|

市场调查报告书

商品编码

1911700

黏合剂:市场占有率分析、产业趋势和统计数据、成长预测(2026-2031)Adhesives - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

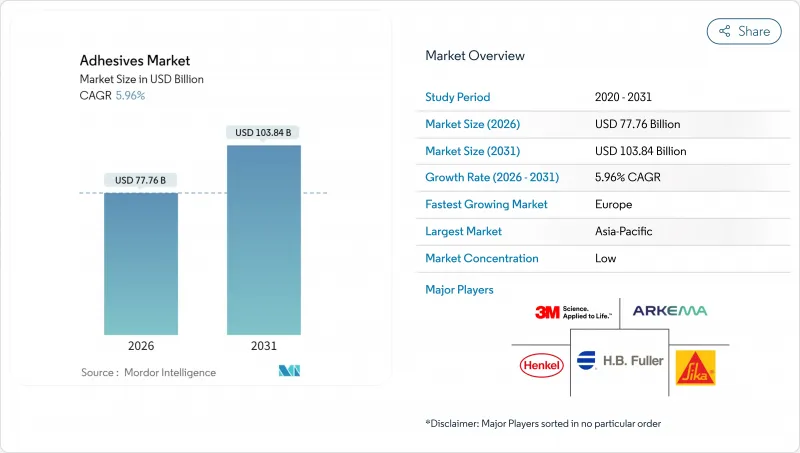

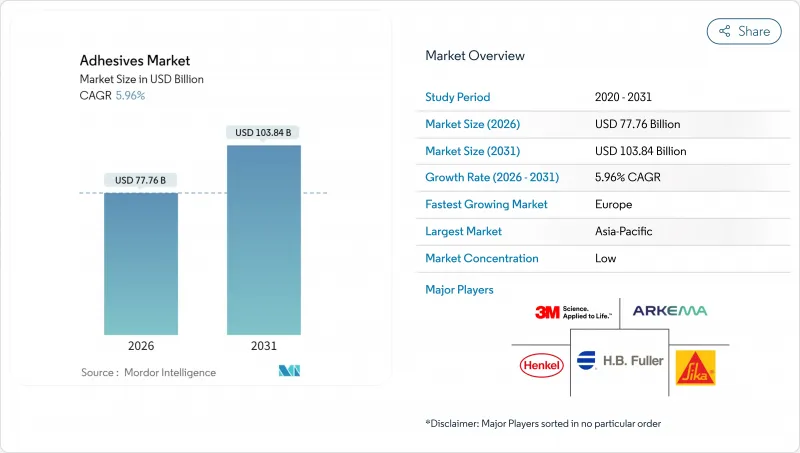

预计黏合剂市场将从 2025 年的 733.9 亿美元成长到 2026 年的 777.6 亿美元,到 2031 年将达到 1,038.4 亿美元,2026 年至 2031 年的复合年增长率为 5.96%。

受电子商务推动的包装自动化扩张、基础设施营运中结构黏合日益受到重视以及汽车製造商为支持轻量化复合材料设计而增加黏合剂用量等因素的影响,市场需求正在加速成长。水性黏合剂占据主导地位,因为品牌需要满足挥发性有机化合物(VOC)法规的要求;而热熔胶平台则因其无溶剂加工和高速生产线相容性而不断扩大市场份额。在树脂领域,丙烯酸树脂在高性能应用方面持续保持主导,而VAE/EVA系统则因其柔软性和成本效益而在建筑领域得到更广泛的应用。区域趋势正在分化,亚太地区引领销售成长,而欧洲则在符合法规要求的高附加价值等级产品方面取得了进展。

全球黏合剂市场趋势与洞察

电子商务的快速成长推动了对安全、快速包装黏合剂的需求。

线上零售仓库正在使用可在毫秒内固化的热熔胶和压敏黏着剂能够承受输送机衝击和多式联运,从而保持包装箱的完整性。履约中心报告订单量实现了两位数成长,主要电商走廊对包装黏合剂的需求增加了15-20%。仅印度的线上零售业预计到2024年将推动包装黏合剂需求增加18%,这主要得益于品牌所有者要求使用适用于热带气候的防篡改密封条。永续性目标进一步推动了水性胶粘剂和生物基胶粘剂的发展,这些胶粘剂与纸张回收过程相容。包装商现在指定使用易剥离的胶粘剂,这种胶粘剂能够保持基材清洁,并便于二次纤维回收。

全球建筑材料升级再造增加结构胶合剂和地板黏合剂的消耗量

亚太地区大型企划规划的加速推进,推动了对高强度、快速固化混凝土-钢材-复合材料材料连接胶合剂的需求,因为机械紧固效率低或失效风险较高。大型瓷砖和预製板需要使用抗剪切黏合剂来缩短施工週期并增强结构完整性。 2024年,瓦克化学扩大了其位于南京和卡尔弗特市的VAE胶粘剂产能,以满足瓷砖和隔热系统建筑黏合剂日益增长的需求。欧洲和北美的节能维修奖励也支撑了对气流阻隔密封胶和保温黏合剂的需求。同时,修订后的建筑规范鼓励使用胶粘连接来提高抗震性能并减少热桥效应。

石油原料价格波动对製造商的利润率带来压力。

乙烯和丙烯等原油单体占黏合剂原料成本的60%之多。 2024年丙烯酸价格波动幅度达25%至30%,导致季度附加费挤压利润空间,尤其对于缺乏避险能力的中小型加工商而言更是如此。外汇波动加重了那些全球采购但本地开票企业的负担。为了降低波动风险,製造商正在采用双重采购和库存风险策略,但这增加了物流复杂性和营运资金需求。

细分市场分析

预计到2025年,丙烯酸类黏合剂将占全球黏合剂市场22.60%的份额,这主要得益于其在建筑建筑幕墙、汽车内部装潢建材和感压标籤等领域优异的耐候性能。 VAE/EVA产品线预计到2031年将以6.28%的复合年增长率成长,主要受柔软性地板材料、磁砖铺贴和包装薄膜层压等应用领域需求成长的推动。聚氨酯类黏合剂在交通运输和航太领域保持着强劲的地位,这些领域对黏合剂的高黏合强度、耐化学性和弹性要求极高。环氧树脂类黏合剂由于固化週期长,增长速度较为缓慢,但其主要应用领域是电子产品和风力涡轮机叶片连接,这些领域需要承受极端高温和疲劳。如今,混合化学技术将丙烯酸类黏合剂的抗紫外线性能与聚氨酯的柔软性相结合,或将VAE的柔韧性与环氧树脂的刚性相结合,从而拓展了配方师的工具箱。

随着加工商不断优化树脂性能以适应特定基材和应用环境,树脂技术的持续创新正推动全球黏合剂市场扩张。丙烯酸酯生产商正投资研发自交联乳化以增强其耐水性和抗泛白性,而VAE供应商则透过提高极性单体含量来改善其与低表面能薄膜的黏合力。生物基原料的需求日益增长,但成本和供应限制了其快速普及。策略性树脂选择越来越注重在法规遵循、使用温度和总应用成本之间取得平衡,这使得製造商能够在同质化终端应用领域中脱颖而出。

此黏合剂报告按树脂类型(聚氨酯、环氧树脂、丙烯酸酯、氰基丙烯酸酯、VAE/EVA 等)、技术类型(水性、溶剂型、反应型等)、终端用户行业类型(建筑、包装、汽车、航太、木工等)和地区类型(亚太、北美、欧洲等)进行结构划分。市场预测以美元计价。

区域分析

亚太地区占全球黏合剂市场的36.30%,主要得益于中国、印度和东南亚地区集中的製造群和公共基础设施投资。中国的城市轨道交通和住宅计划推动了对结构丙烯酸树脂的需求,而印度的瓷砖黏合剂市场则因城市住宅建设的快速发展而以每年超过15%的速度增长。包括汉高和德莎等新工厂在内的区域供应商正在加强本地供应能力并缩短前置作业时间。产能过剩问题依然存在,尤其是EVA和丙烯酸乳液,因为计画中的产能提升可能会因下游需求放缓而导致库存过剩。

预计到2031年,欧洲将保持最高的成长率,年均成长率将达到6.25%,这主要得益于更严格的监管推动加工商转向可再生和低排放系统。将于2026年生效的欧盟包装和包装废弃物法规将要求黏合剂在机械回收过程中完全可分离,且不含PFAS。德国向电动车的转型正在推动对导热和阻燃黏合剂的需求,而法国的建筑维修补贴计画则刺激了对隔热材料黏合剂的需求。

在北美,关税驱动的单体投资增强了供应安全,并维持了稳定成长。计划从2025年起运作的丙烯酸产能(美国墨西哥湾沿岸地区)将降低进口依赖性,并透过缩短运输时间支持区域内的其他化合物生产商。墨西哥作为汽车出口中心,推动了对结构和捲边胶粘剂系统的需求,而加拿大寒冷地区的建筑规范则倾向于使用耐冻黏合剂建造板式住宅。这一趋势取决于基础设施立法的进展和汽车生产週期,但由于製造业的復苏和永续性倡议的推进,预计将保持强劲势头。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 电子商务的快速成长正在推动对安全快速包装黏合剂的需求。

- 由于全球建筑经济的復苏,结构和地板黏合剂的消费量正在增加。

- 轻量化和电动车平台将加速汽车黏合剂的普及应用。

- 人工智慧驱动的配方优化可显着缩短研发时间并降低客製化黏合剂成本。

- 自2025年美国加征关税以来,丙烯酸单体供应的近岸外包将重塑区域生产能力。

- 市场限制

- 石油原料价格波动对黏合剂生产商的利润率带来压力。

- 更严格的挥发性有机化合物(VOC)和化学品法规抑制了溶剂黏合剂的销售

- 全球资深黏合剂配方师短缺,延缓商业化週期

- 价值链分析

- 波特五力模型

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模与成长预测

- 树脂

- 聚氨酯

- 环氧树脂

- 丙烯酸纤维

- 氰基丙烯酸酯

- VAE/EVA

- 硅酮

- 其他树脂

- 透过技术

- 水系统

- 溶剂型

- 反应性

- 热熔胶

- UV固化黏合剂

- 按最终用户行业划分

- 建筑/施工

- 包装

- 车

- 航太工业

- 木工和细木工

- 鞋类和皮革製品

- 卫生保健

- 其他终端用户产业

- 按地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 澳洲

- 印尼

- 马来西亚

- 新加坡

- 泰国

- 亚太其他地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 其他欧洲地区

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率(%)/排名分析

- 公司简介

- 3M

- Aica Kogyo Co..Ltd.

- Arkema

- AVERY DENNISON CORPORATION

- Dow

- HB Fuller Company

- Henkel AG & Co. KGaA

- Huntsman International LLC

- Illinois Tool Works Inc.

- Jowat SE

- MAPEI SpA

- NANPAO RESINS CHEMICAL GROUP

- Pidilite Industries Ltd.

- Sika AG

- Soudal Holding NV

- Wacker Chemie AG

第七章 市场机会与未来展望

The Adhesives market is expected to grow from USD 73.39 billion in 2025 to USD 77.76 billion in 2026 and is forecast to reach USD 103.84 billion by 2031 at 5.96% CAGR over 2026-2031.

Demand accelerates as packaging automation scales with e-commerce, infrastructure programs prioritize structural bonding, and automakers increase adhesive volumes to support lightweight multi-material designs. Water-borne chemistries dominate because brands must meet VOC limits, yet hot-melt platforms gain share through solvent-free processing and rapid line speeds. Within resins, acrylics continue to rule high-performance applications, while VAE/EVA lines capture construction volumes thanks to flexibility and cost efficiency. Regional dynamics diverge, with Asia-Pacific supplying volume growth and Europe advancing premium, regulation-ready grades.

Global Adhesives Market Trends and Insights

E-commerce Boom Enlarging Demand for Secure, High-Speed Packaging Adhesives

Online retail warehouses rely on hot-melt and pressure-sensitive grades that cure in milliseconds yet sustain box integrity through conveyor impacts and multi-modal shipping. Fulfilment centers report double-digit order growth, driving 15-20% volume increases for packaging adhesives in key e-commerce corridors. India's online retail sector alone lifted packaging-adhesive offtake by 18% in 2024 as brand owners mandated tamper-evident bonds suitable for tropical climates. Sustainability goals add momentum for water-borne and bio-sourced options compatible with paper recycling streams. Packagers now specify easily removable grades that leave substrates clean, easing secondary fiber recovery.

Global Construction Upcycle Raising Consumption of Structural and Flooring Adhesives

Megaproject pipelines in Asia-Pacific accelerate uptake of high-strength, fast-set formulations for concrete, steel, and composite bonding where mechanical fasteners are slow or prone to failure. Large-format tiles and pre-fabricated panels need shear-resistant adhesives that shorten installation cycles and enhance structural integrity. Wacker Chemie expanded VAE capacity in Nanjing and Calvert City during 2024 to serve rising construction-adhesive demand in tile and insulation systems. Energy-retrofit incentives in Europe and North America sustain airflow-sealant and insulation-adhesive volumes, while updated building codes champion bonded joints for seismic resilience and thermal-bridge reduction.

Petro-Feedstock Price Volatility Squeezing Manufacturer Margins

Crude-linked monomers such as ethylene and propylene account for up to 60% of adhesive raw-material cost. Acrylic-acid prices swung 25-30% during 2024, forcing quarterly surcharges that erode margins, especially for smaller converters without hedging power. Currency shakiness multiplies the burden for firms that source globally but invoice locally. To blunt volatility, producers adopt dual-sourcing and inventory-risk strategies, yet these raise logistics complexity and working-capital needs.

Other drivers and restraints analyzed in the detailed report include:

- Lightweighting and EV Platforms Accelerating Automotive Adhesive Penetration

- Near-Shoring of Acrylic Monomer Supply in the United States

- Escalating VOC and Chemicals Regulation Curbing Solvent-Borne Sales

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Acrylic systems held a 22.60% share of the global adhesives market in 2025, supported by weather-resistant performance across construction facades, automotive trim, and pressure-sensitive labels. VAE/EVA lines are growing at a 6.28% CAGR through 2031, propelled by flexible flooring, tile-setting, and packaging-film lamination. Polyurethane grades stay entrenched in transportation and aerospace where high bond strength, chemical resistance, and elasticity are critical. Epoxies serve electronics and wind-blade joints that face extreme heat and fatigue, though their growth lags due to longer cure cycles. Hybrid chemistries now combine acrylic UV resistance with polyurethane toughness or VAE flexibility with epoxy rigidity, widening formulator toolkits.

Continuous resin innovation keeps the global adhesives market expanding as converters fine-tune performance for specific substrates and service environments. Acrylic players invest in self-crosslinking emulsions that boost water whitening resistance, while VAE suppliers ramp polar-monomer content to enhance adhesion to low-surface-energy films. Demand for bio-based feedstocks rises, yet cost and supply scalability limit rapid penetration. Strategic resin selection increasingly balances regulatory compliance, service temperature, and total applied cost, enabling manufacturers to differentiate within commoditized end uses.

The Adhesives Report is Segmented by Resin (Polyurethane, Epoxy, Acrylic, Cyanoacrylate, VAE/EVA, and More), Technology (Water-Borne, Solvent-Borne, Reactive, and More), End-User Industry (Building and Construction, Packaging, Automotive, Aerospace, Woodworking and Joinery, and More), and Geography (Asia-Pacific, North America, Europe, and More). The Market Forecasts are Provided in Terms of Value (USD)

Geography Analysis

Asia-Pacific holds 36.30% of the global adhesives market thanks to concentrated manufacturing clusters and public infrastructure spending across China, India, and Southeast Asia. China's urban rail and residential projects spur demand for structural acrylics, while India's tile-adhesive segment grows more than 15% annually on rapid urban housing. Regional suppliers, including new Henkel and tesa plants, enhance local availability and cut lead times. Overcapacity concerns persist, particularly in EVA and acrylic emulsions, where planned expansions risk surplus inventory if downstream uptake slows.

Europe is forecast to post the fastest 6.25% CAGR through 2031 as regulations push converters toward recyclable, low-emission systems. The EU Packaging and Packaging Waste Regulation, effective in 2026, will require adhesives that separate cleanly in mechanical recycling streams and eliminate PFAS content. Germany's EV transition drives demand for thermally conductive and flame-retardant adhesives, while France's building-retrofit subsidies stimulate insulation-bond volumes.

North America records steady momentum as tariff-induced monomer investments bolster supply security. Gulf Coast acrylic-acid capacity coming online from 2025 lessens reliance on imports and supports regional formulators with shorter transit times. Mexico's role as an automotive export hub lifts demand for structural and hem-flange bonding systems, whereas Canada's cold-weather construction codes favor freeze-resistant adhesives for panelized housing. The trajectory hinges on infrastructure-bill progress and automotive production cycles but remains positive amid reshoring and sustainability commitments.

- 3M

- Aica Kogyo Co..Ltd.

- Arkema

- AVERY DENNISON CORPORATION

- Dow

- H.B. Fuller Company

- Henkel AG & Co. KGaA

- Huntsman International LLC

- Illinois Tool Works Inc.

- Jowat SE

- MAPEI S.p.A.

- NANPAO RESINS CHEMICAL GROUP

- Pidilite Industries Ltd.

- Sika AG

- Soudal Holding N.V.

- Wacker Chemie AG

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 E-commerce boom enlarging demand for secure, high-speed packaging adhesives

- 4.2.2 Global construction upcycle raising consumption of structural and flooring adhesives

- 4.2.3 Lightweighting and EV platforms accelerating automotive adhesive penetration

- 4.2.4 AI-driven formulation optimisation slashing research and development timelines and custom-bonding costs

- 4.2.5 Near-shoring of acrylic monomer supply in US post-2025 tariffs reshapes regional capacity

- 4.3 Market Restraints

- 4.3.1 Petro-feedstock price volatility squeezing adhesive manufacturer margins

- 4.3.2 Escalating VOC and chemicals regulation curbing solvent-borne adhesive sales

- 4.3.3 Global shortage of senior adhesive formulators slowing commercialisation cycles

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Competitive Rivalry

5 Market Size and Growth Forecasts (Value)

- 5.1 By Resin

- 5.1.1 Polyurethane

- 5.1.2 Epoxy

- 5.1.3 Acrylic

- 5.1.4 Cyanoacrylate

- 5.1.5 VAE/EVA

- 5.1.6 Silicone

- 5.1.7 Other Resins

- 5.2 By Technology

- 5.2.1 Water-borne

- 5.2.2 Solvent-borne

- 5.2.3 Reactive

- 5.2.4 Hot Melt

- 5.2.5 UV Cured Adhesives

- 5.3 By End-user Industry

- 5.3.1 Building and Construction

- 5.3.2 Packaging

- 5.3.3 Automotive

- 5.3.4 Aerospace

- 5.3.5 Woodworking and Joinery

- 5.3.6 Footwear and Leather

- 5.3.7 Healthcare

- 5.3.8 Other End-user Industries

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 Japan

- 5.4.1.3 India

- 5.4.1.4 South Korea

- 5.4.1.5 Australia

- 5.4.1.6 Indonesia

- 5.4.1.7 Malaysia

- 5.4.1.8 Singapore

- 5.4.1.9 Thailand

- 5.4.1.10 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Spain

- 5.4.3.6 Russia

- 5.4.3.7 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 3M

- 6.4.2 Aica Kogyo Co..Ltd.

- 6.4.3 Arkema

- 6.4.4 AVERY DENNISON CORPORATION

- 6.4.5 Dow

- 6.4.6 H.B. Fuller Company

- 6.4.7 Henkel AG & Co. KGaA

- 6.4.8 Huntsman International LLC

- 6.4.9 Illinois Tool Works Inc.

- 6.4.10 Jowat SE

- 6.4.11 MAPEI S.p.A.

- 6.4.12 NANPAO RESINS CHEMICAL GROUP

- 6.4.13 Pidilite Industries Ltd.

- 6.4.14 Sika AG

- 6.4.15 Soudal Holding N.V.

- 6.4.16 Wacker Chemie AG

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment