|

市场调查报告书

商品编码

1685209

增黏剂市场机会、成长动力、产业趋势分析及 2025 - 2034 年预测Tackifier Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

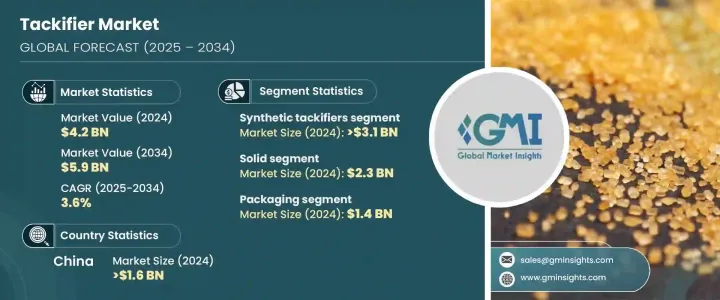

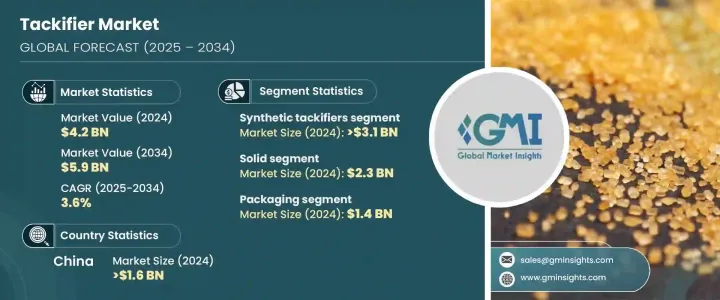

2024 年全球增黏剂市场规模达到 42 亿美元,并有望稳定成长,预计 2025 年至 2034 年期间的复合年增长率为 3.6%。增粘剂在黏合剂配方中起着至关重要的作用,可增强其黏性并提高各行业的附着力。随着对高性能黏合剂的需求不断增长,特别是在包装、汽车、建筑和卫生领域,对先进增粘剂解决方案的需求也在增加。市场对热熔胶 (HMA) 的需求激增,特别是在不织布卫生产品和软包装领域,进一步推动了产业扩张。

市场成长的主要驱动力包括黏合剂技术的不断进步和向环保解决方案的转变。随着产业越来越重视永续性,向生物基增黏剂的转变正在加速。这些来自可再生资源的替代品具有较低的挥发性有机化合物(VOC)排放量,因此成为致力于遵守严格环境法规的公司的首选。此外,电子商务的快速扩张和对高效包装黏合剂的日益增长的需求正在推动全球的需求。在黏合剂性能至关重要的行业中,例如汽车组装和医疗应用,增粘剂提供卓越的黏合能力,增强了其在现代製造业中不可或缺的作用。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 42亿美元 |

| 预测值 | 59亿美元 |

| 复合年增长率 | 3.6% |

合成增黏剂领域在 2024 年的价值为 31 亿美元,占市场主导地位,预计在预测期内的复合年增长率为 3.5%。合成增粘剂来自脂肪族烃、C9芳烃和合成多萜等石油基来源,因其出色的热稳定性、强的粘合性能以及与各种粘合剂的兼容性而受到广泛青睐。包装、建筑和汽车等行业都严重依赖这些增粘剂在极端条件下的耐用性和效率。它们能够在高温和各种环境条件下保持黏合力,使其成为寻求持久黏合解决方案的製造商的首选。

固体增黏剂领域在 2024 年创造了 23 亿美元的收入,预计到 2034 年将以 3.4% 的复合年增长率成长。固体增粘剂因其成本效益高、易于操作以及在压敏胶和热熔胶应用中的卓越性能而备受追捧。它们具有很强的聚合物相容性和热稳定性,是需要耐用、灵活的黏合解决方案的行业的理想选择。从工业包装和建筑到卫生产品和汽车应用,固体增黏剂继续成为不断发展的黏合剂领域的基本组成部分。

2024 年中国增黏剂市场价值为 16 亿美元,预计到 2034 年将以 3.4% 的复合年增长率扩大。作为全球製造业强国,中国凭藉其强大的工业基础和各种应用对黏合剂不断增长的需求在市场上占据主导地位。包装、建筑和汽车行业的快速成长大大增加了对增粘剂的需求。此外,中国蓬勃发展的电子商务产业正在推动对高品质包装黏合剂的需求,进一步巩固了中国在全球市场的领导地位。随着工业化和基础设施的持续发展,中国仍然是塑造增黏剂产业未来的关键参与者。

目录

第 1 章:方法论与范围

- 市场范围和定义

- 基础估算与计算

- 预测计算

- 资料来源

- 基本的

- 次要

- 付费来源

- 公共资源

第 2 章:执行摘要

第 3 章:产业洞察

- 产业生态系统分析

- 影响价值链的因素

- 利润率分析

- 中断

- 未来展望

- 製造商

- 经销商

- 供应商概况

- 利润率分析

- 重要新闻及倡议

- 监管格局

- 衝击力

- 成长动力

- 各行业对胶黏剂的需求增加

- 环保增黏剂需求上升

- 亚太地区工业成长

- 产业陷阱与挑战

- 限制合成增黏剂的环境法规

- 成长动力

- 成长潜力分析

- 波特的分析

- PESTEL 分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 竞争定位矩阵

- 战略展望矩阵

第 5 章:市场估计与预测:按产品类型,2021-2034 年

- 主要趋势

- 合成增黏剂

- 天然增黏剂

第六章:市场估计与预测:依形式,2021-2034

- 主要趋势

- 坚硬的

- 液体

- 树脂分散体

第 7 章:市场估计与预测:按应用,2021 年至 2034 年

- 主要趋势

- 包装

- 建造

- 非织物

- 装订

- 汽车

- 其他的

第 8 章:市场估计与预测:按地区,2021 年至 2034 年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- 中东及非洲

- 南非

- 沙乌地阿拉伯

- 阿联酋

第九章:公司简介

- Arkema

- BASF SE

- Eastman Chemical

- Exxon Mobil

- HB Fuller

- Henkel AG & Co. KGaA

- Kolon Industries

- KRATON

- SI Group

- ZEON

The Global Tackifier Market reached USD 4.2 billion in 2024 and is poised for steady growth, projected to expand at a CAGR of 3.6% between 2025 and 2034. Tackifiers play a crucial role in adhesive formulations by enhancing their stickiness and improving adhesion across various industries. With the growing demand for high-performance adhesives, particularly in the packaging, automotive, construction, and hygiene sectors, the need for advanced tackifier solutions is on the rise. The market is witnessing a surge in demand for hot-melt adhesives (HMAs), particularly in nonwoven hygiene products and flexible packaging, further propelling industry expansion.

Key drivers of market growth include continuous advancements in adhesive technologies and a rising shift toward environmentally friendly solutions. As industries increasingly prioritize sustainability, the transition to bio-based tackifiers is accelerating. These alternatives, derived from renewable sources, offer lower volatile organic compound (VOC) emissions, making them a preferred choice for companies aiming to comply with stringent environmental regulations. Additionally, the rapid expansion of e-commerce and the growing need for efficient packaging adhesives are fueling demand across the globe. In industries where adhesive performance is critical, such as automotive assembly and medical applications, tackifiers provide superior bonding capabilities, reinforcing their indispensable role in modern manufacturing.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $4.2 Billion |

| Forecast Value | $5.9 Billion |

| CAGR | 3.6% |

The synthetic tackifiers segment, valued at USD 3.1 billion in 2024, dominates the market and is projected to grow at a CAGR of 3.5% over the forecast period. Derived from petroleum-based sources such as aliphatic hydrocarbons, C9 aromatics, and synthetic polyterpenes, synthetic tackifiers are widely favored for their outstanding thermal stability, strong adhesion properties, and compatibility with various adhesives. Industries such as packaging, construction, and automotive heavily rely on these tackifiers for their durability and efficiency in extreme conditions. Their ability to maintain adhesion under high temperatures and diverse environmental conditions makes them a top choice for manufacturers seeking long-lasting adhesive solutions.

The solid tackifier segment generated USD 2.3 billion in 2024 and is expected to grow at a 3.4% CAGR through 2034. Solid tackifiers are highly sought after due to their cost-effectiveness, ease of handling, and exceptional performance in pressure-sensitive and hot-melt adhesive applications. Their strong polymer compatibility and thermal stability make them ideal for industries that require durable and flexible bonding solutions. From industrial packaging and construction to hygiene products and automotive applications, solid tackifiers continue to be a fundamental component in the evolving adhesive landscape.

China tackifier market was valued at USD 1.6 billion in 2024 and is anticipated to expand at a CAGR of 3.4% through 2034. As a global manufacturing powerhouse, China dominates the market due to its strong industrial base and rising demand for adhesives across various applications. The rapid growth of the packaging, construction, and automotive industries has significantly increased the need for tackifiers. Additionally, China's booming e-commerce sector is driving demand for high-quality packaging adhesives, further solidifying the country's leadership in the global market. With continued industrialization and infrastructure development, China remains a key player in shaping the future of the tackifier industry.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definitions

- 1.2 Base estimates & calculations

- 1.3 Forecast calculations

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021-2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factor affecting the value chain

- 3.1.2 Profit margin analysis

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufacturers

- 3.1.6 Distributors

- 3.2 Supplier landscape

- 3.3 Profit margin analysis

- 3.4 Key news & initiatives

- 3.5 Regulatory landscape

- 3.6 Impact forces

- 3.6.1 Growth drivers

- 3.6.1.1 Increased adhesive demand across industries

- 3.6.1.2 Rise in eco-friendly tackifier demand

- 3.6.1.3 Growth in Asia-Pacific’s industries

- 3.6.2 Industry pitfalls & challenges

- 3.6.2.1 Environmental regulations limiting synthetic tackifiers

- 3.6.1 Growth drivers

- 3.7 Growth potential analysis

- 3.8 Porter’s analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Product Type, 2021-2034 (USD Billion) (Kilo Tons)

- 5.1 Key trends

- 5.2 Synthetic tackifiers

- 5.3 Natural tackifiers

Chapter 6 Market Estimates & Forecast, By Form, 2021-2034 (USD Billion) (Kilo Tons)

- 6.1 Key trends

- 6.2 Solid

- 6.3 Liquid

- 6.4 Resin dispersions

Chapter 7 Market Estimates & Forecast, By Application, 2021-2034 (USD Billion) (Kilo Tons)

- 7.1 Key trends

- 7.2 Packaging

- 7.3 Construction

- 7.4 Non-woven

- 7.5 Bookbinding

- 7.6 Automotive

- 7.7 Others

Chapter 8 Market Estimates & Forecast, By Region, 2021-2034 (USD Billion) (Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 UK

- 8.3.2 Germany

- 8.3.3 France

- 8.3.4 Italy

- 8.3.5 Spain

- 8.3.6 Russia

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 South Korea

- 8.4.5 Australia

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.6 MEA

- 8.6.1 South Africa

- 8.6.2 Saudi Arabia

- 8.6.3 UAE

Chapter 9 Company Profiles

- 9.1 Arkema

- 9.2 BASF SE

- 9.3 Eastman Chemical

- 9.4 Exxon Mobil

- 9.5 H.B. Fuller

- 9.6 Henkel AG & Co. KGaA

- 9.7 Kolon Industries

- 9.8 KRATON

- 9.9 SI Group

- 9.10 ZEON