|

市场调查报告书

商品编码

1910867

欧洲挖掘装载机市场:市场份额分析、行业趋势、统计数据和成长预测(2026-2031 年)Europe Excavator And Loaders - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

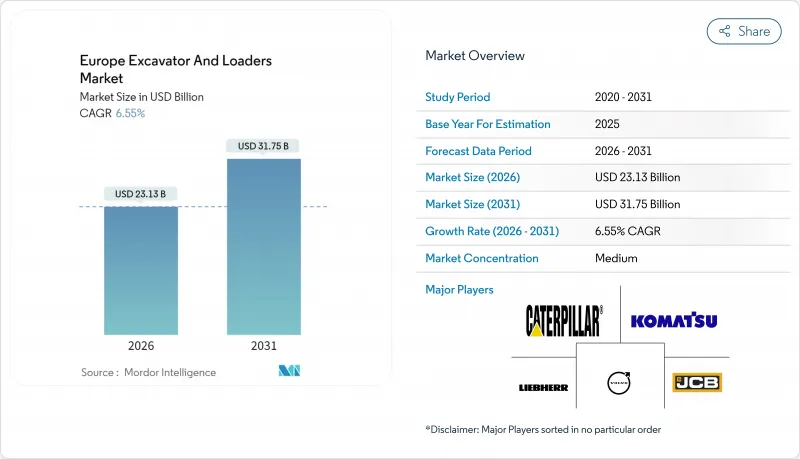

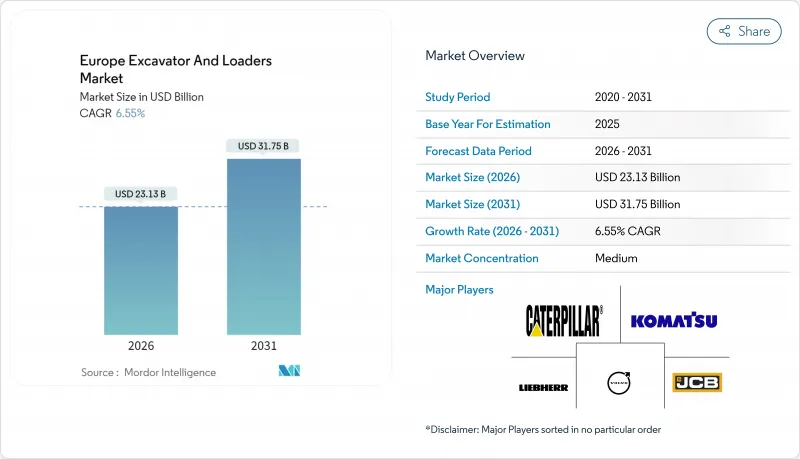

欧洲挖土机和装载机市场预计到 2026 年价值 231.3 亿美元,高于 2025 年的 217.1 亿美元,预计到 2031 年将达到 317.5 亿美元,2026 年至 2031 年的复合年增长率为 6.55%。

来自欧洲绿色交易的资金支持、疫情后计划延误的消除以及严格的第五阶段排放法规,共同推动了资本投资的持续成长,使其能够抵御短期经济波动。电动和混合动力机械的推出如今已达到年度产品週期,加速了从柴油动力系统向欧洲的转型,并使欧洲成为零排放工地的早期试验场。由于高利率和复杂的合规成本,设备即服务模式(EaaS)正日益普及,因为按使用量付费比直接拥有更具吸引力。竞争格局围绕着工地自动化展开,包括数位双胞胎、车队远端资讯处理和空中软体更新,这些技术将重型设备转变为互联资产,除了提升实体生产力外,还能提供终身数据价值。

欧洲挖掘装载机市场趋势与洞察

欧盟绿色交易基础设施资金激增

欧盟已累计1兆欧元用于气候相关支出,目标是在2030年前实现这一目标,其中数十亿欧元将用于铁路电气化、节能公共建筑和可再生能源电网。公共采购越来越指定使用第五阶段排放标准或全电动设备,迫使租赁车队更换老旧的柴油设备。向一家大型租赁集团提供的1亿欧元贷款用于扩充其电动车队,就是一个很好的例子,说明了优惠融资如何加速私部门的现代化进程。以生命週期排放而非前期成本来评估竞标的采购政策正在加速推广,并在北欧地区引发对电池驱动挖掘机、伸缩加长型堆高机和现场发电机的螺旋式增长。

疫情后建筑需求集中化

疫情封锁导致数百个市政和商业计划延期,累积订单在2025年初达到历史新高。随着限制措施的逐步解除,延期项目与新的绿色交易项目同步推进,运转率达到历史新高。由于承包商优先考虑完工而非成本订单,中型挖土机的每日租金涨幅高达两位数。这种集中积压的工程使原始设备製造商(OEM)能够清晰了解2026年之前的生产计画,从而实现零件本地化采购,并为建立区域电池组组装以缩短交货时间提供了依据。

租赁车队规模不断扩大,抑制了购买意愿。

到2024年,欧洲租赁收入将成长超过2%,超过建筑业GDP成长率。部分高空作业平台的租赁渗透率已超过80%。整合商正在收购区域中心、集中采购并协商批量折扣,这给原始设备製造商(OEM)的单一利润率带来了压力。承包商正转向可变成本模式,而製造商则将重点转向维护合约和残值保证。然而,由于车队长期使用资产,销售量仍受到限制。

细分市场分析

预计到2025年,挖土机将占欧洲施工机械市场收入的58.10%,复合年增长率达11.3%。这表明,配备动臂和铲斗的多功能平台正在承担许多先前由专用机械完成的任务。灵活的小型挖土机能够在狭窄排放气体受控的城市工地中灵活穿梭,而45吨级的挖土机则可用于挖掘铁路路堤和铺设离岸风力发电基础。整合式倾斜旋转器和快速连接器系统可将附件更换时间缩短至几秒钟,从而提高设备运作。随着原始设备製造商(OEM)将机器控制软体和无线校准功能整合到挖土机中,挖土机正在发展成为能够根据3D现场资料进行公分级精确平整的自主工作站。远端控制驾驶室提高了安全性并扩大了作业范围——随着欧洲劳动力老化,这成为一项至关重要的优势。

滑移装载机、轮式装载机和后铲在物料装载和公共作业中仍然发挥着重要作用,但随着配备抓斗和托盘叉附件的挖土机能够提供类似的功能,它们的成长速度正在放缓。战后住宅的现代化改造增加了对配备伸缩臂的高空拆除挖土机的需求。伸缩臂叉装机利用远端资讯处理技术即时测量叉臂角度,进一步模糊了不同机型之间的界限,从而辅助操作人员并满足保险公司的要求。这种融合趋势凸显了欧洲施工机械市场参与企业为何要围绕模组化平台而非传统的单一类别重新设计产品系列。

儘管柴油/液压系统仍占据欧洲施工机械市场92.70%的份额,但电动车型19.1%的复合年增长率证实,电动化已从推测变为必然。最初,电动化主要应用于3吨以下的小型机械,因为运作週期与目前的电池能量密度相符。但如今,原始设备製造商(OEM)的蓝图已涵盖配备可更换电池组的10-14吨挖土机和6立方公尺轮式装载机。公共机构正在采用电动滑移装载机进行对噪音敏感的夜间作业,理由是这有助于改善工人健康和提高週边居民的接受度。采石场也重新开始使用併网电缆驱动的机械,这些机械配备再生製动系统,并与现场破碎机连接,从而提高能源效率。

对于远离充电站的长时间土木工程作业现场,柴油-电力混合动力机械正在填补一个过渡性的市场空白。目前正在斯堪地那维亚矿山进行测试的燃料电池原型机已实现了连续运作八小时而性能无衰减,但氢气供应网络仍在建设中。动力系统的日益多样化表明,欧洲施工机械市场正朝着多能源格局发展。车队管理人员在选择动力传动系统之前,必须全面考虑当地的排放法规、运作週期和总能源成本。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 欧盟绿色交易基础设施资金筹措热潮

- 清理疫情后建筑积压

- 第五阶段排放气体标准推动车队更新

- 斯堪的斯堪地那维亚强制要求零排放场所

- 透过数位双胞胎技术普及现场自动化

- 设备即服务经营模式

- 市场限制

- 租赁车辆的增加会减少购买量

- 高利率环境抑制资本投资

- 电池材料成本波动

- 经销商网路的整合阻碍了新进入者。

- 价值/供应链分析

- 技术展望

- 监管环境

- 波特五力模型

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模及成长预测(价值(美元)及销售量(单位))

- 按机器类型

- 挖土机

- 小型(小于6吨)

- 中型(6至14吨)

- 履带

- 轮型

- 水陆两用

- 大型(超过45吨)

- 装载机

- 轮式装载机

- 滑移装载机

- 小型履带装载机

- 后铲式装载机

- 小型铰接式装载机

- 挖土机

- 按驱动类型

- 柴油/液压

- 电的

- 杂交种

- 氢燃料电池(新兴)

- 电缆/网格繫绳类型

- 按运作重量(吨)

- 少于6

- 6~14

- 14~30

- 30~45

- 45岁以上

- 按最终用途行业划分

- 建造

- 采矿和采石

- 农业/林业

- 废弃物和回收

- 公共产业和城市基础设施

- 租赁公司

- 透过使用

- 挖土和土方工程

- 物料输送

- 拆卸

- 景观设计

- 除雪

- 道路建设/维护管理

- 按国家/地区

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 荷兰

- 瑞典

- 挪威

- 其他欧洲地区

第六章 竞争情势

- 市场集中度

- 策略发展与伙伴关係

- 市占率分析

- 公司简介

- Caterpillar Inc.

- Komatsu Ltd.

- Volvo Construction Equipment

- CNH Industrial NV(CASE and New Holland)

- Deere and Company

- Hitachi Construction Machinery

- Liebherr-International Deutschland GmbH

- Doosan Bobcat Co.

- Kobelco Construction Machinery

- Manitou BF SA

- Yanmar Construction Equipment

- JCB Ltd.

- Kubota Corp.

- Sany Europe

- XCMG Europe

- Wacker Neuson SE

- Hyundai Construction Equipment Europe

- Mecalac SAS

- Wirtgen Group(John Deere)

- Avant Tecno Oy

第七章 市场机会与未来展望

Europe Excavator And Loaders market size in 2026 is estimated at USD 23.13 billion, growing from 2025 value of USD 21.71 billion with 2031 projections showing USD 31.75 billion, growing at 6.55% CAGR over 2026-2031.

A confluence of European Green Deal funding, pent-up post-pandemic project backlogs, and aggressive stage-V emission rules sustains a capital-expenditure upswing that is resilient to short-term economic volatility. Electric and hybrid machinery launches now occur on annual product-cycle cadences, accelerating the region's migration away from diesel powertrains and establishing Europe as an early-adopter laboratory for zero-emission job-sites. Equipment-as-a-Service models are gaining traction because high interest rates and complex compliance costs make usage-based access more attractive than outright ownership. Competitive dynamics increasingly revolve around digital-twin job-site automation, fleet telematics, and over-the-air software updates, turning heavy machines into connected assets that deliver lifetime data value in addition to physical productivity.

Europe Excavator And Loaders Market Trends and Insights

EU Green-Deal Infrastructure Funding Boom

The European Union has earmarked EUR 1 trillion for climate-aligned spending through 2030, channeling billions into rail electrification, energy-efficient public buildings, and renewable-ready grids. Public tenders increasingly stipulate stage-V or fully electric equipment, prompting rental fleets to overhaul aging diesel inventories. A EUR 100 million loan extended to a leading rental group for electric fleet expansion exemplifies how concessional finance levers private modernization cycles. Procurement policies that score bids on life-cycle emissions rather than upfront cost accelerate adoption, creating an upward spiral in demand for battery-powered excavators, telehandlers, and site-generators across Northern Europe.

Post-Pandemic Construction Backlog Release

Lockdowns delayed hundreds of municipal and commercial projects, inflating contractor order books to record highs entering 2025. As restrictions eased, simultaneous execution of deferred and new Green-Deal workstreams pushed utilization rates past historical ceilings. Rental day-rates for mid-range excavators climbed into double-digit premiums because contractors prioritized job completion over cost containment. The backlog convergence grants OEMs visibility on production runs through 2026, allowing them to localize component sourcing and justify regional battery pack assembly lines that shorten delivery lead-times.

Growth of Rental Fleets Suppressing Purchases

European rental turnover grow by over 2% in 2024 and continues to outpace construction GDP, with certain aerial platform categories now achieving over 80% rental penetration. Consolidators acquire regional depots, centralize procurement, and negotiate volume discounts that depress OEM line-item margins. As contractors shift toward variable costs, manufacturers pivot to servicing agreements and residual-value guarantees, but unit sales still temper as fleets sweat assets over longer cycles.

Other drivers and restraints analyzed in the detailed report include:

- Stage V Emission Norms Driving Fleet Renewal

- Zero-Emission Site Mandates in Scandinavia

- High Interest-Rate Environment Dampening CAPEX

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Excavators generated 58.10% of Europe construction equipment market revenue in 2025 and are forecasted for an 11.3% CAGR, illustrating how versatile boom-and-bucket platforms absorb many tasks once assigned to specialized machines. Agile mini models maneuver through tight urban sites subject to zero-emission ordinances, while 45-ton units tackle rail embankment cuts and offshore wind foundation work. Integrated tilt-rotators and quick-coupler systems shrink attachment change-over to seconds, amplifying utilization across day-parts. As OEMs embed machine-control software and over-the-air calibration, excavators evolve into autonomous workstations capable of centimeter-level grading guided by 3D site files. Remote-operation cabs stationed offsite improve safety and widen labor pools, a critical benefit amid an aging European workforce.

Skid steers, wheel loaders, and backhoes maintain relevance in material loading and multi-purpose municipal duties, yet their growth lags because excavators fitted with grapple or pallet-fork attachments can achieve similar throughput. High reach demolition excavators with telescopic booms are seeing increased demand as cities modernize post-war housing blocks. Telescopic handlers blur category lines further, as telematics measure fork-load angles in real time, assisting operators and satisfying insurer requirements. This convergence underscores why Europe construction equipment market participants redesign portfolios around modular platforms rather than traditional siloed categories.

Diesel/hydraulic systems still account for 92.70% of Europe construction equipment market size, but electric models' 19.1% CAGR reinforces that the tipping point has shifted from speculative to inevitable. Early adoption focused on <3 ton minis where duty cycles align with current battery density; today OEM roadmaps list 10-14 ton excavators and 6 m3 wheel loaders with shift-able swappable packs. Public agencies procure electric skid steers for noise-sensitive night work, citing operator health benefits and neighborhood acceptance. Grid-tethered cable machines re-emerge in quarries, linking regenerative braking to onsite crushers and improving energy efficiency.

Hybrid diesel-electric variants fill an interim niche on long-duration civil engineering jobs far from charging depots. Fuel-cell prototypes field-tested in Scandinavian mines demonstrate eight-hour runtimes without performance drop-off, though hydrogen supply chains remain nascent. The drive-type spectrum signals that the Europe construction equipment market is transitioning into a multi-energy landscape, where fleet managers weigh local emission rules, duty cycles, and total-energy pricing before specifying powertrains.

The Europe Excavator and Loaders Market Report is Segmented by Machinery Type (Excavators and Loaders), Drive Type (Diesel/Hydraulic, Electric, and More), Operating Weight (Below 6t, 6 To 14t, and More), End-Use Industry (Construction, Mining and Quarrying, and More), Application (Excavation and Earthmoving and More), and Country (Germany and More). The Market Forecasts are Provided in Terms of Value (USD) and Volume (Units).

List of Companies Covered in this Report:

- Caterpillar Inc.

- Komatsu Ltd.

- Volvo Construction Equipment

- CNH Industrial N.V. (CASE and New Holland)

- Deere and Company

- Hitachi Construction Machinery

- Liebherr-International Deutschland GmbH

- Doosan Bobcat Co.

- Kobelco Construction Machinery

- Manitou BF SA

- Yanmar Construction Equipment

- JCB Ltd.

- Kubota Corp.

- Sany Europe

- XCMG Europe

- Wacker Neuson SE

- Hyundai Construction Equipment Europe

- Mecalac SAS

- Wirtgen Group (John Deere)

- Avant Tecno Oy

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 EU Green-Deal Infrastructure Funding Boom

- 4.2.2 Post-Pandemic Construction Backlog Release

- 4.2.3 Stage V Emission Norms Driving Fleet Renewal

- 4.2.4 Zero-Emission Site Mandates in Scandinavia

- 4.2.5 Digital-Twin Job-Site Automation Uptake

- 4.2.6 Equipment-as-a-Service Business Models

- 4.3 Market Restraints

- 4.3.1 Growth of Rental Fleets Suppressing Purchases

- 4.3.2 High Interest-Rate Environment Dampening CAPEX

- 4.3.3 Battery-Material Cost Volatility

- 4.3.4 Dealer-Network Consolidation Blocking New Entrants

- 4.4 Value / Supply-Chain Analysis

- 4.5 Technological Outlook

- 4.6 Regulatory Landscape

- 4.7 Porter's Five Forces

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

5 Market Size and Growth Forecasts (Value (USD) and Volume (Units))

- 5.1 By Machinery Type

- 5.1.1 Excavators

- 5.1.1.1 Mini (Below 6 t)

- 5.1.1.2 Midi (6 to 14 t)

- 5.1.1.3 Crawler

- 5.1.1.4 Wheeled

- 5.1.1.5 Amphibious

- 5.1.1.6 Large (Above 45 t)

- 5.1.2 Loaders

- 5.1.2.1 Wheel Loader

- 5.1.2.2 Skid Steer Loader

- 5.1.2.3 Compact Track Loader

- 5.1.2.4 Backhoe Loader

- 5.1.2.5 Small Articulated Loader

- 5.1.1 Excavators

- 5.2 By Drive Type

- 5.2.1 Diesel / Hydraulic

- 5.2.2 Electric

- 5.2.3 Hybrid

- 5.2.4 Hydrogen Fuel-Cell (emerging)

- 5.2.5 Cable / Grid-tethered

- 5.3 By Operating Weight (t)

- 5.3.1 Below 6

- 5.3.2 6 to 14

- 5.3.3 14 to 30

- 5.3.4 30 to 45

- 5.3.5 Above 45

- 5.4 By End-Use Industry

- 5.4.1 Construction

- 5.4.2 Mining and Quarrying

- 5.4.3 Agriculture and Forestry

- 5.4.4 Waste and Recycling

- 5.4.5 Utilities and Urban Infrastructure

- 5.4.6 Rental Companies

- 5.5 By Application

- 5.5.1 Excavation and Earthmoving

- 5.5.2 Material Handling

- 5.5.3 Demolition

- 5.5.4 Landscaping

- 5.5.5 Snow Removal

- 5.5.6 Road Building and Maintenance

- 5.6 By Country

- 5.6.1 Germany

- 5.6.2 United Kingdom

- 5.6.3 France

- 5.6.4 Italy

- 5.6.5 Spain

- 5.6.6 Netherlands

- 5.6.7 Sweden

- 5.6.8 Norway

- 5.6.9 Rest of Europe

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves and Partnerships

- 6.3 Market Share Analysis

- 6.4 Company Profiles (Includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Caterpillar Inc.

- 6.4.2 Komatsu Ltd.

- 6.4.3 Volvo Construction Equipment

- 6.4.4 CNH Industrial N.V. (CASE and New Holland)

- 6.4.5 Deere and Company

- 6.4.6 Hitachi Construction Machinery

- 6.4.7 Liebherr-International Deutschland GmbH

- 6.4.8 Doosan Bobcat Co.

- 6.4.9 Kobelco Construction Machinery

- 6.4.10 Manitou BF SA

- 6.4.11 Yanmar Construction Equipment

- 6.4.12 JCB Ltd.

- 6.4.13 Kubota Corp.

- 6.4.14 Sany Europe

- 6.4.15 XCMG Europe

- 6.4.16 Wacker Neuson SE

- 6.4.17 Hyundai Construction Equipment Europe

- 6.4.18 Mecalac SAS

- 6.4.19 Wirtgen Group (John Deere)

- 6.4.20 Avant Tecno Oy

7 Market Opportunities and Future Outlook

- 7.1 White-Space and Unmet-Need Assessment