|

市场调查报告书

商品编码

1581323

LIB温度控管/热逸散防止模组包装的技术开发与市场预测(~2035年)<2024> LIB Thermal Management /Thermal Runaway Prevention Module Pack Technology Development and Market Outlook (~2035) |

||||||

儘管近期电动车销售下滑导致市场成长放缓,但电动车产业的乐观前景依然没有改变。

随着各国加强二氧化碳排放法规,汽车製造商必须销售电动车才能避免法规带来的处罚。因此,向电动车的转型势必会取得进展。然而,由于消费者无法轻易忽视买家对电动车的各种负面评价,电动车製造商面临许多课题,例如充电便利性、续航里程以及电池起火安全性。尤其值得一提的是,电动车的电池起火问题不仅仅是一个技术问题,而是一个直接关係到社会安全的关键问题,因此彻底的验证必不可少。

欧盟执委会计画于2026年实施新的电池法规,而电池护照正是其中的核心。

本报告对二次电池产业进行了调查和分析,并探讨了电动车电池模组组的最新技术趋势,特别是製造商应对热失控的对策和技术。

影像

目录

第1章 电池组的概念和定义

- 电池组的基本概念

- 电动车中电池组的意义

- 电池单元、电池模组、电池组的意义

- 电动车平台、电池组、模组

- 电动车平台中电池组的基本配置

- 如何连接电芯和模组(串联/并联)

- 电池容量/电池可用能量

- 电池SOC、SOH、DOD的意义

- 电池充放电(C速率)

- 电池组的规格

- 电池组的热管理

- 如何管理电池组的热管理

- 最佳电池组热管理(设计係数)

- 如何冷却/加热电池组

第2章 电池组结构与开发趋势

- 电池组结构

- 电池组结构(分解图)

- 电池组组件

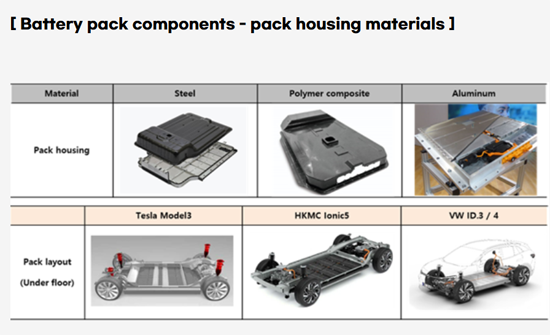

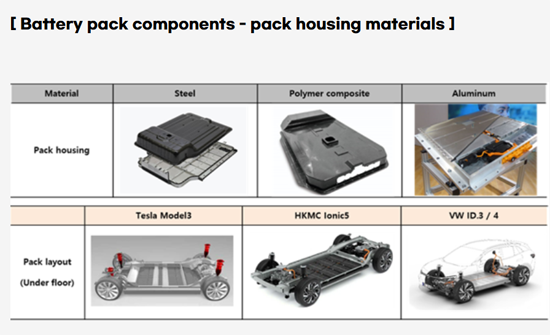

- 电池组外壳材料

- 不同 xEV 车型的电池外壳使用情况(盖板、托盘)

- 电池组密封垫

- 电池组完整性与验证(CAE、IP 测试)

- CMA(电芯模组组装)结构(方形、软包、圆柱形)

- CMA 盖板

- 压缩垫

- 冷却系统类型1

- 冷却系统类型2

- 冷却系统类型3

- 冷却系统类型4

- TIM(热感介面材料)的结构和特性:各材料

- 模组用TIM(热感介面材料)

- BMS(电池管理系统)结构与特征

- PRA(电力继电器集合)

- MSD(手动服务隔离开关)

- HVIL连接器(高压连锁连接器)

- 感测器(温度感测器,电流感测器)

- 电池组开发情形:各OEM平台

- 电池组概念变更:按电动车平台

- 电池组特性:依电动车平台

- 大众汽车的MEB平台

- 现代汽车的E-GMP平台

- 通用汽车的Ultium平台

- 无模组电池组的技术趋势

- 宁德时代、比亚迪的CTP技术

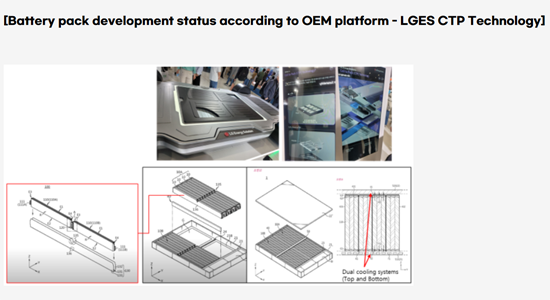

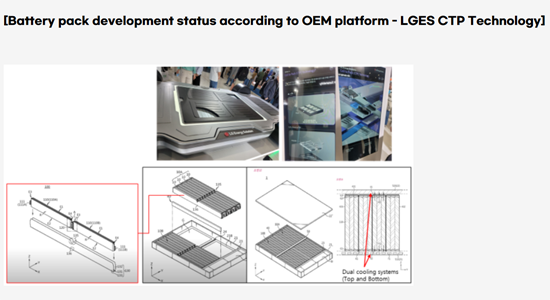

- LGES的CTP技术

- SK on的CTP技术

- 特斯拉的新型电池组结构(Cell to Vehicle)

- 混合动力电池组的使用(蔚来NCM-LFP电池单元CTP)

- 混合动力电池组的使用(宁德时代AB电池组)

第3章 电动车用电池组的规格分析与摘要

- 电动车用电池组的规格分析

- EV电池电池单元·包装的销售价格的预测

- 小客车电动车用电池组的平均容量(kWh)

- 电动车用电池组的能量密度的分析(kWh/kg)

- 电动车用电池组的使用可能的能源的分析

- 电池组的主要零组件的重量比

- 电池组的主要零组件的成本结构

- EV用电池组的主要的规格的摘要1

- EV用电池组的主要的规格的摘要2

- EV用电池组的主要的规格的摘要3(使用可能的电池组容量)

第4章 电动车电池组趋势电池热失控预防技术

- 热失控现象及其成因

- 电池组的阻燃需求

- 热失控预防解决方案(热失控屏障)

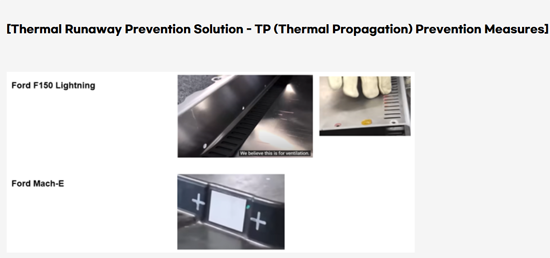

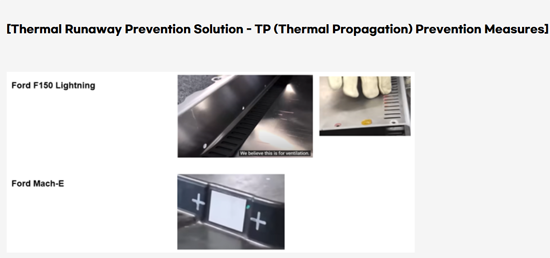

- 防止热扩散(TP)的措施

- 模组内部TBA(热障组件)的应用

- 模组外部TBA(热障组件)的应用

- 特性:依TP材料分类

- 模组/电池组级TP解决方案:透气技术

- 两种电池组透气解决方案(1级、2级)

- 电池组透气的典型设计(1级、2级)

- 电芯/模组/电池组级气体透气孔的应用

- 关键设计与效能考量

- 产品需求:1级、2级透气

- 测试要求

- 基准案例分析

- 云母绝缘替代品

- 云母材料特性

- TRP 纸产品特性

- 其他替代材料

第5章 电池组的主要元件供应商

- 电池组零组件厂商(世界/国内)

- KET

- Younghwa Tech

- LS EV Korea

- WOORY INDUSTRIAL

- Hyunwoo Industrial

- YURA CORPORATION

- Kyungshin

- Mobase Electronics (Seoyeon Electronics)

- Aluco

- Hanon Systems

- Saint-Gobain PPL

- INZI CONTROLS

- SEBANG GLOBAL BATTERY

- 温度控管材料厂商

- Alkegen

- Morgan

- Rogers

- Laird

- ASPEN

- Pamica

- Glory

第6章 EV·包装市场预测

- EV市场预测

- 全球搭乘用EV市场预测:BEV/PHEV

- 全球xEV电池的需求与预测

- 全球EV电池电池单元·包装的市场规模

- 全球主要EV製造商预测

- 包装市场预测

- 电动车的包装的市场规模及预测

- 包装零组件市场预测

- 电动车的包装零组件的市场规模预测

- 包装材料市场预测

- 电池组外壳材料市场规模展望

- 电池组热管理材料市场规模展望

- 热管理解决方案材料市场规模展望

- 电芯间结构材料市场规模展望

- 温度控管材料的市场规模预测

第7章 包装的专利趋势

- 国内电池企业的专利申请情形

- 国内电池企业的专利案例

- 电池组结构安全领域专利案例

- 电池组热失控领域专利案例

- 电池组热失控领域专利案例

Although the recent slump in electric vehicle sales has slowed things down a bit, the optimistic outlook for the electric vehicle industry remains.

As each country strengthens its carbon emissions, automakers will not be able to afford the penalties imposed by the regulations unless they sell electric vehicles. Therefore, it is clear that the transition to electric vehicles will continue. However, since consumers cannot lightly overlook the various negative views of buyers regarding electric vehicles, electric vehicle manufacturers have issues to solve, such as easy charging, long driving range, and safety from battery fires. In particular, the issue of electric vehicle battery fires is not a simple technical issue, but rather an important issue directly related to social safety, so it cannot help but be thoroughly verified.

The EU executive is planning to implement a new battery regulation in 2026, and the core of this is the Battery Passport. Therefore, battery manufacturers also need to strengthen battery safety and transparency to respond to international regulations. Accordingly, this report will examine recent technology trends in battery modules and packs for electric vehicles, and in particular, examine the response measures and technologies of each manufacturer related to thermal runaway.

This report not only explains the basic concepts of secondary battery packs and the basic concepts of thermal management, but also describes the battery pack structure, development trends, and battery pack components, and also analyzes and summarizes the development status of battery packs according to the major OEM platforms, major EV electric vehicle battery pack specifications, trends in battery thermal runaway response technologies, and a detailed description of the thermal runaway prevention solution (Thermal Runaway Barrier), introduces major battery pack component companies and thermal management, thermal runaway companies, and provides an outlook on the EV market, pack market, and thermal management material market. The last chapter covers the current status and cases of related battery pack patent trends.

Strong Points of This Report:

- 1. Easy to understand explanation of basic concepts of battery packs and battery pack thermal management

- 2. Easy to understand pack technology trends of major OEMs such as VW, Hyundai, GM, CATL, BYD, LGES, Skon, Tesla, and NiO

- 3. Summary of major EV battery pack specifications (usable battery pack capacity) and detailed analysis of sales price and energy density

- 4. Detailed analysis of battery thermal runaway response technology trends and prevention solutions that have recently emerged as issues

- 5. Detailed information on development trends of domestic and foreign battery pack component manufacturers and thermal runaway companies

- 6. EV market outlook, pack market outlook, and pack thermal management material market outlook

- 7. Understanding pack patent trends through patent cases in pack structural safety, thermal runaway, and CTP fields

VISUALS

Table of Contents

1. Battery pack concept and definition

- 1.1. Basic concept of battery pack

- Meaning of battery pack in electric vehicles

- Meaning of battery cell, battery module, and battery pack

- Electric vehicle platform and pack, module

- Basic configuration of pack in electric vehicle platform

- Cell and module connection method (Serial / Parallel)

- Battery capacity / Usable energy in battery

- Meaning of battery SOC, SOH, DOD

- Battery charge/discharge (C-rate)

- Battery pack specification

- 1.2. Thermal management of battery pack

- Pack thermal management method

- Optimal pack thermal management (design factor)

- Cooling and heating method of pack

2. Battery pack structure and development trends

- 2.1. Battery pack structure

- Pack structure (Exploded view)

- 2.2. Battery pack components

- Pack housing material

- Battery housing application status by xEV vehicle type (Cover, Tray)

- Pack Sealing Gasket

- Pack Integrity and Validation (CAE, IP test)

- CMA (Cell Module Assembly) structure (prismatic, pouch, cylindrical type)

- CMA Cover

- Compression pad

- Cooling system Type 1

- Cooling system Type 2

- Cooling system Type 3

- Cooling system Type 4

- TIM(Thermal Interface Material) configuration and characteristics by material

- TIM(Thermal Interface Material) for module

- BMS(Battery Management System) structure and characteristics

- PRA (Power Relay Assembly)

- MSD (Manual Service Disconnector)

- HVIL connector (High Voltage Interlock connector)

- Sensors (Temperature and current sensors)

- 2.3. Battery pack development status by OEM platform

- Concept change of pack by EV platform

- Pack features by EV platform

- VW's MEB platform

- Hyundai Motor's E-GMP platform

- GM's Ultium platform

- Technology trends of module-free battery packs

- CATL, BYD's CTP Technology

- LGES's CTP Technology

- SK on's CTP Technology

- Tesla's New structural battery pack (Cell to Vehicle)

- Application of Hybrid Battery Pack (NIO NCM-LFP battery cell CTP)

- Application of Hybrid Battery Pack (CATL AB battery Pack)

3. Electric vehicle battery pack specification analysis and summary

- 3.1. Electric vehicle battery pack specification analysis

- 3.2. EV battery cell and pack sales price forecast

- 3.3. Passenger car electric vehicle battery pack average capacity (kWh)

- 3.4. Electric vehicle battery pack energy density analysis (kWh/kg)

- 3.5. Electric vehicle battery pack usable energy analysis

- 3.6. Weight ratio of major battery pack components

- 3.7. Cost composition of major battery pack components

- 3.8. Summary of major EV battery pack specifications 1

- 3.9. Summary of major EV battery pack specifications 2

- 3.10. Summary of major EV battery pack specifications 3 (Usable battery pack capacity)

4. Battery thermal runaway response technology trends

- 4.1. Thermal runaway phenomenon and causes

- 4.2. The need for battery pack flame retardancy

- 4.3. Thermal runaway prevention solutions (Thermal Runaway Barrier)

- TP (Thermal Propagation) prevention measures

- TBA (Thermal Barrier Assembly) applied inside the module

- TBA (Thermal Barrier Assembly) applied outside the module

- Characteristics by TP material

- TP solutions at module and pack levels: Venting technology

- Two types of battery pack venting solutions (Level 1, Level 2)

- General design of battery pack venting (Level 1, Level 2)

- Vent application for De-gas at cell, module and pack level

- Key design and performance considerations

- Product requirements: Level 1, Level 2 venting

- Test requirements

- Benchmark case analysis

- Insulating materials for Thermal Barriers that can replace Mica

- Mica material properties

- TRP Paper product properties

- Other alternative materials

5. Battery Pack Major Component Suppliers

- 5.1. Battery Pack Component Manufacturers (Global / Domestic)

- KET

- Younghwa Tech

- LS EV Korea

- WOORY INDUSTRIAL

- Hyunwoo Industrial

- YURA CORPORATION

- Kyungshin

- Mobase Electronics (Seoyeon Electronics)

- Aluco

- Hanon Systems

- Saint-Gobain PPL

- INZI CONTROLS

- SEBANG GLOBAL BATTERY

- 5.2. Thermal management material manufacturers

- Alkegen

- Morgan

- Rogers

- Laird

- ASPEN

- Pamica

- Glory

6. EV & Pack Market Outlook

- 6.1. EV market outlook

- Global passenger EV market outlook by BEV/PHEV

- Global xEV battery demand and outlook

- Global EV battery cell and pack market size

- Outlook by global EV major maker

- 6.2. Pack market outlook

- Pack market size and outlook for electric vehicles

- 6.3. Pack component market outlook

- Market size outlook for electric vehicle pack components

- 6.4. Pack material market outlook

- Market size outlook for pack housing materials

- Market size outlook for pack thermal management materials

- Market size outlook for TP solution materials

- Market size outlook for cell-to-cell structure materials

- 6.5. Market size outlook for thermal management materials

7. Pack Patent Trends

- 7.1. Status of domestic battery company patent applications

- 7.2. Domestic battery company patent cases

- Patent cases in the field of pack structural safety

- Patent cases in the field of pack thermal runaway

- Patent cases in the field of pack CTP