|

市场调查报告书

商品编码

1773391

结构黏合剂市场机会、成长动力、产业趋势分析及 2025 - 2034 年预测Structural Bonding Agents Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

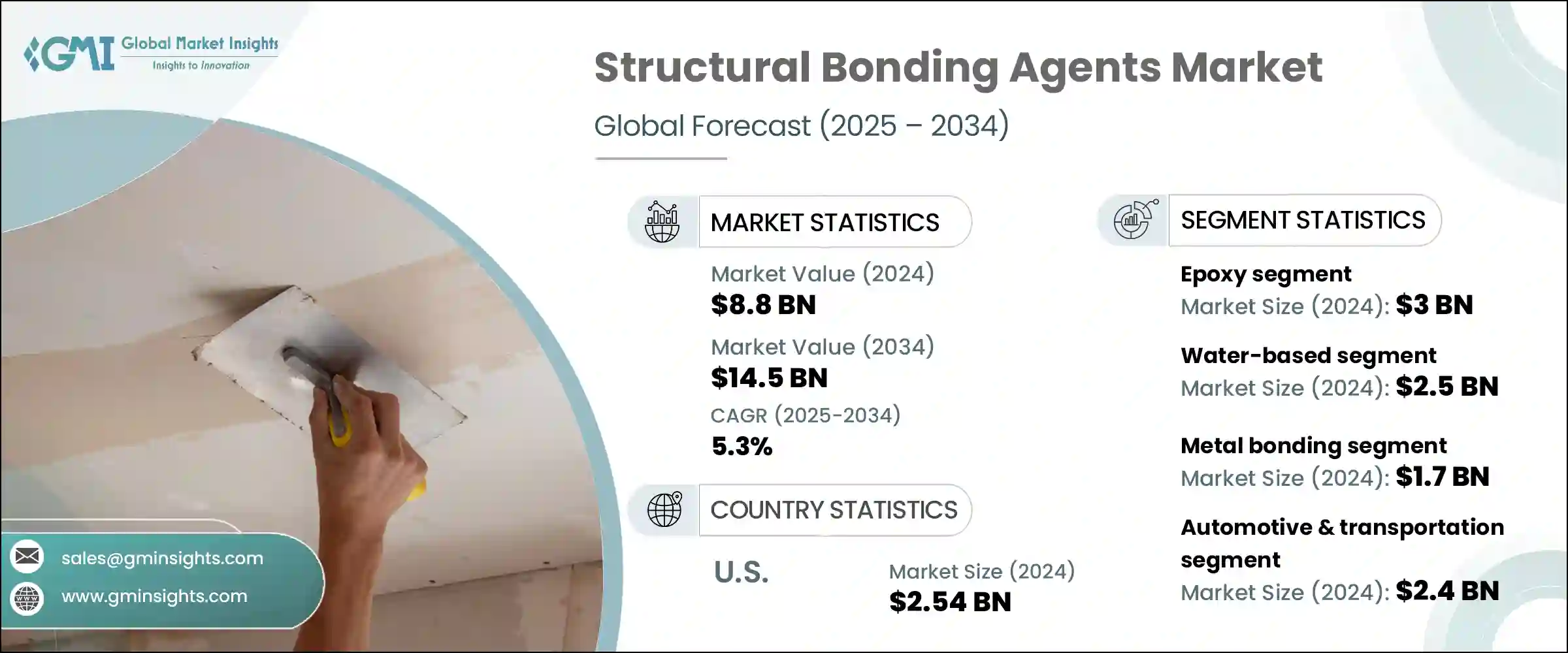

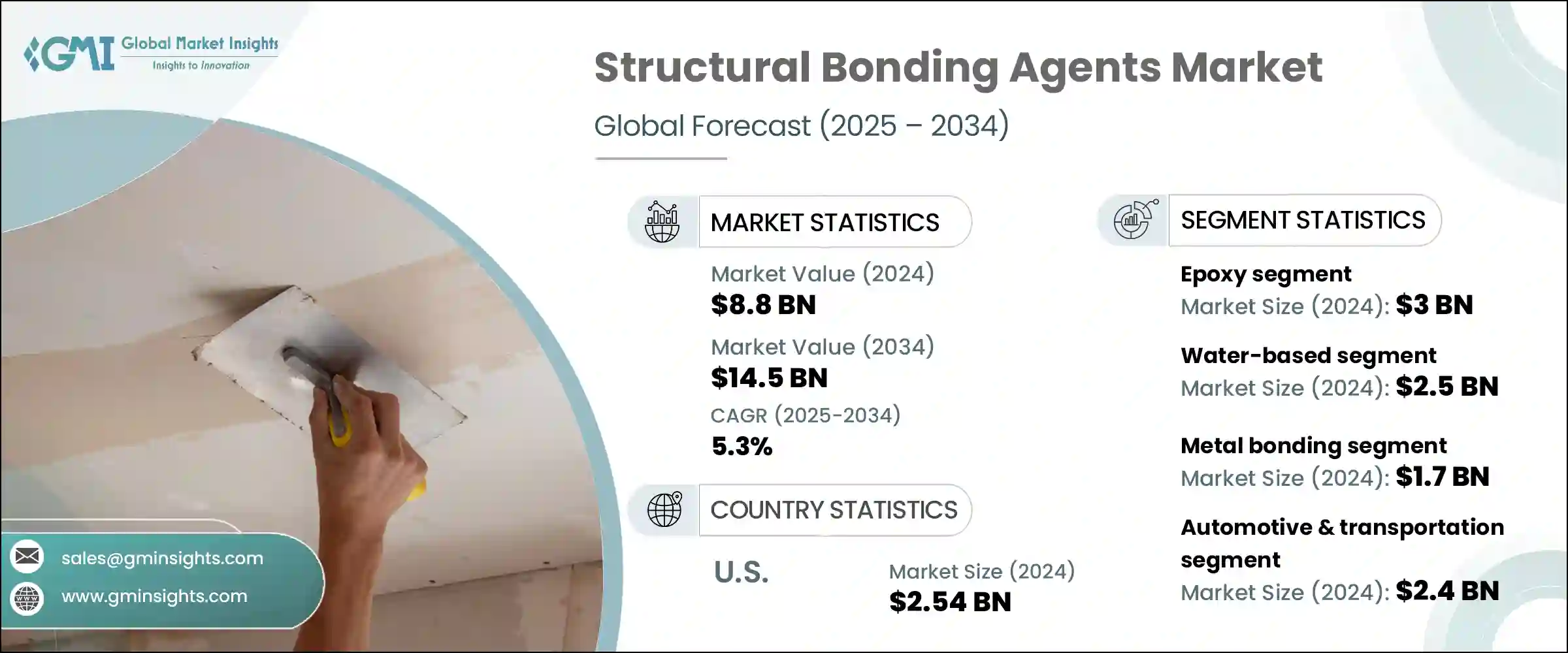

2024年,全球结构黏合剂市场规模达88亿美元,预计到2034年将以5.3%的复合年增长率成长,达到145亿美元。市场扩张的驱动因素有很多,其中最显着的是汽车和航太工业对轻量化材料日益增长的需求。这些行业越来越多地使用黏合剂来支持更轻的复合材料,这有助于在不牺牲结构强度的情况下提高燃油效率、减少排放。

复合材料凭藉其优异的强度重量比和耐用性,在各种应用中的日益普及也推动了市场的成长。结构性黏合剂在提升这些材料在严苛环境下的性能和接受度方面发挥着至关重要的作用。此外,全球正在进行的建设项目也显着促进了需求成长,因为黏合剂在负载分布、美观度和抗环境压力方面均优于传统的机械紧固件。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 88亿美元 |

| 预测值 | 145亿美元 |

| 复合年增长率 | 5.3% |

新兴趋势也指向永续性,製造商专注于环保、低VOC和无溶剂的黏合剂,以满足更严格的法规和消费者偏好。这种转变不仅是出于环保合规的考虑,也是出于对更健康的室内空气品质和减少生态影响日益增长的需求。随着绿建筑认证和排放标准日益严格,企业正在积极改进其黏合剂配方,以符合不断变化的全球基准。市场对水性和生物基结构黏合剂的偏好日益增长,尤其是在建筑、包装和运输等可持续性已成为核心设计考虑因素的行业。

2024年,环氧树脂市场的规模达30亿美元,预计到2034年将以5%的复合年增长率成长。环氧树脂胶黏剂因其在航太、汽车、建筑和电子等行业的广泛应用而引领市场。这类胶合剂具有优异的机械强度、耐化学性,以及黏合金属和轻质复合材料的能力,使其成为高成长产业中不可或缺的材料。此外,它们能够有效分配负载,并提供美观的饰面,这也进一步增加了市场需求。

2024年,水性结构胶合剂市场规模达25亿美元,预计2034年将以5.8%的复合年增长率成长。在严格的环保法规和低VOC配方趋势的推动下,水性胶合剂正日益受到青睐,尤其是在建筑和包装行业。这些胶合剂提供了更安全、更环保的替代方案,且不会影响黏合强度或性能。

2024年,美国结构黏合剂市场规模达25.4亿美元,预计2025年至2034年复合年增长率为4.8%。美国市场的成长主要得益于航太和汽车产业对高性能、轻量化黏合解决方案的需求,以及对基础设施和建筑项目的大量投资。黏合剂技术的创新和政府的利多政策将继续推动市场扩张。

全球结构黏合剂市场的领导企业,例如阿科玛集团、汉高股份公司、3M公司、西卡股份公司和HB Fuller公司,正在多个策略层面积极竞争。结构黏合剂市场的公司透过专注于创新和扩展针对新兴产业需求的产品组合(尤其是轻质环保黏合剂)来巩固其地位。他们投入大量资金进行研发,以开发符合环境法规并提高性能的配方。与汽车、航太和建筑领域的主要参与者建立策略合作与伙伴关係有助于扩大市场范围和信誉。此外,向快速成长地区的地理扩张也支持了收入成长。

目录

第一章:方法论

- 市场范围和定义

- 研究设计

- 研究方法

- 资料收集方法

- 资料探勘来源

- 全球的

- 地区/国家

- 基础估算与计算

- 基准年计算

- 市场评估的主要趋势

- 初步研究和验证

- 主要来源

- 预测模型

- 研究假设和局限性

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 供应商概况

- 利润率

- 每个阶段的增值

- 影响价值链的因素

- 中断

- 产业衝击力

- 成长动力

- 产业陷阱与挑战

- 市场机会

- 成长潜力分析

- 监管格局

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 波特的分析

- PESTEL分析

- 价格趋势

- 按地区

- 按产品

- 未来市场趋势

- 科技与创新格局

- 当前的技术趋势

- 新兴技术

- 专利态势

- 贸易统计(HS编码)(註:仅提供重点国家的贸易统计资料)

- 主要进口国

- 主要出口国

- 永续性和环境方面

- 永续实践

- 减少废弃物的策略

- 生产中的能源效率

- 环保倡议

- 碳足迹考量

第四章:竞争格局

- 介绍

- 公司市占率分析

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- MEA

- 按地区

- 公司矩阵分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 关键进展

- 併购

- 伙伴关係与合作

- 新产品发布

- 扩张计划

第五章:市场估计与预测:依产品类型,2021-2034

- 主要趋势

- 环氧树脂

- 单组分环氧树脂

- 双组分环氧树脂

- 改质环氧树脂

- 聚氨酯

- 单组分聚氨酯

- 双组分聚氨酯

- 丙烯酸纤维

- 氰基丙烯酸酯

- 改性丙烯酸酯

- 甲基丙烯酸甲酯(MMA)

- 硅酮

- 其他的

第六章:市场估计与预测:依技术,2021-2034 年

- 主要趋势

- 水性

- 溶剂型

- 热熔胶

- 反应式

- 其他的

第七章:市场估计与预测:按应用,2021-2034

- 主要趋势

- 金属黏合

- 钢

- 铝

- 其他金属

- 复合材料黏接

- 碳纤维复合材料

- 玻璃纤维复合材料

- 其他复合材料

- 塑胶黏接

- 热塑性塑料

- 热固性塑料

- 木材黏合

- 玻璃黏合

- 混凝土和石材黏合

- 多材料黏合

- 其他的

第八章:市场估计与预测:按最终用途产业,2021-2034 年

- 主要趋势

- 汽车与运输

- 搭乘用车

- 商用车

- 电动车

- 轨

- 其他的

- 航太

- 商用飞机

- 军用机

- 通用航空

- 空间应用

- 建筑与施工

- 住宅

- 商业的

- 工业的

- 基础设施

- 风能

- 陆域风电

- 离岸风电

- 海洋

- 造船

- 船舶建造

- 海上结构

- 电子产品

- 消费性电子产品

- 工业电子

- 医疗的

- 工业装配

- 其他的

第九章:市场估计与预测:按地区,2021-2034

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 欧洲其他地区

- 亚太地区

- 中国

- 印度

- 日本

- 澳洲

- 韩国

- 亚太其他地区

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 拉丁美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 阿联酋

- 中东和非洲其他地区

第十章:公司简介

- Henkel AG & Co. KGaA

- 3M Company

- Sika AG

- HB Fuller Company

- Huntsman Corporation

- Arkema Group

- Lord Corporation (Parker Hannifin Corporation)

- Ashland Global Holdings Inc.

- Illinois Tool Works Inc.

- Dow Inc.

- Mapei SpA

- RPM International Inc.

- Permabond LLC

- Master Bond Inc.

- Dymax Corporation

- Jowat SE

- Delo Industrial Adhesives

- Pidilite Industries Ltd.

- Parson Adhesives, Inc.

- Hernon Manufacturing, Inc.

The Global Structural Bonding Agents Market was valued at USD 8.8 billion in 2024 and is estimated to grow at a CAGR of 5.3% to reach USD 14.5 billion by 2034. The market expansion is driven by several factors, most notably the rising demand for lightweight materials in the automotive and aerospace industries. These sectors are increasingly incorporating bonding agents to support lighter composite materials, which help boost fuel efficiency and reduce emissions without sacrificing structural strength.

The growing adoption of composite materials across various applications also fuels market growth, thanks to their superior strength-to-weight ratio and durability. Structural bonding agents play a crucial role by enhancing the performance and acceptance of these materials in challenging environments. Additionally, ongoing global construction projects contribute significantly to demand, as bonding agents offer advantages over traditional mechanical fasteners in terms of load distribution, aesthetics, and resistance to environmental stressors.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $8.8 Billion |

| Forecast Value | $14.5 Billion |

| CAGR | 5.3% |

Emerging trends also point toward sustainability, with manufacturers focusing on eco-friendly, low-VOC, and solvent-free adhesives to meet stricter regulations and consumer preferences. This shift is not only driven by environmental compliance but also by the increasing demand for healthier indoor air quality and reduced ecological impact. As green building certifications and emissions standards become more stringent, companies are proactively reformulating their bonding agents to align with evolving global benchmarks. The market is witnessing a growing preference for water-based and bio-based structural adhesives, particularly in sectors like construction, packaging, and transportation, where sustainability has become a core design consideration.

The epoxy segment held a market value of USD 3 billion in 2024 and is expected to grow at a 5% CAGR through 2034. Epoxy adhesives lead the market due to their wide-ranging applications in industries like aerospace, automotive, construction, and electronics. These adhesives provide excellent mechanical strength, chemical resistance, and the ability to bond both metals and lightweight composites, making them indispensable in high-growth sectors. Their ability to distribute loads effectively and deliver visually appealing finishes adds to their demand.

The water-based structural bonding agents segment accounted for USD 2.5 billion in 2024 and is anticipated to grow at a CAGR of 5.8% through 2034. Driven by stringent environmental regulations and a shift toward low-VOC formulations, water-borne adhesives are gaining traction, especially in the construction and packaging industries. These adhesives provide a safer, more environmentally friendly alternative without compromising bond strength or performance.

U.S. Structural Bonding Agents Market was valued at USD 2.54 billion in 2024 and is forecasted to grow at a CAGR of 4.8% from 2025 to 2034. Growth in the U.S. is largely fueled by the demand for high-performance, lightweight bonding solutions in the aerospace and automotive sectors, alongside substantial investments in infrastructure and construction projects. Innovation in adhesive technology and favorable government policies continue to bolster market expansion.

Leading players in the Global Structural Bonding Agents Market, such as Arkema Group, Henkel AG & Co. KGaA, 3M Company, Sika AG, and H.B. Fuller Company, are actively competing across several strategic dimensions. Companies in the structural bonding agents market strengthen their position by focusing on innovation and expanding product portfolios tailored to emerging industry needs, particularly lightweight and eco-friendly adhesives. They invest heavily in R&D to develop formulations that comply with environmental regulations while enhancing performance. Strategic collaborations and partnerships with key players in the automotive, aerospace, and construction sectors help expand market reach and credibility. Additionally, geographic expansion into fast-growing regions supports revenue growth.

Table of Contents

Chapter 1 Methodology

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Product Type

- 2.2.3 Technology

- 2.2.4 Application

- 2.2.5 End Use Industry

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.6.1 Technology and Innovation landscape

- 3.6.2 Current technological trends

- 3.6.3 Emerging technologies

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By product

- 3.8 Future market trends

- 3.9 Technology and Innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (HS code) (Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly initiatives

- 3.13 Carbon footprint considerations

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates & Forecast, By Product Type, 2021-2034 (USD Billion) (Kilo Tons)

- 5.1 Key trends

- 5.2 Epoxy

- 5.2.1 One-component epoxy

- 5.2.2 Two-component epoxy

- 5.2.3 Modified epoxy

- 5.3 Polyurethane

- 5.3.1 One-component polyurethane

- 5.3.2 Two-component polyurethane

- 5.4 Acrylic

- 5.4.1 Cyanoacrylates

- 5.4.2 Modified acrylics

- 5.5 Methyl methacrylate (MMA)

- 5.6 Silicone

- 5.7 Others

Chapter 6 Market Estimates & Forecast, By Technology, 2021-2034 (USD Billion) (Kilo Tons)

- 6.1 Key trends

- 6.2 Water-based

- 6.3 Solvent-based

- 6.4 Hot melt

- 6.5 Reactive

- 6.6 Others

Chapter 7 Market Estimates & Forecast, By Application, 2021-2034 (USD Billion) (Kilo Tons)

- 7.1 Key trends

- 7.2 Metal Bonding

- 7.2.1 Steel

- 7.2.2 Aluminum

- 7.2.3 Other metals

- 7.3 Composite bonding

- 7.3.1 Carbon fiber composites

- 7.3.2 Glass fiber composites

- 7.3.3 Other composites

- 7.4 Plastic bonding

- 7.4.1 Thermoplastics

- 7.4.2 Thermosets

- 7.5 Wood bonding

- 7.6 Glass bonding

- 7.7 Concrete and stone bonding

- 7.8 Multi-material bonding

- 7.9 Others

Chapter 8 Market Estimates & Forecast, By End Use Industry, 2021-2034 (USD Billion) (Kilo Tons)

- 8.1 Key trends

- 8.2 Automotive & transportation

- 8.2.1 Passenger vehicles

- 8.2.2 Commercial vehicles

- 8.2.3 Electric vehicles

- 8.2.4 Rail

- 8.2.5 Others

- 8.3 Aerospace

- 8.3.1 Commercial aircraft

- 8.3.2 Military aircraft

- 8.3.3 General aviation

- 8.3.4 Space applications

- 8.4 Building & construction

- 8.4.1 Residential

- 8.4.2 Commercial

- 8.4.3 Industrial

- 8.4.4 Infrastructure

- 8.5 Wind Energy

- 8.5.1 Onshore wind

- 8.5.2 Offshore wind

- 8.6 Marine

- 8.6.1 Shipbuilding

- 8.6.2 Boat Building

- 8.6.3 Offshore structures

- 8.7 Electronics

- 8.7.1 Consumer electronics

- 8.7.2 Industrial electronics

- 8.8 Medical

- 8.9 Industrial assembly

- 8.10 Others

Chapter 9 Market Estimates & Forecast, By Region, 2021-2034 (USD Billion) (Kilo Tons)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 Germany

- 9.3.2 UK

- 9.3.3 France

- 9.3.4 Italy

- 9.3.5 Spain

- 9.3.6 Rest of Europe

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 Australia

- 9.4.5 South Korea

- 9.4.6 Rest of Asia Pacific

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.5.4 Rest of Latin America

- 9.6 Middle East & Africa

- 9.6.1 Saudi Arabia

- 9.6.2 South Africa

- 9.6.3 UAE

- 9.6.4 Rest of Middle East & Africa

Chapter 10 Company Profiles

- 10.1 Henkel AG & Co. KGaA

- 10.2 3M Company

- 10.3 Sika AG

- 10.4 H.B. Fuller Company

- 10.5 Huntsman Corporation

- 10.6 Arkema Group

- 10.7 Lord Corporation (Parker Hannifin Corporation)

- 10.8 Ashland Global Holdings Inc.

- 10.9 Illinois Tool Works Inc.

- 10.10 Dow Inc.

- 10.11 Mapei S.p.A.

- 10.12 RPM International Inc.

- 10.13 Permabond LLC

- 10.14 Master Bond Inc.

- 10.15 Dymax Corporation

- 10.16 Jowat SE

- 10.17 Delo Industrial Adhesives

- 10.18 Pidilite Industries Ltd.

- 10.19 Parson Adhesives, Inc.

- 10.20 Hernon Manufacturing, Inc.