|

市场调查报告书

商品编码

1766195

AAC(加气混凝土)砌块市场机会、成长动力、产业趋势分析及2025-2034年预测AAC (Autoclaved Aerated Concrete) Blocks Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

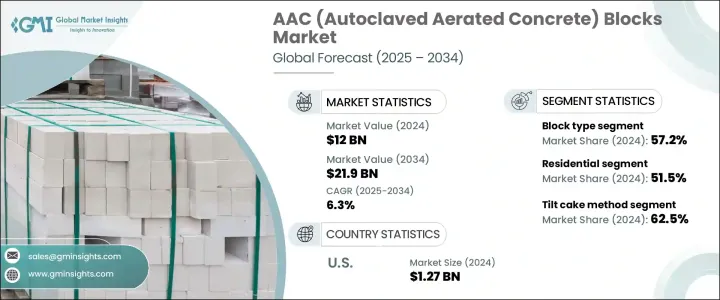

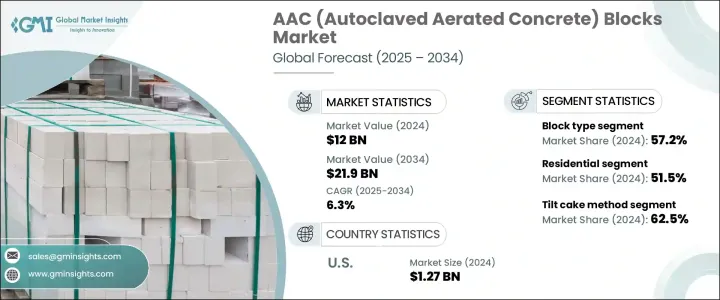

2024年,全球加气混凝土(AAC)砌块市场规模达120亿美元,预计到2034年将以6.3%的复合年增长率成长,达到219亿美元。随着对减少环境影响的建筑材料的需求不断增长,该市场正在稳步扩张。 AAC块以其轻质、可持续、使用安全天然的原材料和工业废料製成而闻名,使其成为传统砖块的绿色替代品。其生产过程比红粘土砖节能约30%,从而显着降低碳排放。在印度等快速成长的经济体中,这些材料因其支持国家永续发展目标并符合节能建筑规范而日益受到青睐。

AAC砌块的隔热性能有助于防止室内过热,减少对冷却系统的依赖。这有助于降低能耗、节省成本并带来环境效益。印度等国政府机构支持的能源效率标准进一步鼓励AAC块在房地产和公共基础设施领域的应用。快速的城市发展、持续的基础设施建设以及智慧城市倡议下向环保建筑的转变,都在推动市场扩张。 AAC砌块也因其易于运输和安装、减少施工时间和人工而受到青睐。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 120亿美元 |

| 预测值 | 219亿美元 |

| 复合年增长率 | 6.3% |

就产品类型而言,砌块变体在2024年占据了57.2%的市场份额,占据了市场主导地位。标准尺寸的砌块因其在成本、重量和隔热性能方面的良好平衡,广泛应用于住宅和商业建筑。对于大型项目,巨型砌块的使用日益增多,以减少接缝数量并加快墙体安装速度。诸如过樑和U型砌块等互补形状的砌块正变得越来越普遍,成为结构支撑和管道通道的增值解决方案,通常无需额外的模板。

生产方法是加气混凝土市场的另一个关键因素。倾斜式砌块法在2024年占62.5%的市场份额,处于领先地位。这种方法需要在垂直切割砌块之前对混合料进行部分固化,从而实现高产量并优化垂直空间利用率。它仍然是业内最成熟的方法,具有可扩展性。然而,由于修边,它可能造成额外的材料浪费,并且比较新的自动化技术需要更多的人工投入。

2024年,美国加气混凝土(AAC)砌块市场占据85%的市场份额,估值达12.7亿美元。美国的成长得益于强劲的基础设施建设以及对绿色建筑替代品的需求激增。为了满足这一需求并减少对进口材料的依赖,美国国内产能正在不断扩大,从而确保更好的市场准入和更有效率的交付。这进一步巩固了AAC作为美国建筑业关键材料的地位。

塑造全球加气混凝土 (AAC) 砌块市场的主要公司包括 Aercon AAC、H+H International A/S、CSR Limited (Hebel)、ACICO Industries Company 和 Xella Group。这些公司透过创新、扩张业务范围和强大的分销策略保持竞争力。为了提升市场份额,AAC 砌块製造商正专注于策略性倡议,例如扩大产能、在高需求地区设立工厂以及与建筑公司建立合资企业。许多公司正在改进其製造技术,以减少浪费并提高产品一致性。针对特定建筑功能进行砌块设计创新,以及在监管和绿色建筑框架中推广 AAC 的努力,也正成为关键策略。此外,向承包商和建筑师宣传 AAC 块的优势,有助于其在新兴市场和成熟市场中得到更广泛的应用。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 供应商概况

- 利润率

- 每个阶段的增值

- 影响价值链的因素

- 中断

- 产业衝击力

- 成长动力

- 对永续建筑材料的需求不断增长

- 能源效率和隔热效益

- 快速城市化和基础设施发展

- 轻量性能及施工速度优势

- 产业陷阱与挑战

- 原物料价格波动

- 运输成本和物流

- 熟练劳动力短缺

- 区域建筑规范合规性

- 市场机会

- 绿建筑认证项目

- 製造业的技术进步

- 新兴市场的扩张

- 预製和模组化建筑的成长

- 成长动力

- 成长潜力分析

- 监管格局

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 波特的分析

- PESTEL分析

- 价格趋势

- 按地区

- 按产品

- 未来市场趋势

- 技术和创新格局

- 当前的技术趋势

- 新兴技术

- 专利态势

- 贸易统计(HS编码)(註:仅提供重点国家的贸易统计资料)

- 主要进口国

- 主要出口国

- 永续性和环境方面

- 永续实践

- 减少废弃物的策略

- 生产中的能源效率

- 环保倡议

- 碳足迹考量

第四章:竞争格局

- 介绍

- 公司市占率分析

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- MEA

- 按地区

- 公司矩阵分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 关键进展

- 併购

- 伙伴关係与合作

- 新产品发布

- 扩张计划

第五章:市场估计与预测:依产品类型,2021 年至 2034 年

- 主要趋势

- 区块类型

- 标准块

- 巨型积木

- 过梁块

- U形块

- 其他的

- 尺寸

- 小型(长度最多 400 毫米)

- 中型(长度400-600毫米)

- 大型(长度600mm以上)

第六章:市场估计与预测:按原料,2021 年至 2034 年

- 主要趋势

- 水泥

- 莱姆

- 粉煤灰

- 硅砂/石英砂

- 铝粉

- 石膏

- 其他的

第七章:市场估计与预测:按应用,2021 年至 2034 年

- 主要趋势

- 墙体施工

- 外墙

- 内墙

- 隔间墙

- 屋顶隔热

- 地板元素

- 门楣

- 覆层板

- 其他的

第八章:市场估计与预测:按最终用途产业,2021 年至 2034 年

- 主要趋势

- 住宅建筑

- 独栋住宅

- 多户建筑

- 经济适用房项目

- 商业建筑

- 办公大楼

- 零售空间

- 饭店及餐饮业

- 教育机构

- 医疗保健设施

- 工业建筑

- 製造工厂

- 仓库

- 其他的

- 基础建设发展

- 其他的

第九章:市场估计与预测:依生产方式,2021 年至 2034 年

- 主要趋势

- 倾斜蛋糕法

- 平饼法

- 其他的

第十章:市场估计与预测:按地区,2021 年至 2034 年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 西班牙

- 义大利

- 欧洲其他地区

- 亚太地区

- 中国

- 印度

- 日本

- 澳洲

- 韩国

- 亚太其他地区

- 拉丁美洲

- 巴西

- 墨西哥

- 拉丁美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 阿联酋

- 中东和非洲其他地区

第 11 章:公司简介

- ACICO Industries Company

- Aercon AAC

- AKG Gazbeton

- Biltech Building Elements Limited

- Broco Industries

- Buildmate Projects Pvt. Ltd

- CSR Limited (Hebel)

- Eastland Building Materials Co., Ltd.

- H+H International A/S

- JK Lakshmi Cement Ltd.

- Magicrete Building Solutions Pvt. Ltd.

- Solbet Sp. z oo

- UAL Industries Limited

- Xella Group

The Global AAC (Autoclaved Aerated Concrete) Blocks Market was valued at USD 12 billion in 2024 and is estimated to grow at a CAGR of 6.3% to reach USD 21.9 billion by 2034. This market is expanding steadily as demand increases for building materials that reduce environmental impact. AAC blocks are recognized for being lightweight, sustainable, and made using safe, natural raw materials and industrial waste-making them a green alternative to conventional bricks. Their production process consumes around 30% less energy than red clay bricks, contributing to significantly lower carbon emissions. In fast-growing economies like India, these materials are gaining momentum as they support national sustainability goals and align with energy-efficient construction norms.

The thermal insulation offered by AAC blocks helps prevent excess indoor heat, reducing reliance on cooling systems. This contributes to lower power usage, cost savings, and environmental benefits. Energy efficiency standards backed by government agencies in countries such as India further encourage AAC adoption in real estate and public infrastructure. Rapid urban growth, ongoing infrastructure development, and a shift toward environmentally sound construction under smart city initiatives are all fueling market expansion. AAC blocks are also preferred for being easy to transport and install, reducing construction time and labor.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $12 Billion |

| Forecast Value | $21.9 Billion |

| CAGR | 6.3% |

In terms of product type, block variants dominated the market with a 57.2% share in 2024. Standard-sized blocks are widely used in both residential and commercial construction due to their favorable balance of cost, weight, and insulation. For larger-scale projects, jumbo blocks are increasingly used to reduce the number of joints and speed up wall installation. Complementary shapes like lintels and U-blocks are becoming more prevalent as value-added solutions for structural support and conduit passage, often eliminating the need for additional formwork.

Production methods are another key factor in the AAC market. The tilt cake method led with a 62.5% market share in 2024. This method involves partially curing the mix before cutting the blocks vertically, allowing high-volume output and optimal vertical space usage. It remains the most established method in the industry, ideal for scalability. However, it may create additional material waste due to trimming and requires more manual input than newer automated techniques.

United States AAC (Autoclaved Aerated Concrete) Blocks Market held 85% share in 2024, with a valuation of USD 1.27 billion. The country's growth is tied to robust infrastructure development and a surge in demand for green construction alternatives. Domestic production capacity is expanding to meet this demand and reduce reliance on imported materials, ensuring better market access and delivery efficiency. This has further strengthened the position of AAC as a key material in the US construction sector.

Major companies shaping the Global AAC (Autoclaved Aerated Concrete) Blocks Market include Aercon AAC, H+H International A/S, CSR Limited (Hebel), ACICO Industries Company, and Xella Group. These players remain competitive through innovation, expanding footprints, and strong distribution strategies. To boost their market presence, AAC block manufacturers are focusing on strategic moves such as capacity expansion, plant setup in high-demand regions, and entering joint ventures with construction firms. Many companies are enhancing their manufacturing technologies to reduce waste and improve product consistency. Innovation in block design to cater to specific building functions, and efforts to promote AAC in regulatory and green building frameworks, are also becoming critical strategies. Additionally, educating contractors and architects about the benefits of AAC blocks supports wider adoption across both emerging and mature markets.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Product type

- 2.2.3 Raw Material

- 2.2.4 Application

- 2.2.5 End use industry

- 2.2.6 Production process

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Growing demand for sustainable construction materials

- 3.2.1.2 Energy efficiency and thermal insulation benefits

- 3.2.1.3 Rapid urbanization and infrastructure development

- 3.2.1.4 Lightweight properties and construction speed advantages

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 Raw material price fluctuations

- 3.2.2.2 Transportation costs and logistics

- 3.2.2.3 Skilled labor shortages

- 3.2.2.4 Regional building code compliance

- 3.2.3 Market opportunities

- 3.2.3.1 Green building certification programs

- 3.2.3.2 Technological advancements in manufacturing

- 3.2.3.3 Expansion in emerging markets

- 3.2.3.4 Prefabricated and modular construction growth

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.6.1 Technology and Innovation Landscape

- 3.6.2 Current technological trends

- 3.6.3 Emerging technologies

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By product

- 3.8 Future market trends

- 3.9 Technology and Innovation Landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (HS code) (Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and Environmental Aspects

- 3.12.1 Sustainable Practices

- 3.12.2 Waste Reduction Strategies

- 3.12.3 Energy Efficiency in Production

- 3.12.4 Eco-friendly Initiatives

- 3.13 Carbon Footprint Considerations

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates and Forecast, By Product Type, 2021 – 2034 (USD Billion) (Kilo Tons)

- 5.1 Key trends

- 5.2 Block type

- 5.2.1 Standard blocks

- 5.2.2 Jumbo blocks

- 5.2.3 Lintel blocks

- 5.2.4 U-shaped blocks

- 5.2.5 Others

- 5.3 Size

- 5.3.1 Small (Up to 400mm Length)

- 5.3.2 Medium (400-600mm Length)

- 5.3.3 Large (Above 600mm Length)

Chapter 6 Market Estimates and Forecast, By Raw Material, 2021 – 2034 (USD Billion) (Kilo Tons)

- 6.1 Key trends

- 6.2 Cement

- 6.3 Lime

- 6.4 Fly Ash

- 6.5 Silica sand/quartz sand

- 6.6 Aluminum powder

- 6.7 Gypsum

- 6.8 Others

Chapter 7 Market Estimates and Forecast, By Application, 2021 – 2034 (USD Billion) (Kilo Tons)

- 7.1 Key trends

- 7.2 Wall construction

- 7.2.1 External walls

- 7.2.2 Internal walls

- 7.2.3 Partition walls

- 7.3 Roof insulation

- 7.4 Floor elements

- 7.5 Lintels

- 7.6 Cladding panels

- 7.7 Others

Chapter 8 Market Estimates and Forecast, By End Use Industry, 2021 – 2034 (USD Billion) (Kilo Tons)

- 8.1 Key trends

- 8.2 Residential construction

- 8.2.1 Single-family homes

- 8.2.2 Multi-family buildings

- 8.2.3 Affordable housing projects

- 8.3 Commercial construction

- 8.3.1 Office buildings

- 8.3.2 Retail spaces

- 8.3.3 Hotels and hospitality

- 8.3.4 Educational institutions

- 8.3.5 Healthcare facilities

- 8.4 Industrial construction

- 8.4.1 Manufacturing plants

- 8.4.2 Warehouses

- 8.4.3 Others

- 8.5 Infrastructure development

- 8.6 Others

Chapter 9 Market Estimates and Forecast, By Production Method, 2021 – 2034 (USD Billion) (Kilo Tons)

- 9.1 Key trends

- 9.2 Tilt cake method

- 9.3 Flat cake method

- 9.4 Others

Chapter 10 Market Estimates and Forecast, By Region, 2021 – 2034 (USD Billion) (Kilo Tons)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 Germany

- 10.3.2 UK

- 10.3.3 France

- 10.3.4 Spain

- 10.3.5 Italy

- 10.3.6 Rest of Europe

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 Australia

- 10.4.5 South Korea

- 10.4.6 Rest of Asia Pacific

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.5.3 Rest of Latin America

- 10.6 Middle East and Africa

- 10.6.1 Saudi Arabia

- 10.6.2 South Africa

- 10.6.3 UAE

- 10.6.4 Rest of Middle East and Africa

Chapter 11 Company Profiles

- 11.1 ACICO Industries Company

- 11.2 Aercon AAC

- 11.3 AKG Gazbeton

- 11.4 Biltech Building Elements Limited

- 11.5 Broco Industries

- 11.6 Buildmate Projects Pvt. Ltd

- 11.7 CSR Limited (Hebel)

- 11.8 Eastland Building Materials Co., Ltd.

- 11.9 H+H International A/S

- 11.10 JK Lakshmi Cement Ltd.

- 11.11 Magicrete Building Solutions Pvt. Ltd.

- 11.12 Solbet Sp. z o.o

- 11.13 UAL Industries Limited

- 11.14 Xella Group