|

市场调查报告书

商品编码

1910474

高纯度氧化铝(HPA):市占率分析、产业趋势与统计、成长预测(2026-2031)High-Purity Alumina (HPA) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

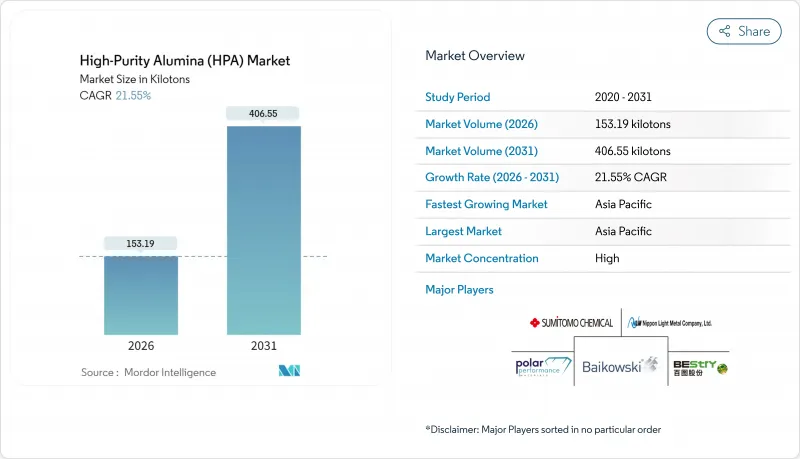

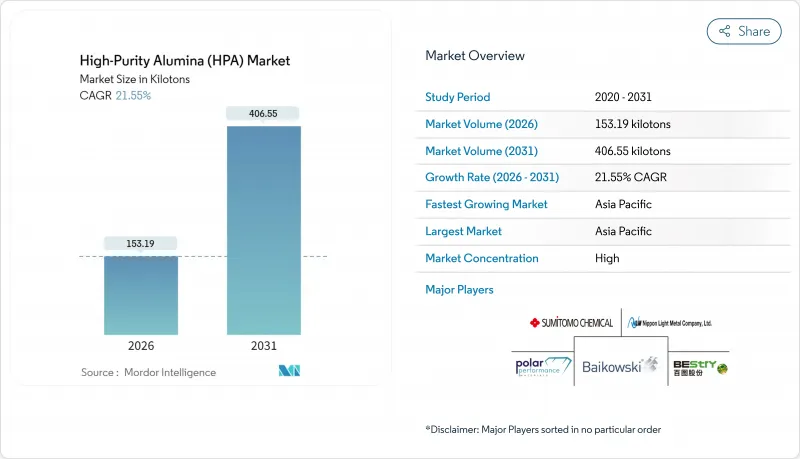

2025 年高纯度氧化铝 (HPA) 市场价值为 126.03 千吨,预计到 2031 年将达到 406.55 千吨,高于 2026 年的 153.19 千吨。

预测期(2026-2031 年)的复合年增长率预计为 21.55%。

这种陡峭的成长轨迹反映了锂离子电池需求的激增、LED照明的持续发展势头以及先进封装技术加速应用。电动车和储能计划数量的成长正推动高纯度氧化铝(HPA)朝向超高纯度方向发展,而生产商则竞相运作基于盐酸浸出和溶剂萃取方法等低成本、低碳的生产设施。同时,图案化蓝宝石基板和更大晶圆尺寸的创新正在提高LED晶片的产量比率,从而稳定了对传统4N级氧化铝的需求。半导体晶圆厂正在推动6N级氧化铝在共封装光学元件和垂直GaN元件中的应用,这为结构性需求增添了新的维度。儘管高昂的生产成本仍然是推广应用的主要障碍,但快速的规模化生产正在缩小与低纯度氧化铝的成本差距,使电池和电力电子领域的早期采用者能够承受价格溢价。

全球高纯度氧化铝(HPA)市场趋势及展望

对LED照明的需求不断成长

蓝宝石基板是高亮度LED的基础,因为它们能够承受高热负荷并保持光学透明度。从2-4吋晶圆到6-8吋晶圆的过渡提高了单次熔炼的晶片产量,从而提高了产量比率并降低了晶圆成本。图案化蓝宝石基板使光提取效率提高了高达40%,直接提高了每瓦流明数。铯掺杂石榴石陶瓷的研究已将发光效率提高到261.98 lm/W,突破了高功率白光发光装置的性能极限。柔性奈米压印微影术技术进一步缩短了製程时间,使微结构LED的生产效率提高了六倍。这些进步共同推动了5N级蓝宝石在超高亮度元件中的选择性应用,而LED製造商仍然依赖4N级高功率蓝宝石基板。

锂离子电池市场需求不断成长

搭乘用电动车 (EV) 和固定式储能係统中高功率密度电池的快速普及,推动了对采用 5N 和 6N 高纯度氧化铝 (HPA) 的隔膜涂层的需求。这种基于氧化铝奈米层的涂层能够改善热关断特性并抑制枝晶生长,从而实现快速充电和延长循环寿命。 Altech 公司基于其位于德国的年产 8000 吨 HPA 涂层工厂的硅负极项目,旨在实现比石墨更高的能量保持率。该计划的净现值 (NPV) 为 6.84 亿欧元(约 7.9355 亿美元),内部收益率 (IRR) 为 34%,证实了优质 HPA 的商业性潜力。中国电池 OEM 厂商已开始测试采用陶瓷涂层隔板的 6N HPA,用于新一代快充电池,这标誌着大规模生产合格测试的转捩点。

高纯度氧化铝成本高昂

煅烧和多次重结晶步骤会导致高能耗,尤其是对于价格较高的5N和6N牌号氧化铝。 Alpha HPA的溶剂萃取方法声称可减少70%的碳排放,并透过省去铝金属萃取步骤显着降低电力消耗量消耗。虽然这缩小了成本差距,但类似装置的广泛运作仍需两到三年时间,这将影响短期采购预算。工业氧化铝现货价格的波动进一步加剧了特种用户长期供应合约谈判的复杂性。

细分市场分析

截至2025年,4N级氧化铝将占总出货量的73.12%,主要用于製造通用LED的蓝宝石晶圆。同时,受半导体和下一代电池应用对亚ppm级杂质含量要求的推动,6N级氧化铝的出货量预计将以22.22%的复合年增长率增长。 Alpha HPA的闭合迴路溶剂萃取先导工厂实现了试剂的完全回收利用,降低了可变生产成本,从而促进了5N级和6N级氧化铝的广泛应用。製造商正在采用混合策略,为大规模生产的LED应用提供4N级氧化铝,同时将增加的产能分配给6N级氧化铝,以满足高利润合约的需求。电池OEM厂商已开始强制要求快充电池采用5N级或更高等级的涂层,提高了传统上对价格敏感地区的需求稳定性。节能提纯技术的研发投入不断活性化,可望部分消除成本差异,加速高纯度氧化铝市场中高阶等级的扩张。

由于成熟的供应链和丰富的矾土原料,传统的铝醇盐水解製程预计到2025年将占全球铝产量的87.25%。然而,新参与企业更青睐盐酸浸出工艺,该工艺因其每吨投资成本低、易于去除杂质等优点,正以22.35%的复合年增长率快速增长。一项结合放电等离子緻密化和无压精整的两阶段烧结技术的研究表明,该技术不仅缩短了炉内加工时间,还能将抗弯强度提高19%。新兴的东南亚冶炼厂正在采用模组化盐酸再生系统,以减少酸的消耗和废水排放,从而符合日益严格的区域环境法规。现有企业则透过在老旧的水解生产线上改造溶剂萃取纯化製程来提高纯度,从而维持其市场地位。从中长期来看,欧洲和北美提案的碳强度揭露规则可能会成为技术选择的决定性因素,使潜在投资倾向于隐含排放较低的浸出工厂。

区域分析

在中国完整的氧化铝价值链以及日本和韩国在LED和半导体製造领域的主导地位的支撑下,预计到2025年,亚太地区将占高纯氧化铝市场规模的75.61%。受电动车的积极普及、晶圆厂的兴起以及澳洲新建溶剂萃取精炼厂的运作等因素的推动,该地区市场预计到2031年将以22.85%的年均成长率成长。

在北美,联邦政府的奖励措施正推动半导体产业的復苏,而不断扩大的公共充电基础设施也提振了对锂离子电池的需求。加拿大和美国拥有强大的电网,这有助于它们实现低碳生产目标。虽然南美洲、中东和非洲的贡献相对较小,但随着矾土丰富的国家向下游产业多元化发展,这些地区蕴藏着长期的成长机会。

巴西正在製定特种氧化铝的激励措施,沙乌地阿拉伯正在探索氧化铝精炼厂,以配合其更广泛的矿产策略,这些地区为寻求地理多元化的高纯度氧化铝市场参与企业提供了选择。

其他福利:

- Excel格式的市场预测(ME)表

- 分析师支持(3个月)

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 对LED照明的需求不断成长

- 锂离子电池市场需求不断成长

- 半导体产业对高纯度氧化铝的需求日益增长

- 在电动车电力电子模组中采用基于HPA的热界面材料

- 电子产业需求增加

- 市场限制

- 高纯度氧化铝高成本

- 低成本替代品的可用性

- 全球原料供应有限

- 价值链分析

- 波特五力模型

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代产品和服务的威胁

- 竞争程度

第五章 市场规模与成长预测

- 按纯度等级(按类型)

- 4N

- 5N

- 6N

- 透过製造技术

- 水解

- 盐酸浸出

- 透过使用

- LED照明

- 磷光体

- 半导体

- 锂离子电池

- 技术陶瓷

- 其他(防刮玻璃、光学镜片等)

- 按最终用户行业划分

- 电子设备

- 车

- 储能

- 医疗设备

- 工业製造

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 马来西亚

- 泰国

- 印尼

- 越南

- 亚太其他地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 北欧国家

- 土耳其

- 俄罗斯

- 其他欧洲地区

- 南美洲

- 巴西

- 阿根廷

- 哥伦比亚

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 卡达

- 阿拉伯聯合大公国

- 奈及利亚

- 埃及

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率(%)分析

- 公司简介

- Advanced Energy Minerals

- Altech Advanced Materials

- Alpha HPA

- Baikowski SA

- Bestry

- Hebei Pengda New Materials Technology Co., Ltd.

- HONGHE CHEMICAL

- Nippon Light Metal Company, Ltd.

- Polar Performance Materials

- RusAL

- Sasol

- Saint-Gobain

- Shandong Keheng Crystal Material Technology Co., Ltd.

- Sumitomo Chemical Co., Ltd.

- Xuancheng Jingrui New Materials Co., Ltd.

第七章 市场机会与未来展望

The High-Purity Alumina Market was valued at 126.03 kilotons in 2025 and estimated to grow from 153.19 kilotons in 2026 to reach 406.55 kilotons by 2031, at a CAGR of 21.55% during the forecast period (2026-2031).

This steep growth curve reflects surging demand from lithium-ion batteries, sustained momentum in LED lighting, and accelerating adoption in advanced semiconductor packaging. An expanding base of electric-vehicle and energy-storage projects is pulling HPA grades toward ultra-high purities, while producers race to commission lower-cost, lower-carbon capacity based on hydrochloric-acid leaching and solvent-extraction routes. At the same time, breakthroughs in patterned sapphire substrates and larger wafer formats are lifting LED chip yields and keeping traditional 4N demand stable. Semiconductor fabs are pushing for 6N grades that support co-packaged optics and vertical GaN devices, adding another layer of structural demand. Although high production cost remains the primary brake on broader uptake, rapid scale-up is narrowing the cost gap versus lower-purity aluminas, and early adopters in batteries and power electronics are absorbing the premium.

Global High-Purity Alumina (HPA) Market Trends and Insights

Increasing Demand for LED-Based Lighting

Sapphire substrates remain the backbone of high-brightness LEDs because they tolerate high thermal loads and sustain optical clarity. Migration from 2-4 to 6-8 in wafers has raised chip throughput per melt, boosted yield, and lowered die cost. Patterned sapphire substrates now lift light-extraction efficiency by up to 40%, directly improving lumens per watt. Research on Ce-doped garnet ceramics has pushed luminous efficiency to 261.98 lm W-1, stretching the performance ceiling for high-power white emitters. Flexible nanoimprint lithography further cuts process time, raising microstructured LED productivity six-fold. Together, these advances keep LED producers firmly anchored to 4N HPA while opening selective pull-through for 5N grades in ultra-high-luminance devices.

Growing Demand from Lithium-Ion Battery Markets

Rapid scale-up of power-dense cells in passenger EVs and stationary storage propels separator-coating demand for 5N and 6N HPA. Coatings based on alumina nanolayers improve thermal shut-down behavior and suppress dendrite growth, enabling faster charging and longer cycle life. Altech's silicon-anode program, underpinned by an 8,000 tons/year HPA coating plant in Germany, targets 30% higher energy retention versus graphite baselines. The project's EUR 684 million (~USD 793.55 million) NPV and 34% IRR confirm commercial traction for premium grades. Battery OEMs in China are already trialing 6N HPA on ceramic-coated separators for next-generation fast-charge cells, marking a pivot point for large-volume qualifying runs.

High Cost of High-Purity Alumina

Calcination and multiple recrystallization stages keep energy use high, especially for 5N and 6N grades, which can trade at price premiums. Alpha HPA's solvent-extraction route, which bypasses the aluminum-metal step, claims 70% lower carbon emissions and a significant cut in power intensity. While this narrows the cost delta, widespread commissioning of similar plants is still two to three years away, exposing near-term procurement budgets. Spot price volatility in industrial alumina further complicates long-term offtake negotiations for specialty users.

Other drivers and restraints analyzed in the detailed report include:

- Increasing Usage in Semiconductors

- Adoption of HPA-Based Thermal Interface Materials in EV Power-Electronics Modules

- Availability of Low-Cost Alternatives

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

In 2025, the 4N grade commanded 73.12% of total volume, anchored by sapphire wafers for general-purpose LEDs. At the same time, 6N shipments are on a 22.22% CAGR path, lifted by semiconductor and next-generation battery uses that demand sub-ppm impurity levels. Alpha HPA's closed-loop solvent-extraction pilot demonstrated full reagent recycling, lowering variable production cost, and making 5N and 6N more accessible. Manufacturers are adopting hybrid strategies, producing 4N for mass LED use and diverting incremental capacity to 6N to serve high-margin contracts. As battery OEMs begin to mandate more than or equal to 5N coatings for fast-charge cells, demand elasticity improves even in traditionally price-sensitive regions. Heightened research and development around energy-efficient purification is expected to close a portion of the cost gap, accelerating the premium-grade mix within the High-Purity Alumina market.

The legacy aluminum-alkoxide hydrolysis route delivered 87.25% of global output in 2025, owing to mature supply chains and ample bauxite feedstock. However, new entrants are favoring hydrochloric-acid leaching, which is scaling at a 22.35% CAGR, encouraged by lower capex per tonne and easier impurity bleed-off. Two-step sintering studies that combine spark-plasma densification with pressureless finishing showed a 19% flexural-strength gain alongside reduced furnace time. Emerging Southeast Asian refineries use modular HCl regeneration units to cut acid consumption and shrink effluent loads, aligning with stricter regional environmental norms. Incumbents are retrofitting older hydrolysis lines with solvent-extraction polishing stages to raise purity yields, preserving market position. Over the medium term, technology choice may hinge on proposed carbon-intensity disclosure rules in Europe and North America, potentially tipping marginal investment toward leach-based plants that score lower on embedded emissions.

The High Purity Alumina Market Report Segments the Industry by Type (4N, 5N, and 6N), Production Technology (Hydrolysis and Hydrochloric Acid Leaching), Application (LED Lighting, Phosphor, Semiconductor, Lithium-Ion (Li-Ion) Batteries, and More), End-User Industry (Electronics, Automotive, Energy Storage, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa).

Geography Analysis

Asia-Pacific accounted for 75.61% of the High Purity Alumina market volume in 2025, supported by China's integrated alumina value chain and Japan's and South Korea's leadership in LED and semiconductor fabrication. The region's market is projected to add 22.85% annually through 2031, thanks to aggressive EV roll-outs, growing wafer fabs, and new solvent-extraction refineries coming online in Australia.

North America is leveraging federal incentives for semiconductor reshoring and growing public-charging infrastructure that lifts lithium-ion battery demand. Canada and the United States benefit from stable electricity grids, supporting low-carbon production ambitions. South America, the Middle East, and Africa contribute modestly but represent long-run opportunities as bauxite-rich nations seek downstream diversification.

Brazil has outlined incentives for specialty alumina, while Saudi Arabia investigates alumina refining linked to its broader minerals strategy. These regions provide optionality for High-Purity Alumina market participants seeking geographic risk diversification.

- Advanced Energy Minerals

- Altech Advanced Materials

- Alpha HPA

- Baikowski SA

- Bestry

- Hebei Pengda New Materials Technology Co., Ltd.

- HONGHE CHEMICAL

- Nippon Light Metal Company, Ltd.

- Polar Performance Materials

- RusAL

- Sasol

- Saint-Gobain

- Shandong Keheng Crystal Material Technology Co., Ltd.

- Sumitomo Chemical Co., Ltd.

- Xuancheng Jingrui New Materials Co., Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increasing Demand for Led-based Lighting

- 4.2.2 Growing Demand from Lithium-ion Battery Markets

- 4.2.3 Increasing Usage of High Purity Alumina in Semiconductors

- 4.2.4 Adoption of HPA-Based Thermal Interface Materials in EV Power-Electronics Modules

- 4.2.5 Increasing Demand from the Electronics Industry

- 4.3 Market Restraints

- 4.3.1 High Cost of High-purity Alumina

- 4.3.2 Availabity of Low Cost Alternatives

- 4.3.3 Limited Availability of Raw Material Across the Globe

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitute Products and Services

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Purity Level (Type)

- 5.1.1 4N

- 5.1.2 5N

- 5.1.3 6N

- 5.2 By Production Technology

- 5.2.1 Hydrolysis

- 5.2.2 Hydrochloric Acid Leaching

- 5.3 By Application

- 5.3.1 LED Lighting

- 5.3.2 Phosphor

- 5.3.3 Semiconductor

- 5.3.4 Lithium-ion Batteries

- 5.3.5 Technical Ceramics

- 5.3.6 Others (Scratch-Resistant Glass, Optical Lenses, etc.)

- 5.4 By End-User Industry

- 5.4.1 Electronics

- 5.4.2 Automotive

- 5.4.3 Energy Storage

- 5.4.4 Medical Devices

- 5.4.5 Industrial Manufacturing

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Malaysia

- 5.5.1.6 Thailand

- 5.5.1.7 Indonesia

- 5.5.1.8 Vietnam

- 5.5.1.9 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Nordic Countries

- 5.5.3.7 Turkey

- 5.5.3.8 Russia

- 5.5.3.9 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Colombia

- 5.5.4.4 Rest of South America

- 5.5.5 Middle-East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 Qatar

- 5.5.5.3 United Arab Emirates

- 5.5.5.4 Nigeria

- 5.5.5.5 Egypt

- 5.5.5.6 South Africa

- 5.5.5.7 Rest of Middle-East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%) Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Advanced Energy Minerals

- 6.4.2 Altech Advanced Materials

- 6.4.3 Alpha HPA

- 6.4.4 Baikowski SA

- 6.4.5 Bestry

- 6.4.6 Hebei Pengda New Materials Technology Co., Ltd.

- 6.4.7 HONGHE CHEMICAL

- 6.4.8 Nippon Light Metal Company, Ltd.

- 6.4.9 Polar Performance Materials

- 6.4.10 RusAL

- 6.4.11 Sasol

- 6.4.12 Saint-Gobain

- 6.4.13 Shandong Keheng Crystal Material Technology Co., Ltd.

- 6.4.14 Sumitomo Chemical Co., Ltd.

- 6.4.15 Xuancheng Jingrui New Materials Co., Ltd.

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment

- 7.2 Application in Scratch-resistant Glasses for Smartphones and Watches

- 7.3 Growing Applications in Manufacturing Optical Lenses