|

市场调查报告书

商品编码

1911308

印度工业自动化:市场份额分析、行业趋势、统计数据和成长预测(2026-2031)India Industrial Automation - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

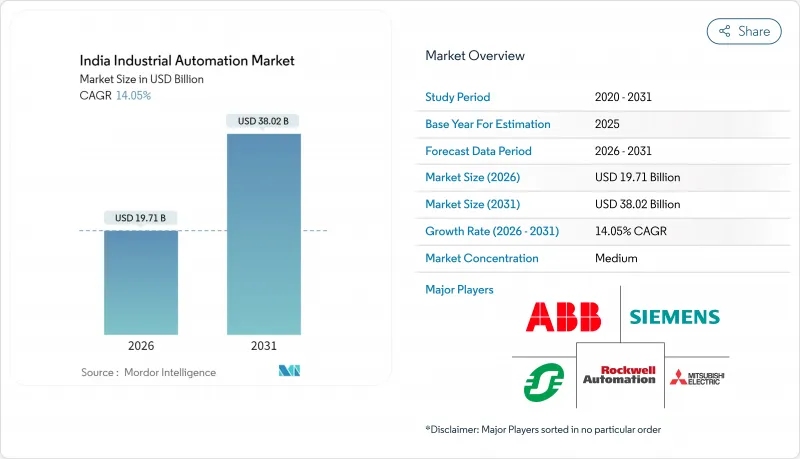

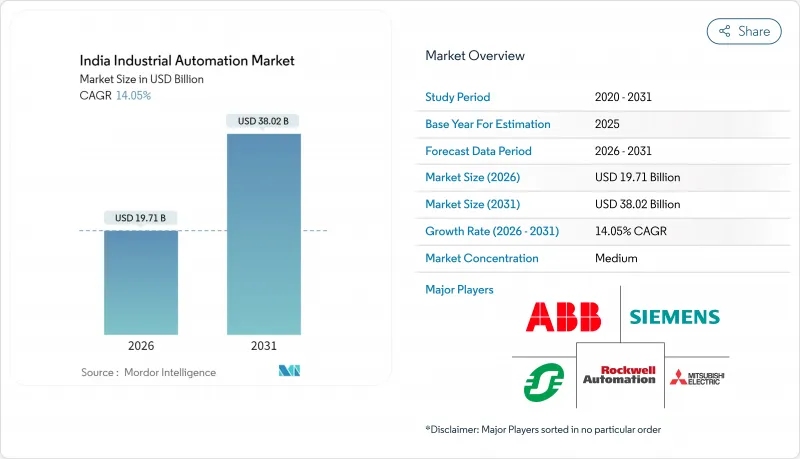

2025年印度工业自动化市场价值为172.8亿美元,预计到2031年将达到380.2亿美元,而2026年为197.1亿美元。

预测期(2026-2031 年)的复合年增长率预计为 14.05%。

持续的政策支援、老旧工厂的快速现代化改造以及感测器价格的下降共同支撑了两位数的成长。生产连结奖励计画计划,促进了外国直接投资,并引发了现有设施维修的蓬勃发展,从而提高了生产力和出口竞争力。跨国公司扩大了其本地生产基地,以缩短供应链并规避进口关税,而中型企业则采用了基于云端的执行软体来克服资金限制。同时,私营部门主导的5G试点计画和边缘运算平台缓解了延迟问题,并促进了流程工厂预测性维护的实施。儘管网路安全措施和熟练劳动力的供应仍然是关键问题,但政策主导的升级週期已使需求保持了稳健的成长动能。 [1]

印度工业自动化市场趋势与洞察

加速「印度製造」製造业投资,推动自动化普及

自2024年以来,外国直接投资(FDI)流入扩大了工厂自动化的整体预算。西门子投资100亿印度卢比(约1.205亿美元)用于扩大驱动器和控制器的生产,三菱电机投资22亿印度卢比(约2,650万美元)用于建造本地组装。这些对现有设施的升级改造专注于扩充性和模组化设备,而不是新的资本投资,从而实现了更快的投资回报和更高的产能运转率。古吉拉突邦、马哈拉斯特拉邦和泰米尔纳德邦的丛集正在吸引相关供应商,并在整个价值链中传播技术诀窍。出口导向製造商也在整合全球品质标准,从而推动了对先进运动控制、节能驱动器和机器安全系统的需求。

政府的生产连结奖励计画机制加速了侨民产业的现代化。

生产连结奖励计画计划 (PLI) 已拨款 1,402 亿印度卢比(约 16.9 亿美元),用于支持能够证明其已做好工业 4.0 准备的行业,该计划将持续到 2025 年。汽车产业的申请者必须证明其生产线已完全连网,并配备 PLC 控制站和即时品质监控系统,才能继续获得增量补贴。电子产品製造商则面临更严格的标准,包括预测性维护能力以及对分包商 100% 的可追溯性。这项规则的设计将放大下游需求,因为一级供应商要求三级供应商实施相容的自动化层,使零件、模具和包装合作伙伴的市场参与度翻倍。

三级供应商对资本支出的高度敏感度限制了自动化技术的采用。

中小型零件供应商的EBITDA获利率仅为 8-12%,应收帐款週期长达 90-120 天,这限制了其可用于自动化的自由现金流。全面的设备升级需要相当于年销售额 15-20% 的资金,许多公司如果没有补贴融资,难以克服这一障碍。虽然信用担保降低了贷款机构的风险权重,但抵押品要求和核准延迟仍然阻碍了自动化技术的快速普及。这可能导致生态系统两极化,一级和二级供应商快速数位化,而三级供应商则落后,破坏了原始设备製造商 (OEM) 所重视的同步生产模式。

细分市场分析

到2025年,工业控制系统将占据印度工业自动化市场份额的37.15%,这主要得益于汽车行业对PLC的强劲需求以及化学工业对DCS的广泛应用。同时,随着云端製造执行系统(MES)订阅模式的普及降低了进入门槛,软体收入预计将以15.05%的复合年增长率成长。预计到2031年,印度工业自动化市场软体解决方案的规模将翻倍,这主要得益于中型企业将ERP、MES和品质分析整合到单一系统中。现场设备的成长得益于价格适中的感测器的普及以及钢铁厂和食品加工厂对预测性维护的日益重视。此外,由于混合架构需要持续的网路修补程式和模型重新训练,业务收益也在不断增长。

为了应对保险公司日益严格的审查,大多数控制系统升级方案都内建了增强型网路安全模组和基于角色的存取控制。同时,随着监管审核追踪要求对设计修订进行数位签章签名,产品生命週期管理软体在汽车和航太领域正赢得订单。人机介面已采用平板电脑式触控屏,将操作员训练时间缩短至三天以内。这些变化共同推动收入来源向持续的软体订阅和管理服务转移,而硬体仍然是基础。

到2025年,可程式自动化将占收入的41.45%,这主要得益于需要快速更改配方的混合型组装。然而,随着工厂将人工智慧、机器视觉和边缘分析技术整合到封闭回路型优化系统中,整合式超自动化正以16.35%的复合年增长率快速成长。像塔塔钢铁这样的早期采用者,在现有SCADA系统上迭加人工智慧预测模型后,计划外停机时间减少了20%。如果目前的普及速度持续下去,到2031年,印度与超自动化相关的工业自动化市场规模可能达到123.5亿美元。

统一的资料层对于向超自动化转型至关重要,供应商已将MQTT仲介和OPC-UA网关与控制器升级捆绑在一起。到2025年,劳动力再培训预算将增加25%,用于增加对多技能培训计画的投入,以使操作人员能够胜任人工智慧辅助的工作流程。监管审核现在建议采用能够记录所有程式参数以实现可追溯性的自动化系统,这进一步加速了向整合式堆迭的转型。

其他福利:

- Excel格式的市场预测(ME)表

- 分析师支持(3个月)

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 加速「印度製造」製造业投资

- 政府生产关联激励计划对各行业的激励措施

- 微型、微企业(MSMEs)现有设施数位化维修的快速扩展

- 工业感测器成本正在大幅下降

- 显着趋势:Start-Ups主导中型工厂对人工智慧驱动的预测性维护的需求

- 一个鲜为人知的趋势:与排碳权挂钩的能源密集型金属产业自动化

- 市场限制

- 三级供应商对资本支出(CAPEX)高度敏感

- 系统整合商生态系统分散,存在品质差距

- 一个鲜为人知的趋势:OT网路的网路安全保险费不断上涨

- 一个被忽略的趋势:技术工人从产业丛集外流

- 产业价值链分析

- 监管环境

- 技术展望

- 波特五力分析

- 新进入者的威胁

- 供应商的议价能力

- 买方的议价能力

- 替代品的威胁

- 产业间竞争

第五章 市场规模与成长预测

- 透过解决方案

- 工业控制系统

- 分散式控制系统(DCS)

- 监控与数据采集(SCADA)

- 可程式逻辑控制器(PLC)

- 人机介面(HMI)

- 其他控制系统

- 现场设备

- 感测器和发射器

- 阀门和致动器

- 马达和驱动器

- 机器人技术

- 其他现场设备

- 软体

- 产品生命週期管理(PLM)

- 企业资源规划(ERP)

- 製造执行系统(MES)

- 其他软体

- 服务

- 一体化

- 维护和培训

- 工业控制系统

- 按自动化类型

- 固定自动化

- 可程式自动化

- 灵活或模组化自动化

- 整合式或高度自动化

- 按最终用户行业划分

- 汽车/运输设备

- 石油和天然气

- 食品/饮料

- 製药和生命科学

- 电力/公共产业

- 电子和半导体

- 化工/石油化工

- 金属和采矿

- 消费品(快速消费品)

- 包装

- 其他的

- 透过部署模式

- 本地部署

- 云

- 杂交种

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Siemens Limited

- ABB India Limited

- Yokogawa India Ltd.

- Rockwell Automation India Pvt. Ltd.

- Schneider Electric India Pvt. Ltd.

- Honeywell Automation India Ltd.

- Emerson Automation Solutions India Pvt. Ltd.

- Mitsubishi Electric India Pvt. Ltd.

- Omron Automation Private Limited

- Bosch Rexroth India Pvt. Ltd.

- B and R Industrial Automation Pvt. Ltd.

- Larsen and Toubro Ltd.

- Fanuc India Pvt. Ltd.

- Delta Electronics India Pvt. Ltd.

- GE Power India Ltd.

- Tata Elxsi Ltd.

- Wipro Enterprises Pvt. Ltd.

- Akyapak India Pvt. Ltd.

- Bajaj Electricals Ltd.

- Bharat Heavy Electricals Ltd.

第七章 市场机会与未来展望

The India industrial automation market was valued at USD 17.28 billion in 2025 and estimated to grow from USD 19.71 billion in 2026 to reach USD 38.02 billion by 2031, at a CAGR of 14.05% during the forecast period (2026-2031).

Ongoing policy support, rapid modernization of legacy plants, and falling sensor prices together sustain double-digit expansion. Foreign direct investment swelled after the Production Linked Incentive program linked cash disbursements to Industry 4.0 readiness, triggering a wave of brownfield retrofits that lift productivity and export competitiveness. Multinationals increased local manufacturing footprints to shorten supply chains and avoid import duties, while mid-tier enterprises adopted cloud-based execution software to overcome capital constraints. Meanwhile, private 5G pilots and edge computing platforms reduced latency concerns and encouraged predictive maintenance rollouts in process plants. Cybersecurity readiness and skilled labour availability remain watchpoints, yet the policy-driven upgrade cycle keeps demand on a strong growth path.[1]

India Industrial Automation Market Trends and Insights

Accelerated Make in India Manufacturing Investments Drive Automation Uptake

Foreign direct investment flowing into the country after 2024 elevated overall factory-automation budgets. Siemens committed INR 10,000 million (USD 120.5 million) to expand production of drives and controllers, while Mitsubishi Electric directed INR 2,200 million (USD 26.5 million) toward local assembly lines. These brownfield upgrades emphasize scalable, modular equipment rather than greenfield capacity, enabling faster returns and higher asset utilization. Clusters in Gujarat, Maharashtra, and Tamil Nadu attract allied suppliers, spreading technical know-how along the value chain. Export-oriented manufacturers also integrate global quality benchmarks, tightening demand for advanced motion control, energy-efficient drives, and machine safety systems.

Government PLI Scheme Incentives Accelerate Discrete Industry Modernization

The Production Linked Incentive program disbursed INR 140,200 million (USD 1.69 billion) by 2025 to discrete industries on the condition of demonstrable Industry 4.0 compliance. Automotive applicants must showcase fully networked production lines with PLC-controlled stations and real-time quality monitoring to keep receiving tranche payments. Electronics manufacturers face even stricter benchmarks such as predictive maintenance capability and 100 percent traceability across subcontractors. This rule design amplifies downstream demand because Tier-1 suppliers press Tier-3 vendors to install compatible automation layers, multiplying market pull across component, tooling, and packaging partners.

High CAPEX Sensitivity Among Tier-3 Suppliers Constrains Automation Adoption

Smaller component vendors often operate on 8-12% EBITDA margins and face 90-120-day receivable cycles, leaving limited free cash for automation. Comprehensive upgrades can require capital equal to 15-20% of annual revenue, a hurdle that many cannot clear without subsidized loans. While the credit guarantee scheme reduces risk weightings for lenders, collateral requirements and approval delays still deter quick uptake. This creates a bifurcated ecosystem where Tier-1 and Tier-2 firms digitize rapidly while Tier-3 lags, potentially undermining the synchronous production models favoured by OEMs.

Other drivers and restraints analyzed in the detailed report include:

- Rapid Expansion of Brownfield Digital Retrofits Across MSMEs

- Sharp Decline in Industrial Sensor Costs Enables Widespread IoT Adoption

- Fragmented System-Integrator Ecosystem Creates Quality Gaps

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Industrial control systems retained 37.15% India industrial automation market share in 2025, anchored by robust PLC demand in automotive and DCS rollouts in chemicals. Software revenue, however, is climbing at a 15.05% CAGR as cloud-hosted manufacturing execution suites become subscription-priced, lowering entry hurdles. The India industrial automation market size for software solutions is projected to double between 2026 and 2031 as mid-tier firms integrate ERP, MES, and quality analytics into a single stack. Field devices gained from cheaper sensors, expanding predictive-maintenance deployments in steel mills and food processing plants. Service revenue also rose because hybrid architectures need ongoing cyber-patching and model retraining.

Enhanced cybersecurity modules and role-based access controls now come bundled inside most control-system upgrades, addressing rising insurance scrutiny. Meanwhile, product lifecycle management software wins orders in automotive and aerospace because regulatory audit trails demand digitally signed design revisions. Human-machine interfaces adopt tablet-style touchscreens, shortening operator training to under three days. Collectively, these shifts pivot revenue toward recurring software subscriptions and managed services, though hardware remains foundational.

Programmable automation accounted for 41.45% revenue in 2025, favoured for mixed-model assembly lines that need rapid recipe changes. Yet integrated hyper-automation is expanding at a 16.35% CAGR as plants converge AI, machine vision, and edge analytics into closed-loop optimization. Early adopters like Tata Steel logged a 20% cut in unplanned downtime after overlaying AI predictive models on legacy SCADA. The India industrial automation market size tied to hyper-automation could reach USD 12.35 billion by 2031 if current adoption curves hold.

Transitioning to hyper-automation requires unified data layers, so vendors bundle MQTT brokers and OPC-UA gateways with controller upgrades. Workforce retraining budgets rose 25% in 2025 as firms invest in multi-skilling programs to align operators with AI-assisted workflows. Regulatory audits now prefer automation systems that log every process parameter for traceability, further reinforcing the move toward integrated stacks.

The India Industrial Automation Market Report is Segmented by Solution (Industrial Control Systems, Field Devices, Software, and Services), Automation Type (Fixed, Programmable, Flexible, and Integrated), End-User Industry (Automotive, Oil and Gas, Food and Beverage, Pharmaceuticals, Power, Electronics, and More), and Deployment Mode (On-Premise, Cloud, and Hybrid). The Market Forecasts are Provided in Terms of Value (USD).

List of Companies Covered in this Report:

- Siemens Limited

- ABB India Limited

- Yokogawa India Ltd.

- Rockwell Automation India Pvt. Ltd.

- Schneider Electric India Pvt. Ltd.

- Honeywell Automation India Ltd.

- Emerson Automation Solutions India Pvt. Ltd.

- Mitsubishi Electric India Pvt. Ltd.

- Omron Automation Private Limited

- Bosch Rexroth India Pvt. Ltd.

- B and R Industrial Automation Pvt. Ltd.

- Larsen and Toubro Ltd.

- Fanuc India Pvt. Ltd.

- Delta Electronics India Pvt. Ltd.

- GE Power India Ltd.

- Tata Elxsi Ltd.

- Wipro Enterprises Pvt. Ltd.

- Akyapak India Pvt. Ltd.

- Bajaj Electricals Ltd.

- Bharat Heavy Electricals Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Accelerated "Make in India" manufacturing investments

- 4.2.2 Government PLI scheme incentives for discrete industries

- 4.2.3 Rapid expansion of brownfield digital retrofits across MSMEs

- 4.2.4 Sharp decline in industrial sensor costs

- 4.2.5 Under-the-radar: Start-up led AI-driven predictive maintenance demand from mid-tier plants

- 4.2.6 Under-the-radar: Carbon-credit linked automation for energy-intensive metals vertical

- 4.3 Market Restraints

- 4.3.1 High CAPEX sensitivity among Tier-3 suppliers

- 4.3.2 Fragmented system-integrator ecosystem quality gaps

- 4.3.3 Under-the-radar: Cyber-insurance premium escalation for OT networks

- 4.3.4 Under-the-radar: Skilled labour flight from industrial clusters

- 4.4 Industry Value-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Suppliers

- 4.7.3 Bargaining Power of Buyers

- 4.7.4 Threat of Substitutes

- 4.7.5 Industry Rivalry

5 MARKET SIZE AND GROWTH FORECASTS

- 5.1 By Solution

- 5.1.1 Industrial Control Systems

- 5.1.1.1 Distributed Control System (DCS)

- 5.1.1.2 Supervisory Control and Data Acquisition (SCADA)

- 5.1.1.3 Programmable Logic Controller (PLC)

- 5.1.1.4 Human Machine Interface (HMI)

- 5.1.1.5 Other Control Systems

- 5.1.2 Field Devices

- 5.1.2.1 Sensors and Transmitters

- 5.1.2.2 Valves and Actuators

- 5.1.2.3 Motors and Drives

- 5.1.2.4 Robotics

- 5.1.2.5 Other Field Devices

- 5.1.3 Software

- 5.1.3.1 Product Lifecycle Management (PLM)

- 5.1.3.2 Enterprise Resource Planning (ERP)

- 5.1.3.3 Manufacturing Execution System (MES)

- 5.1.3.4 Other Software

- 5.1.4 Services

- 5.1.4.1 Integration

- 5.1.4.2 Maintenance and Training

- 5.1.1 Industrial Control Systems

- 5.2 By Automation Type

- 5.2.1 Fixed Automation

- 5.2.2 Programmable Automation

- 5.2.3 Flexible or Modular Automation

- 5.2.4 Integrated or Hyper-Automation

- 5.3 By End-user Industry

- 5.3.1 Automotive and Transportation

- 5.3.2 Oil and Gas

- 5.3.3 Food and Beverage

- 5.3.4 Pharmaceuticals and Life Sciences

- 5.3.5 Power and Utilities

- 5.3.6 Electronics and Semiconductors

- 5.3.7 Chemicals and Petrochemicals

- 5.3.8 Metals and Mining

- 5.3.9 Fast-Moving Consumer Goods (FMCG)

- 5.3.10 Packaging

- 5.3.11 Others

- 5.4 By Deployment Mode

- 5.4.1 On-Premise

- 5.4.2 Cloud

- 5.4.3 Hybrid

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Siemens Limited

- 6.4.2 ABB India Limited

- 6.4.3 Yokogawa India Ltd.

- 6.4.4 Rockwell Automation India Pvt. Ltd.

- 6.4.5 Schneider Electric India Pvt. Ltd.

- 6.4.6 Honeywell Automation India Ltd.

- 6.4.7 Emerson Automation Solutions India Pvt. Ltd.

- 6.4.8 Mitsubishi Electric India Pvt. Ltd.

- 6.4.9 Omron Automation Private Limited

- 6.4.10 Bosch Rexroth India Pvt. Ltd.

- 6.4.11 B and R Industrial Automation Pvt. Ltd.

- 6.4.12 Larsen and Toubro Ltd.

- 6.4.13 Fanuc India Pvt. Ltd.

- 6.4.14 Delta Electronics India Pvt. Ltd.

- 6.4.15 GE Power India Ltd.

- 6.4.16 Tata Elxsi Ltd.

- 6.4.17 Wipro Enterprises Pvt. Ltd.

- 6.4.18 Akyapak India Pvt. Ltd.

- 6.4.19 Bajaj Electricals Ltd.

- 6.4.20 Bharat Heavy Electricals Ltd.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment