|

市场调查报告书

商品编码

1851235

自动化加气混凝土(AAC):市场占有率分析、产业趋势、统计数据、成长预测(2025-2030 年)Autoclaved Aerated Concrete (AAC) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

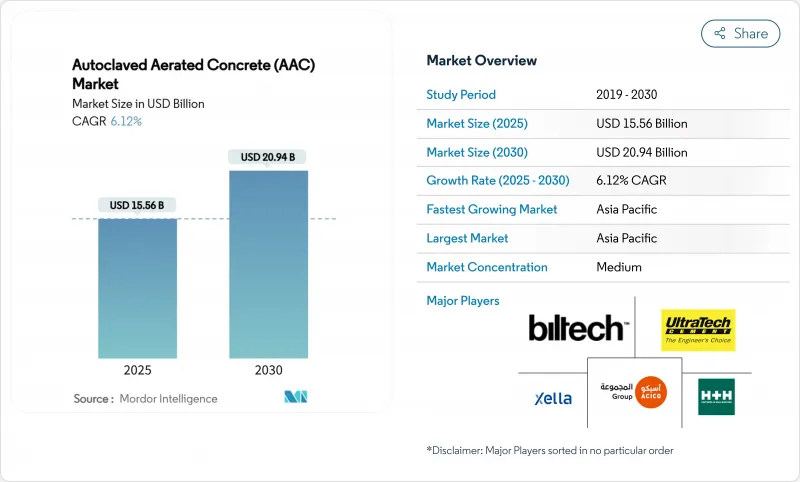

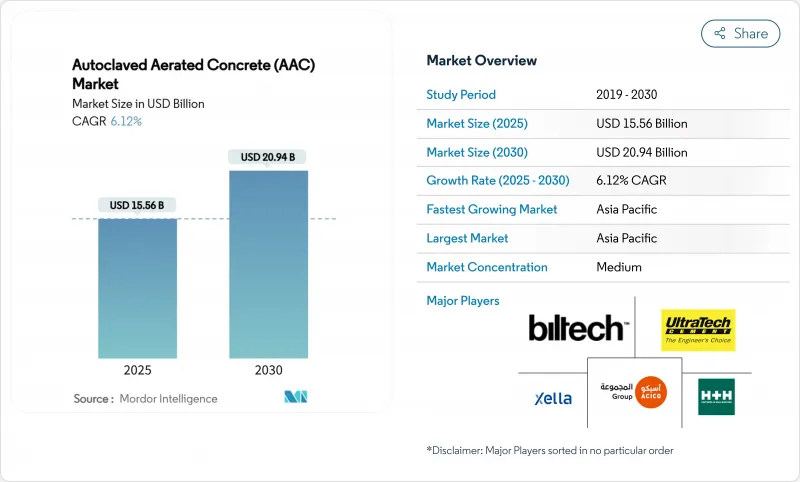

预计到 2025 年,高压釜气混凝土市场规模将达到 155.6 亿美元,到 2030 年将达到 209.4 亿美元,预测期(2025-2030 年)复合年增长率为 6.12%。

绿建筑规范、对抗震结构日益增长的需求以及模组化建筑的快速普及推动了加气混凝土(AAC)的成长,这些因素都凸显了AAC的轻质和节能特性。虽然砌块仍然是传统的砌砖材料,但随着预製构件重新定义计划工期,预製板的应用也日益普及。亚太地区的需求量占全球近一半,这主要得益于都市化和基础建设;而北美和欧洲则面临严格的能源和抗震法规。製造商正在扩大产能并实现工厂自动化,以满足激增的需求、优化成本结构并加强区域供应链。

全球自动化加气混凝土(AAC)市场趋势与洞察

新建和重建工程的需求不断增长

新兴经济体住宅和商业建筑的激增使得轻质材料对于降低地基荷载和缩短计划至关重要。自动加气混凝土(AAC)的重量可减轻30-40%,从而实现薄型化和更快的楼层间移动。印度的房屋建设蓬勃发展,本土製造商BigBloc Construction正在扩大产能,以满足都市区日益增长的房屋批准需求。维修工程也青睐AAC,因为其精准的砌块设计简化了维修,且不会维修建筑结构。其四小时的防火等级提高了商业维修的合规性,而其防霉基质则使其在潮湿气候下更具吸引力。这些因素共同推动了自动加气混凝土市场的持续成长。

严格的绿建筑法规和LEED认证的采用

旨在减少建筑隐含碳排放的政策正在改变世界各地的材料选择。美国政府已拨款1.6亿美元用于永续材料基准测试,明确鼓励采用加气混凝土(AAC)。美国环保署(EPA)的2024年低碳标籤为製造商提供了一条清晰的途径来量化其气候优势,从而提高竞标在公共计划投标中的得分。 H+H美国的目标是到2050年实现净零排放运营,与欧盟的脱碳目标保持一致。加气混凝土厚度为200毫米,R值为1.43,可节省10-20%的营运能耗,并含有回收的飞灰,符合循环经济标准。

与粘土块和混凝土块相比,初始成本较高

由于建筑商优先考虑采购价格而非全生命週期成本节约,人们对加气混凝土(AAC)价格较高的认知阻碍了其广泛应用。然而,在印度主要城市,传统红砖的价格最近已比加气混凝土高出约20%,促使买家转向更轻的替代方案。 2025年关税上调(钢材价格将上涨10-25%,混凝土价格将上涨3-7%)缩小了加气混凝土的成本差距。部分地区工厂数量有限,将导致交付价格上涨15-20%。宣传宣传活动强调加气混凝土可节能30%并减少劳动成本,正逐步改变采购决策,使其更重视整体拥有成本。

细分市场分析

到2024年,砌块将占总销售额的54.78%,这反映了承包商数十年来对其的熟悉程度以及广泛的分销网络。同时,随着建筑商转向预製外墙,到2030年,板材的复合年增长率将达到7.81%。板材的蓬勃发展体现了建设产业日益工业化的趋势。工厂预製的模组运抵现场即可使用,从而减少废弃物并缩短工期。板材因其接缝更少,能够形成更严密的保温层并降低空气渗透损失,因此备受高层住宅建筑的青睐。

在低层住宅领域,砌块结构仍占据主导地位,尤其是在劳动力充足且现场施工技术盛行的市场。然而,板材技术的创新动能丝毫没有减弱的迹象。钢筋混凝土墙板正在承担承重任务,导热係数为0.11 W/mK的屋顶模组满足了零能耗建筑的目标。自动化锯木生产线和机器人搬运技术正在降低板材生产成本,并推动高压釜加气混凝土(AAC)市场从手工砌块铺设转变为工业板材组装。

区域分析

亚太地区预计到2024年将占全球销售额的46.78%,并将在2030年前以7.28%的复合年增长率加速成长。中国和印度是主要的需求驱动力,这主要得益于大型住宅大型企划和国家基础建设规划。政府对低碳建筑规范的诱因进一步推动了加气混凝土(AAC)的普及。日本和韩国因其抗震性能而采用加气混凝土,而澳洲则因其住宅能源标准而维持了稳定的市场占有率。亚太地区原料的高度自给自足以及不断提高的自动化程度,使其成本竞争力得以维持,从而巩固了该地区的市场主导地位。

在北美,美国西部地区日益严格的防火要求以及各气候区对建筑围护结构日益严苛的要求,正推动着自动加气混凝土(AAC)的復兴。美国)的低碳排放标籤促进了公共采购,而加拿大修订后的能源标准也为这一趋势注入了动力。墨西哥的住房奖励策略与区域情况相辅相成,共同推动了自动加气混凝土市场的强劲成长。

欧洲成熟的建筑市场正受惠于严格的碳排放目标:德国和英国正积极维修建筑改造,而北欧市场则朝着近零能耗标准迈进。欧盟绿色交易的融资将支持工厂升级和新生产线的建设。随着物流和资料中心建设的蓬勃发展,对防火隔热外壳的需求日益增长,中东欧地区的建筑市场也因此出现閒置频段成长。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 新建和重建需求不断增长

- 严格的绿建筑法规和LEED认证的采用

- 政府对低碳材料的奖励

- 模组化异地建造的兴起

- 对抗震轻质砖块的需求

- 市场限制

- 与粘土砖和混凝土砖相比,初始成本较高。

- 承重应用中的结构限制

- 铝粉发泡供应及价格波动

- 价值链分析

- 波特五力模型

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模与成长预测

- 依产品类型

- 堵塞

- 控制板

- 楣

- 瓦

- 其他(U型块、楼板/屋顶构件)

- 透过施工方法

- 现场石匠

- 预製件/模组

- 透过使用

- 住宅

- 商业的

- 工业的

- 其他用途(道路、公用设施围护结构、隔音屏障)

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲和纽西兰

- ASEAN

- 亚太其他地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 北欧国家

- 波兰

- 荷兰

- 罗马尼亚

- 捷克共和国

- 其他欧洲地区

- 南美洲

- 巴西

- 阿根廷

- 哥伦比亚

- 其他南美洲

- 中东和非洲

- 沙乌地阿拉伯

- 以色列

- 卡达

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- ACICO Group

- AERCON AAC

- Asahi Kasei Corporation

- Bauroc AS

- Biltech Building Elements Limited

- BirlaNu Limited

- Eastland Building Materials Co., Ltd

- Eco Green

- Ecostone AAC

- H+H UK Limited

- JK Lakshmi Cement Ltd.

- Renacon

- SOLBET

- Starken AAC Sdn Bhd

- STT Turk Gazbeton

- Thomas Armstrong(Concrete Blocks)Ltd

- UAL Industries Limited

- UltraTech Cement Ltd.

- Xella International

第七章 市场机会与未来展望

The Autoclaved Aerated Concrete Market size is estimated at USD 15.56 billion in 2025, and is expected to reach USD 20.94 billion by 2030, at a CAGR of 6.12% during the forecast period (2025-2030).

Growth is fueled by tightening green-building mandates, rising demand for seismic-resilient structures, and the rapid adoption of modular construction, all of which highlight AAC's lightweight, energy-efficient profile. Blocks continue to dominate traditional masonry, yet panels are gaining momentum as prefabrication revamps project timelines. Asia-Pacific commands nearly half of global demand on the back of urbanization and infrastructure outlays, while North America and Europe capitalize on strict energy and seismic codes. Manufacturers are scaling capacity and automating plants to match demand spikes, improve cost structures, and strengthen regional supply chains.

Global Autoclaved Aerated Concrete (AAC) Market Trends and Insights

Growing Demand from New-Build & Renovation Construction

Surging residential and commercial starts in emerging economies have made lightweight materials indispensable because they lower foundation loads and shorten project cycles. AAC cuts dead weight by 30-40%, enabling slimmer foundations and quicker floor-to-floor progress, which is vital in dense city cores. India's housing drive illustrates the trend; domestic producer BigBloc Construction is expanding capacity to keep pace with elevated urban housing approvals. Renovation schemes also prefer AAC because its precision blocks streamline retrofits without reforging structure lines. Four-hour fire ratings boost compliance in commercial refurbishments, and its mold-proof matrix appeals in humid climates. Together, these factors underpin sustained Autoclaved Aerated Concrete market growth.

Stringent Green-Building Codes & LEED Adoption

Policies aimed at curbing embodied carbon are reshaping material selection worldwide. The US government's USD 160 million funding for sustainable-materials benchmarking explicitly encourages AAC uptake. EPA's 2024 low-carbon label gives manufacturers a clear route to quantify climate advantages, enhancing bid scores on public projects. Europe mirrors the shift; H+H UK is targeting net-zero operations by 2050, in line with EU decarbonization goals. With an R-value of 1.43 for 200 mm thickness, AAC delivers 10-20% operational energy savings and incorporates recycled fly ash, satisfying circular-economy criteria.

High Upfront Cost vs. Clay & Concrete Blocks

Perceptions of premium pricing hinder AAC's penetration where contractors prioritize purchase price over life-cycle savings. However, traditional red bricks recently became roughly 20% more expensive than AAC in key Indian metros, nudging buyers toward the lighter alternative. Material-price volatility is reshaping comparisons; 2025 tariffs elevated steel by 10-25% and concrete by 3-7%, eroding AAC's cost differential. Limited local plants in some regions still inflate delivered prices by 15-20%. Education campaigns stressing 30% energy-bill reductions and lower labor needs are gradually reframing procurement decisions around total cost of ownership.

Other drivers and restraints analyzed in the detailed report include:

- Government Incentives for Low-Carbon Materials

- Modular Off-Site Construction Uptake

- Volatile Supply & Price of Aluminum Powder Foaming Agent

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Blocks held 54.78% of 2024 revenue, reflecting decades of contractor familiarity and broad distribution networks. In parallel, panels are charting a 7.81% CAGR through 2030 as builders pivot toward prefabricated envelopes. The panel boom embodies the construction industry's industrialization push: factory-cut modules arrive field-ready, reducing waste and compressing schedules. Developers favor panels in tall residential towers because fewer joints mean tighter thermal envelopes and lower infiltration losses.

The blocks segment remains central to low-rise housing, especially in markets where labor is abundant and on-site techniques dominate. Yet panel innovation is relentless. Reinforced wall panels now handle load-bearing duties, and roof modules with thermal conductivity of 0.11 W/mK meet zero-energy-building targets. Automated saw lines and robotic handling have cut panel-fabrication costs, underpinning an Autoclaved Aerated Concrete market shift from craft-based block laying to industrial panel assembly.

The Autoclaved Aerated Concrete Market Report is Segmented by Product Type (Block, Panel, Lintel, Tile, Others), Construction Method (On-Site Masonry, Prefabricated/Modular), Application (Residential, Commercial, Industrial, Other Applications), and Geography (Asia-Pacific, North America, Europe, South America, Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific held 46.78% of global revenue in 2024 and is accelerating at 7.28% CAGR to 2030. China and India anchor demand, driven by housing mega-projects and state infrastructure pipelines. Government incentives for low-carbon building methods further tip specifications toward AAC. Japan and South Korea adopt AAC for seismic safety, while Australia's home-energy codes sustain steady uptake. High regional self-sufficiency in raw materials and rising automation keep unit costs competitive, cementing Asia-Pacific's dominance.

North America is experiencing a renaissance in AAC usage, propelled by wildfire resilience requirements in the western United States and stricter building envelopes across climate zones. The EPA's low-embodied-carbon label is catalyzing public procurement, and Canada's national energy code revision amplifies momentum. Mexico's housing stimulus complements the regional picture, leading to a robust Autoclaved Aerated Concrete market trajectory.

Europe's mature landscape benefits from stringent carbon targets: Germany and the UK aggressively retrofit buildings, while Nordic markets edge toward near-zero-energy codes. EU Green Deal financing supports plant upgrades and new lines. Central and Eastern Europe provide white-space growth as booming logistics and data-center construction seek fire-safe, thermally efficient shells.

- ACICO Group

- AERCON AAC

- Asahi Kasei Corporation

- Bauroc AS

- Biltech Building Elements Limited

- BirlaNu Limited

- Eastland Building Materials Co., Ltd

- Eco Green

- Ecostone AAC

- H+H UK Limited

- JK Lakshmi Cement Ltd.

- Renacon

- SOLBET

- Starken AAC Sdn Bhd

- STT Turk Gazbeton

- Thomas Armstrong (Concrete Blocks) Ltd

- UAL Industries Limited

- UltraTech Cement Ltd.

- Xella International

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing demand from new-build & renovation construction

- 4.2.2 Stringent green-building codes & LEED adoption

- 4.2.3 Government incentives for low-carbon materials

- 4.2.4 Modular off-site construction uptake

- 4.2.5 Demand for seismic-resilient lightweight blocks

- 4.3 Market Restraints

- 4.3.1 High upfront cost vs. clay & concrete blocks

- 4.3.2 Structural limitations in load-bearing applications

- 4.3.3 Volatile supply & price of aluminum powder foaming agent

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size & Growth Forecasts (Value)

- 5.1 By Product Type

- 5.1.1 Block

- 5.1.2 Panel

- 5.1.3 Lintel

- 5.1.4 Tile

- 5.1.5 Others (U-blocks, floor/roof elements)

- 5.2 By Construction Method

- 5.2.1 On-site masonry

- 5.2.2 Prefabricated/modular

- 5.3 By Application

- 5.3.1 Residential

- 5.3.2 Commercial

- 5.3.3 Industrial

- 5.3.4 Other Applications (roads, utility enclosures, noise-barrier walls)

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 Australia and New Zealand

- 5.4.1.6 ASEAN

- 5.4.1.7 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Spain

- 5.4.3.6 Nordic Countries

- 5.4.3.7 Poland

- 5.4.3.8 Netherlands

- 5.4.3.9 Romania

- 5.4.3.10 Czech Republic

- 5.4.3.11 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Colombia

- 5.4.4.4 Rest of South America

- 5.4.5 Middle East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 Israel

- 5.4.5.3 Qatar

- 5.4.5.4 South Africa

- 5.4.5.5 Rest of Middle East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.4.1 ACICO Group

- 6.4.2 AERCON AAC

- 6.4.3 Asahi Kasei Corporation

- 6.4.4 Bauroc AS

- 6.4.5 Biltech Building Elements Limited

- 6.4.6 BirlaNu Limited

- 6.4.7 Eastland Building Materials Co., Ltd

- 6.4.8 Eco Green

- 6.4.9 Ecostone AAC

- 6.4.10 H+H UK Limited

- 6.4.11 JK Lakshmi Cement Ltd.

- 6.4.12 Renacon

- 6.4.13 SOLBET

- 6.4.14 Starken AAC Sdn Bhd

- 6.4.15 STT Turk Gazbeton

- 6.4.16 Thomas Armstrong (Concrete Blocks) Ltd

- 6.4.17 UAL Industries Limited

- 6.4.18 UltraTech Cement Ltd.

- 6.4.19 Xella International

7 Market Opportunities & Future Outlook

- 7.1 White-space & unmet-need assessment