|

市场调查报告书

商品编码

1684613

製药机械市场机会、成长动力、产业趋势分析与 2025 - 2034 年预测Pharmaceuticals Machinery Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

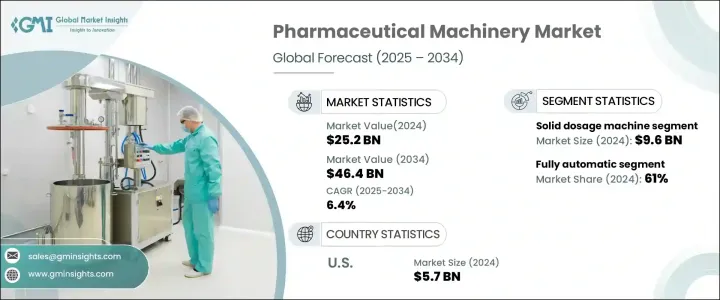

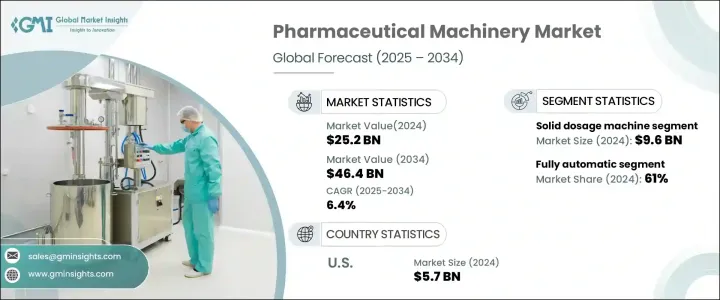

2024 年全球製药机械市场价值为 252 亿美元,并有望大幅成长,预计 2025 年至 2034 年期间的复合年增长率为 6.4%。这一强劲的成长轨迹受到全球对医药产品需求不断增长的推动,人口老化、慢性病发病率不断上升以及个人化医疗的日益普及推动。製造技术的进步,加上仿製药和疫苗生产的加速,进一步扩大了市场的潜力。不断发展的生物製药产业专注于生物製剂、生物相似药和创新疗法,也需要最先进的机器,为製造商创造有利可图的机会。严格的监管要求必然需要先进的设备来确保精准度和合规性,而对製药合约製造组织(CMO)的日益依赖是加速市场扩张的重要因素。

目前,药品生产很大程度上依赖为满足特定需求而量身订製的尖端机械。生物製剂、疫苗和生物相似药的生产需要专门的设备,例如高精度填充系统和无菌加工机械,以维持最高的品质和安全标准。 CMO 和合约开发和製造组织 (CDMO) 正在投资先进技术,确保它们能够满足多家製药公司的大规模生产需求。此次合作进一步增强了产业能力,提高了生产效率和灵活性。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 252亿美元 |

| 预测值 | 464亿美元 |

| 复合年增长率 | 6.4% |

2024 年,固体剂量机领域将成为市场领导者,创收 96 亿美元。预计 2025 年至 2034 年期间的复合年增长率为 6.8%。固体剂型,包括片剂、胶囊和粉末,是製药业使用最广泛的剂型,需要高效率、自动化和高速的机械。製造商越来越重视客製化和法规遵循性,以满足特定的生产要求。此外,生物製剂和生物相似药产量的不断增长,也增加了对发酵槽、搅拌器和干燥器等专用设备的需求,这些设备对于将活性药物成分 (API) 转化为成品至关重要。

全自动操作模式在 2024 年占据了 61% 的市场份额,预计到 2034 年的复合年增长率为 6.6%。全自动机器简化了药品(包括药片、胶囊和注射)的高速生产流程,管理了填充、封盖、贴标和包装等关键功能。这些机器满足了生产对精度和效率日益增长的需求,确保了一致的品质并降低了错误率。半自动机器将自动化与人工监督相结合,为追求灵活性和效率的製造商提供了替代方案。

美国製药机械市场规模在 2024 年达到 57 亿美元,预计到 2034 年将以 6.5% 的复合年增长率成长。该地区的成长得益于对创新药物的需求不断增加、疫苗製造的进步以及对小批量和个人化药物生产的关注。人口老化和慢性病发病率上升导致的医疗保健需求不断增长,进一步凸显了市场的不断扩大。

目录

第 1 章:方法论与范围

- 市场范围和定义

- 基础估算与计算

- 预测计算。

- 资料来源

- 基本的

- 次要

- 付费来源

- 公共资源

第 2 章:执行摘要

第 3 章:产业洞察

- 产业生态系统分析

- 影响价值链的因素。

- 利润率分析。

- 中断

- 未来展望

- 製造商

- 经销商

- 供应商概况

- 利润率分析。

- 重要新闻及倡议

- 监管格局

- 衝击力

- 成长动力

- 药品需求不断成长

- 不断成长的生物製药产业

- 产业陷阱与挑战

- 初始成本高且营运复杂

- 供应链中断

- 成长动力

- 技术概览

- 成长潜力分析

- 波特的分析

- PESTEL 分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 竞争定位矩阵

- 战略展望矩阵

第 5 章:市场估计与预测:按机器类型,2021 年至 2034 年

- 主要趋势

- 固体剂量机

- 压片机

- 压片机

- 片剂除尘器

- 其他(药片检查等)

- 胶囊填充机

- 胶囊抛光机

- 胶囊分离器

- 其他(胶囊检查等)

- 其他(软胶囊封装等)

- 压片机

- 加工机

- 混合

- V 型搅拌机

- 锥形混合机

- 其他(IBC搅拌机等)

- 造粒

- 高剪切製粒机

- 振盪造粒机

- 其他(comill等)

- 流体化床干燥机

- 实验室流体化床干燥机

- 其他(生产流体化床干燥机等)

- 薄膜包衣

- 实验室薄膜涂层

- 其他(生产薄膜包衣等)

- 混合

- 分析仪器

- 药物片剂测试

- 锭剂硬度计

- 药片易碎性测定仪

- 溶离度测试仪

- 其他(崩解试验仪等)

- 明胶测定仪

- 明胶强度测定仪

- 明胶霜强度

- 其他(明胶透明度测试仪等)

- 药物片剂测试

- 包装机

- 泡罩包装机

- 封盖机

- 装盒机

- 感应封口机

- 管道填充物

- 其他(柜檯等)

- 印刷机

- 其他(物料搬运等)

第六章:市场估计与预测:依营运模式,2021-2034 年

- 主要趋势

- 手动的

- 半自动

- 全自动

第 7 章:市场估计与预测:按应用,2021 年至 2034 年

- 主要趋势

- 配方

- 灌装和包装

- 消毒

- 品质管制

- 其他(仓储等)

第 8 章:市场估计与预测:按配销通路,2021-2034 年

- 主要趋势

- 直接销售

- 间接销售

第 9 章:市场估计与预测:按地区,2021 年至 2034 年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- 中东及非洲

- 阿联酋

- 沙乌地阿拉伯

- 南非

第十章:公司简介

- ACG

- Bausch+Strobel

- CECLE Machine

- Fette Compacting

- GEA

- Glatt

- IMA

- Korsch

- Paul Mueller

- RIVA

- Romaco

- SaintyCo

- Sartorius

- SED Pharma

- Syntegon Technology

The Global Pharmaceuticals Machinery Market was valued at USD 25.2 billion in 2024 and is poised for substantial growth, projected to expand at a CAGR of 6.4% between 2025 and 2034. This robust growth trajectory is fueled by the rising global demand for pharmaceutical products, driven by an aging population, the increasing prevalence of chronic diseases, and the growing adoption of personalized medicine. Advancements in manufacturing technologies, coupled with the accelerated production of generic drugs and vaccines, further amplify the market's potential. The evolving biopharmaceutical sector, with its focus on biologics, biosimilars, and innovative therapeutics, also demands state-of-the-art machinery, creating lucrative opportunities for manufacturers. Stringent regulatory requirements necessitate advanced equipment for precision and compliance, and the increasing reliance on pharmaceutical contract manufacturing organizations (CMOs) is an essential factor in accelerating market expansion.

Pharmaceutical production now relies heavily on cutting-edge machinery tailored to meet specific needs. The manufacturing of biologics, vaccines, and biosimilars requires specialized equipment, such as high-precision fill-finish systems and sterile processing machinery, to maintain the highest quality and safety standards. CMOs and contract development and manufacturing organizations (CDMOs) are investing in advanced technologies, ensuring they can meet large-scale production demands for multiple pharmaceutical companies. This collaboration further enhances the industry's capabilities, allowing for greater efficiency and flexibility in production.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $25.2 Billion |

| Forecast Value | $46.4 Billion |

| CAGR | 6.4% |

In 2024, the solid dosage machine segment emerged as the market leader, generating USD 9.6 billion. It is anticipated to grow at a CAGR of 6.8% between 2025 and 2034. Solid dosage forms, including tablets, capsules, and powders, are the most widely used in the pharmaceutical industry, necessitating highly efficient, automated, and high-speed machinery. Manufacturers increasingly prioritize customization and regulatory compliance to meet specific production requirements. Additionally, the growing production of biologics and biosimilars has increased the need for specialized equipment such as fermentation tanks, mixers, and dryers, critical in converting active pharmaceutical ingredients (APIs) into finished products.

The fully automatic operational mode accounted for 61% of the market share in 2024, with growth projected at a CAGR of 6.6% through 2034. Fully automatic machines streamline high-speed production processes for pharmaceuticals, including tablets, capsules, and injectables, managing critical functions such as filling, capping, labeling, and packaging. These machines address the rising demand for precision and efficiency in production, ensuring consistent quality and reduced error rates. Semi-automatic machines, blending automation with manual oversight, offer an alternative for manufacturers seeking flexibility and efficiency.

The US pharmaceuticals machinery market reached USD 5.7 billion in 2024 and is forecasted to grow at a CAGR of 6.5% through 2034. Growth in this region is driven by increasing demand for innovative drugs, advancements in vaccine manufacturing, and a focus on small-batch and personalized medicine production. Rising healthcare needs, fueled by an aging population and a higher prevalence of chronic conditions, further underscore the expanding market.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definitions

- 1.2 Base estimates & calculations

- 1.3 Forecast calculations.

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021-2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factor affecting the value chain.

- 3.1.2 Profit margin analysis.

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufacturers

- 3.1.6 Distributors

- 3.2 Supplier landscape

- 3.3 Profit margin analysis.

- 3.4 Key news & initiatives

- 3.5 Regulatory landscape

- 3.6 Impact forces

- 3.6.1 Growth drivers

- 3.6.1.1 Rising pharmaceutical demand

- 3.6.1.2 Growing biopharmaceutical sector

- 3.6.2 Industry pitfalls & challenges

- 3.6.2.1 High initial costs and operational complexities

- 3.6.2.2 Disruptions in supply chains

- 3.6.1 Growth drivers

- 3.7 Technological overview

- 3.8 Growth potential analysis

- 3.9 Porter's analysis

- 3.10 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Machine Type, 2021-2034 (USD Billion) (Thousand Units)

- 5.1 Key trends

- 5.2 Solid dosage machine

- 5.2.1 Tablet press machine

- 5.2.1.1 Tablet press

- 5.2.1.2 Tablet dedusters

- 5.2.1.3 Others (tablet inspection etc.)

- 5.2.2 Capsule filling machine

- 5.2.2.1 Capsule polishers

- 5.2.2.2 Capsule separator

- 5.2.2.3 Others (capsule inspection etc.)

- 5.2.3 Others (softgel encapsulation etc.)

- 5.2.1 Tablet press machine

- 5.3 Processing machine

- 5.3.1 Mixing

- 5.3.1.1 V blender

- 5.3.1.2 Cone blender

- 5.3.1.3 Others (IBC blender etc.)

- 5.3.2 Granulation

- 5.3.2.1 High shear granulator

- 5.3.2.2 Oscillating granulator

- 5.3.2.3 Others (comill etc.)

- 5.3.3 Fluid bed dryers

- 5.3.3.1 Lab fluid bed dryer

- 5.3.3.2 Others (production fluid bed dryer etc.)

- 5.3.4 Film coating

- 5.3.4.1 Lab film coating

- 5.3.4.2 Others (production film coating etc.)

- 5.3.1 Mixing

- 5.4 Analytical instruments

- 5.4.1 Pharmaceutical tablet testing

- 5.4.1.1 Tablet hardness tester

- 5.4.1.2 Tablet friability tester

- 5.4.1.3 Dissolution tester

- 5.4.1.4 Others (disintegration tester etc.)

- 5.4.2 Gelatin tester

- 5.4.2.1 Gelatin strength tester

- 5.4.2.2 Gelatin bloom strength

- 5.4.2.3 Others (gelatin transparency tester etc.)

- 5.4.1 Pharmaceutical tablet testing

- 5.5 Packaging machine

- 5.5.1 Blister packers

- 5.5.2 Cappers

- 5.5.3 Cartoners

- 5.5.4 Induction sealers

- 5.5.5 Tube fillers

- 5.5.6 Others (counters etc.)

- 5.6 Printing machine

- 5.7 Others (material handling etc.)

Chapter 6 Market Estimates & Forecast, By Mode of Operation, 2021-2034 (USD Billion) (Thousand Units)

- 6.1 Key trends

- 6.2 Manual

- 6.3 Semi-automatic

- 6.4 Fully automatic

Chapter 7 Market Estimates & Forecast, By Application, 2021-2034 (USD Billion) (Thousand Units)

- 7.1 Key trends

- 7.2 Formulation

- 7.3 Filling & packaging

- 7.4 Sterilization

- 7.5 Quality control

- 7.6 Others (storage etc.)

Chapter 8 Market Estimates & Forecast, By Distribution Channel, 2021-2034 (USD Billion) (Thousand Units)

- 8.1 Key trends

- 8.2 Direct sales

- 8.3 Indirect sales

Chapter 9 Market Estimates & Forecast, By Region, 2021-2034 (USD Billion) (Thousand Units)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 UK

- 9.3.2 Germany

- 9.3.3 France

- 9.3.4 Italy

- 9.3.5 Spain

- 9.3.6 Russia

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 South Korea

- 9.4.5 Australia

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.6 MEA

- 9.6.1 UAE

- 9.6.2 Saudi Arabia

- 9.6.3 South Africa

Chapter 10 Company Profiles

- 10.1 ACG

- 10.2 Bausch+Strobel

- 10.3 CECLE Machine

- 10.4 Fette Compacting

- 10.5 GEA

- 10.6 Glatt

- 10.7 IMA

- 10.8 Korsch

- 10.9 Paul Mueller

- 10.10 RIVA

- 10.11 Romaco

- 10.12 SaintyCo

- 10.13 Sartorius

- 10.14 SED Pharma

- 10.15 Syntegon Technology