|

市场调查报告书

商品编码

1911466

标籤:市场占有率分析、产业趋势与统计、成长预测(2026-2031)Label - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

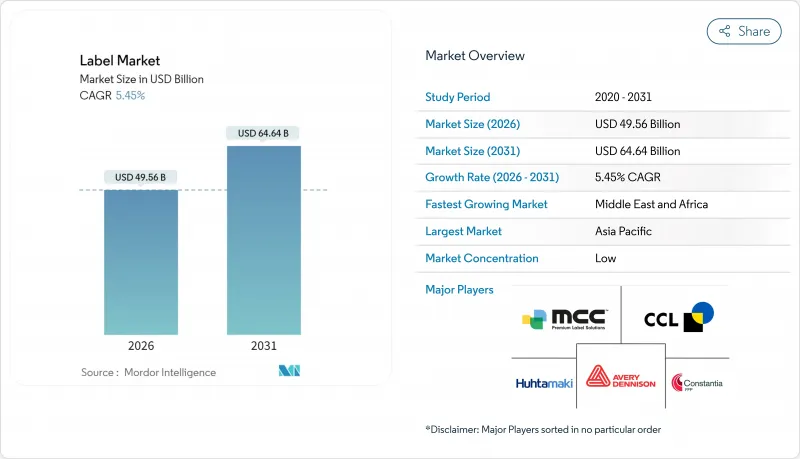

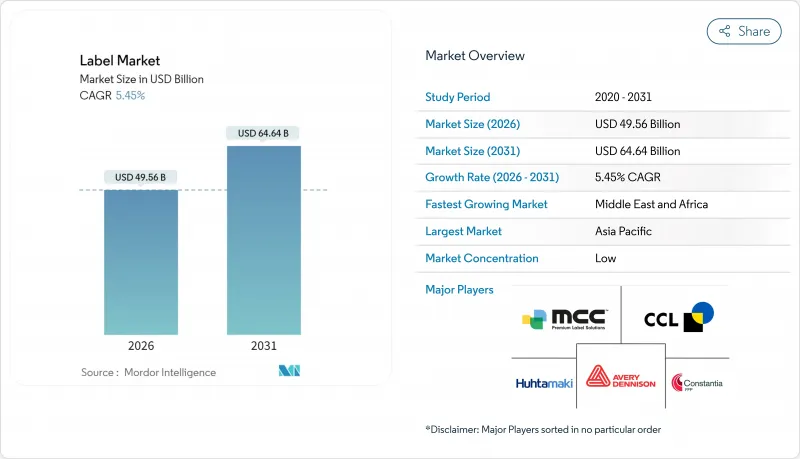

全球标籤市场预计到 2025 年将达到 470 亿美元,到 2026 年将达到 495.6 亿美元,到 2031 年将达到 646.4 亿美元,预测期(2026-2031 年)的复合年增长率为 5.45%。

这种稳定成长的趋势反映了标籤产业适应变化的能力,例如电子商务的扩张、永续性法规的实施以及智慧包装的普及。监管对可再生材料的压力持续促使加工商转向无衬里结构和生物基薄膜,而零售商对即时产品认证的需求正在加速向智慧包装的转型。数位印刷的经济效益有利于小批量生产和客製化,儘管其在总产量中所占比例不高,但利润率却有所提高。能够大规模整合RFID、NFC和QR码解决方案的公司将获得竞争优势,这些解决方案可以将标籤转变为资料触点,从而增强供应链的透明度和消费者参与度。儘管某些饮料品类面临直接贴标的威胁,但这些因素共同为标籤市场的持续成长奠定了基础。

全球标籤市场趋势与洞察

电子商务的快速成长推动了可变数据运输标籤的发展

预计2023年全球小包裹量将达到217亿件,2029年将达到290亿件,这将给标籤加工商带来压力,他们需要提供能够处理即时订单资料的标籤。体积重量收费和全通路支援要求标籤上的图形能够经得起自动化分类流程的考验。亚马逊2023年15.7%的包裹量成长凸显了市场对耐用型热敏和压敏黏着剂的庞大需求。物流业者倾向于选择黏合剂,而品牌所有者则需要能够进行临时客製化的标籤布局。因此,投资高速数位印刷机的标籤加工商能够获得更高的溢价,以实现快速的印刷作业切换,这也巩固了电子商务作为标籤市场结构性成长引擎的地位。

永续性法规加速无底纸和可回收纸张形式的推广

欧盟包装及包装废弃物法规要求到2030年,包装材料的可回收率(按重量计)达到70%,这鼓励对标籤面、底纸和黏合剂进行重新设计。 CELAB-Europe的目标是到2025年回收75%的废旧底纸,并正在推进收集方案的实施,使其超越自愿试点阶段。美国各州的延伸生产者责任制(EPR)计画使得合规包装和不合规包装之间的费用差异高达300%,使永续性成为利润驱动因素。采用无底纸标籤的加工商可减少高达40%的废弃物,并提高物流效率。材料科学的进步,例如含有85%可再生原料的生物基黏合剂,正在促进这一转型,同时又不影响应用速度,从而进一步增强了这一驱动因素对标籤市场成长的长期影响。

原料成本波动

美国墨西哥湾沿岸的飓风扰乱了石化产品的供应,导致丙烯酸树脂和聚烯的采购趋紧,进而推高了黏合剂价格并延长了前置作业时间。预计到2026年,欧洲黏合剂市场规模将达到222亿欧元,该市场也在争夺同样的原料,这给购买力较弱的小型加工商带来了压力。为了因应市场波动,加工商增加了安全库存,增加了营运资金需求,短期内利润受到挤压,限制了标籤市场的扩张。

细分市场分析

到2025年,压敏黏着剂将占据32.75%的市场份额,这得益于其在食品、个人护理和物流等广泛应用领域的多功能性。套标产品虽然目前绝对销售量较小,但随着品牌商追求360度全景影像和防永续性功能,预计将以8.71%的复合年增长率成长。套标的日益普及正在推动高端饮料和营养补充剂领域标籤市场规模的成长,而环绕式标籤则面临着被瓶盖印刷和压纹等製程替代的风险。在压敏黏着剂领域,可回收黏合剂的持续创新(可减少35%的碳足迹)有助于在日益严格的永续发展审查下维持市场份额。因此,市场两极化的趋势日益明显。大众饮料正转向直接印刷,而高端产品则采用先进的套标,这两种路径都在强化全球标籤市场中差异化的价值平台。

柔版印刷凭藉其速度和成本优势,尤其适用于5万米以上的连续印刷,预计到2025年将占据标籤市场57.55%的份额。然而,数位喷墨和静电照相技术将以8.87%的复合年增长率成长,儘管产量仅占4.10%,但其收入将占16.20%。它们的优势在于依靠软体驱动的作业切换来减少停机时间并实现产品种类多样化。近期复合黑墨专利的出现,加速了其在多孔基材上的干燥速度,提高了印刷机的生产效率并降低了单位成本。虽然凹版印刷、胶印和网版印刷等传统印刷方式在烫金酒标和高速罐头标籤等细分市场仍占有一席之地,但投资趋势显然更倾向于数位技术。未来几年,掌握混合印刷工作流程的加工商将进一步拓展其在不断增长的标籤市场的渗透,同时赢得大批量通用标籤和高端客製化标籤的市场份额。

区域分析

亚太地区将继续保持其领先地位,到2025年将占据44.60%的标籤市场份额,推动要素中国庞大的市场规模和印度包装食品市场的成长。政府对先进製造业的支持以及印刷设备製造商的集中,将降低资本投资成本,并促进产能扩张。泰国和韩国推行无标籤瓶的做法,反映了亚太地区一些监管机构愿意突破传统做法,进而影响全球关于永续标籤的讨论。

预计中东和非洲地区2025年的营收成长率仅为6.10%,但到2031年,其复合年增长率将达到5.24%,这主要得益于食品加工投资和零售业现代化。沙乌地阿拉伯的NEOM等大型企划以及埃及的工业园区将推动瓦楞纸箱和标籤的需求,而非洲的电子商务平台将促进运输标籤的成长。然而,由于缺乏衬纸回收基础设施,无衬纸解决方案仍处于发展阶段,这为向该地区出口承包技术的供应商创造了成长机会。

北美是技术标竿地区,拥有超过2000家加工商和庞大的数位印刷机装机量。沃尔玛的RFID强制令以及履约仓库的兴起正在推动智慧标籤的需求。欧洲市场虽然已趋于成熟,但在可回收性法规方面仍保持领先地位,推动了可水洗黏合剂和单一材料解决方案的普及。随着宏观环境的趋于稳定,南美市场正在復苏,一家领先的巴西饮料公司通过在其风味水SKU中采用套筒标籤来扩展其产品线。这些跨区域的趋势共同构成了全球标籤市场平衡且充满机会的模式。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 电子商务的快速成长推动了可变数据运输标籤的发展

- 永续性法规推动了无衬纸和可回收纸张形式的发展。

- 食品饮料产业对优质、符合监管要求的包装的需求日益增长。

- 透过智慧/互联包装(QR码、RFID)开发新的收入来源

- 日益严格的电动车电池安全法规正在推动对高性能感压标籤的需求。

- 东协无标定瓶试点计画推广直接在容器上印刷

- 市场限制

- 原料成本波动(薄膜、黏合剂)

- 转向立式袋和直接印刷技术

- 全球缺乏衬垫废弃物回收基础设施

- 由于无标定瓶装法规的出台,环绕式包装的需求正在萎缩。

- 价值/供应链分析

- 监管环境

- 技术展望

- 波特五力模型

- 新进入者的威胁

- 买方的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

- 供应链分析

- 评估新冠肺炎疫情及其地缘政治影响

第五章 市场规模及成长预测(以金额为准,2021-2030 年)

- 按标籤类型

- 感压标籤

- 拉伸套

- 套模标籤

- 湿胶标籤

- 热感标籤

- 环绕式标籤

- 透过印刷技术

- 柔版印刷

- 凹版印刷

- 抵销

- 数位(喷墨和静电照相)

- 萤幕和其他类比设备

- 材料

- 纸和纸板

- PVC

- PET

- 聚乙烯和聚丙烯

- 生物基可堆肥薄膜

- 按最终用户行业划分

- 食品/饮料

- 製药和医疗保健

- 个人护理和化妆品

- 零售和物流

- 工业与汽车

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 其他欧洲地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 澳洲和纽西兰

- 亚太其他地区

- 中东和非洲

- 中东

- 阿拉伯聯合大公国

- 土耳其

- 沙乌地阿拉伯

- 非洲

- 南非

- 奈及利亚

- 其他非洲地区

- 中东

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- CCL Industries Inc.

- Avery Dennison Corporation

- Multi-Color Corporation

- Huhtamaki Oyj

- Constantia Flexibles GmbH

- UPM Raflatac(UPM Group)

- Mondi plc

- Fuji Seal International Inc.

- Fort Dearborn Company

- Lintec Corporation

- 3M Company

- Smurfit WestRock

- Amcor plc

- Taghleef Industries

- Stora Enso Oyj

- Xeikon BV

- KRIS Flexipacks Pvt Ltd

- Royal Sens Group

- Leading Edge Labels & Packaging

第七章 市场机会与未来展望

The Global label market was valued at USD 47 billion in 2025 and estimated to grow from USD 49.56 billion in 2026 to reach USD 64.64 billion by 2031, at a CAGR of 5.45% during the forecast period (2026-2031).

This steady trajectory reflects the sector's capacity to adjust to e-commerce expansion, sustainability regulations, and smart packaging adoption. Regulatory pressure for recyclable materials continues to push converters toward liner-less constructions and bio-based films, while retailers' demand for real-time product authentication accelerates the shift toward connected packaging. Digital printing's economics favor short runs and customization, raising margins despite its modest share of total output. Competitive momentum favors firms that can integrate RFID, NFC, and QR solutions at scale, turning labels into data touchpoints that enhance supply-chain visibility and consumer engagement. The convergence of these forces positions the label market for durable growth even as direct-to-container printing presents a substitution threat in specific beverage categories.

Global Label Market Trends and Insights

E-commerce Boom Driving Variable-Data Shipping Labels

Worldwide parcel volume reached 21.7 billion in 2023 and is tracking toward 29 billion by 2029, pushing converters to supply labels capable of real-time, order-specific data. Dimensional-weight billing and omnichannel fulfillment require scannable graphics that survive automated sortation. Amazon's 15.7% volume surge in 2023 underscores the scale of demand for durable thermal and pressure-sensitive constructions. Logistics providers prefer adhesives that remain tacky across diverse corrugated substrates, while brand owners seek layouts that accommodate late-stage customization. As a result, converters investing in high-speed digital presses capture the premium associated with quick-change print jobs, reinforcing e-commerce as a structural growth engine for the label market.

Sustainability Regulations Accelerating Liner-Less and Recyclable Formats

The EU Packaging and Packaging Waste Regulation mandates 70% recyclability by weight by 2030, compelling redesign of face stocks, liners, and adhesives. CELAB-Europe targets recycling of 75% of spent liners by 2025, pushing collection schemes beyond voluntary pilots. Extended Producer Responsibility in U.S. states imposes fee differentials as high as 300% between compliant and non-compliant packaging, making sustainability a profit determinant. Converters responding with liner-less labels reduce waste by up to 40% and unlock logistics efficiencies. Material science advances, including bio-adhesives with 85% renewable content, ease the transition without sacrificing application speed, reinforcing the driver's long-term impact on label market growth.

Raw-Material Cost Volatility

Petrochemical supply disruptions from hurricanes in the U.S. Gulf Coast have tightened feedstock availability for acrylics and polyolefins, lifting adhesive prices and extending lead times. Europe's adhesives market, expected to reach EUR 22.2 billion by 2026, competes for the same inputs, squeezing smaller converters that lack purchasing leverage. To manage volatility, converters hold larger safety stocks, raising working-capital needs and pressuring earnings in the short term, thereby restraining label market expansion.

Other drivers and restraints analyzed in the detailed report include:

- Food and Beverage Demand for Premium Compliance-Driven Packaging

- Smart/Connected Packaging Opening New Revenue Streams

- Shift Toward Stand-Up Pouches and Direct-to-Object Printing

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Pressure-sensitive formats held 32.75% of the label market share in 2025, thanks to their versatility across food, personal care, and logistics applications. Sleeve products, although smaller in absolute terms, are projected to expand at an 8.71% CAGR as brand owners pursue 360-degree graphics and tamper evidence. This sleeve uptake lifts the label market size in premium beverages and nutraceuticals, while wrap-around formats encounter substitution risk from cap-print and embossing. Pressure-sensitive innovation continues with recyclable adhesives 35% lower carbon footprints help sustain share even as sustainability scrutiny intensifies. Consequently, a two-track pattern sets in: commodity beverages pivot to direct print, while premium SKUs adopt sophisticated sleeves, each path reinforcing differentiated value pools inside the global label market.

Flexography controlled 57.55% of the label market size in 2025 due to speed and cost advantages on runs above 50,000 linear meters. Digital inkjet and electrophotography, however, are pacing at 8.87% CAGR, securing 16.20% of revenue from just 4.10% of output. The economics hinge on software-driven job changeovers that slash downtime and enable SKU proliferation. Recent patents on composite black inks accelerate drying on porous substrates, boosting press throughput and lowering per-unit cost. .Analog stalwarts gravure, offset, and screen retain niches such as foil-on-foil spirits labels and high-speed canning, yet investment trends unambiguously favor digital. Over the outlook period, converters that master hybrid press workflows capture both commodity scale and premium customization, deepening their penetration of the expanding label market.

The Global Label Market Report is Segmented by Label Type (Pressure-Sensitive, Shrink and Stretch Sleeves, and More), Printing Technology (Flexography, Gravure, Offset, Digital, Screen and Other Analog), Material (Paper and Paperboard, PVC, and More), End-User Industry (Food and Beverages, Pharmaceutical and Healthcare, and More), and Geography (North America, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific led with 44.60% of label market share in 2025, fueled by China's scale and India's growth in packaged foods. Government incentives for advanced manufacturing and the clustering of press-builders lower capital costs, encouraging capacity additions. Thailand's and South Korea's shifts toward labelless bottles illustrate how some APAC regulators leapfrog legacy practices, thereby shaping the global conversation on sustainable labeling.

Middle East and Africa, though only 6.10% of 2025 revenue, will post a 5.24% CAGR through 2031, propelled by food-processing investments and retail modernization. Mega-projects in Saudi Arabia's NEOM and Egypt's industrial zones spur corrugated and label demand, while African e-commerce platforms fuel shipping-label growth. Limited liner recycling infrastructure, however, keeps liner-less solutions nascent, offering upside for suppliers exporting turnkey technologies into the region.

North America remains the technological bellwether, home to over 2,000 converters and a deep installed base of digital presses. RFID mandates at Walmart and the proliferation of direct-fulfillment warehouses intensify demand for smart labels. Europe, while mature, continues to set the regulatory pace on recyclability, driving adoption of wash-off adhesives and mono-material solutions. South America rebounds as macro conditions stabilize; Brazil's beverage giants adopt sleeves for flavored-water SKUs, widening product breadth. Collectively, cross-regional dynamics reinforce a balanced yet opportunity-rich landscape for the global label market.

- CCL Industries Inc.

- Avery Dennison Corporation

- Multi-Color Corporation

- Huhtamaki Oyj

- Constantia Flexibles GmbH

- UPM Raflatac (UPM Group)

- Mondi plc

- Fuji Seal International Inc.

- Fort Dearborn Company

- Lintec Corporation

- 3M Company

- Smurfit WestRock

- Amcor plc

- Taghleef Industries

- Stora Enso Oyj

- Xeikon BV

- KRIS Flexipacks Pvt Ltd

- Royal Sens Group

- Leading Edge Labels & Packaging

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 E-commerce boom driving variable-data shipping labels

- 4.2.2 Sustainability regulations accelerating liner-less and recyclable formats

- 4.2.3 Food-and-beverage demand for premium compliance-driven packaging

- 4.2.4 Smart/connected packaging (QR, RFID) opening new revenue streams

- 4.2.5 EV battery-safety mandates spurring high-spec pressure-sensitive labels

- 4.2.6 ASEAN label-free bottle pilots catalyzing direct-to-container printing

- 4.3 Market Restraints

- 4.3.1 Raw-material cost volatility (films, adhesives)

- 4.3.2 Shift toward stand-up pouches and direct-to-object printing

- 4.3.3 Limited global liner-waste recycling infrastructure

- 4.3.4 Emerging label-free bottle regulations shrinking wrap-around demand

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Competitive Rivalry

- 4.8 Supply-Chain Analysis

- 4.9 Assessment of COVID-19 and Geopolitical Impacts

5 MARKET SIZE & GROWTH FORECASTS (VALUE, 2021-2030)

- 5.1 By Label Type

- 5.1.1 Pressure-Sensitive Labels

- 5.1.2 Shrink and Stretch Sleeves

- 5.1.3 In-Mold Labels

- 5.1.4 Wet-Glue Labels

- 5.1.5 Thermal-Transfer Labels

- 5.1.6 Wrap-Around Labels

- 5.2 By Printing Technology

- 5.2.1 Flexography

- 5.2.2 Gravure

- 5.2.3 Offset

- 5.2.4 Digital (Inkjet and Electrophotographic)

- 5.2.5 Screen and Other Analog

- 5.3 By Material

- 5.3.1 Paper and Paperboard

- 5.3.2 PVC

- 5.3.3 PET

- 5.3.4 PE and PP

- 5.3.5 Bio-based and Compostable Films

- 5.4 By End-User Industry

- 5.4.1 Food and Beverages

- 5.4.2 Pharmaceutical and Healthcare

- 5.4.3 Personal Care and Cosmetics

- 5.4.4 Retail and Logistics

- 5.4.5 Industrial and Automotive

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Russia

- 5.5.3.7 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 India

- 5.5.4.4 South Korea

- 5.5.4.5 Australia and New Zealand

- 5.5.4.6 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 UAE

- 5.5.5.1.2 Turkey

- 5.5.5.1.3 Saudi Arabia

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Nigeria

- 5.5.5.2.3 Rest of Africa

- 5.5.5.1 Middle East

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 CCL Industries Inc.

- 6.4.2 Avery Dennison Corporation

- 6.4.3 Multi-Color Corporation

- 6.4.4 Huhtamaki Oyj

- 6.4.5 Constantia Flexibles GmbH

- 6.4.6 UPM Raflatac (UPM Group)

- 6.4.7 Mondi plc

- 6.4.8 Fuji Seal International Inc.

- 6.4.9 Fort Dearborn Company

- 6.4.10 Lintec Corporation

- 6.4.11 3M Company

- 6.4.12 Smurfit WestRock

- 6.4.13 Amcor plc

- 6.4.14 Taghleef Industries

- 6.4.15 Stora Enso Oyj

- 6.4.16 Xeikon BV

- 6.4.17 KRIS Flexipacks Pvt Ltd

- 6.4.18 Royal Sens Group

- 6.4.19 Leading Edge Labels & Packaging

7 MARKET OPPORTUNITIES & FUTURE OUTLOOK

- 7.1 White-Space & Unmet-Need Assessment