|

市场调查报告书

商品编码

1740911

数位纺织印花设备市场机会、成长动力、产业趋势分析及2025-2034年预测Digital Textile Printing Equipment Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

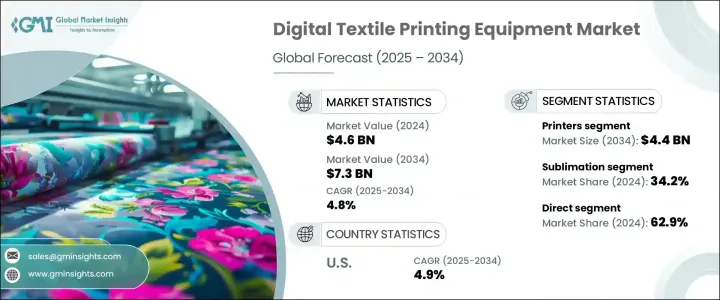

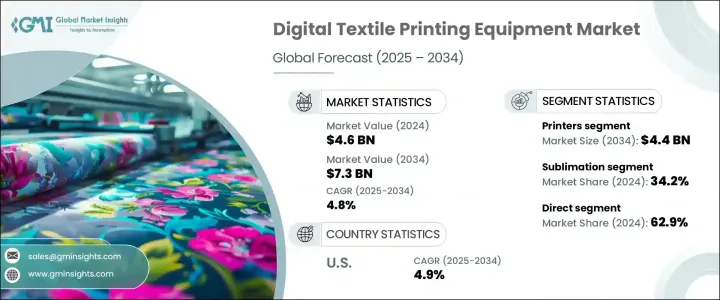

2024年,全球数位纺织印花设备市场规模达46亿美元,预计2034年将以4.8%的复合年增长率成长,达到73亿美元。这一增长主要源于个性化和短版纺织品生产需求的不断增长。随着消费者偏好转向独特的客製化商品,尤其是在时尚、家居和促销商品领域,对灵活高效的生产方式的需求激增。数位纺织印花因其能够快速交付原型、快速週转和经济高效的小批量生产而成为首选解决方案,而这些是传统印花工艺无法比拟的。快时尚的兴起和全球电子商务的蓬勃发展也做出了巨大贡献,因为按需印刷有助于品牌保持敏捷,并能快速回应不断变化的趋势。小型品牌和独立设计师尤其受益于能够生产限量版设计,而无需过度投入大宗库存,这与人们对永续和极简主义消费模式日益增长的偏好相契合。

印花机在数位纺织印花设备领域中占有最重要的份额。这些设备至关重要,因为它们能够将数位图案以高精度和高效率直接转印到织物上。由于持续的技术创新,尤其是在列印头设计、透过多程和单程配置实现的列印速度以及与各种纺织品的兼容性等方面,印花机的主导地位预计将持续下去。这些改进使企业能够满足服装、室内装潢和软牌等各种应用领域日益增长的需求。随着性能和输出品质的提升,印花机越来越被视为新兴和成熟纺织市场的策略投资。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 46亿美元 |

| 预测值 | 73亿美元 |

| 复合年增长率 | 4.8% |

就墨水类型而言,市场分为昇华墨水、活性墨水、酸性墨水、颜料墨水和包括分散墨水在内的其他类型墨水。其中,昇华墨水占最大份额,2024 年约为 34.2%,预计到 2034 年将以 3.8% 的复合年增长率增长。昇华墨水因其能够在聚酯纤维等合成纤维上呈现鲜艳持久的色彩而广受欢迎。这些墨水是运动服、横幅和促销品的首选,这些产品对耐用性和耐洗性有很高的要求。它们也因其生态效率而受到认可,因为它们耗水量更少,几乎不需要后处理。随着产业持续向合成纺织品基料发展,昇华技术的使用也随之扩大,巩固了其在市场上的主导地位。

在检视此类设备的销售方式时,数位纺织印花设备市场可分为直接和间接分销管道。 2024年,直销通路的市占率约为62.9%,预计到2034年将以4.6%的复合年增长率成长。这种方式之所以受到青睐,是因为它能让製造商与最终用户建立更牢固的关係,从而提供更优质的服务、培训和技术支援。直接互动也能让製造商获得即时回馈,帮助他们改进产品和服务,更能满足客户需求。这种更紧密的客户互动对于需要持续支援和客製化的复杂数位化营运系统尤其重要。

在美国,数位纺织印花设备市场规模在2024年超过6亿美元,预计2034年将以4.9%的复合年增长率成长。由于注重技术创新以及订製服装和家居装饰需求的不断增长,美国已成为该市场的重要参与者。该市场受益于发达的时尚产业、较高的数位化普及率以及消费者对环保产品日益增长的兴趣。先进的印花系统,尤其是支援直接成衣印花和捲对捲印花配置的系统,正受到寻求可扩展和可持续解决方案的企业的青睐。

影响该领域竞争的关键因素包括列印速度、解析度、墨水灵活性、环境永续性以及整体拥有成本。设备製造商不断改进自动化、多材料相容性和环保墨水配方等功能,以赢得竞争优势。节水节能技术的发展也体现了对更永续营运的追求,这些技术不仅降低了营运成本,也吸引了具有环保意识的消费者和品牌。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 影响价值链的因素

- 利润率分析

- 中断

- 未来展望

- 製造商

- 经销商

- 零售商

- 川普政府关税分析

- 对贸易的影响

- 贸易量中断

- 报復措施

- 对产业的影响

- 供应方影响(原料)

- 主要材料价格波动

- 供应链重组

- 生产成本影响

- 需求面影响(售价)

- 价格传导至终端市场

- 市占率动态

- 消费者反应模式

- 受影响的主要公司

- 策略产业反应

- 供应链重组

- 定价和产品策略

- 政策参与

- 展望与未来考虑

- 对贸易的影响

- 供应商格局

- 利润率分析

- 重要新闻和倡议

- 监管格局

- 衝击力

- 成长动力

- 包装和加工食品的需求不断增长

- 技术进步

- 越来越重视永续包装

- 产业陷阱与挑战

- 初期投资及维护成本高

- 处理各种包装材料的复杂性

- 成长动力

- 成长潜力分析

- 交易分析

- 波特的分析

- PESTEL分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 竞争定位矩阵

- 战略展望矩阵

第五章:市场估计与预测:依组件类型,2021 - 2034 年

- 主要趋势

- 印表机

- 预处理机

- 后处理机器

- 油墨供应和固化系统

第六章:市场估计与预测:依印刷製程类型,2021 - 2034 年

- 主要趋势

- 直接织物(DTF)

- 直接成衣印花(DTG)

第七章:市场估计与预测:依油墨类型,2021 - 2034 年

- 主要趋势

- 昇华

- 反应式

- 酸

- 颜料

- 其他(解散等)

第八章:市场估计与预测:依最终用途,2021 - 2034 年

- 主要趋势

- 服饰和服饰

- 家纺

- 技术纺织品

- 软牌

- 旗帜和横幅

- 工业应用

第九章:市场估计与预测:按配销通路,2021 - 2034 年

- 主要趋势

- 直接的

- 间接

第十章:市场估计与预测:按地区,2021-2034 年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 义大利

- 西班牙

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- MEA

- 南非

- 沙乌地阿拉伯

- 阿联酋

第 11 章:公司简介

- Atexco

- Brother Industries

- D.Gen

- Durst Phototechnik

- EFI (Electronics For Imaging)

- HP Inc.

- JTeck

- Klieverik

- Konica Minolta

- Kornit Digital

- Mimaki Engineering

- MS Printing Solutions

- Roland DG

- Seiko Epson

- Veika

The Global Digital Textile Printing Equipment Market was valued at USD 4.6 billion in 2024 and is estimated to grow at a CAGR of 4.8% to reach USD 7.3 billion by 2034. This growth is largely fueled by an increasing demand for personalized and short-run textile production. As consumer preferences shift toward unique and tailored items, especially in fashion, home furnishings, and promotional merchandise, the need for flexible and efficient production methods has surged. Digital textile printing has become the go-to solution due to its ability to deliver quick prototypes, fast turnaround, and cost-effective small-batch runs-something that traditional printing processes cannot offer. The rise of fast fashion and the global e-commerce boom have also contributed significantly, as on-demand printing helps brands stay agile and responsive to changing trends. Smaller labels and independent designers, in particular, benefit from the ability to produce limited-edition designs without overcommitting to bulk inventory, which aligns with the growing preference for sustainable and minimalist consumption patterns.

Printers represent the most significant share within the digital textile printing equipment segment. These machines are essential because they directly transfer digital designs onto fabrics with high accuracy and efficiency. Their dominance is expected to continue, thanks to continuous technological innovation-especially in areas like printhead design, print speeds through multi-pass and single-pass configurations, and compatibility with a wide range of textiles. These improvements enable businesses to meet the increasing demand across diverse applications such as apparel, interior decor, and soft signage. As performance and output quality improve, printers are increasingly seen as a strategic investment across both emerging and established textile markets.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $4.6 Billion |

| Forecast Value | $7.3 Billion |

| CAGR | 4.8% |

In terms of ink types, the market is divided into sublimation, reactive, acid, pigment, and other varieties, including disperse inks. Among these, sublimation ink held the largest share at approximately 34.2% in 2024 and is forecasted to grow at a CAGR of 3.8% through 2034. Sublimation inks have gained popularity because they produce vivid, long-lasting colors on synthetic fabrics like polyester. These inks are preferred for sports apparel, banners, and promotional goods that demand high durability and wash resistance. They are also recognized for their eco-efficiency, as they use less water and require minimal post-processing. As the industry continues to move toward synthetic textile bases, the use of sublimation technology is expanding accordingly, reinforcing its dominant role in the market.

When examining how this equipment is sold, the digital textile printing equipment market is segmented into direct and indirect distribution channels. The direct sales channel held a market share of around 62.9% in 2024 and is anticipated to grow at a CAGR of 4.6% by 2034. This method is preferred because it allows manufacturers to build stronger relationships with end-users, providing better service, training, and technical support. Direct interactions also enable manufacturers to receive real-time feedback, helping them refine their products and services to better align with customer needs. This closer customer engagement is especially vital for complex, digitally operated systems that require ongoing support and customization.

In the United States, the digital textile printing equipment market exceeded USD 600 million in 2024 and is set to grow at a CAGR of 4.9% through 2034. The country has become a significant player due to its focus on technological innovation and the expanding demand for custom apparel and home decor. The market benefits from a well-developed fashion industry, high digital adoption rates, and increasing consumer interest in eco-conscious products. Advanced printing systems, particularly those that support direct-to-garment and roll-to-roll configurations, are gaining traction among businesses seeking scalable and sustainable solutions.

Key factors shaping competition in this sector include print speed, resolution, ink flexibility, environmental sustainability, and overall cost of ownership. Equipment manufacturers are continuously advancing features such as automation, multi-material compatibility, and eco-friendly ink formulations to gain a competitive edge. The push toward more sustainable operations is also evident in the development of water-efficient and energy-saving technologies, which not only reduce operational costs but also appeal to environmentally aware consumers and brands.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definition

- 1.2 Base estimates & calculations

- 1.3 Forecast parameters

- 1.4 Data sources

- 1.4.1 Primary

- 1.5 Secondary

- 1.5.1.1 Paid sources

- 1.5.1.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factor affecting the value chain

- 3.1.2 Profit margin analysis

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufacturers

- 3.1.6 Distributors

- 3.1.7 Retailers

- 3.2 Trump administration tariffs analysis

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.3 Supply-side impact (raw materials)

- 3.2.3.1 Price volatility in key materials

- 3.2.3.2 Supply chain restructuring

- 3.2.3.3 Production cost implications

- 3.2.3.4 Demand-side impact (selling price)

- 3.2.3.5 Price transmission to end markets

- 3.2.3.6 Market share dynamics

- 3.2.3.7 Consumer response patterns

- 3.2.4 Key companies impacted

- 3.2.5 Strategic industry responses

- 3.2.5.1 Supply chain reconfiguration

- 3.2.5.2 Pricing and product strategies

- 3.2.5.3 Policy engagement

- 3.2.6 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Supplier landscape

- 3.4 Profit margin analysis

- 3.5 Key news & initiatives

- 3.6 Regulatory landscape

- 3.7 Impact forces

- 3.7.1 Growth drivers

- 3.7.1.1 Rising demand for packaged and processed foods

- 3.7.1.2 Technological advancements

- 3.7.1.3 Increasing focus on sustainable packaging

- 3.7.2 Industry pitfalls & challenges

- 3.7.2.1 High initial investment and maintenance costs

- 3.7.2.2 Complexity in handling diverse packaging materials

- 3.7.1 Growth drivers

- 3.8 Growth potential analysis

- 3.9 Trade analysis

- 3.10 Porter's analysis

- 3.11 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Component Type, 2021 - 2034, (USD Billion) (Thousand Units)

- 5.1 Key trends

- 5.2 Printers

- 5.3 Pre-Treatment machines

- 5.4 Post-Treatment machines

- 5.5 Ink supply & curing systems

Chapter 6 Market Estimates & Forecast, By Printing Process Type, 2021 - 2034, (USD Billion) (Thousand Units)

- 6.1 Key trends

- 6.2 Direct-to-Fabric (DTF)

- 6.3 Direct-to-Garment (DTG)

Chapter 7 Market Estimates & Forecast, By Ink Type, 2021 - 2034, (USD Billion) (Thousand Units)

- 7.1 Key trends

- 7.2 Sublimation

- 7.3 Reactive

- 7.4 Acid

- 7.5 Pigment

- 7.6 Others (disperse, etc.)

Chapter 8 Market Estimates & Forecast, By End Use, 2021 - 2034, (USD Billion) (Thousand Units)

- 8.1 Key trends

- 8.2 Clothing and apparel

- 8.3 Home textiles

- 8.4 Technical textiles

- 8.5 Soft aignage

- 8.6 Flags and banners

- 8.7 Industrial applications

Chapter 9 Market Estimates & Forecast, By Distribution Channel, 2021 - 2034, (USD Billion) (Thousand Units)

- 9.1 Key trends

- 9.2 Direct

- 9.3 Indirect

Chapter 10 Market Estimates & Forecast, By Region, 2021 -2034 (USD Billion) (Thousand Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 UK

- 10.3.2 Germany

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 Japan

- 10.4.3 India

- 10.4.4 South Korea

- 10.4.5 Australia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.6 MEA

- 10.6.1 South Africa

- 10.6.2 Saudi Arabia

- 10.6.3 UAE

Chapter 11 Company Profiles (Business Overview, Financial Data, Product Landscape, Strategic Outlook, SWOT Analysis)

- 11.1 Atexco

- 11.2 Brother Industries

- 11.3 D.Gen

- 11.4 Durst Phototechnik

- 11.5 EFI (Electronics For Imaging)

- 11.6 HP Inc.

- 11.7 JTeck

- 11.8 Klieverik

- 11.9 Konica Minolta

- 11.10 Kornit Digital

- 11.11 Mimaki Engineering

- 11.12 MS Printing Solutions

- 11.13 Roland DG

- 11.14 Seiko Epson

- 11.15 Veika