|

市场调查报告书

商品编码

1907339

润滑油添加剂:市场占有率分析、产业趋势与统计、成长预测(2026-2031)Lubricant Additives - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

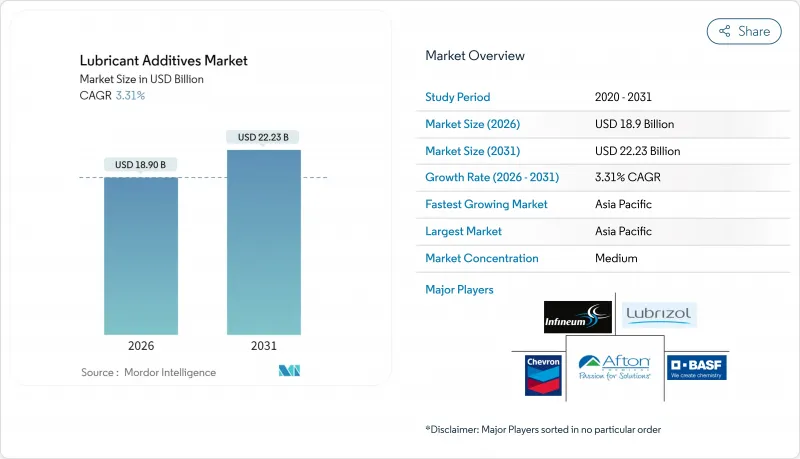

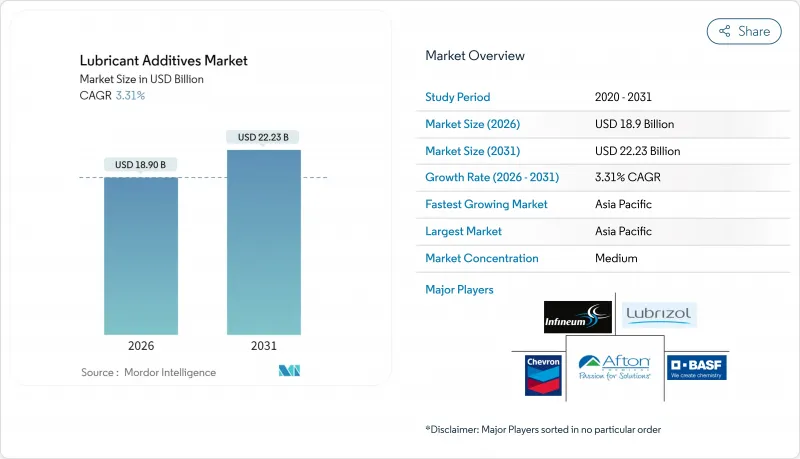

预计到 2026 年,润滑油添加剂市场规模将达到 189 亿美元,高于 2025 年的 182.9 亿美元。预计到 2031 年,该市场规模将达到 222.3 亿美元,2026 年至 2031 年的复合年增长率为 3.31%。

这一稳步扩张反映了润滑油产业从销售主导成长转变为价值驱动型创新的趋势,而高端添加剂化学技术抵消了润滑油需求放缓的影响。以2025年3月推出的ILSAC GF-7为首的不断完善的监管体系,正在加速采用先进的多功能添加剂,以满足更严格的排放气体和更低的黏度要求。亚太地区拥有最大的区域市场份额和最高的成长势头,中国和印度製造业的扩张支撑了汽车和工业润滑油的强劲消费。竞争格局强调技术差异化而非价格优势,例如路博润于2025年2月推出的新一代低SAP机油的Solsperse W60超分散剂。儘管延长换油週期和电气化限制了添加剂的使用,但奈米级创新和更严格的排放气体法规仍在持续推动高价值解决方案的需求。

全球润滑油添加剂市场趋势与洞察

严格的排放气体环境法规

ILSAC GF-7 标准将于 2025 年 3 月生效,该标准要求添加剂供应商在更严格的磷和硫含量限制下,保护正时链条并抑制低速预燃。针对 SAE 0W-16 机油的全新欧洲 ACEA 2023 C7 等级,正在黏度指数增进剂,这些改进剂和改进剂能够比基础油提高至少 0.3% 的燃油经济性。随着汽车製造商转向 0W-8 等级的机油,添加剂配方必须在燃油经济性、抗磨性能和抗氧化稳定性之间取得平衡。这种平衡提升了高纯度清洁剂和先进抗磨增强剂的价值。区域监管趋同加速了性能标准的全球统一,鼓励跨国供应商投资于通用型添加剂平台,而不是针对特定区域的配方。能够快速获得认证的供应商将增强其与调配商和原始设备製造商 (OEM) 的谈判地位。

中东和非洲工业基础设施的扩张

沙乌地阿拉伯的「2030愿景」下游多元化计画正在创建合资企业,旨在更靠近丰富的原材料产地生产添加剂。例如,沙乌地阿美与嘉实多的合资工厂以及瑞富集团与法拉比石化公司的合作项目,都体现了该地区迈向自力更生的步伐。一体化综合设施将降低依赖进口的非洲製造商的物流成本,并缩短红海走廊沿线客户的前置作业时间。从长远来看,这些投资将建立一个出口基地,以满足亚太地区不断增长的需求,同时保护当地调配商免受全球运费波动的影响。区域各国政府也正在透过税收优惠和地租优惠等诱因来促进特种化学品丛集的发展,从而提高新设施的财务可行性。随着产能的扩大,添加剂供应商将能够根据中东和非洲市场独特的极端气候和燃料特性来调整其配方。

延长车辆和机械的换油週期

在美国,乘用车的换油週期已从5000英里延长至10000英里,风力发电机机齿轮箱的润滑油寿命目标为36个月。内置于过滤器中的状态监测感测器可实现数据驱动的维护,将维护推迟到油氧化或颗粒物含量触发警报。虽然每次加註润滑油时的添加剂含量增加,但年度添加剂总用量却在下降。这促使润滑油调配公司将销售重心转向高端长效品牌,给专注于通用化学品的供应商带来了压力。独立维修店的业务收益下降,推动了消费者延长换油週期的做法。为了弥补这一损失,添加剂生产商正在推广清洁液和过滤器调节片等辅助产品,但这些产品的普及程度有限。

细分市场分析

到2025年,分散剂和乳化剂将占总收入的29.13%,这反映了它们在保持烟尘和氧化副产物悬浮以及防止清漆形成方面发挥的关键作用。随着原始设备製造商(OEM)转向颗粒物负荷更高的缸内喷油发动机,预计到2031年,该细分市场将以4.32%的复合年增长率增长,超过润滑油添加剂市场的整体增速。受分散剂驱动的润滑油添加剂市场规模预计将稳步扩大,因为对硫酸盐灰分和磷含量的监管限制日益严格,推动了对能够在低添加剂下发挥作用的高效聚异丁烯琥珀酰亚胺化学品的需求。

由于市场转向使用低黏度等级(例如 0W-8)的润滑油,聚合物基黏度指数增进剂占据了第二大市场份额。低黏度等级的润滑油即使在高温运作环境下也需要更强的油膜强度。随着换油週期的延长,保持基础油黏度变得越来越重要,因此清洁剂和腐蚀抑制剂的需求保持稳定。摩擦改良剂在乘用车和重型机油中的重要性日益凸显,这些润滑油正力求提高 1% 的燃油经济性。同时,极压添加剂在工业齿轮油和金属加工液中仍发挥核心作用。供应商正在将这些化学品整合到多功能配方中,并在严格的灰分预算内优化用量。这一趋势使得配方师能够用更少的 SKU 满足全球引擎测试标准。

润滑油添加剂报告按功能类型(分散剂/乳化剂、黏度指数增进剂、清洁剂、腐蚀抑制剂等)、润滑油类型(引擎油、变速箱/液压油、金属加工液等)、最终用户产业(汽车/其他运输设备、发电、重型机械等)和地区(亚太地区、北美、欧洲等)进行分析。

区域分析

预计到2025年,亚太地区将以45.05%的市占率引领全球市场,并在2031年之前维持3.98%的复合年增长率。中国垂直整合的石化联合企业生产价格具竞争力的II类和III类基础油,供应添加剂调配厂,从而满足国内和出口需求。印度正利用与生产挂钩的激励措施吸引对特种化学品产业的投资,将其打造成为东协组装的采购中心。日本和韩国提供独特的聚合物改质剂和高纯度分散剂,而泰国和越南则为区域内原始设备製造商(OEM)的售后服务项目提供经济高效的调配服务。

北美在製定全球性能规范方面仍然发挥着重要作用。总部位于美国的API和ILSAC委员会主导新类别的引进,并推动着配套添加剂测试通讯协定在全球的普及。儘管车辆电气化和延长换油週期限制了销售成长,但该地区的车队所有者仍然要求更高的抗氧化稳定性和燃油经济性,从而保持添加剂的高单位价值。墨西哥汽车组装能的扩张进一步支撑了区域需求,因为原始设备製造商(OEM)正在将其供应链本地化,以遵守贸易协定中在地采购限制。

欧洲拥有成熟的车辆保有量,并实施全球最高标准的环保法规。 ACEA 2023 标准和提案的欧 VII 标准强制要求润滑油与颗粒过滤器相容,并采用超低黏度等级,这迫使配方师在灰分限制和涡轮增压器清洁度之间取得平衡。德国化工巨头供应先进的抗氧化剂和摩擦改进剂,而英国拥有重要的添加剂研发中心。俄罗斯的地缘政治局势限制了技术转让,但其国内调配商仍在继续使用传统的工业润滑油添加剂。

南美洲正经历温和扩张,其中巴西引领成长,农业机械化程度的提高带动了重型柴油润滑油消费量的成长。阿根廷的能源改革促进了页岩气开发,从而带动了对齿轮油和钻井设备液压油的需求。沙乌地阿拉伯的「2030愿景」下游计划以及阿联酋致力于成为区域海事服务中心的努力,都刺激了对船用和工业润滑油的需求。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 严格的排放气体环境法规

- 中东和非洲工业产能扩张

- 亚太地区汽车润滑油需求激增

- 汽车製造商正越来越多地转向高性能机油

- 奈米添加剂封装技术的出现

- 市场限制

- 延长车辆和机械的更换週期

- 透过电气化降低引擎机油消耗

- PIB 和其他关键化学品的供应不稳定

- 价值链分析

- 波特五力模型

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模与成长预测

- 依功能类型

- 分散剂和乳化剂

- 黏度指数增进剂

- 清洁剂

- 腐蚀抑制剂

- 抗氧化剂

- 极压添加剂

- 摩擦改进剂(FM)

- 其他函数类型

- 按润滑剂类型

- 机油

- 传动和液压油

- 金属加工油

- 通用工业油

- 齿轮油

- 润滑脂

- 加工油

- 其他润滑剂类型

- 按最终用户行业划分

- 汽车和其他运输设备

- 发电

- 重型机械

- 冶金与金属加工

- 食品/饮料

- 其他终端用户产业

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- ASEAN

- 亚太其他地区

- 北美洲

- 美国

- 墨西哥

- 加拿大

- 欧洲

- 德国

- 英国

- 俄罗斯

- 义大利

- 法国

- 其他欧洲地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率(%)/排名分析

- 公司简介{包括全球概览、市场概览、核心业务板块、现有财务资讯、策略资讯、主要企业市场排名/份额、产品和服务以及近期发展动态}

- AFTON CHEMICAL

- BASF

- BRB International BV

- Chevron Corporation

- DOG Deutsche Oelfabrik

- Dorf Ketal Chemicals

- Dover Chemical Corporation

- Evonik Industries AG

- GANESH BENZOPLAST LIMITED.

- INFINEUM INTERNATIONAL LIMITED

- ITALMATCH CHEMICALS SPA

- Kangtai Lubricant Additives Co., Ltd.

- King Industries, Inc.

- Lanxess

- MULTISOL LIMITED

- Nouryon

- RT Vanderbilt Holding Company, Inc.

- Shepherd Chemical

- The Lubrizol Corporation

- Wuxi South Petroleum Additives Co., Ltd.

第七章 市场机会与未来展望

Lubricant Additives Market size in 2026 is estimated at USD 18.9 billion, growing from 2025 value of USD 18.29 billion with 2031 projections showing USD 22.23 billion, growing at 3.31% CAGR over 2026-2031.

This measured expansion reflects the industry's shift from volume-driven growth toward value-focused innovation, where premium additive chemistries offset moderating lubricant demand. Rising regulatory stringency, led by the March 2025 introduction of ILSAC GF-7, has accelerated the uptake of sophisticated multi-functional packages that support tighter emission limits and lower viscosities. Asia-Pacific commands both the largest regional presence and the highest growth momentum because manufacturing expansion in China and India underpins robust automotive and industrial lubricant consumption. Competitive dynamics emphasize technology differentiation rather than price, exemplified by Lubrizol's launch of Solsperse W60 Hyperdispersant in February 2025, a product positioned for next-generation low-SAPs engine oils. Extended drain intervals and electrification temper absolute additive volumes, yet nano-scale innovations and stricter emission standards sustain demand for high-value solutions.

Global Lubricant Additives Market Trends and Insights

Stringent Environmental Regulations on Emissions

ILSAC GF-7 took effect in March 2025 and compels additive suppliers to mitigate low-speed pre-ignition while safeguarding timing chains under tighter phosphorus and sulfur caps. New ACEA 2023 C7 categories in Europe target SAE 0W-16 oils, spurring demand for friction modifiers and viscosity index improvers that deliver at least 0.3% fuel-economy gains versus reference oils. As OEMs push toward 0W-8 grades, additive formulations must reconcile fuel efficiency with wear protection and oxidative stability. This balancing act elevates the value of high-purity detergent chemistries and advanced antiwear boosters. Regulatory convergence across regions accelerates global harmonization of performance standards, incentivizing multinational suppliers to invest in versatile additive platforms rather than region-specific blends. Suppliers that demonstrate rapid certification capabilities secure stronger bargaining power with both blenders and OEMs.

Industrial Capacity Build-up in MEA

Downstream diversification programs under Saudi Arabia's Vision 2030 have triggered joint ventures that localize additive production close to abundant feedstocks. Projects such as the prospective Aramco-Castrol facility and Richful Group's partnership with Farabi Petrochemicals illustrate regional momentum toward self-reliance. Integrated complexes lower logistics costs for import-dependent African manufacturers and shorten lead times for customers across the Red Sea corridor. Over the long term, these investments create an export platform serving Asia-Pacific demand spikes while insulating local blenders from global freight volatility. Regional governments also incentivize specialty chemical clusters through tax holidays and preferential land leases, amplifying the financial viability of greenfield facilities. As installed capacity rises, additive suppliers can tailor formulations to climatic extremes and fuel qualities characteristic of MEA markets.

Extended Drain Intervals in Vehicles and Machinery

Passenger-car oil-change intervals in the United States have doubled from 5,000 miles to 10,000 miles, while wind-turbine gearboxes now target 36-month lubricant life cycles. Condition-monitoring sensors embedded in filters enable data-driven maintenance that defers service until oil oxidation or particle levels trigger alarms. Although each oil fill contains a higher additive loading, the aggregate annual additive volume contracts. Blenders therefore shift marketing toward premium long-life brands, squeezing suppliers focused on commodity chemistries. Independent workshops lose service revenue, reinforcing consumer adoption of extended intervals. To compensate, additive manufacturers promote supplemental products such as flush fluids and filter-conditioner tablets, but uptake remains limited.

Other drivers and restraints analyzed in the detailed report include:

- Surging Automotive Lubricant Demand in Asia-Pacific

- Rising OEM Shift to High-Performance Engine Oils

- Electrification Curbing Engine-Oil Volumes

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Dispersants and emulsifiers accounted for 29.13% of 2025 revenues, reflecting their critical role in keeping soot and oxidation by-products suspended to prevent varnish formation. The segment is forecast to grow at a 4.32% CAGR through 2031, outpacing the lubricant additives market as OEMs migrate to gasoline direct-injection engines with elevated particulate loading. The lubricant additives market size attributed to dispersants is projected to expand steadily because regulatory caps on sulfated ash and phosphorus intensify the need for highly efficient polyisobutylene succinimide chemistries that operate at lower treat rates.

Polymeric viscosity index improvers hold the second-largest share, benefiting from the pivot toward low-viscosity grades such as 0W-8 that require robust film strength at high operating temperatures. Detergents and corrosion inhibitors enjoy stable demand as extended drain intervals magnify the importance of base-number retention. Friction modifiers gain relevance in passenger-car and heavy-duty oils targeting a 1% fuel-economy improvement, while extreme-pressure additives remain core to industrial gear oils and metalworking fluids. Suppliers consolidate these chemistries into multi-functional packages to optimize treat levels within stringent ash budgets, a trend that enables formulators to meet global engine-test matrices with fewer SKUs.

The Lubricant Additives Report is Segmented by Function Type (Dispersants and Emulsifiers, Viscosity Index Improvers, Detergents, Corrosion Inhibitors, and More), Lubricant Type (Engine Oil, Transmission and Hydraulic Fluid, Metalworking Fluid, and More), End-User Industry (Automotive and Other Transportation, Power Generation, Heavy Equipment, and More), and Geography (Asia-Pacific, North America, Europe, and More).

Geography Analysis

Asia-Pacific dominated the global landscape with 45.05% share in 2025 and is anticipated to register a 3.98% CAGR through 2031. China's vertically integrated petrochemical complexes generate competitively priced Group II and Group III base oils that feed additive blend plants, supporting local and export demand. India leverages production-linked incentives to attract investment in specialty chemicals, transforming the country into a sourcing hub for ASEAN assemblers. Japan and South Korea contribute proprietary polymer modifiers and high-purity dispersants, while Thailand and Vietnam offer cost-efficient blending services for regional OEM service-fill programs.

North America retains significant influence through its role in setting global performance specifications. API and ILSAC committees headquartered in the United States drive new category introductions, compelling worldwide adoption of accompanying additive test protocols. While vehicle electrification and extended drain intervals temper volume growth, fleet owners in the region demand superior oxidative stability and fuel-efficiency credentials, sustaining high per-unit additive value. Mexico's expanding automotive assembly capacity further underpins regional demand as OEMs localize supply chains to meet trade-agreement content rules.

Europe combines a mature car parc with some of the world's strictest environmental regulations. ACEA 2023 standards and Euro VII proposals mandate particulate filter compatibility and ultra-low-viscosity grades, forcing formulators to balance ash limits against turbocharger cleanliness. German chemical majors supply advanced antioxidants and friction modifiers, while the United Kingdom maintains notable additive research and development hubs. Russia's geopolitical situation restricts technology transfer, yet domestic blenders continue to consume traditional additive packages for industrial oils.

South America experiences moderate expansion led by Brazil, where agricultural mechanization boosts heavy-duty diesel lubricant consumption. Energy reforms in Argentina encourage shale development, translating into gear-oil and hydraulic-fluid demand for drilling equipment. Saudi Arabia's Vision 2030 downstream projects and United Arab Emirates' push to become a regional maritime services center stimulate demand for marine and industrial lubricants.

- AFTON CHEMICAL

- BASF

- BRB International BV

- Chevron Corporation

- D.O.G Deutsche Oelfabrik

- Dorf Ketal Chemicals

- Dover Chemical Corporation

- Evonik Industries AG

- GANESH BENZOPLAST LIMITED.

- INFINEUM INTERNATIONAL LIMITED

- ITALMATCH CHEMICALS SPA

- Kangtai Lubricant Additives Co., Ltd.

- King Industries, Inc.

- Lanxess

- MULTISOL LIMITED

- Nouryon

- RT Vanderbilt Holding Company, Inc.

- Shepherd Chemical

- The Lubrizol Corporation

- Wuxi South Petroleum Additives Co., Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Stringent environmental regulations on emissions

- 4.2.2 Industrial capacity build-up in MEA

- 4.2.3 Surging automotive lubricant demand in Asia-Pacific

- 4.2.4 Rising OEM shift to high-performance engine oils

- 4.2.5 Emergence of nano-additive packages

- 4.3 Market Restraints

- 4.3.1 Extended drain intervals in vehicles and machinery

- 4.3.2 Electrification curbing engine-oil volumes

- 4.3.3 Volatile supply of PIB and other key chemistries

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Function Type

- 5.1.1 Dispersants and Emulsifiers

- 5.1.2 Viscosity Index Improvers

- 5.1.3 Detergents

- 5.1.4 Corrosion Inhibitors

- 5.1.5 Oxidation Inhibitors

- 5.1.6 Extreme-pressure Additives

- 5.1.7 Friction Modifiers (FM)

- 5.1.8 Other Function Types

- 5.2 By Lubricant Type

- 5.2.1 Engine Oil

- 5.2.2 Transmission and Hydraulic Fluid

- 5.2.3 Metalworking Fluid

- 5.2.4 General Industrial Oil

- 5.2.5 Gear Oil

- 5.2.6 Grease

- 5.2.7 Process Oil

- 5.2.8 Other Lubricant Types

- 5.3 By End-user Industry

- 5.3.1 Automotive and Other Transportation

- 5.3.2 Power Generation

- 5.3.3 Heavy Equipment

- 5.3.4 Metallurgy and Metal Working

- 5.3.5 Food and Beverage

- 5.3.6 Other End-Users Industries

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 ASEAN

- 5.4.1.6 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Mexico

- 5.4.2.3 Canada

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 Russia

- 5.4.3.4 Italy

- 5.4.3.5 France

- 5.4.3.6 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles {includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments}

- 6.4.1 AFTON CHEMICAL

- 6.4.2 BASF

- 6.4.3 BRB International BV

- 6.4.4 Chevron Corporation

- 6.4.5 D.O.G Deutsche Oelfabrik

- 6.4.6 Dorf Ketal Chemicals

- 6.4.7 Dover Chemical Corporation

- 6.4.8 Evonik Industries AG

- 6.4.9 GANESH BENZOPLAST LIMITED.

- 6.4.10 INFINEUM INTERNATIONAL LIMITED

- 6.4.11 ITALMATCH CHEMICALS SPA

- 6.4.12 Kangtai Lubricant Additives Co., Ltd.

- 6.4.13 King Industries, Inc.

- 6.4.14 Lanxess

- 6.4.15 MULTISOL LIMITED

- 6.4.16 Nouryon

- 6.4.17 RT Vanderbilt Holding Company, Inc.

- 6.4.18 Shepherd Chemical

- 6.4.19 The Lubrizol Corporation

- 6.4.20 Wuxi South Petroleum Additives Co., Ltd.

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment