|

市场调查报告书

商品编码

1740871

汽车烧结煞车片市场机会、成长动力、产业趋势分析及2025-2034年预测Automotive Sintered Brake Pads Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

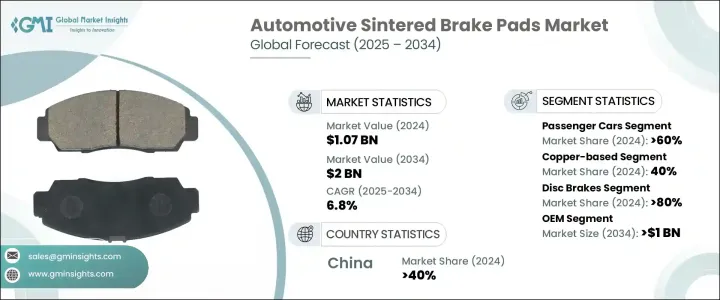

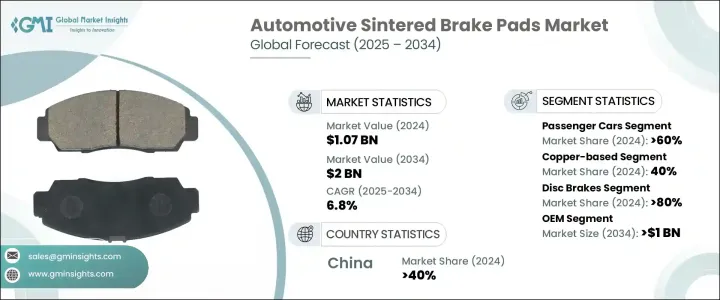

2024年,全球汽车烧结煞车片市场规模达10.7亿美元,预估年复合成长率为6.8%,到2034年将达到20亿美元。这主要得益于对耐用高性能煞车系统需求的激增,尤其是在卡车和巴士等商用车辆领域。随着全球物流和货运流动性的不断扩大,对可靠、持久耐用的煞车解决方案的需求变得前所未有的重要。基础设施建设的不断推进、交通网络投资的不断增加以及电子商务活动的持续增长,直接影响了商用车辆的保有量,显着推动了对烧结煞车片的需求。此外,汽车产业持续向性能优化和安全性提升转变,使烧结煞车片成为创新的前沿。汽车製造商和车队营运商越来越重视能够承受极端条件、最大程度缩短维护週期并在各种地形上提供稳定性能的煞车零件。随着永续性问题的日益加剧,製造商也不断创新环保材料和工艺,进一步拓宽全球烧结煞车片的市场范围。

烧结煞车片采用在极高温度和压力下熔合金属颗粒製成,从而形成緻密且高度耐用的零件。即使在最剧烈的煞车情况下,这种製程也使煞车片具有出色的耐热、耐摩擦和耐磨损性能。它们在快速减速、陡峭下坡和重型牵引等情况下表现出色,在这些情况下,保持稳定的性能至关重要。烧结煞车片在潮湿、泥泞或崎岖的地形中也能保持卓越的煞车效率,使其成为越野和全天候驾驶的首选。其坚固的结构有助于最大限度地减少变形,从而延长使用寿命并减少更换次数。烧结煞车片在波动的负载和极端温度下提供稳定煞车的能力,巩固了其作为消费和商用车辆领域首选煞车片的地位。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 10.7亿美元 |

| 预测值 | 20亿美元 |

| 复合年增长率 | 6.8% |

就车型而言,汽车烧结煞车片市场细分为乘用车、商用车和两轮车。 2024年,乘用车市场占据了60%的市场份额,预计到2034年将达到10亿美元。这一主导地位反映出消费者对节油、低维护煞车系统日益增长的需求。烧结煞车片性能稳定可靠,磨损少,是日常城市通勤和偶尔高速公路驾驶的理想选择。其更长的使用寿命可降低整体维护成本,并提高车辆的耐用性,对注重价值的买家以及豪华车主都具有强大的吸引力。

依材料细分,市场可分为铜基、陶瓷基、铁基、碳基及其他基材料。铜基烧结煞车片在2024年占据40%的市场份额,占据市场主导地位。其优异的热稳定性和导电性使其成为高速重载应用的理想选择。这类煞车片广泛应用于跑车、商用卡车和越野车,这些车辆对煞车精度和耐用性有严格的要求。透过降低更换频率,铜基煞车片可为车队营运商和私家车主节省大量成本,进一步巩固了其日益普及的市场地位。

受印度、泰国和印尼等新兴经济体汽车产业快速扩张的推动,亚太地区汽车烧结煞车片市场在2024年占据了40%的主导份额。都市化进程加快、可支配收入增加以及车主数量不断增长,加大了原始设备製造商(OEM)在烧结煞车片等高端零件上的应用压力。同时,该地区商用车和两轮车销售的不断增长进一步刺激了市场需求,尤其是在公共交通系统和物流车队中,这些车队致力于提高安全性和效率。

引领汽车烧结煞车片市场的领导企业包括日清纺、克诺尔、布雷博、天纳克、博世、瀚德、爱德克斯、MAT Holdings、爱信精机和曙光煞车。这些公司正积极投资研发,推出性能更佳、耐用性更强、环境影响更小的先进烧结煞车片。创新包括开发符合日益严格的排放标准并同时提升安全性的新材料。与汽车製造商和供应商建立策略合作伙伴关係和联盟也有助于企业在竞争激烈的市场中拓展市场范围、增强产品组合併获得新的客户群。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 供应商格局

- 利润率分析

- 川普政府关税

- 对贸易的影响

- 贸易量中断

- 报復措施

- 对产业的影响

- 供给侧影响(原料)

- 主要材料价格波动

- 供应链重组

- 生产成本影响

- 需求面影响(售价)

- 价格传导至终端市场

- 市占率动态

- 消费者反应模式

- 供给侧影响(原料)

- 受影响的主要公司

- 策略产业反应

- 供应链重组

- 定价和产品策略

- 政策参与

- 展望与未来考虑

- 对贸易的影响

- 技术与创新格局

- 专利分析

- 重要新闻和倡议

- 监管格局

- 价格趋势

- 成本細項分析

- 衝击力

- 成长动力

- 运动型和豪华型车辆对高性能煞车系统的需求不断增长

- 全球商用车和货运业的成长

- 摩托车越来越多地采用烧结煞车片,以提高耐用性和耐热性

- 不断扩大的建筑和采矿业需要重型煞车解决方案

- 产业陷阱与挑战

- 与有机或半金属替代品相比,烧结垫的成本更高

- 由于烧结材料的侵蚀性,煞车盘磨损加剧

- 成长动力

- 成长潜力分析

- 波特的分析

- PESTEL分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 竞争定位矩阵

- 战略展望矩阵

第五章:市场估计与预测:依资料,2021 - 2034 年

- 主要趋势

- 铜

- 陶瓷製品

- 铁

- 碳

- 其他的

第六章:市场估计与预测:依车型,2021 - 2034 年

- 主要趋势

- 搭乘用车

- 掀背车

- 轿车

- 越野车

- 商用车

- 轻型商用车

- 平均血红素 (MCV)

- 丙型肝炎病毒

- 两轮车

- 摩托车

- 踏板车和轻型摩托车

第七章:市场估计与预测:按应用,2021 - 2034 年

- 主要趋势

- 碟式煞车

- 鼓式煞车

第八章:市场估计与预测:依销售管道,2021 - 2034 年

- 主要趋势

- OEM

- 售后市场

- 批发分销商

- 零售店

- 线上零售平台

第九章:市场估计与预测:按地区,2021 - 2034 年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 西班牙

- 义大利

- 俄罗斯

- 北欧人

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳新银行

- 东南亚

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- MEA

- 阿联酋

- 南非

- 沙乌地阿拉伯

第十章:公司简介

- ADVICS

- Aisin Seiki

- Akebono Brake

- ASK Automotive

- Bosch

- Brake Parts

- Brembo

- EBC Brakes

- Haldex

- Hawk Performance

- Hitachi Chemical

- ICER Brakes

- ITT

- Knorr-Bremse

- MAT Holdings

- Miba

- Nisshinbo

- Sangsin Brake

- SBS Friction

- Tenneco

The Global Automotive Sintered Brake Pads Market was valued at USD 1.07 billion in 2024 and is estimated to grow at a CAGR of 6.8% to reach USD 2 billion by 2034, primarily fueled by the surging demand for durable and high-performance braking systems, especially in commercial vehicles like trucks and buses. As global logistics and freight mobility continue to expand, the need for reliable, long-lasting braking solutions has never been more critical. Growing infrastructure development, rising investments in transportation networks, and a consistent surge in e-commerce activities have directly impacted the growth of commercial vehicles on the road, significantly boosting the demand for sintered brake pads. Moreover, the automotive sector's ongoing shift towards performance optimization and safety enhancement has placed sintered brake pads at the forefront of innovation. Automakers and fleet operators increasingly prioritize brake components that can withstand extreme conditions, minimize maintenance cycles, and deliver consistent performance across varied terrains. As sustainability concerns intensify, manufacturers are also innovating with eco-friendly materials and processes, further broadening the market scope for sintered brake pads globally.

Sintered brake pads are manufactured by fusing metallic particles under extremely high temperatures and pressures, resulting in dense, highly durable components. This method gives the pads exceptional resistance to heat, friction, and wear, even under the most intense braking scenarios. They excel in rapid deceleration, steep descents, and heavy towing situations, where maintaining consistent performance is crucial. Sintered brake pads also maintain superior braking efficiency in wet, muddy, or rough terrains, making them a preferred choice for off-road and all-weather driving conditions. Their robust structure helps minimize deformation, ensuring a longer lifespan and fewer replacements. The ability of sintered brake pads to deliver stable braking under fluctuating loads and temperature extremes has cemented their position as the go-to option for both consumer and commercial vehicle segments.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $1.07 Billion |

| Forecast Value | $2 Billion |

| CAGR | 6.8% |

In terms of vehicle types, the automotive sintered brake pads market is segmented into passenger cars, commercial vehicles, and two-wheelers. In 2024, the passenger car segment accounted for a 60% market share and is projected to generate USD 1 billion by 2034. This dominance reflects the growing consumer inclination toward fuel-efficient, low-maintenance braking systems. Sintered brake pads deliver consistent, reliable performance and reduce wear, making them ideal for daily urban commutes and occasional highway drives. Their extended lifespan results in lower overall maintenance costs and greater vehicle durability, appealing strongly to value-segment buyers as well as luxury vehicle owners.

When it comes to material segmentation, the market is divided into copper-based, ceramic-based, iron-based, carbon-based, and others. Copper-based sintered brake pads led the market with a 40% share in 2024. Their excellent thermal stability and conductivity make them ideal for high-speed and heavy-load applications. These pads are widely used in sports cars, commercial trucks, and off-road vehicles where braking precision and durability are non-negotiable. By reducing the frequency of replacements, copper-based pads offer substantial cost savings for fleet operators and private vehicle owners alike, reinforcing their growing popularity.

The Asia Pacific Automotive Sintered Brake Pads Market held a commanding 40% share in 2024, driven by the rapid expansion of the automobile sector in emerging economies like India, Thailand, and Indonesia. Soaring urbanization, rising disposable incomes, and an increasing number of car owners have intensified the pressure on original equipment manufacturers (OEMs) to incorporate top-tier components such as sintered brake pads. At the same time, the growing sales of commercial vehicles and two-wheelers across the region have further fueled demand, particularly among public transport systems and logistics fleets keen on enhancing safety and efficiency.

Leading players shaping the automotive sintered brake pads market include Nisshinbo, Knorr-Bremse, Brembo, Tenneco, Bosch, Haldex, ADVICS, MAT Holdings, Aisin Seiki, and Akebono Brake. These companies are aggressively investing in research and development initiatives to roll out advanced sintered brake pads that offer improved performance, greater durability, and reduced environmental impact. Innovations include the development of new materials that comply with increasingly stringent emission standards while simultaneously enhancing safety. Strategic partnerships and alliances with automotive manufacturers and suppliers are also helping companies extend their market reach, strengthen product portfolios, and access new customer bases in a highly competitive landscape.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.1.1 Research approach

- 1.1.2 Data collection methods

- 1.2 Base estimates and calculations

- 1.2.1 Base year calculation

- 1.2.2 Key trends for market estimates

- 1.3 Forecast model

- 1.4 Primary research & validation

- 1.4.1 Primary sources

- 1.4.2 Data mining sources

- 1.5 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Supplier landscape

- 3.3 Profit margin analysis

- 3.4 Trump administration tariffs

- 3.4.1 Impact on trade

- 3.4.1.1 Trade volume disruptions

- 3.4.1.2 Retaliatory measures

- 3.4.2 Impact on the industry

- 3.4.2.1 Supply-side impact (raw materials)

- 3.4.2.1.1 Price volatility in key materials

- 3.4.2.1.2 Supply chain restructuring

- 3.4.2.1.3 Production cost implications

- 3.4.2.2 Demand-side impact (selling price)

- 3.4.2.2.1 Price transmission to end markets

- 3.4.2.2.2 Market share dynamics

- 3.4.2.2.3 Consumer response patterns

- 3.4.2.1 Supply-side impact (raw materials)

- 3.4.3 Key companies impacted

- 3.4.4 Strategic industry responses

- 3.4.5 Supply chain reconfiguration

- 3.4.5.1 Pricing and product strategies

- 3.4.5.2 Policy engagement

- 3.4.6 Outlook and future considerations

- 3.4.1 Impact on trade

- 3.5 Technology & innovation landscape

- 3.6 Patent analysis

- 3.7 Key news & initiatives

- 3.8 Regulatory landscape

- 3.9 Price trends

- 3.10 Cost breakdown analysis

- 3.11 Impact forces

- 3.11.1 Growth drivers

- 3.11.1.1 Rising demand for high-performance braking systems in sports and luxury vehicles

- 3.11.1.2 Growth in global commercial vehicle and freight transportation sectors

- 3.11.1.3 Increased adoption of sintered pads in motorcycles for durability and heat resistance

- 3.11.1.4 Expanding construction and mining industries requiring heavy-duty braking solutions

- 3.11.2 Industry pitfalls & challenges

- 3.11.2.1 Higher cost of sintered pads compared to organic or semi-metallic alternatives

- 3.11.2.2 Increased brake disc wear due to the aggressive nature of sintered materials

- 3.11.1 Growth drivers

- 3.12 Growth potential analysis

- 3.13 Porter's analysis

- 3.14 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Material, 2021 - 2034 ($Bn, Units)

- 5.1 Key trends

- 5.2 Copper

- 5.3 Ceramic

- 5.4 Iron

- 5.5 Carbon

- 5.6 Others

Chapter 6 Market Estimates & Forecast, By Vehicle, 2021 - 2034 ($Bn, Units)

- 6.1 Key trends

- 6.2 Passenger cars

- 6.2.1 Hatchback

- 6.2.2 Sedan

- 6.2.3 SUV

- 6.3 Commercial vehicles

- 6.3.1 LCV

- 6.3.2 MCV

- 6.3.3 HCV

- 6.4 Two-wheelers

- 6.4.1 Motorcycles

- 6.4.2 Scooters & mopeds

Chapter 7 Market Estimates & Forecast, By Application, 2021 - 2034 ($Bn, Units)

- 7.1 Key trends

- 7.2 Disc brakes

- 7.3 Drum brakes

Chapter 8 Market Estimates & Forecast, By Sales Channel, 2021 - 2034 ($Bn, Units)

- 8.1 Key trends

- 8.2 OEM

- 8.3 Aftermarket

- 8.3.1 Wholesale distributors

- 8.3.2 Retail stores

- 8.3.3 Online retail platforms

Chapter 9 Market Estimates & Forecast, By Region, 2021 - 2034 ($Bn, Units)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 UK

- 9.3.2 Germany

- 9.3.3 France

- 9.3.4 Spain

- 9.3.5 Italy

- 9.3.6 Russia

- 9.3.7 Nordics

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 South Korea

- 9.4.5 ANZ

- 9.4.6 Southeast Asia

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.6 MEA

- 9.6.1 UAE

- 9.6.2 South Africa

- 9.6.3 Saudi Arabia

Chapter 10 Company Profiles

- 10.1 ADVICS

- 10.2 Aisin Seiki

- 10.3 Akebono Brake

- 10.4 ASK Automotive

- 10.5 Bosch

- 10.6 Brake Parts

- 10.7 Brembo

- 10.8 EBC Brakes

- 10.9 Haldex

- 10.10 Hawk Performance

- 10.11 Hitachi Chemical

- 10.12 ICER Brakes

- 10.13 ITT

- 10.14 Knorr-Bremse

- 10.15 MAT Holdings

- 10.16 Miba

- 10.17 Nisshinbo

- 10.18 Sangsin Brake

- 10.19 SBS Friction

- 10.20 Tenneco