|

市场调查报告书

商品编码

1910434

气体检测:市场占有率分析、产业趋势与统计、成长预测(2026-2031)Gas Detectors - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

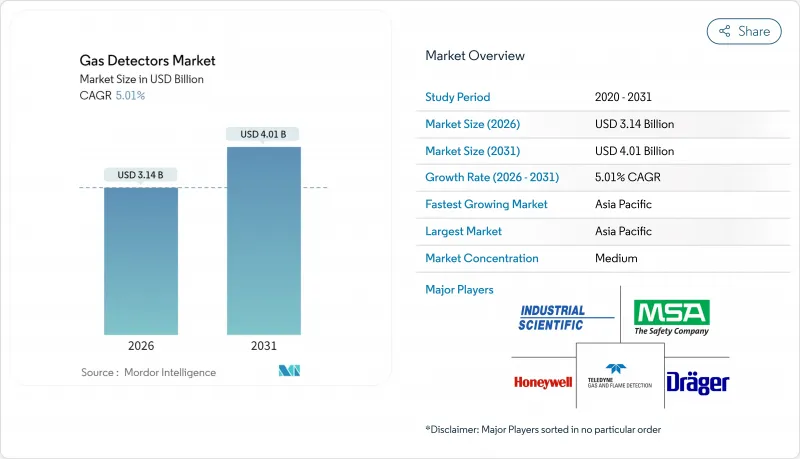

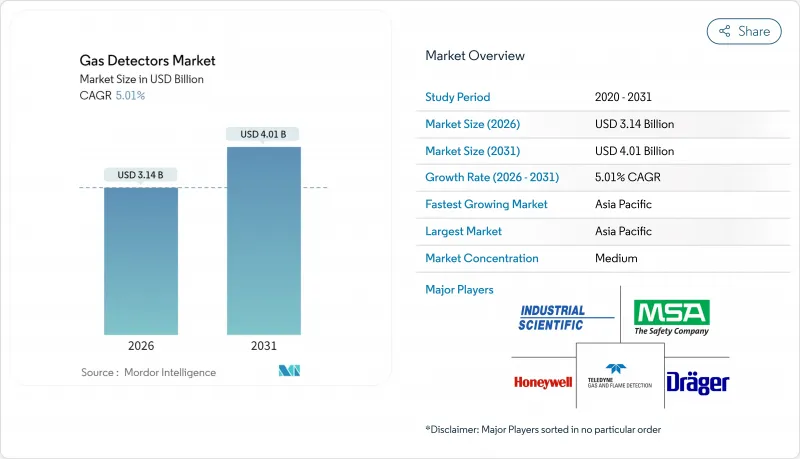

2025年气体检测市场价值为29.9亿美元,预计到2031年将达到40.1亿美元,而2026年为31.4亿美元。

预计在预测期(2026-2031 年)内,复合年增长率将达到 5.01%。

这一成长轨迹反映了对即时工人安全解决方案的资本投资不断增加、现有工厂维修需求日益增长,以及为预测分析引擎提供资讯的互联感测平台的整合。美国职业安全与健康管理局 (OSHA)、美国消防协会 (NFPA) 72 和美国矿业法规的严格执行正在推动设备更新换代,而中游液化天然气枢纽、氢气生产设施和锂离子电池生产线的持续扩张则推动了对可燃性气体和有毒气体监测基础设施的需求。更美国的网路安全法规正在推动对能够将认证感测器硬体与安全物联网软体堆迭相结合的供应商的需求。虽然有线网路在现有(棕地)设施中仍然占据主导地位,但无线网状拓扑结构和多年电池模组的进步正在降低总安装成本,并开闢尚未开发的市场领域,例如远端井口和临时检修区。随着成熟的全球供应商寻求捍卫其市场份额,以应对拥有专业能力、承诺低漂移率、氢气特异性或基于订阅的校准服务的新兴参与企业,竞争日益激烈。

全球气体检测市场趋势与洞察

危险产业严格的工人安全法规

监管机构强制要求采用即时环境遥测技术而非定期抽查,促使矿场、炼油厂和化工厂部署连续监测网路。美国职业安全与健康管理局 (OSHA) 的「2025 年数据驱动检查计画」鼓励营运商将传统的单气体侦测仪升级为连网的多气体阵列,以便将测量数据传输到中央控制面板。美国煤炭法规强制要求对矿井排水通道 (MDR) 进行认证,这导致防爆固定式通风口和用于地下甲烷3D测绘的无人机载感测器订单激增。地方政府供水事业必须遵守 NFPA 820阈值中关于硫化氢的门槛规定,这促使数千家维修对湿式泵房通风系统进行改造。领先的供应商正在透过预测分析软体来应对这一挑战,该软体能够在警报触发之前检测异常模式,从而符合「零伤害」目标,例如 Industrial Scientific 提出的「到 2050 年消除职场死亡事故」目标。单一炼油厂的年度遵循成本可能超过 10 万美元,这导致了固定的续约週期和服务合约。

智慧互联探测器的应用日益普及

物联网连接正在将气体检测市场从产品销售模式转变为资讯服务生态系统。 Blackline 的 EXO 8 单次充电即可将资料传输到云端长达 100 天,让远端安全团队能够即时监控暴露趋势。霍尼韦尔的 Sensepoint XCL 透过低功耗蓝牙连接到智慧型手机,为技术人员提供逐步指导,并将校准时间缩短高达 30%。预测性仪表板可自动安排感测器更换,从而缓解技术纯熟劳工短缺问题并减少非计划性停机时间。 Industrial Scientific 的 iNet Exchange 等订阅方案将硬体、耗材和分析功能整合到多年合约中,使采购从资本支出转变为营运支出。自动化合规性记录将审核准备时间从数週缩短至数小时,这对于需要应对不同地区法规的跨国公司而言极具吸引力。

初始成本高,产品差异化程度低。

工业用多气体携带式检测仪的单价在500美元到1500美元之间,如果包含安装、试运行和用户培训,价格则翻倍。声称无需校准的产品价格更高,例如AimSafety PM400售价558.57美元,Gas Clip的免维护MGC Simple售价697.07美元。低成本的亚洲仿製品价格比知名品牌低50%,这挤压了利润空间,并延缓了预算紧张的工厂的升级计划。在中型炼油厂,安装一套固定係统(包括认证管道、控制面板和功能测试)的成本通常超过100万美元。在监管执法不力的地区,价格敏感度更高,这使得一些业者能够推迟升级。

细分市场分析

到2025年,有线解决方案将占总收入的50.35%,这主要得益于现有炼油厂、液化天然气工厂和化工园区等场所采用符合危险区域标准的成熟有线迴路。在这些传统环境中,防爆接线盒和抗电磁干扰的铠装电缆仍然是气体侦测市场的首选。然而,由于钻井成本高昂和临时停机计画等因素,无线解决方案预计将在2031年之前以7.05%的复合年增长率成长,从而推动快速部署。早期无线计划电池续航力有限,而第二代网状网路设计单次充电即可运作长达100天,并且可以透过多个网关中继数据,最终接入工厂的监控网路。新建设的氢气枢纽和电池储能工厂正越来越多地将预算分配给混合架构,在这种架构中,无线节点将资料传输到有线安全区域网关,从而兼顾柔软性和确定性运作。监管机构已开始批准具有适当冗余的无线生命安全迴路,这项政策演变正在消除欧盟和美国部分地区等国家采用该技术的传统障碍。为此,设备製造商正将研发重点放在基于韧体的网路安全、OT网路分段以及符合美国美国标准与技术研究院 (NIST) 指南的无线感测器校准程序上。这种转变推高了整体解决方案的平均售价 (ASP),并为供应商带来了远端监控网路状况的订阅收入。这将扩大气体检测市场的价值池,即使在未来五年内,有线节点在感测器数量上仍将占据主导地位。

无线技术的广泛应用也得益于数位转型预算,这些预算旨在将分散的现场设备整合到通用的资产绩效仪錶板下。采购团队在计算总体拥有成本时,淘汰导管、电缆配线架和动火作业许可证等要求通常可以抵消无线分析仪的溢价。此外,更高的移动性还能在检修作业期间扩大安全覆盖范围,因为临时管线变更每天都会产生新的洩漏路径。一家下游石化公司在2024年的检修季试用了无线侦测包,结果显示密闭空间违规事件减少了15%,维护间隔缩短了8%。这些营运成果强化了投资回报模型,巩固了经营团队的支持,并进一步加速了无线技术在整体气体检测市场份额的成长。

区域分析

预计到2025年,亚太地区将占全球收入的48.60%,维持6.92%的最快复合年增长率,这主要得益于中国煤化工联合企业的蓬勃发展、印度新建炼油厂的建设以及东南亚电池供应链投资的增长。中国国家紧急管理部频繁的安全审核迫使设施营运商从未经认证的低成本进口设备转向符合ATEX和IECEx标准的设备。韩国和日本正在加快氢气加註网路的建设,并按照消防安全法规的要求,在每个泵浦中安装双冗余氢气感测器。印度的「Jal Jeevan Mission」(饮用水生命线计画)正在推动数千家水处理厂升级氯气和臭氧监测系统,进一步刺激了市场需求。国内电子製造商正在扩大氮化镓功率开关的生产,为专用氨气和氯化氢检测设备创造了新的机会。

北美在收入方面占据第二大市场份额,这主要得益于日益严格的职业安全与美国)法规、页岩气加工以及墨西哥湾沿岸液化天然气出口终端的发展。纽约市第 157 号地方法律强制要求在 2025 年 5 月前安装住宅天然气探测器,这将在住宅和小规模商业领域催生数百万台气体探测器的需求。在美国,根据《基础设施投资与就业法案》设立的氢能枢纽计画需要建造一个多气体固定网络,并配备加密无线骨干网,订单。加拿大的油砂开采作业指定使用可在低至 -40°C 的温度下保持精度的加热器和分析仪,这使得拥有耐极寒设备系列的供应商占据优势。墨西哥的蒙特雷和巴希奥工业走廊正在将挥发性有机化合物 (VOC) 探测器整合到汽车喷漆车间,以支援原始设备製造商 (OEM) 的永续性审核。

在欧洲,严格的ATEX合规性、能源性能指令(EPBD)下的室内空气品质法规以及脱碳目标共同推动了设备的持续升级。德国莱茵河沿岸的一个大型化学工业区正在投资苯和丁二烯监测,以减少逸散性排放。同时,英国强制要求商业办公室进行二氧化碳监测,以促进员工健康。北海的近海平台要求使用经认证的硫化氢浓度超过100ppm的侦测器,以及覆盖平台上部结构200公尺的开放式红外线装置。东欧成员国正在利用欧盟凝聚基金对区域供热厂进行现代化改造,将一氧化碳和甲烷感测器整合到热电联产模组中。地中海地区的液化天然气进口码头正在采用无线火焰和气体检测装置,以在不中断营运的情况下对现有码头维修。

儘管中东和非洲地区的收入份额较小,但该地区在绿色氢气先导工厂、液化工厂和矿山扩建走廊等领域的应用却十分强劲。海湾合作委员会(GCC)地区的炼油厂正在维修加氢裂解装置以符合欧VI硫排放标准,并在此过程中升级触媒珠珠式低爆炸极限(LEL)检测头。南非矿产资源部加强监管,强制要求在金矿深层隧道中进行连续固定监测。在拉丁美洲,巴西盐层下海上油田需要高规格的侦测器来检测高浓度硫化氢,而智利的锂卤水加工厂正在部署氯化氢分析仪以符合环境法规。预计这些区域趋势将推动气体检测市场在预测期内实现多层次的均衡成长。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 危险产业严格的工人安全法规

- 智慧连网探测器的安装量不断增加

- 即时多气体监测的需求日益增长

- 中游液化天然气和氢能基础设施扩建

- 智慧建筑如何满足室内空气品质法规要求

- 锂离子电池工厂的气体洩漏监测

- 市场限制

- 初始成本高,产品差异化程度低。

- 维护和校准负担

- 工业物联网侦测器的网路安全隐患

- 半导体感测器週期性供不应求

- 供应链分析

- 监管环境

- 技术展望

- 影响市场的宏观经济因素

- 波特五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模与成长预测

- 依沟通类型

- 有线

- 无线的

- 按最终用户行业划分

- 石油和天然气

- 化学品和石油化工

- 供水和污水处理

- 金属和采矿

- 公用事业

- 其他终端用户产业

- 检测器类型

- 固定的

- 电化学

- 半导体

- 光电离

- 催化剂

- 红外线的

- MEMS

- 可携式可携式

- 多气体

- 单气体

- 固定的

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 其他欧洲地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 东南亚

- 亚太其他地区

- 中东和非洲

- 中东

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 其他中东地区

- 非洲

- 南非

- 埃及

- 其他非洲地区

- 中东

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Honeywell International Inc.

- Dragerwerk AG & Co. KGaA

- MSA Safety Incorporated

- Emerson Electric Co.

- Industrial Scientific Corporation

- Teledyne Gas & Flame Detection(Teledyne Technologies Inc.)

- Riken Keiki Co., Ltd.

- Crowcon Detection Instruments Ltd.

- Hanwei Electronics Group Corp.

- Trolex Ltd.

- Sensidyne LP

- New Cosmos Electric Co., Ltd.

- SENSIT Technologies LLC

- International Gas Detectors Ltd.

- GfG Gesellschaft fur Geratebau mbH

- GASTEC Corporation

- Yokogawa Electric Corp.

- Siemens AG-Process Safety Division

- Pem-Tech Inc.

- RKI Instruments Inc.

- WatchGas BV

- Ion Science Ltd.

- Ametek-Sensor Electronics

第七章 市场机会与未来展望

The gas detectors market was valued at USD 2.99 billion in 2025 and estimated to grow from USD 3.14 billion in 2026 to reach USD 4.01 billion by 2031, at a CAGR of 5.01% during the forecast period (2026-2031).

The trajectory reflects rising capital investment in real-time worker-safety solutions, growing retrofit demand across legacy plants, and the integration of connected detection platforms that feed predictive analytics engines. Strict enforcement of OSHA, NFPA 72, and regional mining codes is stimulating equipment replacement cycles, while sustained buildouts of midstream LNG hubs, hydrogen production assets, and lithium-ion battery lines elevate baseline demand for combustible and toxic-gas monitoring. Intensifying cybersecurity rules for safety systems is steering procurement toward vendors that can combine certified sensor hardware with secured IoT software stacks. Although wired networks still dominate brownfield installations, advances in wireless mesh topologies and multiyear battery modules are lowering total installed cost and unlocking untapped niches such as remote wellheads and temporary turnaround zones. Competitive activity is accelerating as incumbent global suppliers defend share against specialist entrants promising lower drift rates, hydrogen specificity, or subscription-based calibration services.

Global Gas Detectors Market Trends and Insights

Stringent Worker-Safety Mandates in Hazardous Industries

Regulators now require live environmental telemetry rather than periodic spot checks, compelling mines, refineries, and chemical complexes to deploy continuous monitoring networks. OSHA's 2025 program of data-driven inspections is motivating operators to replace legacy single-gas units with networked multigas arrays that transmit readings into centralized dashboards. Australian coal legislation mandates mine-drained-roadway (MDR) certification, prompting orders for explosion-proof fixed heads and UAV-mounted sensors that map underground methane in three dimensions. Municipal water utilities must comply with NFPA 820 thresholds for hydrogen sulfide, leading to multi-thousand-unit retrofits of wet-well ventilated spaces. Leading vendors respond with predictive analytics software that flags abnormal patterns before alarms trigger, aligning with zero-harm directives such as Industrial Scientific's vision to eliminate workplace fatalities by 2050. Annual compliance spending can top USD 100,000 for a single refinery, locking in replacement cycles and service contracts.

Rising Installation of Smart, Connected Detectors

IoT connectivity converts the gas detectors market from product sales to data-service ecosystems. Blackline's EXO 8 streams to the cloud for 100 days on a single charge, allowing remote safety teams to watch exposure trends in real time. Honeywell's Sensepoint XCL pairs with smartphones through Bluetooth Low Energy, guiding technicians step-by-step and shortening calibration windows by up to 30%. Predictive dashboards schedule sensor replacement automatically, mitigating skilled-labor shortages and cutting unplanned downtime. Subscription bundles such as Industrial Scientific's iNet Exchange shift procurement from capex to opex, bundling hardware, consumables, and analytics in multi-year contracts. Automated compliance logs shave audit preparation from weeks to hours, an attractive benefit for multinationals juggling disparate regional regulations.

High Upfront Cost and Limited Product Differentiation

Industrial-grade multigas portables range from USD 500 to USD 1,500 per unit, figures that double once installation hardware, commissioning, and user training are included. The AimSafety PM400 lists at USD 558.57 while Gas Clip's maintenance-free MGC Simple commands USD 697.07, highlighting price premiums linked to no-calibration claims. Low-cost Asian clones undercut established brands by up to 50%, compressing margins and delaying replacement programs in budget-constrained plants. Fixed-system installs often exceed USD 1 million for a mid-size refinery section once certified conduit, control cabinets, and functional testing are included. Price sensitivity is amplified in regions where enforcement remains inconsistent, enabling some operators to defer upgrades.

Other drivers and restraints analyzed in the detailed report include:

- Growing Demand for Real-Time Multigas Monitoring

- Expansion of Midstream LNG and Hydrogen Infrastructure

- Maintenance-Calibration Burdens

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

The wired segment held 50.35% of 2025 revenue as established refineries, LNG trains, and chemical parks rely on proven hardwired loops that meet hazardous-area standards. In these legacy environments, the gas detectors market continues to favor flameproof junction boxes and armored cable runs that withstand electromagnetic interference. However, wireless solutions are on a 7.05% CAGR through 2031, buoyed by projects where trenching costs or temporary turnaround schedules favor rapid deployment. Early-generation radio systems suffered from limited battery life, yet second-generation mesh designs now deliver up to 100 days of uptime on a single charge and can hop data through multiple gateways to reach a plant's supervisory control network. New-build hydrogen hubs and battery plants increasingly budget for hybrid architectures in which wireless nodes feed hardwired safe-area gateways, blending flexibility with deterministic uptime. Regulators are beginning to clear suitably redundant wireless life-safety loops, a policy evolution that removes a historic adoption barrier in jurisdictions such as the European Union and parts of the United States. Equipment manufacturers thus channel research and development into firmware-based cybersecurity, OT network segmentation, and over-the-air sensor calibration routines that align with National Institute of Standards and Technology guidelines. The shift lifts overall solution ASPs and introduces subscription revenue as vendors monitor network health remotely, thus enlarging the gas detectors market value pool even though absolute sensor counts continue to favor wired nodes for the next five years.

Wireless uptake also benefits from digital transformation budgets that seek to unify disparate field instruments under common asset-performance dashboards. When procurement teams tally the total cost of ownership, the elimination of conduit, cable trays, and hot-work permits often offsets the premium list price of wireless analyzers. Added mobility widens safety coverage during turnaround events, where temporary pipework changes create fresh leak paths each day. Downstream petrochemical players that trialed wireless packs during 2024 turnaround seasons report 15% fewer confined-space entry violations and 8% shorter maintenance windows. These operational wins reinforce payback models and solidify management buy-in, further accelerating wireless share gains within the broader gas detectors market.

The Gas Detectors Market Report is Segmented by Communication Type (Wired, and Wireless), Detector Type (Fixed - Electrochemical, Semiconductor, and More), End-User Industry (Oil and Gas, Chemicals and Petrochemicals, Water and Wastewater, Metal and Mining, and More), and Geography (North America, South America, Europe, Asia-Pacific, Middle East, and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific accounted for 48.60% of global revenue in 2025 and is forecast to maintain the fastest 6.92% CAGR, anchored by China's surge in coal-to-chemicals complexes, India's new-build refineries, and Southeast Asia's battery-supply-chain investment wave. Frequent safety audits under China's Ministry of Emergency Management are compelling facility operators to replace uncertified low-cost imports with ATEX and IECEx-compliant equipment. South Korea and Japan accelerate hydrogen refueling networks, each pump incorporating dual redundant hydrogen sensors as mandated by fire codes. India's Jal Jeevan Mission triggers upgrades in chlorine and ozone monitoring across thousands of water plants, further widening demand. Domestic electronics firms ramp gallium-nitride power-switch fabrication, creating fresh opportunities for specialty ammonia and hydrogen chloride detection.

North America ranks second by revenue share, driven by OSHA enforcement, shale gas processing, and liquid-natural-gas export terminals along the Gulf Coast. New York City's Local Law 157 requires residential natural-gas detectors by May 2025, injecting multi-million-unit volume into the residential and light-commercial slice of the gas detectors market. U.S. hydrogen hubs funded under the Infrastructure Investment and Jobs Act prescribe multigas fixed networks with encrypted wireless backbones, stimulating orders for hydrogen-specific sensors. Canada's oil sands operations specify heaters and analyzers that remain accurate at -40 °C, favoring vendors with arctic-rated equipment lines. Mexico's industrial corridors around Monterrey and Bajio integrate VOC detectors in auto-paint shops to meet OEM sustainability audits.

Europe maintains strict ATEX compliance, EPBD indoor-air-quality mandates, and decarbonization targets that collectively sustain steady upgrades. Germany's large chemical basin along the Rhine invests in benzene and butadiene monitoring to cut fugitive emissions, while the United Kingdom enforces CO2 monitoring in commercial offices to improve occupant well-being. Offshore North Sea platforms demand detector heads certified for hydrogen sulfide concentrations exceeding 100 ppm, alongside open-path infrared units that span 200 metres across platform topsides. Eastern European member states leverage EU cohesion funds to modernize district-heating plants, integrating carbon-monoxide and methane sensors into combined-heat-and-power modules. Mediterranean LNG import terminals adopt wireless flame and gas packages to retrofit legacy jetties without disrupting operations.

The Middle East and Africa region captures a smaller revenue share but sees robust adoption in green-hydrogen pilot plants, liquefaction trains, and mining expansion corridors. GCC refiners retrofit hydrocracker units to meet Euro VI sulfur limits, upgrading catalytic bead LEL heads in the process. South African gold mines face stricter Department of Mineral Resources oversight that mandates continuous fixed monitoring in deep-level shafts. In Latin America, Brazil's pre-salt offshore fields require high-specification detectors rated for high hydrogen-sulfide concentrations, while Chile's lithium brine processors install hydrogen-chloride analyzers to comply with environmental statutes. Collectively, these regional dynamics sustain balanced multilayer growth in the gas detectors market across the forecast horizon.

- Honeywell International Inc.

- Dragerwerk AG & Co. KGaA

- MSA Safety Incorporated

- Emerson Electric Co.

- Industrial Scientific Corporation

- Teledyne Gas & Flame Detection (Teledyne Technologies Inc.)

- Riken Keiki Co., Ltd.

- Crowcon Detection Instruments Ltd.

- Hanwei Electronics Group Corp.

- Trolex Ltd.

- Sensidyne LP

- New Cosmos Electric Co., Ltd.

- SENSIT Technologies LLC

- International Gas Detectors Ltd.

- GfG Gesellschaft fur Geratebau mbH

- GASTEC Corporation

- Yokogawa Electric Corp.

- Siemens AG - Process Safety Division

- Pem-Tech Inc.

- RKI Instruments Inc.

- WatchGas B.V.

- Ion Science Ltd.

- Ametek - Sensor Electronics

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Stringent worker-safety mandates in hazardous industries

- 4.2.2 Rising installation of smart, connected detectors

- 4.2.3 Growing demand for real-time multigas monitoring

- 4.2.4 Expansion of midstream LNG and hydrogen infrastructure

- 4.2.5 Indoor air-quality compliance in smart buildings

- 4.2.6 Lithium-ion battery plants' gas-leak scrutiny

- 4.3 Market Restraints

- 4.3.1 High upfront cost and limited product differentiation

- 4.3.2 Maintenance-calibration burdens

- 4.3.3 Cyber-security concerns in IIoT-enabled detectors

- 4.3.4 Periodic semiconductor-sensor supply shortages

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Impact of Macroeconomic Factors on the Market

- 4.8 Porter's Five Forces Analysis

- 4.8.1 Bargaining Power of Suppliers

- 4.8.2 Bargaining Power of Buyers

- 4.8.3 Threat of New Entrants

- 4.8.4 Threat of Substitutes

- 4.8.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Communication Type

- 5.1.1 Wired

- 5.1.2 Wireless

- 5.2 By End-User Industry

- 5.2.1 Oil and Gas

- 5.2.2 Chemicals and Petrochemicals

- 5.2.3 Water and Wastewater

- 5.2.4 Metal and Mining

- 5.2.5 Utilities

- 5.2.6 Other End-User Industries

- 5.3 By Detector Type

- 5.3.1 Fixed

- 5.3.1.1 Electrochemical

- 5.3.1.2 Semiconductor

- 5.3.1.3 Photo-ionization

- 5.3.1.4 Catalytic

- 5.3.1.5 Infra-red

- 5.3.1.6 MEMS

- 5.3.2 Portable and Transportable

- 5.3.2.1 Multi-Gas

- 5.3.2.2 Single-Gas

- 5.3.1 Fixed

- 5.4 By Geography

- 5.4.1 North America

- 5.4.1.1 United States

- 5.4.1.2 Canada

- 5.4.1.3 Mexico

- 5.4.2 South America

- 5.4.2.1 Brazil

- 5.4.2.2 Argentina

- 5.4.2.3 Rest of South America

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Spain

- 5.4.3.6 Russia

- 5.4.3.7 Rest of Europe

- 5.4.4 Asia-Pacific

- 5.4.4.1 China

- 5.4.4.2 Japan

- 5.4.4.3 India

- 5.4.4.4 South Korea

- 5.4.4.5 South-East Asia

- 5.4.4.6 Rest of Asia-Pacific

- 5.4.5 Middle East and Africa

- 5.4.5.1 Middle East

- 5.4.5.1.1 Saudi Arabia

- 5.4.5.1.2 United Arab Emirates

- 5.4.5.1.3 Rest of Middle East

- 5.4.5.2 Africa

- 5.4.5.2.1 South Africa

- 5.4.5.2.2 Egypt

- 5.4.5.2.3 Rest of Africa

- 5.4.5.1 Middle East

- 5.4.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Honeywell International Inc.

- 6.4.2 Dragerwerk AG & Co. KGaA

- 6.4.3 MSA Safety Incorporated

- 6.4.4 Emerson Electric Co.

- 6.4.5 Industrial Scientific Corporation

- 6.4.6 Teledyne Gas & Flame Detection (Teledyne Technologies Inc.)

- 6.4.7 Riken Keiki Co., Ltd.

- 6.4.8 Crowcon Detection Instruments Ltd.

- 6.4.9 Hanwei Electronics Group Corp.

- 6.4.10 Trolex Ltd.

- 6.4.11 Sensidyne LP

- 6.4.12 New Cosmos Electric Co., Ltd.

- 6.4.13 SENSIT Technologies LLC

- 6.4.14 International Gas Detectors Ltd.

- 6.4.15 GfG Gesellschaft fur Geratebau mbH

- 6.4.16 GASTEC Corporation

- 6.4.17 Yokogawa Electric Corp.

- 6.4.18 Siemens AG - Process Safety Division

- 6.4.19 Pem-Tech Inc.

- 6.4.20 RKI Instruments Inc.

- 6.4.21 WatchGas B.V.

- 6.4.22 Ion Science Ltd.

- 6.4.23 Ametek - Sensor Electronics

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment