|

市场调查报告书

商品编码

1766222

塑胶加工机械市场机会、成长动力、产业趋势分析及2025-2034年预测Plastic Processing Machinery Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

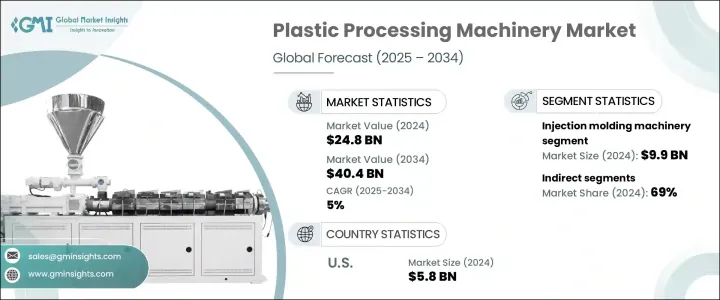

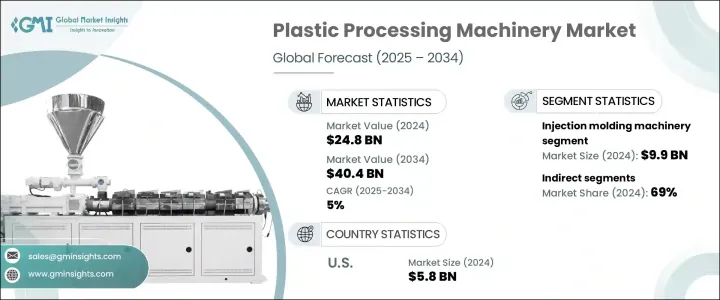

2024年,全球塑胶加工机械市场规模达248亿美元,预计到2034年将以5%的复合年增长率成长,达到404亿美元。汽车、包装、建筑和消费品等行业的扩张推动了这一成长。製造商越来越需要生产更轻、更永续、更客製化的塑胶包装,这需要先进的机械设备。此外,汽车产业越来越依赖工程塑胶来减轻车辆重量、提高燃油效率并减少排放。都市化进程加快和可支配收入的提高也推动了住房、电子产品和食品包装领域塑胶产品的消费。

为了应对这些趋势,塑胶加工机械市场正在不断发展,更加重视自动化、智慧製造和永续性。企业越来越重视节能环保的生产方式,对能够快速适应新模具、新材料和新产量的机械的需求也日益增长。随着消费者对个人化产品的需求日益增加,市场正转向能够灵活处理各种聚合物并适应不同生产规模的设备。随着技术的快速进步,企业必须满足各行各业不断变化的需求,这些产业需要创新和多样化的产品系列。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 248亿美元 |

| 预测值 | 404亿美元 |

| 复合年增长率 | 5% |

注塑机械市场规模最大,2024 年市场价值达 99 亿美元,预计 2025 年至 2034 年的复合年增长率将达到 4.8%。注塑机械因其多功能性以及大量生产高品质精密塑胶零件的能力,在汽车、包装、电子、医疗设备和消费品等行业需求旺盛。对于生产具有复杂几何形状的精密零件而言,这项技术仍然是最具成本效益和可扩展性的选择。

间接分销市场在2024年占69%,预计2025年至2034年期间将维持4.8%的复合年增长率。此配销通路在新兴市场和小型企业中发挥关键作用,提供物流支援、处理进口法规以及提供售后服务。在亚洲、拉丁美洲和非洲部分地区等地区,间接通路对于市场渗透至关重要。

2024年,美国塑胶加工机械市场规模达58亿美元,预计2025年至2034年期间的复合年增长率将达到5.5%,这主要得益于汽车、医疗保健、航太和消费品等关键产业的强劲需求。受回流计划和政府激励措施推动,美国国内製造业成长,这推动了这一增长。先进永续技术的采用,以及国内生产的復苏,正在推动对轻量化、高性价比塑胶零件的需求。

全球塑胶加工机械市场的主要参与者包括住友重工、恩格尔奥地利、克劳斯玛菲集团、阿博格、赫斯基注塑系统、日本製钢所、科倍隆、莱芬豪森集团、巴顿菲尔辛辛那提、戴维斯标准、震雄集团、米拉克龙、日精树脂工业、海天国际控股和威猛巴顿菲尔。为加强影响力和市场地位,塑胶加工机械市场的企业正专注于多项策略性措施。这些措施包括投资研发,以创造更节能、更环保、性能更高的机械。他们也正在扩大产品组合,以满足新兴产业和客製化解决方案的需求。此外,企业正在与经销商和经销商建立策略合作伙伴关係,以扩大业务范围,尤其是在本地支援至关重要的新兴市场。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 供应商概况

- 利润率

- 每个阶段的增值

- 影响价值链的因素

- 中断

- 产业衝击力

- 成长动力

- 产业陷阱与挑战

- 机会

- 成长潜力分析

- 未来市场趋势

- 科技与创新格局

- 当前的技术趋势

- 新兴技术

- 价格趋势

- 按地区

- 依产品类型

- 监理框架

- 标准和认证

- 环境法规

- 进出口法规

- 波特五力分析

- PESTEL分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 按地区

- 公司矩阵分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 关键进展

- 併购

- 伙伴关係与合作

- 新产品发布

- 扩张计划

第五章:市场估计与预测:依类型,2021-2034

- 主要趋势

- 注塑机械

- 吹塑机械

- 挤压机械

- 热成型机械

- 3D塑胶印表机

- 其他的

第六章:市场估计与预测:依塑胶类型,2021-2034

- 主要趋势

- 商品塑料

- 工程塑料

- 高性能塑料

- 辅助建筑空间

- 再生塑胶

- 其他(可生物降解塑胶等)

第七章:市场估计与预测:按运营,2021-2034

- 主要趋势

- 手动的

- 半自动

- 自动的

第八章:市场估计与预测:按最终用途产业,2021-2034 年

- 主要趋势

- 包装

- 消费品

- 建造

- 汽车

- 卫生保健

- 电子产品

- 其他(航太等)

第九章:市场估计与预测:按配销通路,2021-2034

- 主要趋势

- 直销

- 间接销售

第十章:市场估计与预测:按地区,2021-2034

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- MEA

- 阿联酋

- 沙乌地阿拉伯

- 南非

第 11 章:公司简介

- ARBURG

- Battenfeld-Cincinnati

- Chen Hsong Holdings Limited

- Coperion

- Davis-Standard

- ENGEL AUSTRIA

- Haitian International Holdings

- Husky Injection Molding Systems

- KraussMaffei Group

- Milacron

- Nissei Plastic Industrial

- Reifenhauser Group

- Sumitomo Heavy Industries

- The Japan Steel Works

- WITTMANN BATTENFELD

The Global Plastic Processing Machinery Market was valued at USD 24.8 billion in 2024 and is estimated to grow at a CAGR of 5% to reach USD 40.4 billion by 2034. The expansion of industries like automotive, packaging, construction, and consumer goods is driving this growth. Manufacturers are increasingly required to produce lighter, more sustainable, and customized plastic packaging, which demands advanced machinery. Additionally, the automotive sector is increasingly relying on engineered plastics to reduce vehicle weight, improve fuel efficiency, and decrease emissions. Growing urbanization and rising disposable incomes are also increasing plastic product consumption in housing, electronics, and food packaging.

In response to these trends, the plastic processing machinery market is evolving with a greater focus on automation, smart manufacturing, and sustainability. Companies are prioritizing energy-efficient and eco-friendly production methods, and there's rising demand for machinery that can quickly adapt to new molds, materials, and production volumes. As consumers demand more personalized products, the market is shifting towards equipment that offers flexibility and can handle a wide variety of polymers at different production scales. With rapid technological advances, businesses must meet the changing needs of industries that require innovation and diverse product ranges.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $24.8 Billion |

| Forecast Value | $40.4 Billion |

| CAGR | 5% |

The injection molding machinery segment, valued at USD 9.9 billion in 2024, is the largest and is anticipated to grow at a CAGR of 4.8% from 2025 to 2034. Injection molding machinery is in high demand across industries like automotive, packaging, electronics, medical devices, and consumer goods due to its versatility and ability to mass-produce high-quality, precise plastic components. This technology remains the most cost-effective and scalable option for producing intricate parts with complex geometries.

The indirect distribution segment represented a 69% share in 2024 and is expected to maintain a CAGR of 4.8% from 2025 to 2034. This distribution channel plays a critical role in emerging markets and smaller enterprises, providing logistical support, handling import regulations, and offering after-sales service. In regions like Asia, Latin America, and parts of Africa, indirect channels are vital for market penetration.

United States Plastic Processing Machinery Market was valued at USD 5.8 billion in 2024 and is expected to grow at a CAGR of 5.5% from 2025 to 2034, driven by strong demand across key sectors like automotive, healthcare, aerospace, and consumer goods. Increased domestic manufacturing due to reshoring initiatives and government incentives are fueling this growth. The adoption of advanced and sustainable technologies, along with the resurgence of domestic production, is boosting demand for lightweight and cost-effective plastic components.

Key players in the Global Plastic Processing Machinery Market include Sumitomo Heavy Industries, ENGEL AUSTRIA, KraussMaffei Group, ARBURG, Husky Injection Molding Systems, The Japan Steel Works, Coperion, Reifenhauser Group, Battenfeld-Cincinnati, Davis-Standard, Chen Hsong Holdings Limited, Milacron, Nissei Plastic Industrial, Haitian International Holdings, and WITTMANN BATTENFELD. To strengthen their presence and market position, companies in the plastic processing machinery market are focusing on several strategic initiatives. These include investing in research and development to create more energy-efficient, eco-friendly, and high-performance machinery. They are also expanding their product portfolios to cater to emerging industries and meet the demand for customized solutions. Furthermore, companies are forming strategic partnerships with distributors and resellers to expand their reach, especially in emerging markets where local support is crucial.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Type

- 2.2.3 Plastic type

- 2.2.4 End use

- 2.2.5 Distribution channel

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls & challenges

- 3.2.3 Opportunities

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and Innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By product type

- 3.7 Regulatory framework

- 3.7.1 Standards and certifications

- 3.7.2 Environmental regulations

- 3.7.3 Import export regulations

- 3.8 Porter's five forces analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East and Africa

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates & Forecast, By Type, 2021-2034 (USD Billion) (Thousand Units)

- 5.1 Key trends

- 5.2 Injection molding machinery

- 5.3 Blow molding machinery

- 5.4 Extrusion machinery

- 5.5 Thermoforming machinery

- 5.6 3d plastic printers

- 5.7 Others

Chapter 6 Market Estimates & Forecast, By Plastic Type, 2021-2034 (USD Billion) (Thousand Units)

- 6.1 Key trends

- 6.2 Commodity plastics

- 6.3 Engineering plastics

- 6.4 High-performance plastics

- 6.5 Auxiliary building spaces

- 6.6 Recycled plastics

- 6.7 Others (biodegradable plastics, etc.)

Chapter 7 Market Estimates & Forecast, By Operation, 2021-2034 (USD Billion) (Thousand Units)

- 7.1 Key trends

- 7.2 Manual

- 7.3 Semi-Automatic

- 7.4 Automatic

Chapter 8 Market Estimates & Forecast, By End Use Industry, 2021-2034 (USD Billion) (Thousand Units)

- 8.1 Key trends

- 8.2 Packaging

- 8.3 Consumer products

- 8.4 Construction

- 8.5 Automotive

- 8.6 Healthcare

- 8.7 Electronics

- 8.8 Others (aerospace, etc.)

Chapter 9 Market Estimates & Forecast, By Distribution Channel, 2021-2034 (USD Billion) (Thousand Units)

- 9.1 Key trends

- 9.2 Direct sales

- 9.3 Indirect sales

Chapter 10 Market Estimates & Forecast, By Region, 2021-2034 (USD Billion) (Thousand Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 UK

- 10.3.2 Germany

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.3.6 Russia

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 South Korea

- 10.4.5 Australia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.6 MEA

- 10.6.1 UAE

- 10.6.2 Saudi Arabia

- 10.6.3 South Africa

Chapter 11 Company Profiles

- 11.1 ARBURG

- 11.2 Battenfeld-Cincinnati

- 11.3 Chen Hsong Holdings Limited

- 11.4 Coperion

- 11.5 Davis-Standard

- 11.6 ENGEL AUSTRIA

- 11.7 Haitian International Holdings

- 11.8 Husky Injection Molding Systems

- 11.9 KraussMaffei Group

- 11.10 Milacron

- 11.11 Nissei Plastic Industrial

- 11.12 Reifenhauser Group

- 11.13 Sumitomo Heavy Industries

- 11.14 The Japan Steel Works

- 11.15 WITTMANN BATTENFELD