|

市场调查报告书

商品编码

1773481

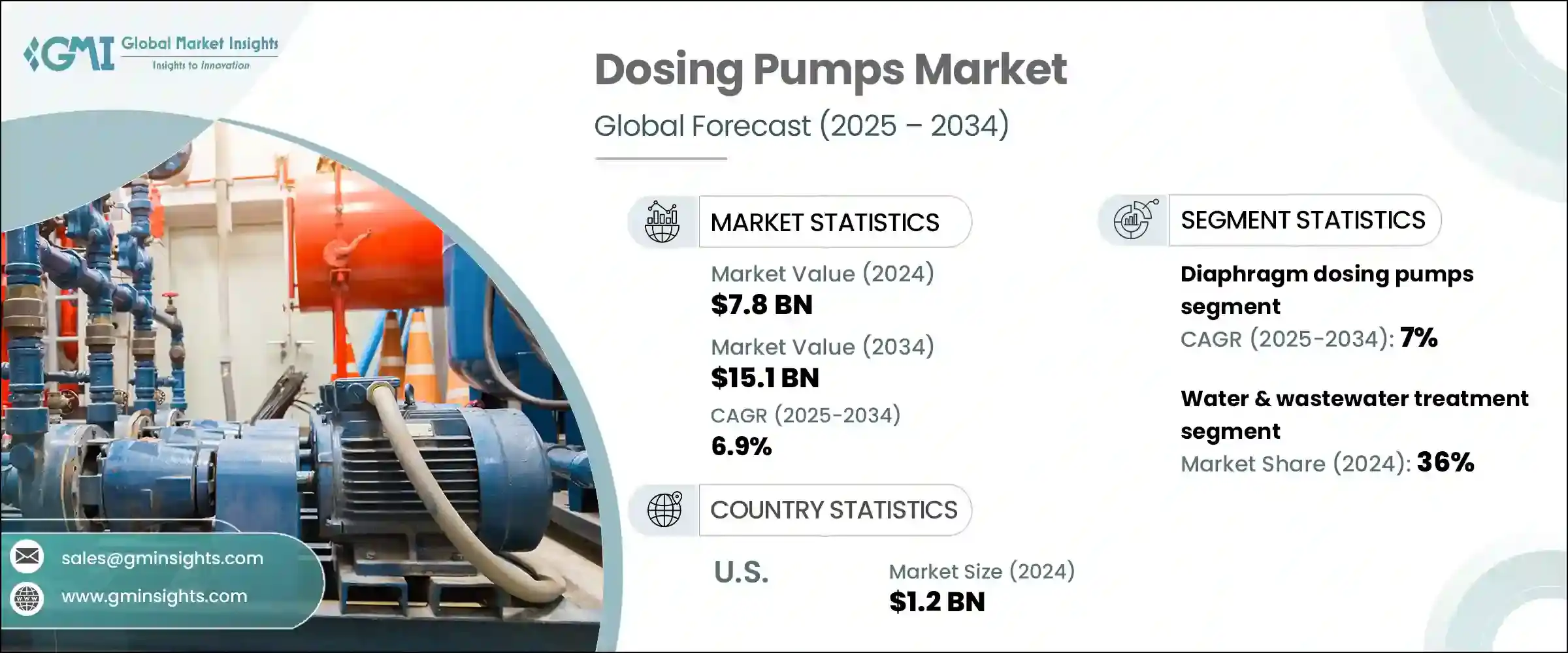

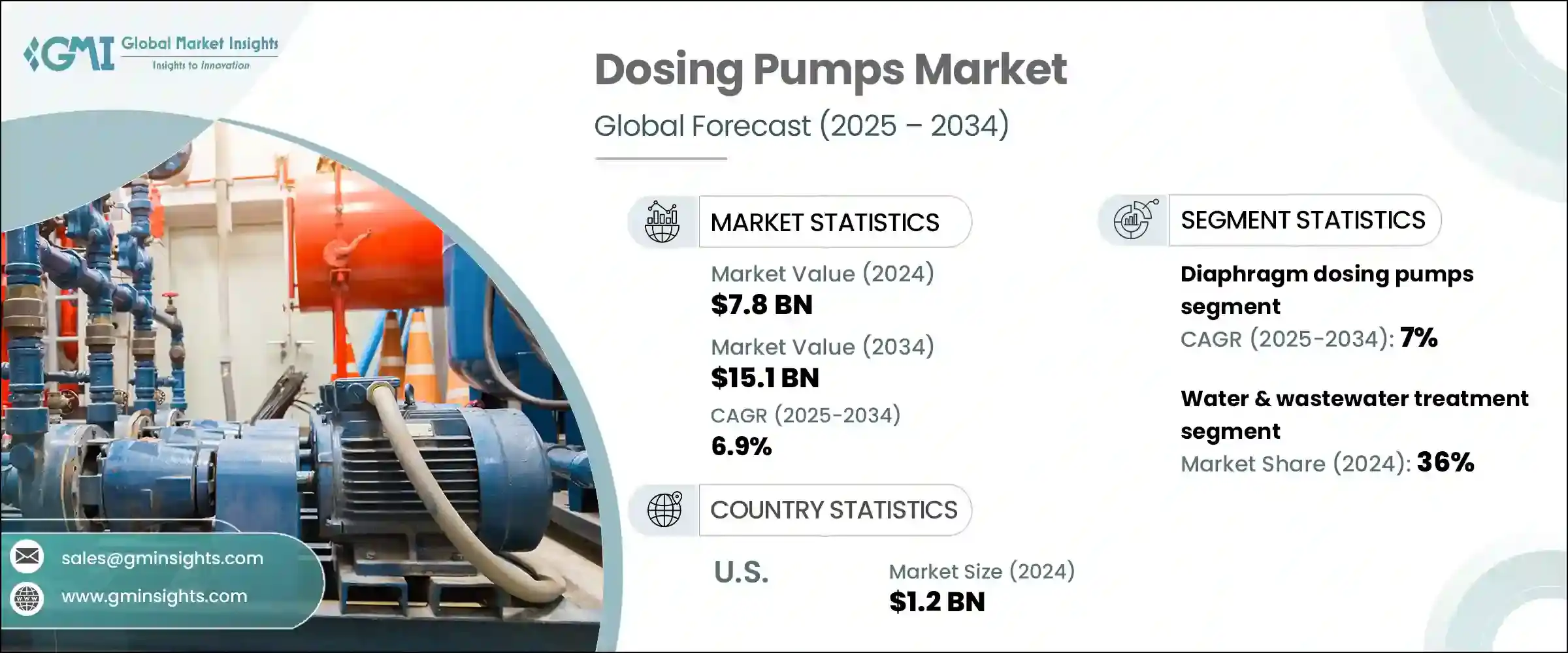

计量帮浦市场机会、成长动力、产业趋势分析及 2025 - 2034 年预测Dosing Pumps Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

2024年全球计量帮浦市场规模达78亿美元,预计2034年将以6.9%的复合年增长率成长,达到151亿美元。数位控制器的整合是关键的成长动力,它能够实现精确的计量、即时监控和自动回馈控制。市政和工业废水处理设施越来越依赖氯、臭氧和紫外线加药系统,而城市中心则部署了本地净水装置。在食品和饮料行业,计量泵对于防腐剂、调味剂和着色剂的精准注入至关重要。石油和天然气行业对用于腐蚀抑制剂的高压泵、用于平台和浮式生产储油船(FPSO)的耐盐防爆系统以及海底管道中甲醇和乙二醇注入系统的需求激增。自动校准和支援物联网的远端连接正在进一步提高效率和预测性维护。

用于处理高黏度、腐蚀性或磨蚀性化学品的计量帮浦技术的持续创新,正在显着拓展各行各业的市场机会。增强聚合物和耐腐蚀合金等先进材料如今正融入泵浦的构造中,以提高其在极端工况下的耐用性和使用寿命。此外,增强的密封机制、变速驱动相容性以及精确的流量控制功能使这些泵浦能够在采矿、废水处理、纸浆和造纸以及石油和天然气等高挑战性应用中高效运作。随着各行各业寻求以最少的停机时间和维护成本实现复杂化学品计量流程的自动化,对这些坚固耐用、高性能计量系统的需求正在稳步增长,为增长和产品多样化开闢了新的途径。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 78亿美元 |

| 预测值 | 151亿美元 |

| 复合年增长率 | 6.9% |

预计到2034年,蠕动计量帮浦市场规模将达到25亿美元,这得益于对卫生流体处理和无污染操作有更高要求的行业需求的不断增长。其密封、非侵入式流体通道使其非常适合生物技术、製药和食品生产等对产品纯度要求极高的产业。无需工具即可轻鬆更换泵管,不仅简化了维护,还能最大限度地延长设备正常运行时间,减少操作延误并降低劳动强度。由于洁净室合规性和产品完整性仍然是这些行业的首要任务,蠕动泵凭藉其确保无菌处理环境并将交叉污染风险降至最低的能力,将继续获得广泛的应用。

随着製造商寻求能够处理腐蚀性流体和危险化学品的耐用、高精度系统,预计到2034年,化学加工计量帮浦市场规模将达到35亿美元。它们与闭环系统相容,旨在最大限度地减少蒸汽排放并最大程度地提高工作场所安全性,使其成为化学、石化和工业製造环境中不可或缺的一部分。这些泵浦越来越多地配置为在高容量工厂中全天候连续使用,在这些工厂中,不间断的化学计量对生产效率至关重要。它们能够在极端温度和压力下运行,再加上自动化程度,使其成为高要求应用的首选。

受基础设施升级和更严格的环保合规要求的推动,北美计量帮浦市场规模预计到2034年将达到30亿美元。随着公用事业单位面临日益增长的现代化老旧水处理基础设施的压力,数位计量帮浦正在迅速取代传统的机械系统。氯、氟化物和其他处理化学品的计量精度提升,确保其符合不断演变的美国环保署(EPA)标准。公用事业单位和工业运营商都优先考虑具有远端监控功能的智慧连网泵,以符合永续发展、降低成本和保护公众健康等更广泛的目标。

全球计量帮浦市场的主要参与者有 Ark Electric & Mechanical、Blue White、Dosimix Technologies、Emec、Firemiks、Grundfos Holding、IDEX Corporation、Ingersoll Rand、IWAKI、KNAUER Wissenschaftliche Gerate、NETZSCH、Nikki Engineering、Phoenix Pumps、ProMinFlow、Wqui、RD、RESS、RESD、MicS、SESSP、AxSP、JMin製造商正在大力投资数位创新,整合物联网连接、远端诊断和自动校准功能,以满足对智慧计量解决方案的需求并减少停机时间。他们也正在开发用于严苛的石油、天然气和工业环境的耐腐蚀、耐热、耐盐和防爆泵。策略性成长策略包括与工程公司和市政公用事业公司建立合作伙伴关係,试行先进系统,特别是在废水和水处理领域。产品组合正在扩展,包括针对食品和生物技术无菌应用量身定制的蠕动模型,而闭式系统化学泵则确保安全性和合规性。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 监管格局

- 产业衝击力

- 成长动力

- 产业陷阱与挑战

- 成长潜力分析

- 波特的分析

- PESTEL分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 战略仪表板

- 策略倡议

- 竞争基准测试

- 创新与永续发展格局

第五章:市场规模及预测:依产品,2021 - 2034

- 主要趋势

- 隔膜泵

- 活塞泵

- 蠕动帮浦

- 其他的

第六章:市场规模与预测:按流量,2021 - 2034 年

- 主要趋势

- ≤50(公升/分钟)

- 50至100(公升/分钟)

- >100(公升/分钟)

第七章:市场规模及预测:依应用,2021 - 2034

- 主要趋势

- 水和废水处理

- 化学加工

- 石油和天然气

- 食品和饮料

- 製药

- 其他的

第八章:市场规模及预测:依最终用途,2021 - 2034

- 主要趋势

- 商业的

- 工业的

- 市政

第九章:市场规模及预测:按地区,2021 - 2034

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 墨西哥

- 欧洲

- 英国

- 法国

- 德国

- 义大利

- 俄罗斯

- 西班牙

- 亚太地区

- 中国

- 日本

- 韩国

- 印度

- 澳洲

- 马来西亚

- 印尼

- 中东和非洲

- 沙乌地阿拉伯

- 阿联酋

- 卡达

- 南非

- 奈及利亚

- 拉丁美洲

- 巴西

- 秘鲁

- 阿根廷

第十章:公司简介

- Ark Electric & Mechanical

- Blue-White

- Dosimix Technologies

- Emec

- Firemiks

- Grundfos Holding

- IDEX Corporation

- Ingersoll Rand

- IWAKI

- KNAUER Wissenschaftliche Gerate

- NETZSCH

- Nikkiso

- Phoenix Pumps

- ProMinent

- PSG

- Roto Pumps

- SEKO

- SPX Flow

- Verder Liquids

- Verito Engineering

- WES

The Global Dosing Pumps Market was valued at USD 7.8 billion in 2024 and is estimated to grow at a CAGR of 6.9% to reach USD 15.1 billion by 2034. The integration of digital controllers, which enable precise dosing, real-time monitoring, and automated feedback control, is a key growth driver. Municipal and industrial wastewater facilities increasingly rely on chlorine, ozone, and UV dosing systems, while urban centers deploy local water purification units. In the food and beverage sector, dosing pumps are vital for accurate injection of preservatives, flavorings, and colorants. The oil and gas industry boosts demand for high-pressure pumps for corrosion inhibitors, salt-resistant and explosion-proof systems for platforms and FPSOs, and methanol and glycol injection in subsea pipelines. Auto-calibration and IoT-enabled remote connectivity are further enhancing efficiency and predictive maintenance.

Continuous innovation in dosing pump technology designed to handle highly viscous, corrosive, or abrasive chemicals is significantly expanding market opportunities across various industrial sectors. Advanced materials, such as reinforced polymers and corrosion-resistant alloys, are now being integrated into pump construction to improve durability and lifespan under extreme operating conditions. Additionally, enhanced sealing mechanisms, variable-speed drive compatibility, and precision flow control features enable these pumps to operate efficiently in challenging applications like mining, wastewater treatment, pulp and paper, and oil & gas. As industries seek to automate complex chemical dosing processes with minimal downtime and maintenance, demand for these rugged, high-performance dosing systems is rising steadily, opening new avenues for growth and product diversification.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $7.8 Billion |

| Forecast Value | $15.1 Billion |

| CAGR | 6.9% |

The peristaltic dosing pumps segment is forecasted to reach USD 2.5 billion by 2034, driven by increasing demand from industries requiring hygienic fluid handling and contamination-free operation. Their sealed, non-invasive fluid pathways make them highly suitable for sectors like biotechnology, pharmaceuticals, and food production, where product purity is critical. The convenience of tool-free tubing replacement not only simplifies maintenance but also maximizes equipment uptime, reducing operational delays and minimizing labor intensity. As cleanroom compliance and product integrity remain top priorities in these industries, peristaltic pumps continue to gain ground for their ability to ensure sterile processing environments with minimal risk of cross-contamination.

The chemical processing dosing pumps segment is expected to reach USD 3.5 billion by 2034 as manufacturers seek durable, high-precision systems capable of handling aggressive fluids and hazardous chemicals. Their compatibility with closed-loop systems-designed to minimize vapor emissions and maximize workplace safety-makes them indispensable in chemical, petrochemical, and industrial manufacturing settings. These pumps are increasingly configured for continuous 24/7 use in high-capacity plants, where uninterrupted chemical dosing is vital to production efficiency. Their capacity to operate under extreme temperatures and pressures, coupled with automation readiness, makes them a preferred choice for demanding applications.

North America Dosing Pumps Market is expected to reach USD 3 billion by 2034, propelled by infrastructure upgrades and stricter environmental compliance mandates. As public utilities face mounting pressure to modernize outdated water treatment infrastructure, digital dosing pumps are rapidly replacing traditional mechanical systems. Enhanced precision in dosing chlorine, fluoride, and other treatment chemicals ensures regulatory alignment with evolving EPA standards. Utilities and industrial operators alike are prioritizing smart, networked pumps with remote monitoring and control capabilities, aligning with broader goals of sustainability, cost reduction, and public health protection.

Key players involved in the Global Dosing Pumps Market are Ark Electric & Mechanical, Blue White, Dosimix Technologies, Emec, Firemiks, Grundfos Holding, IDEX Corporation, Ingersoll Rand, IWAKI, KNAUER Wissenschaftliche Gerate, NETZSCH, Nikkiso, Phoenix Pumps, ProMinent, PSG, Roto Pumps, SEKO, SPX Flow, Verder Liquids, Verito Engineering, W.E.S. Manufacturers are investing heavily in digital innovation-integrating IoT connectivity, remote diagnostics, and auto-calibration features to meet demand for smart dosing solutions and reduce downtime. They are also developing corrosion-, heat-, salt-, and explosion-resistant pumps for demanding oil, gas, and industrial environments. Strategic growth tactics include forming partnerships with engineering firms and municipal utilities to pilot advanced systems, especially in wastewater and water treatment. Product portfolios are being expanded with peristaltic models tailored for food and biotech sterile applications, while closed-system chemical pumps ensure safety and compliance.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.2 Market estimates & forecast parameters

- 1.3 Forecast calculation

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid

- 1.4.2.2 Public

- 1.5 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Regulatory landscape

- 3.3 Industry impact forces

- 3.3.1 Growth drivers

- 3.3.2 Industry pitfalls & challenges

- 3.4 Growth potential analysis

- 3.5 Porter's analysis

- 3.5.1 Bargaining power of suppliers

- 3.5.2 Bargaining power of buyers

- 3.5.3 Threat of new entrants

- 3.5.4 Threat of substitutes

- 3.6 PESTEL analysis

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis, 2024

- 4.3 Strategic dashboard

- 4.4 Strategic initiatives

- 4.5 Competitive benchmarking

- 4.6 Innovation & sustainability landscape

Chapter 5 Market Size and Forecast, By Product, 2021 - 2034 (USD Million)

- 5.1 Key trends

- 5.2 Diaphragm pumps

- 5.3 Piston pumps

- 5.4 Peristaltic pumps

- 5.5 Others

Chapter 6 Market Size and Forecast, By Flow Rate, 2021 - 2034 (USD Million)

- 6.1 Key trends

- 6.2 ≤ 50 (L/min)

- 6.3 50 to 100 (L/min)

- 6.4 > 100 (L/min)

Chapter 7 Market Size and Forecast, By Application, 2021 - 2034 (USD Million)

- 7.1 Key trends

- 7.2 Water & wastewater treatment

- 7.3 Chemical processing

- 7.4 Oil & gas

- 7.5 Food & beverage

- 7.6 Pharmaceutical

- 7.7 Others

Chapter 8 Market Size and Forecast, By End Use, 2021 - 2034 (USD Million)

- 8.1 Key trends

- 8.2 Commercial

- 8.3 Industrial

- 8.4 Municipal

Chapter 9 Market Size and Forecast, By Region, 2021 - 2034 (USD Million)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.2.3 Mexico

- 9.3 Europe

- 9.3.1 UK

- 9.3.2 France

- 9.3.3 Germany

- 9.3.4 Italy

- 9.3.5 Russia

- 9.3.6 Spain

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 Japan

- 9.4.3 South Korea

- 9.4.4 India

- 9.4.5 Australia

- 9.4.6 Malaysia

- 9.4.7 Indonesia

- 9.5 Middle East & Africa

- 9.5.1 Saudi Arabia

- 9.5.2 UAE

- 9.5.3 Qatar

- 9.5.4 South Africa

- 9.5.5 Nigeria

- 9.6 Latin America

- 9.6.1 Brazil

- 9.6.2 Peru

- 9.6.3 Argentina

Chapter 10 Company Profiles

- 10.1 Ark Electric & Mechanical

- 10.2 Blue-White

- 10.3 Dosimix Technologies

- 10.4 Emec

- 10.5 Firemiks

- 10.6 Grundfos Holding

- 10.7 IDEX Corporation

- 10.8 Ingersoll Rand

- 10.9 IWAKI

- 10.10 KNAUER Wissenschaftliche Gerate

- 10.11 NETZSCH

- 10.12 Nikkiso

- 10.13 Phoenix Pumps

- 10.14 ProMinent

- 10.15 PSG

- 10.16 Roto Pumps

- 10.17 SEKO

- 10.18 SPX Flow

- 10.19 Verder Liquids

- 10.20 Verito Engineering

- 10.21 W.E.S.