成本。分散式生产将价值从集中式工厂转移到临床现场,并减少了物流投入。随着航太领域供应趋紧,不断增长的高端需求迫使钴铬合金和钛粉供应商扩大雾化产能。

高性能金属和聚合物高成本

PEEK、PEKK 和航太级钛粉价格高昂,小规模订单化工厂难以负担。雾化器产能有限,等离子喷涂製程能耗庞大,推高了原料成本,而买家又要求批量折扣。供应商夹在要求折扣的客户和要求研发资金的投资者之间,进退两难,导致下一代材料的推出被推迟。因此,汽车和消费品产业目前只采购原型产品和高利润零件,直到成本下降。

细分市场分析

指向性能量沉积技术正以16.98%的复合年增长率快速增长,这主要得益于航太发动机维修领域的需求,该领域所需的公制零件数量超过了粉末床层压成型技术的需求。该领域采用线材作为原料,其成本比粉末低30-50%,因此可重复利用其他系统中剩余的材料。同时,熔融沈积成型(FDM)技术在积层製造和材料市场中占据39.68%的份额,这主要得益于其在教育和设计领域的广泛应用,以及在低应力工业夹具方面的应用。混合式CNC-增材製造平台结合了雷射覆层和五轴加工技术,可在单次装夹中实现所需的公差和表面光洁度。

粉末层熔融仍然是晶格密集型植入和层厚小于 80µm 的火箭涡轮泵零件的基准技术。黏着剂喷涂成型正在发展,可用于製造钢製泵壳和砂型铸造模具,一旦烧结瓶颈得到解决,即可显着提高生产效率。新兴的微波体积製造系统有望实现数量级更快的速度,预示着未来製造时间将不再决定单位经济效益。

区域分析

到2025年,北美将占据积层製造和材料市场36.45%的份额,主要得益于国防预算、NASA的深空探勘计画以及成熟的供应商生态系统。联邦税收优惠和第174条研发费用会计规定正在推动对新生产线的资本投资。 FDA针对3D列印植入的510(k)指南正在缩短医疗设备OEM厂商的产品上市时间,并促进国内粉末消费。

亚太地区是成长最快的地区,复合年增长率达16.55%,这主要得益于中国为减少对进口发动机零件的依赖而加大对国内印表机製造商的投入。新加坡的国家增材製造丛集正在对航太合金进行认证并培训工程师,使该国转型为区域出口中心。印度的生产连结奖励计画计画正在津贴汽车和能源产业购买金属印表机,而澳洲的一个合作研究中心正在利用当地矿石雾化钛粉。

欧洲正着力发展永续性。欧盟的「Fit-for-55」计画鼓励汽车製造商列印轻量化支架,以减少车辆排放气体。欧洲太空总署已展示了首批在国际太空站上製造的不銹钢零件,证实了微重力列印技术在月球基础设施製造中的有效性。德国汽车製造商正在联合开发一种铝硅合金,可实现无缝焊接,且不会产生热裂纹缺陷,为碰撞相关应用树立了新的标竿。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 汽车和航太领域对轻量化零件的需求

- 快速推广患者特异性医疗植入

- 聚合物和金属粉末价格下跌

- 政府资金和标准的协调统一

- 由于循环经济的推广,对再生材料的需求不断增长。

- 面向太空和远端任务的现场微型生产

- 市场限制

- 高性能金属和聚合物高成本

- 对智慧财产权保护的担忧

- 奈米粉末处理的严格环境、健康与安全 (EHS) 法规

- 关键合金元素的供应链波动

- 产业价值链分析

- 监管环境

- 技术展望

- 宏观经济因素的影响

- 波特五力分析

- 新进入者的威胁

- 买方的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模与成长预测

- 透过技术

- 基于聚合物的技术

- 熔融沈积成型(FDM)

- 立体光刻技术(SLA)

- 数位光处理(DLP)

- 材料喷射(PolyJet)

- 黏着剂喷涂成型- 聚合物

- 金属基技术

- 粉末层熔化(SLM,EBM)

- 定向能量沉积

- 陶瓷基技术

- 陶瓷SLA

- 陶瓷黏着剂喷涂成型

- 其他技术

- 基于聚合物的技术

- 依材料类型

- 聚合物

- 热塑性产品(ABS、PLA)

- 工程塑胶(PA、PEEK)

- 光敏树脂

- 高性能热塑性树脂(Artem、Pec)

- 金属

- 钛合金

- 铝合金

- 不銹钢

- 镍基高温合金

- 贵金属

- 陶瓷製品

- 氧化铝

- 氧化锆

- 碳化硅

- 复合材料和其他新兴材料

- 聚合物

- 最终用户

- 航太/国防

- 车

- 卫生保健

- 医疗设备

- 牙科

- 工业机械

- 消费品

- 建造

- 教育与研究

- 其他最终用户

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 欧洲

- 英国

- 德国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 其他欧洲地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 澳洲和纽西兰

- 东南亚

- 亚太其他地区

- 中东

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 土耳其

- 其他中东地区

- 非洲

- 南非

- 奈及利亚

- 埃及

- 其他非洲地区

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- BASF 3D Printing Solutions GmbH

- Evonik Industries AG

- Arkema SA

- Sandvik AB

- Hoganas AB

- Stratasys Ltd.

- 3D Systems Corporation

- General Electric Company(GE Additive)

- EOS GmbH

- Materialise NV

- Desktop Metal Inc.

- Markforged Holding Corporation

- Carpenter Technology Corporation

- Heraeus Holding GmbH

- GKN Powder Metallurgy Holdings GmbH

- HP Inc.

- Prodways Group SA

- SLM Solutions Group AG

- Henkel AG and Co. KGaA

- DSM-Covestro Additive Manufacturing(Covestro AG)

- ExOne Company(Desktop Metal)

第七章 市场机会与未来展望

The additive manufacturing and materials market is expected to grow from USD 95.27 billion in 2025 to USD 110.63 billion in 2026 and is forecast to reach USD 233.58 billion by 2031 at 16.12% CAGR over 2026-2031.

Falling material prices, aerospace demand for lightweight parts, and rapid healthcare adoption shift the additive manufacturing and materials market away from prototyping and into volume production. Standardization programs at NIST and ASTM provide unified qualification pathways that lower certification costs, while government incentives in North America, Europe, and Asia Pacific accelerate factory-level deployment.Competitive intensity rises as vendors integrate software, printers, and qualified powders to deliver turnkey production lines that meet industrial uptime requirements. Simultaneously, circular-economy policies motivate producers to qualify recycled polymer and metal feedstocks, creating cost and sustainability advantages for regions with established waste-processing capacity. Space agencies validate in-orbit metal printing, opening a long-term frontier for on-site micro-production that removes costly launch mass.

Global Additive Manufacturing And Materials Market Trends and Insights

Demand for lightweight components in automotive and aerospace

Aerospace OEMs condense multi-part assemblies into single printed geometries to trim aircraft weight and maintenance. GE Aviation's printed fuel nozzle replaces twenty components and saves carriers USD 1.6 million in lifetime operating costs per aircraft.Boeing integrates titanium lattice brackets on the 787 that cut part cost by USD 2-3 million while meeting structural standards. Automotive firms replicate this consolidation in battery housings and brake systems to extend electric-vehicle range. Topology-optimization software unlocks organic shapes unattainable with machining, giving early adopters a performance edge. ASTM F2792 definitions standardize terminology and testing, helping certifiers approve flight-critical parts faster.

Rapid adoption of patient-specific healthcare implants

Powder-bed fusion enables porous titanium implants that match individual anatomy, improving osseointegration and cutting failure rates. Stryker has produced over 2 million such devices, proving the scalability of hospital-grade additive workflows.The U.S. FDA's point-of-care guidance lets certified hospitals print surgical guides onsite, reducing lead times and inventory costs. Distributed production shifts value from centralized factories to clinical settings, shrinking logistics footprints. Premium demand pushes cobalt-chrome and titanium powder suppliers to scale atomization capacity despite tight aerospace allocation.

High cost of high-performance metals and polymers

PEEK, PEKK, and aerospace-grade titanium powders trade at premiums that smaller job shops struggle to absorb. Limited atomizer capacity and energy-intensive plasma processes elevate raw-material costs just as buyers push for volume pricing. Suppliers face a squeeze between customers requesting discounts and investors demanding R&D spending, delaying next-generation material rollouts. Automotive and consumer sectors therefore confine purchases to prototypes or high-margin components until cost curves fall.

Other drivers and restraints analyzed in the detailed report include:

- Government funding and standards harmonization

- Supply-chain volatility in critical alloying elements

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Directed Energy Deposition posts a 16.98% CAGR, underpinned by aerospace engine repair where meter-scale parts eclipse powder-bed build volumes. This segment benefits from wire feedstock that costs 30-50% less than powder and recoups material unused in other systems. Fused Deposition Modeling, however, retains 39.68% additive manufacturing and materials market share due to its ubiquity in education, design, and low-stress industrial fixtures. Hybrid CNC-additive platforms merge laser cladding with five-axis milling to meet tolerance and surface roughness targets in a single setup.

Powder Bed Fusion remains the benchmark for lattice-rich implants and rocket turbopump components requiring sub-80 µm layer heights. Binder Jetting evolves for steel pump housings and sand casting molds, offering throughput advantages when sintering bottlenecks are solved. Emerging microwave volumetric systems promise order-of-magnitude speed gains, foreshadowing a future where build time no longer dictates unit economics.

The Additive Manufacturing and Materials Market Report is Segmented by Technology (Polymer-Based, Metal-Based, Ceramic-Based, and More), Material Type (Polymers, Metals, Ceramics, Composite, and More), End User (Aerospace and Defense, Automotive, Healthcare, Industrial Machinery, Consumer Products, Construction, Education and Research, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America commands 36.45% additive manufacturing and materials market size in 2025, supported by defense budgets, NASA deep-space initiatives, and a mature supplier ecosystem. Federal tax incentives and Section 174 R&D expensing rules reward capital investment in new production lines. FDA 510(k) guidance for 3D-printed implants accelerates time-to-market for device OEMs, reinforcing domestic powder consumption.

Asia Pacific is the fastest-growing region at a 16.55% CAGR as China funds domestic printer champions to lessen dependence on imported engine parts. Singapore's National Additive Manufacturing cluster certifies aerospace alloys and trains technicians, turning the island into a regional export hub.India's Production-Linked Incentive program subsidizes metal-printer purchases for automotive and energy verticals, while Australia's Cooperative Research Centre advances titanium powder atomization from local ore.

Europe focuses on sustainability; the EU's Fit-for-55 package spurs OEMs to print lightweight brackets that reduce vehicle emissions. The European Space Agency demonstrates the first stainless-steel part fabricated aboard the ISS, validating micro-gravity printing for lunar infrastructure. German carmakers co-develop aluminum-silicon alloys that weld seamlessly without hot-crack defects, setting a benchmark for crash-relevant applications.

- BASF 3D Printing Solutions GmbH

- Evonik Industries AG

- Arkema S.A.

- Sandvik AB

- Hoganas AB

- Stratasys Ltd.

- 3D Systems Corporation

- General Electric Company (GE Additive)

- EOS GmbH

- Materialise NV

- Desktop Metal Inc.

- Markforged Holding Corporation

- Carpenter Technology Corporation

- Heraeus Holding GmbH

- GKN Powder Metallurgy Holdings GmbH

- HP Inc.

- Prodways Group SA

- SLM Solutions Group AG

- Henkel AG and Co. KGaA

- DSM-Covestro Additive Manufacturing (Covestro AG)

- ExOne Company (Desktop Metal)

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Demand for lightweight components in automotive and aerospace

- 4.2.2 Rapid adoption of patient-specific healthcare implants

- 4.2.3 Falling polymer and metal powder prices

- 4.2.4 Government funding and standards harmonisation

- 4.2.5 Circular-economy push for recycled feedstocks

- 4.2.6 On-site micro-production for space and remote missions

- 4.3 Market Restraints

- 4.3.1 High cost of high-performance metals and polymers

- 4.3.2 Intellectual-property protection concerns

- 4.3.3 Stringent EHS rules for nano-powder handling

- 4.3.4 Supply-chain volatility in critical alloying elements

- 4.4 Industry Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Impact of Macroeconomic Factors

- 4.8 Porter's Five Forces Analysis

- 4.8.1 Threat of New Entrants

- 4.8.2 Bargaining Power of Buyers

- 4.8.3 Bargaining Power of Suppliers

- 4.8.4 Threat of Substitutes

- 4.8.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Technology

- 5.1.1 Polymer-based Technologies

- 5.1.1.1 Fused Deposition Modeling (FDM)

- 5.1.1.2 Stereolithography (SLA)

- 5.1.1.3 Digital Light Processing (DLP)

- 5.1.1.4 Material Jetting (PolyJet)

- 5.1.1.5 Binder Jetting - Polymers

- 5.1.2 Metal-based Technologies

- 5.1.2.1 Powder Bed Fusion (SLM, EBM)

- 5.1.2.2 Directed Energy Deposition

- 5.1.3 Ceramic-based Technologies

- 5.1.3.1 Ceramic SLA

- 5.1.3.2 Ceramic Binder Jetting

- 5.1.4 Other Technologies

- 5.1.1 Polymer-based Technologies

- 5.2 By Material Type

- 5.2.1 Polymers

- 5.2.1.1 Commodity Thermoplastics (ABS, PLA)

- 5.2.1.2 Engineering Plastics (PA, PEEK)

- 5.2.1.3 Photopolymer Resins

- 5.2.1.4 High-performance Thermoplastics (ULTEM, PEKK)

- 5.2.2 Metals

- 5.2.2.1 Titanium Alloys

- 5.2.2.2 Aluminum Alloys

- 5.2.2.3 Stainless Steels

- 5.2.2.4 Nickel Super-alloys

- 5.2.2.5 Precious Metals

- 5.2.3 Ceramics

- 5.2.3.1 Alumina

- 5.2.3.2 Zirconia

- 5.2.3.3 Silicon Carbide

- 5.2.4 Composite and Other Emerging Material Feedstocks

- 5.2.1 Polymers

- 5.3 By End User

- 5.3.1 Aerospace and Defense

- 5.3.2 Automotive

- 5.3.3 Healthcare

- 5.3.3.1 Medical Devices

- 5.3.3.2 Dental

- 5.3.4 Industrial Machinery

- 5.3.5 Consumer Products

- 5.3.6 Construction

- 5.3.7 Education and Research

- 5.3.8 Other End Users

- 5.4 By Geography

- 5.4.1 North America

- 5.4.1.1 United States

- 5.4.1.2 Canada

- 5.4.1.3 Mexico

- 5.4.2 South America

- 5.4.2.1 Brazil

- 5.4.2.2 Argentina

- 5.4.2.3 Rest of South America

- 5.4.3 Europe

- 5.4.3.1 United Kingdom

- 5.4.3.2 Germany

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Spain

- 5.4.3.6 Russia

- 5.4.3.7 Rest of Europe

- 5.4.4 Asia Pacific

- 5.4.4.1 China

- 5.4.4.2 Japan

- 5.4.4.3 India

- 5.4.4.4 South Korea

- 5.4.4.5 Australia and New Zealand

- 5.4.4.6 Southeast Asia

- 5.4.4.7 Rest of Asia Pacific

- 5.4.5 Middle East

- 5.4.5.1 United Arab Emirates

- 5.4.5.2 Saudi Arabia

- 5.4.5.3 Turkey

- 5.4.5.4 Rest of Middle East

- 5.4.6 Africa

- 5.4.6.1 South Africa

- 5.4.6.2 Nigeria

- 5.4.6.3 Egypt

- 5.4.6.4 Rest of Africa

- 5.4.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 BASF 3D Printing Solutions GmbH

- 6.4.2 Evonik Industries AG

- 6.4.3 Arkema S.A.

- 6.4.4 Sandvik AB

- 6.4.5 Hoganas AB

- 6.4.6 Stratasys Ltd.

- 6.4.7 3D Systems Corporation

- 6.4.8 General Electric Company (GE Additive)

- 6.4.9 EOS GmbH

- 6.4.10 Materialise NV

- 6.4.11 Desktop Metal Inc.

- 6.4.12 Markforged Holding Corporation

- 6.4.13 Carpenter Technology Corporation

- 6.4.14 Heraeus Holding GmbH

- 6.4.15 GKN Powder Metallurgy Holdings GmbH

- 6.4.16 HP Inc.

- 6.4.17 Prodways Group SA

- 6.4.18 SLM Solutions Group AG

- 6.4.19 Henkel AG and Co. KGaA

- 6.4.20 DSM-Covestro Additive Manufacturing (Covestro AG)

- 6.4.21 ExOne Company (Desktop Metal)

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment