|

市场调查报告书

商品编码

1910497

聚偏聚二氟亚乙烯(PVDF):市场份额分析、产业趋势与统计、成长预测(2026-2031)Polyvinylidene Fluoride (PVDF) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

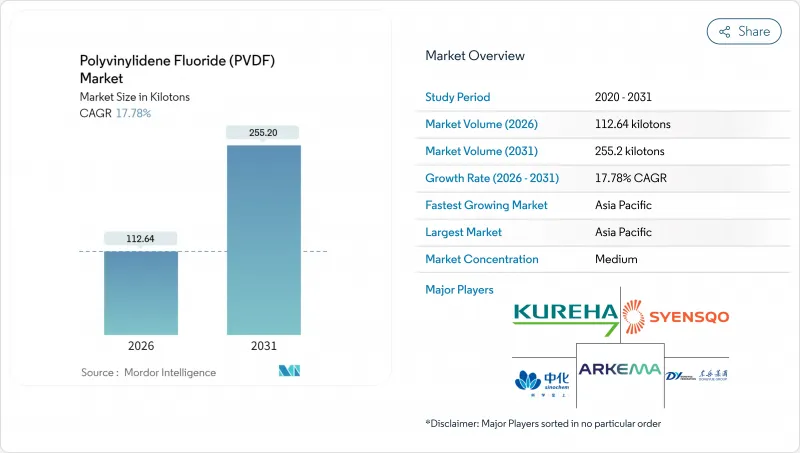

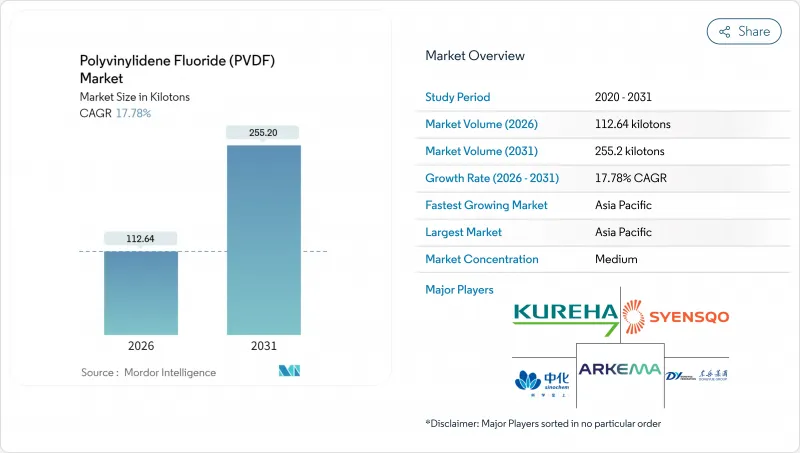

预计聚二氟亚乙烯市场将从 2025 年的 95.64 千吨成长到 2026 年的 112.64 千吨,到 2031 年将达到 255.2 千吨,2026 年至 2031 年的复合年增长率为 17.78%。

交通运输的持续电气化、用于生产10奈米以下晶片的无尘室建设的加速推进,以及基础设施计划对长寿命建筑饰面材料的指定,都支撑着未来几年持续增长的需求。那些能够后向整合二氟乙烯单体生产、在电池製造地附近建立本地生产能力,并为无尘室系统提供应用工程支援的製造商,将拥有可持续的竞争优势。同时,中国现货市场供应过剩导致的价格波动,凸显了审慎扩张产能和签订长期原料采购协议的必要性。政府激励措施,特别是来自美国的1.78亿美元津贴(这将为北美首个世界级规模的工厂奠定基础),表明战略性政策支持在平衡区域供应结构和确保关键行业PVDF稳定供应方面仍然至关重要。

全球聚二氟亚乙烯(PVDF)市场趋势与洞察

电动车电池产量激增

汽车製造商数十亿美元的电气化蓝图直接推动了对专用黏合剂的需求,这些黏合剂能够确保电极在数千次充放电循环中保持完整性。 Syensqo位于奥古斯塔的工厂每年为超过500万个电动车电池组供应PVDF。这一规模得益于美国能源局提供的1.78亿美元津贴,该拨款为建立国内正极黏合剂供应链奠定了基础。随着主要电池製造商的垂直整合程度不断提高,规格范围正在缩小,每个电池组的PVDF用量也随之增加到15-50克/千瓦时,德国汽车工业协会(VDA)已证实了这一点。随着美国、欧洲和印度超级工厂的扩张,拥有本地生产能力的製造商享有运输成本优势和认证接近性,从而增强了区域供应安全。这些趋势共同推高了PVDF的基准消费量和分销利润率,使聚二氟亚乙烯市场成为电动车转型的主要受益者。

对耐化学腐蚀涂料的需求

建筑设计师正持续转向采用PVDF线圈涂布系统,这些涂料在保色性、光泽稳定性和抗粉化性方面均超越了AAMA 2605性能标准。佛罗里达州、德克萨斯州以及颱风频繁的亚太地区的建筑规范强制要求采用这些高品质的涂料,从而将重涂週期延长至30年,并降低建筑幕墙的生命週期成本。工业领域也呈现类似的趋势,化学公司正在对钢製储槽维修,采用耐强酸强碱的PVDF面漆,从而减少因腐蚀导致的停机和监管处罚。随着基础设施奖励策略法案优先考虑建造具有韧性的公共建筑,即使在景气衰退的情况下,涂料价值链也有望实现稳定的销售成长,这进一步巩固了聚二氟亚乙烯市场的防御优势。

原物料价格波动 (VF2)

过去六个月,由于产能快速扩张超过了锂离子电池黏合剂的需求,中国PVDF现货价格持续下跌。由于偏二氟乙烯成本占PVDF现金成本的65%至70%,这种价格波动挤压了利润空间,并扰乱了长期采购合约。西方加工商透过与指数挂钩的配方合约来对冲风险,而亚洲中型挤出製造商仍然面临风险,投机性库存积压加剧了市场波动。在供应趋于合理化之前,采购部门可能会优先考虑原材料来源多元化,并探索代工加工合同,以稳定聚聚二氟亚乙烯市场的原材料供应。

细分市场分析

截至2025年,锂离子电池黏合剂在聚二氟亚乙烯)市场占据了33.62%的主导份额,预计到2031年将以31.05%的复合年增长率增长,这反映了该材料在高能量密度电池化学系统中确立的重要作用。由于其他聚合物会影响循环寿命和倍率性能,主要汽车製造商正在指定PVDF黏合剂用于下一代高镍正极材料。同时,硅增强型负极中更高的负载量也推高了单节电池的消费量,使基础吨位需求翻了一番。

涂料和油漆领域预计将保持稳定、适度的个位数成长,这主要得益于美国建筑幕墙维修的加速以及欧洲绿色建筑法规的推行。电线电缆绝缘材料在资料中心电力网路中的份额不断增长,低烟无卤标准正在取代PVC护套。薄膜、片材和膜材填补了从气体分离模组到强溶剂专用包装等各种细分市场,PVDF优异的阻隔性能使其能够获得较高的溢价。管道和管件服务于半导体和化学工艺,其产量受工厂扩建週期的影响,并在聚二氟亚乙烯市场中拥有最高的毛利率。

聚偏聚二氟亚乙烯市场报告按应用领域(锂离子电池黏合剂、油漆和涂料、管道和配件、薄膜和片材等)、终端用户产业(航太、汽车、建筑和施工、电气和电子等)以及地区(亚太地区、北美地区、欧洲地区等)进行细分。市场预测以数量(吨)和价值(美元)为单位。

区域分析

预计到2025年,亚太地区将占全球出货量的56.12%,并在2031年之前以20.10%的复合年增长率成长。儘管供应的快速扩张导致价格波动,但客户的接近性和规模经济效应已帮助该地区稳固确立了其作为低成本生产中心的地位。为进一步巩固日本的技术优势,KUREHA株式会社计划投资4.7亿美元(700亿日圆)扩建其位于盘城的工厂,以供应用于高镍阴极材料的特种等级产品。政府补贴确保了其战略自主性。在印度和韩国,新兴的超级工厂计划和家电组装行业的扩张带来了不断增长的需求,从而扩大了聚二氟亚乙烯)市场的区域深度。

由于製造业回流政策和《通膨控制法案》(该法案要求使用美国製造的电池材料才能完全符合电动车税额扣抵),北美市场份额正在扩大。 Scienceco位于奥古斯塔的工厂将成为北美最大的单线PVDF工厂之一,每年可为当地供应500万颗电池。为了补充黏合剂的需求,Arkema将其位于卡尔弗特城的工厂扩建了15%,以确保为在亚利桑那州和俄亥俄州建厂的半导体客户提供高纯度等级的PVDF。来自多个领域的需求也在增长,包括沿着墨西哥边境的製造业走廊进口美国製造的PVDF用于汽车线束,以及加拿大油砂运营商指定使用耐腐蚀管道。

在欧洲,绿色交易正逐步淘汰非必要包装中的全氟烷基和多氟烷基物质(PFAS),但允许电池和航太应用领域例外,以平衡增长与监管审查。德国的需求主要由一家汽车製造商的电池合资企业和BASF的阴极活性材料计划支撑,而法国和荷兰的需求则主要来自旨在实现建筑围护结构净零排放的维修项目中对建筑涂料的需求。该地区严格的环境标准推动了具有成熟生命週期优势的聚偏二氟乙烯(PVDF)解决方案的采用,但也增加了合规成本。这造成了一种两极分化的市场格局:顶级供应商在监管日益严格的聚聚二氟亚乙烯市场中蓬勃发展。

南美洲以及中东和非洲仍是新兴市场。巴西的盐层下油田和沙乌地阿拉伯的下游化学联合企业需要PVDF管道,儘管用量较小。非洲的采矿计划正在探索将PVDF膜技术应用于酸性矿山排水处理,这为该技术在资源主导经济体中创造了独特的成长机会。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 电动车电池产量快速成长

- 对耐化学腐蚀涂料的需求

- 半导体洁净室扩建

- 石油和天然气管道防腐蚀

- 航太零件的3D列印

- 市场限制

- 原物料(VF2)价格波动

- 加强对 PFAS 相关法规的监管

- VF2单体生产能力有限

- 价值链分析

- 监管环境

- 波特五力分析

- 供应商的议价能力

- 买方的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

- 新进入者的威胁

- 终端用户产业趋势

- 航太(航太零件生产收入)

- 汽车(汽车产量)

- 建筑与施工(新建建筑占地面积)

- 电气和电子(电气和电子产品生产收入)

- 包装(塑胶包装量)

第五章 市场规模及成长预测(以金额为准及数量)

- 透过使用

- 锂离子电池黏合剂

- 涂料和油漆

- 管道和配件

- 薄膜和片材

- 电线电缆绝缘

- 其他(膜等)

- 按最终用户行业划分

- 航太工业

- 车

- 建筑/施工

- 电气和电子设备

- 工业和机械

- 包装

- 其他终端用户产业

- 按地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 澳洲

- 马来西亚

- 亚太其他地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 法国

- 义大利

- 英国

- 俄罗斯

- 其他欧洲地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中东和非洲

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 奈及利亚

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率(%)/排名分析

- 公司简介

- Arkema

- Dongyue Group

- Gujarat Fluorochemicals Limited

- Hubei Everflon Polymer Co., Ltd.

- Kureha Corporation

- RTP Company

- Sinochem

- Syensqo

- Zhejiang Juhua Co., Ltd.

- ZheJiang Yonghe Refrigerant Co.,Ltd

第七章 市场机会与未来展望

第八章:执行长面临的关键策略挑战

The Polyvinylidene Fluoride market is expected to grow from 95.64 kilotons in 2025 to 112.64 kilotons in 2026 and is forecast to reach 255.2 kilotons by 2031 at 17.78% CAGR over 2026-2031.

Persistent electrification of transportation, accelerating clean-room construction for sub-10 nm chips, and infrastructure projects that specify longer-lasting architectural finishes all reinforce a multi-year demand runway. Producers that combine backward integration into vinylidene fluoride monomer, localized capacity near cell-manufacturing hubs, and application-engineering support in clean-room systems secure durable competitive advantages. Conversely, price volatility in China's oversupplied spot market highlights the need for disciplined capacity addition and long-term feedstock contracts. Government incentives-most notably the United States' USD 178 million grant that anchors North America's first world-scale plant-signal that strategic policy support will remain pivotal in balancing regional supply maps and ensuring PVDF availability for critical industries.

Global Polyvinylidene Fluoride (PVDF) Market Trends and Insights

EV-battery production surge

Automakers' multibillion-dollar electrification roadmaps create direct pull-through for specialized binders that maintain electrode integrity across thousands of charge cycles. Syensqo's Augusta complex will supply PVDF for more than 5 million EV battery packs annually, a scale made viable by the USD 178 million Department of Energy award that anchors domestic cathode-binder chains. Vertical integration by leading cell makers tightens specification windows, raising per-pack PVDF loading to 15-50 g kWh as confirmed by the German automotive association VDA. As gigafactory clusters proliferate in the United States, Europe, and India, producers with local capacity gain freight-cost advantages and proximity to qualification, reinforcing regional supply security. These dynamics collectively raise baseline consumption and channel margins, making the Polyvinylidene Fluoride market a core beneficiary of the EV pivot.

Demand for chemical-resistant coatings

Architectural specifiers continue to migrate to PVDF coil-coating systems that surpass AAMA 2605 performance thresholds in terms of color retention, gloss stability, and chalk resistance. Building codes in Florida, Texas, and typhoon-prone APAC coastal zones increasingly mandate these premium finishes, extending repaint cycles to 30 years and lowering whole-life facade costs. Industrial segments echo the trend: chemical processors retrofit steel tanks with PVDF topcoats that endure aggressive acids and bases, mitigating corrosion downtime and regulatory penalties. With infrastructure stimulus bills prioritizing resilient public buildings, the coatings value chain expects stable volume growth even in macro-downturn scenarios, reinforcing the Polyvinylidene Fluoride market's defensive attributes.

Raw-material (VF2) price volatility

China's spot PVDF price dropped within six months as rapid capacity expansion outstripped Li-ion binder demand. Because vinylidene fluoride accounts for 65-70% of PVDF cash cost, such swings compress margins and disrupt long-term purchasing agreements. Western converters shield themselves through index-linked formula contracts, but Asian mid-tier extruders remain exposed, prompting speculative stock builds that amplify volatility. Until supply rationalizes, procurement teams will prioritize diversified sourcing and consider tolling arrangements to stabilize feedstock availability in the Polyvinylidene Fluoride market.

Other drivers and restraints analyzed in the detailed report include:

- Semiconductor clean-room expansion

- Oil and gas corrosion-control piping

- PFAS-related regulatory scrutiny

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Li-ion battery binders held a commanding 33.62% share of the Polyvinylidene Fluoride market size in 2025 and are forecast to grow at a 31.05% CAGR through 2031, reflecting the material's entrenched role in high-energy-density cell chemistries. Leading automakers specify PVDF binders for next-generation nickel-rich cathodes because alternative polymers undermine cycle life and rate capability. Simultaneously, higher loading levels in silicon-enhanced anodes elevate per-cell consumption, multiplying baseline tonnage requirements.

Coatings and paints are expected to contribute steady mid-single-digit growth as infrastructure funding accelerates facade retrofits in the United States and green-building mandates in Europe. Wire and cable insulation gains a share in data-center power networks, where low-smoke, halogen-free standards are displacing PVC jackets. Films, sheets, and membranes address niche segments-ranging from gas-separation modules to specialty packaging for aggressive solvents-where PVDF's barrier properties justify premium pricing. Pipes and fittings serve semiconductor and chemical processes, with unit volumes sensitive to fab expansion cycles, yet they command the highest gross margins in the Polyvinylidene Fluoride market.

The Polyvinylidene Fluoride Market Report is Segmented by Application (Li-Ion Battery Binders, Coatings and Paints, Pipes and Fittings, Films and Sheets, and More), End-User Industry (Aerospace, Automotive, Building and Construction, Electrical and Electronics, and More), and Geography (Asia-Pacific, North America, Europe, and More). The Market Forecasts are Provided in Terms of Volume (Tons) and Value (USD).

Geography Analysis

The Asia-Pacific region accounted for 56.12% of global shipments in 2025 and is projected to grow at a 20.10% CAGR through 2031. Although rapid supply buildouts sparked price volatility, proximity to customers and scale economies keep APAC firmly positioned as the hub of low-cost production. Japan reinforces the region's technology edge: Kureha's USD 470 million (JPY 70 billion) expansion at its Iwaki plant will deliver specialty grades tailor-made for high-nickel cathodes while government subsidies safeguard strategic autonomy. India and South Korea are adding incremental demand through nascent gigafactory pipelines and growing consumer electronics assembly, broadening regional depth within the Polyvinylidene Fluoride market.

North America's share advances on the back of re-shoring policies and the Inflation Reduction Act, which requires U.S.-sourced battery materials to unlock full EV tax credits. Syensqo's Augusta facility will be the continent's largest single-line PVDF plant, underpinning local supply for five million batteries each year. Complementing binders, Arkema's 15% capacity hike at Calvert City secures high-purity grades for semiconductor customers building fabs in Arizona and Ohio. Mexico's border manufacturing corridor imports U.S. PVDF for automotive harnesses, while Canada's oil-sands operators specify corrosion-proof piping, adding multi-segment pull.

Europe balances growth with regulatory scrutiny as the bloc's Green Deal phases out PFAS in non-essential packaging but preserves exemptions for battery and aerospace uses. Germany anchors demand through automaker battery JVs and BASF's cathode-active-material projects, whereas France and the Netherlands drive architectural-coating volumes for retrofit programs that target net-zero building envelopes. The region's stringent environmental standards promote the adoption of PVDF solutions with proven life-cycle benefits, yet they also increase compliance costs, creating a bifurcated landscape where best-in-class suppliers thrive amid tightening regulations in the Polyvinylidene Fluoride market.

South America, the Middle East, and Africa remain emerging theatres. Brazil's pre-salt oil fields and Saudi Arabia's downstream chemical complexes require PVDF pipe, albeit in lower total tonnage. African mining ventures are exploring PVDF membrane technology for acid-mine drainage treatment, creating niche growth opportunities that elevate the technology's profile in resource-driven economies.

- Arkema

- Dongyue Group

- Gujarat Fluorochemicals Limited

- Hubei Everflon Polymer Co., Ltd.

- Kureha Corporation

- RTP Company

- Sinochem

- Syensqo

- Zhejiang Juhua Co., Ltd.

- ZheJiang Yonghe Refrigerant Co.,Ltd

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 EV-battery Production Surge

- 4.2.2 Demand for Chemical-resistant Coatings

- 4.2.3 Semiconductor Clean-room Expansion

- 4.2.4 Oil and Gas Corrosion-control Piping

- 4.2.5 3-D-printing Aerospace Parts

- 4.3 Market Restraints

- 4.3.1 Raw-material (VF2) Price Volatility

- 4.3.2 PFAS-related Regulatory Scrutiny

- 4.3.3 Limited VF2 Monomer Capacity

- 4.4 Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Porter's Five Forces Analysis

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Threat of Substitutes

- 4.6.4 Competitive Rivalry

- 4.6.5 Threat of New Entrants

- 4.7 End-use Sector Trends

- 4.7.1 Aerospace (Aerospace Component Production Revenue)

- 4.7.2 Automotive (Automobile Production)

- 4.7.3 Building and Construction (New Construction Floor Area)

- 4.7.4 Electrical and Electronics (Electrical and Electronics Production Revenue)

- 4.7.5 Packaging (Plastic Packaging Volume)

5 Market Size and Growth Forecasts (Value and Volume)

- 5.1 By Application

- 5.1.1 Li-ion Battery Binders

- 5.1.2 Coatings and Paints

- 5.1.3 Pipes and Fittings

- 5.1.4 Films and Sheets

- 5.1.5 Wire and Cable Insulation

- 5.1.6 Others (Membranes, etc.)

- 5.2 By End-User Industry

- 5.2.1 Aerospace

- 5.2.2 Automotive

- 5.2.3 Building and Construction

- 5.2.4 Electrical and Electronics

- 5.2.5 Industrial and Machinery

- 5.2.6 Packaging

- 5.2.7 Other End-user Industries

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 Japan

- 5.3.1.3 India

- 5.3.1.4 South Korea

- 5.3.1.5 Australia

- 5.3.1.6 Malaysia

- 5.3.1.7 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 France

- 5.3.3.3 Italy

- 5.3.3.4 United Kingdom

- 5.3.3.5 Russia

- 5.3.3.6 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 United Arab Emirates

- 5.3.5.3 Nigeria

- 5.3.5.4 South Africa

- 5.3.5.5 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Arkema

- 6.4.2 Dongyue Group

- 6.4.3 Gujarat Fluorochemicals Limited

- 6.4.4 Hubei Everflon Polymer Co., Ltd.

- 6.4.5 Kureha Corporation

- 6.4.6 RTP Company

- 6.4.7 Sinochem

- 6.4.8 Syensqo

- 6.4.9 Zhejiang Juhua Co., Ltd.

- 6.4.10 ZheJiang Yonghe Refrigerant Co.,Ltd

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment