|

市场调查报告书

商品编码

1374456

单晶(单颗粒)正极技术趋势及市场展望<2023> Single Crystal (Single Particle) Cathode Technology Development Trend and Market Outlook |

||||||

单晶正极的量产迫在眉睫,这将显着提高电动车电池的性能,中韩企业之间的竞争预计将加剧。

目前市售电动车电池中使用的正极材料具有由多种金属化合物晶体组成的多晶结构。然而,在轧製过程中以及在充电和放电过程中,这些颗粒之间经常会出现裂缝以获得均匀的厚度。这种裂缝的重复出现会导致材料劣化,增加电池内气体的形成,并缩短充电/放电循环和电池寿命。

与多晶不同,单晶不会受到这个问题的影响,因为颗粒保持完整。此外,增加镍含量以增加容量会降低结构稳定性并增加火灾风险。因此,单晶阴极的发展应运而生,作为应对此一课题的解决方案。

单晶阴极透过消除残留材料、降低缺陷机率并消除清洁步骤来降低成本并提高产量。这步骤对于阴极製造中去除杂质非常重要,但对于单晶技术来说并不是必需的。

单晶阴极的实际应用将扩大高镍阴极的应用范围。减少气体产生可延长电池寿命,同时允许容纳更多活性材料,从而提高能量密度。如果将这项技术引入电动车的电池组中,则可以用更少的电池数量一次充电行驶超过500公里,有望打造出可以行驶更远距离的车型。这种改变游戏规则的潜力有望同时降低成本并提高效能。

然而,单晶阴极也有缺点。与多晶材料不同,大型单晶材料具有较高的初始电阻,这使得施加所需电压成为一个课题。结果,输出仍然很低,从而阻碍了电池性能的提高。

然而,单晶阴极需要额外的步骤并在更高的电压下工作,这会增加电池温度。此外,单晶颗粒在压延过程中容易受到损坏,而压延是电极製造的重要组成部分。

因此,在大规模生产的早期阶段,单晶很可能与多晶混合,而不是以纯形式生产。

中国企业已经生产了NCM523、622的单晶阴极,LG Chem、Ecopro BEM、L&F、POSCO FutureM等国内企业也已完成开发并正在与客户进行品质测试。目标是单晶 NCA 和 NCM,似乎已准备好进行大规模生产。

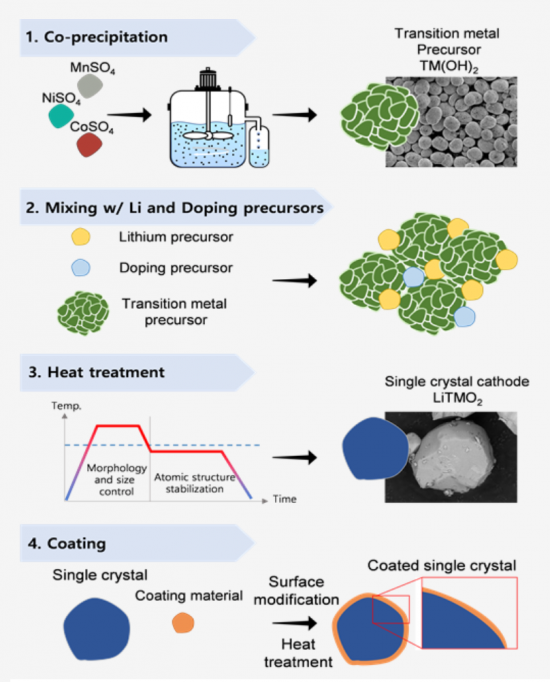

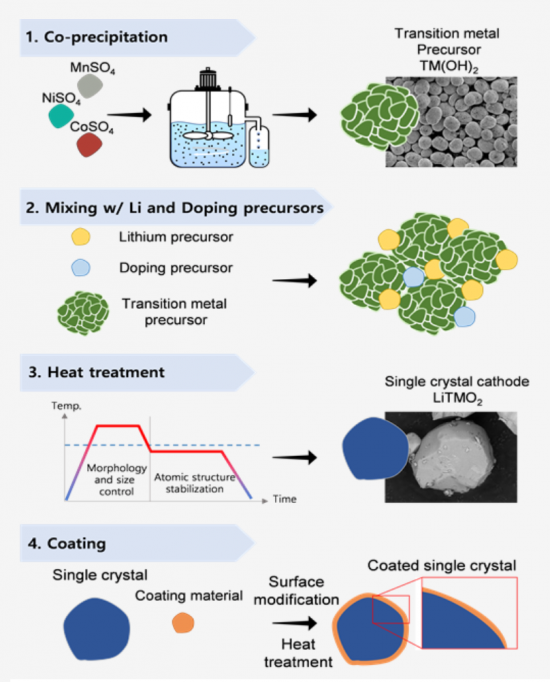

行业专家预测,单晶阴极的性能和品质取决于涂层技术和单晶製造工艺,以确保耐用性。基本上,重点是有效处理表面并同时增加颗粒尺寸。

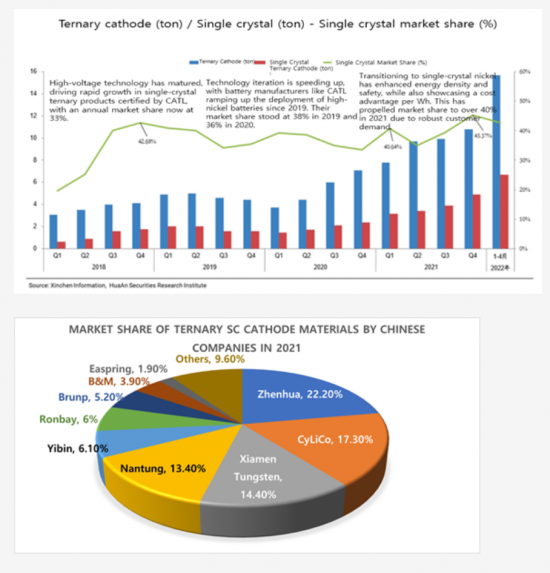

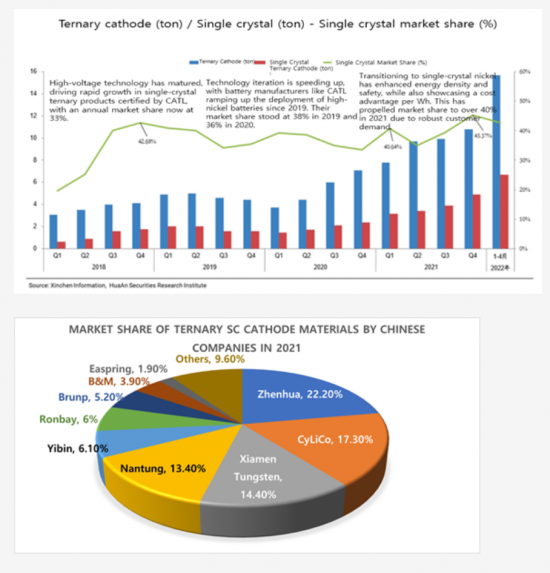

目前,中国前五家企业占了量产单晶阴极市场约75%的占有率。

从韩国正极材料公司的公告来看,SNE Research预计将从今年(2023年)开始供应样品,2025年产量将超过12万吨。目前生产的三元单晶正极中,NCM523等5系单晶的比例最高,达60-70%。NCM622等6系单晶的比例为18-25%。对于Ni含量在80%以上的8系,生产比例从2021年开始将增加,目前约为15%。预计这一比例将持续上升。

据SNE Research称,韩国没有镍含量的产量数据,因此目前很难预测市场。然而,就中国而言,预计到 2025 年 Hi-Ni 的销售额将达到约 42 亿美元,Mid-Ni 的销售额将达到 92 亿美元。到2030年,Hi-Ni市场预计将成长至约240亿美元,Mid-Ni市场将成长至238亿美元。

本报告对中国和韩国单晶(单颗粒)正极市场进行了调查分析,提供了研究趋势、未来展望、主要合成方法比较、专利分析等。

通用单晶富镍层状正极材料的合成及附加改质製程示意图

目录

第一章正极材料概述

- 正极材料发展史

- 正极材料最新趋势

- 正极材料发展现况:依类型

第2章 单晶富镍层状正极的研究趋势及未来展望

- 单晶富镍层状材料研究的必要性

- 单晶正极材料的定义

- 单晶正极材料技术发展现状

- 透过材料的单颗粒形成进行改进

- 目前超导正极材料技术发展的限制及其克服研究

第3章 单晶镍基正极材料:基础与进展

- 概述

- 镍基正极材料

- 镍基层状氧化物的问题

- 单晶镍基层状氧化物的起源

- 单晶镍基层状氧化物的合成

- 单晶与多晶材料的比较研究

- 单晶镍基正极材料的最新进展

- 结果和结论

第四章单晶富镍NCM正极减容机制研究

- 概述

- 富镍单晶与多晶正极基本特性评价

第五章富镍单晶正极材料的颗粒控制(烧结製程的应用)

- 概述

- 实验说明

- 实验结果

- 烧结製程应用结果

第六章 单晶NMC正极材料的完全干法合成

- 概述

- 干法合成

- 干法合成结果及讨论

第7章 单晶NCM523正极材料的一次合成

- 概述

- NCM523的合成

- 材料性能评估

- 电化学性质

- 实验结果与讨论

第8章 单晶NCM正极材料的合成与改质:生长机制

- 概述

- NCM正极的生长机制

- 固态反应

- 固液流变反应

- 熔盐熔剂中的晶体生长

- 形式修改

第9章 单晶阴极的发展:DOE计划

第十章 单晶正极材料企业专利分析

- Tesla

- LG Chem

- SM Lab

- Nano One Materials

- POSCO Future M

- COSMO Advanced Materials & Technology

- L&F

- Easpring

- BASF Shan Shan

- GEM

- XTC (Xiamen Tungsten)

- Henan Kelong

- Hyundai Motor Company/Kia Corporation

- 6K Inc.

- Dynanonic

- Suzhou Long Power

- Fengchao Energy

- Ecopro BM

- Umicore

第十一章 单晶正极材料产业发展趋势

- LG Chem

- POSCO FutureM

- EcoPro BM

- Zhenhua E-Chem (ZEC)

- Chanyuan Lico

- Ronbay

- XTC (Xiamen Tungsten)

- Tianjin B&M

- Easpring

- Reshane

- Yibin Libode

- Wanxing 123

- GEM

第十二章 单晶阴极市场展望

- 中国单晶产量(2017-2022)

- 中国单晶正极材料产量及占有率(2019年-2022年4月)

- 中国SC三元正极材料产量分布(2019年-2022年1季)

- 中国三元SC正极材料产量占比(2019年-2022年1季)

- 中国三元SC正极材料市场渗透率(2019年至2022年第一季)

- 中国三元SC正极材料市场占有率:依公司划分(2021年)

- 中国三元SC正极材料企业产量及市占率(2021年)

- 韩国和中国三元单晶产量预测

- 韩国三元SC正极材料产量及市场展望

- 中国三元正极材料中单晶正极占比

- 中国三元单晶正极材料产能占比预测

- 中国市场预测:以三元单晶正极材料为主

参考

The mass production of single-crystal cathodes, poised to significantly enhance electric vehicle battery performance, is imminent, heralding an anticipated escalation in competition between Chinese and Korean companies.

In commercial electric vehicle batteries, the cathode materials currently employed consist of polycrystalline structures comprising multiple metal compound crystals. However, cracks often develop between these particles during the rolling process to achieve uniform thickness, as well as during charging and discharging. With repeated cycles, these cracks expand, resulting in material deterioration, increased gas generation within the battery, and a decline in charging/discharging cycles, ultimately diminishing battery longevity.

Single crystals, unlike their polycrystalline counterparts, are immune to this issue as their particles remain intact. Moreover, as nickel content rises to boost capacity, structural stability decreases, heightening the risk of fire. Hence, the development of single crystal cathodes emerges as a solution to this challenge.

Single crystal cathodes offer cost savings and enhanced yields by eliminating residual materials, thereby lowering defect probability and obviating the need for a washing process. This step, crucial in cathode manufacturing for impurity removal, becomes unnecessary with single crystal technology.

The commercialization of single-crystal cathodes is poised to broaden the utilization of high-nickel cathodes. With reduced gas generation, battery lifespan extends while accommodating more active material, boosting energy density. Implementing this in electric vehicle battery packs could enable over 500 km of driving range on a single charge with fewer cells, facilitating longer-range vehicle models. This potential game-changer promises both cost reduction and performance enhancement simultaneously.

Yet, single crystal cathodes also pose drawbacks. Unlike polycrystalline counterparts, large single crystal materials exhibit high initial resistance, challenging the application of desired voltage. Consequently, output remains low, impeding battery performance enhancement.

However, single crystal cathodes entail extra processing steps and operate at higher voltages, potentially raising battery temperatures. Moreover, single crystal particles are susceptible to damage during the calendering process, a crucial part of electrode manufacturing.

Consequently, in the initial stages of mass production, single crystals are likely to be blended with polycrystals rather than being produced in their pure form.

Chinese companies are already producing single crystal cathodes for NCM523 and 622, and domestic companies such as LG Chem, Ecopro BEM, L&F, and POSCO FutureM have also completed development and are conducting quality tests with clients. The targets are single crystal NCA and NCM, and it can be seen that they are ready for mass production.

Industry experts anticipate that the performance and quality of single crystal cathodes will hinge on coating technology to ensure durability and the manufacturing process of single crystals. Essentially, the focus lies in effectively conducting surface treatment while simultaneously augmenting particle size.

Currently, the market for mass-produced single crystal cathodes is dominated by the top 5 Chinese companies, which account for about 75% of the total market.

According to announcements by Korean cathode material companies, SNE Research predicts that they will start supplying samples this year (2023) and produce more than 120,000 tons in 2025. Currently, in the case of Chinese ternary single crystal cathodes, the proportion of 5 series single crystals, such as NCM 523, is the highest at 60% to 70%. The proportion of 6 series single crystals, such as NCM622, is 18 to 25%. In the case of 8 series with a Ni content of 80% or higher, the production ratio has increased since 2021 and currently accounts for about 15%. This proportion is expected to continue to increase.

According to SNE Research, it is difficult to predict the market for Korea at this time because there is no data on production volume by Ni content. However, in the case of China, Hi-Ni is expected to be about $4.2 billion and Mid-Ni is expected to be $9.2 billion in 2025. In 2030, Hi-Ni is expected to be about $24 billion and Mid-Ni is expected to be $23.8 billion, so the market for Hi-Ni is expected to be larger.

Strong Points of this report:

- 1. Cover fundamental and advances in the development of single-crystal Ni-rich cathode materials

- 2. Include a very detailed study of research trends and future prospects for single-crystal Ni-rich cathode materials.

- 3. Include content on research regarding the capacity degradation mechanism of single-crystal Ni-rich cathodes.

- 4. Compare major synthesis methods for single-crystal NCM cathode materials

- 5. Detailed recent developments and patent analysis of single-crystal cathode material manufacturers

- 6. Market outlook for single-crystal cathode materials

[Schematic diagram of general single-crystal Ni-rich layered cathode material synthesis and additional modification process]

Table of Contents

1. Overview of Cathode Materials

- 1.1. History of Cathode Material Development

- 1.2. Recent Trends in Cathode Materials

- 1.2.1. Layered Oxide Cathode Materials

- 1.2.2. Spinel Oxide Cathode Material

- 1.2.3. Polyanionic Oxide (PAO) Cathode Materials

- 1.3. Development Status of Cathode Materials by Type

- 1.3.1. Microstructure Modification

- 1.3.2. Removal of Cathode Cracks

- 1.3.3. Application of the One-Pot process

- 1.3.4. Microwave Processing

2. Research Trends and Future Prospects of Single Crystal Ni-rich Layered Cathodes

- 2.1. Need for Research on Single Crystal Ni-rich Layered Materials

- 2.1.1. The Need for Ni-rich Layered Materials (Advantages)

- 2.1.2. Degradation Mechanisms of Ni-rich Layered Cathode Materials

- 2.1.3. Need for Single Crystallization (Monoparticulation) of Ni-rich Layered Cathode Materials

- 2.2. Definition of Single-crystal Cathode Material

- 2.3. Development Status of Single-crystal Cathode Material Technology

- 2.3.1. Single-particle Ni-rich Layered Material Synthesis Research

- 2.3.2. Research on Sintering Methods for Synthesis of Single-particle Ni-rich Layered Materials

- 2.3.3. Study on Modifying Materials to Enhance Performance of Single-particle Ni-rich Layered Materials

- 2.3.3.1. Surface Coating Research

- 2.3.3.2. Elemental Substitution Study (Doping)

- 2.3.3.2.1. Single Doping

- 2.3.3.2.2. Dual Doping

- 2.3.3.3. Electrolyte Optimization

- 2.3.4. Utilization Strategies for Single-Crystal Ni-Based Layered Materials

- 2.3.4.1. Advantages of Single-Crystallization in Ni-Based Layered Cathodes for Electrode Design

- 2.3.4.2. Disadvantages of Single-Crystallization in Ni-Based Layered Cathodes for Electrode Design

- 2.3.4.3. Research on Addressing Challenges in Single-Crystallization of Ni-Based Layered Materials

- 2.4. Improvement Through Material Single-Particle Formation

- 2.4.1. Mitigation of Particle Breakage Characteristics

- 2.4.4.1. Pressing Stage in Electrode Manufacturing

- 2.4.2. Particle Breakage During Charge-Discharge Processes

- 2.4.3. Quantitative Reduction of Surface Degradation through Reduced Specific Surface Area

- 2.4.4. Energy Density Increase

- 2.4.5. Washing Process Omission

- 2.4.1. Mitigation of Particle Breakage Characteristics

- 2.5. Limitations of Current SC Cathode Material Technology Development and Research for Overcoming Them

- 2.5.1. Degradation of Material Crystal Structure Due to Difficulties in Optimizing Synthesis Conditions

- 2.5.2. Particle Size Limit

3. Single-Crystal Ni-Based Cathode Materials: Fundamentals and Advances

- 3.1. Overview

- 3.2. Ni-based Cathode Materials

- 3.2.1. Chemical Structure

- 3.2.2. Electronic Structure

- 3.3. Challenges of Ni-based Layered Oxides

- 3.3.1. Synthesis Difficulties

- 3.3.2. Structural Instability

- 3.3.3. Chemical Instability

- 3.3.4. Mechanical Performance Degradation

- 3.3.5. Safety Issues

- 3.4. Origin of Single-Crystal Ni-Based Layered Oxides

- 3.5. Synthesis of Single-Crystal Ni-based Layered Oxides

- 3.5.1. Synthesis Methods

- 3.6. Comparative Study of Single-Crystal and Polycrystalline Materials

- 3.7. Recent Advances in Single-Crystal Ni-Based Cathode Materials

- 3.7.1. Doping and Surface Coating

- 3.7.2. Mechanical Research

- 3.8. Results and Conclusion

4. Study of Capacity Fading Mechanism of Single-crystal Ni-rich NCM Cathode

- 4.1. Overview

- 4.2. Assessment of Fundamental Properties in Ni-rich Single-crystal and Polycrystalline Cathodes

- 4.2.1. Single-crystal and Polycrystalline Cathode Synthesis

- 4.2.2. Composition and Analysis of Single-crystal and Polycrystalline Cathodes

- 4.2.3. Electrochemical Properties of Single-crystal and Polycrystalline Cathodes

- 4.2.4. Structural Stress Analysis of Single-crystal and Polycrystalline Cathode Materials

- 4.2.5. In-situ XRD Analysis of Single-crystal and Polycrystalline Cathodes

- 4.2.6. TEM Analysis of Single-crystal and Polycrystalline Cathode Materials

- 4.2.7. Results and Conclusions

5. Particle Control of Ni-rich Monocrystalline Cathode Materials (Application of Sintering Process)

- 5.1. Overview

- 5.2. Experiment Description

- 5.3. Experimental Results

- 5.3.1. Optimization of Sintering Additives for Promoting Crystal Growth

- 5.3.2. Crystal Growth Mechanism

- 5.3.3. Ni-rich Structure of a Single Crystal Cathode

- 5.3.4. Performance of Ni-rich Single Crystal Cathodes

- 5.4. Application Results of Sintering Treatment

6. All-Dry Synthesis of Single-Crystal NMC Cathode Materials

- 6.1. Overview

- 6.2. Dry Synthesis

- 6.3. Dry Synthesis Results and Discussion

- 6.3.1. Precursor Structure and Morphology

- 6.3.2. Effect of Sintering Conditions on NMC Formation

- 6.3.3. Single-crystal NCM from Ball-milled Precursors

- 6.3.4. Conclusion

7. One-Spot Synthesis of Single Crystal NCM523 Cathode Material

- 7.1. Overview

- 7.2. Synthesis of NCM523

- 7.3. Characterization of Materials

- 7.4. Electrochemical Properties

- 7.5. Experiment Results and Discussion

- 7.5.1. Cathode Material Synthesis Product Analysis

- 7.5.2. Electrochemical Properties of Cathode Materials

- 7.5.3. Conclusion

8. Synthesis and Modification of Single-Crystal NCM Cathode Materials:Growth Mechanism

- 8.1. Overview

- 8.2. Growth Mechanism for NCM Cathodes

- 8.3. Solid State Reaction

- 8.4. Solid-Liquid Rheological Reaction

- 8.5. Crystal Growth in Molten Salt Flux

- 8.6. Modification of morphology

- 8.6.1. Control of Shape

- 8.6.2. Facet Control

- 8.6.3. Conclusion

9. Development of Single-Crystal Cathodes: DOE Program

- 9.1. Ultrafast Hydrothermal Synthesis of Ni-rich Single-Crystal Cathodes

- 9.2. Scaling up of High Performance Single Crystalline Ni-rich Cathode Materials with Advanced Lithium

- 9.3. Single-Crystal Cathodes for High-Performance All-Solid-State LIBs

10. Patent Analysis of Single Crystal Cathode Material Companies

- 10.1. Tesla

- 10.2. LG Chem

- 10.3. SM Lab

- 10.4. Nano One Materials

- 10.5. POSCO Future M

- 10.6. COSMO Advanced Materials & Technology

- 10.7. L&F

- 10.8. Easpring

- 10.9. BASF Shan Shan

- 10.10. GEM

- 10.11. XTC (Xiamen Tungsten)

- 10.12. Henan Kelong

- 10.13. Hyundai Motor Company / Kia Corporation

- 10.14. 6K Inc.

- 10.15. Dynanonic

- 10.16. Suzhou Long Power

- 10.17. Fengchao Energy

- 10.18. Ecopro BM

- 10.19. Umicore

11. Single-Crystal Cathode Material Industry Trends

- 11.1. LG Chem

- 11.2. POSCO FutureM

- 11.3. EcoPro BM

- 11.4. Zhenhua E-Chem(ZEC)

- 11.5. Chanyuan Lico

- 11.6. Ronbay

- 11.7. XTC (Xiamen Tungsten)

- 11.8. Tianjin B&M

- 11.9. Easpring

- 11.10. Reshane

- 11.11. Yibin Libode

- 11.12. Wanxing 123

- 11.13. GEM

12. Single Crystal Cathode Market Outlook

- 12-1. 2017~2022H1 China Single Crystal Production Volume

- 12-2. 2019~2022.04 Production Volume and Share of Single Crystal Cathode Materials in China

- 12-3. 2019~2022Q1 Distribution of production volume by SC ternary cathode materials in China

- 12-4. 2019~2022Q1 Share of production by ternary SC cathode material in China

- 12-5. 2019~2022Q1 Market Penetration by Ternary SC Cathode Materials in China

- 12-6. Market Share of Ternary SC Cathode Materials by Chinese Companies in 2021

- 12-7. Production Volume and Market Share of Ternary SC cathode Material Companies in China in 2021

- 12-8. Korea-China Ternary Single Crystal Production Forecast

- 12-9. Korean Ternary SC Cathode Material Mroduction Volume and Market Outlook

- 12-10. Percentage of Single-crystal Cathodes among Ternary Cathode Materials in China

- 12-11. Forecast of Production Volume Ratio by Chinese Ternary Single Crystal Cathode Material

- 12-12. China Market Forecast by Ternary Single Crystal Cathode Material