|

市场调查报告书

商品编码

1885809

整体硬质合金刀具市场机会、成长驱动因素、产业趋势分析及预测(2025-2034年)Solid Carbide Tools Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

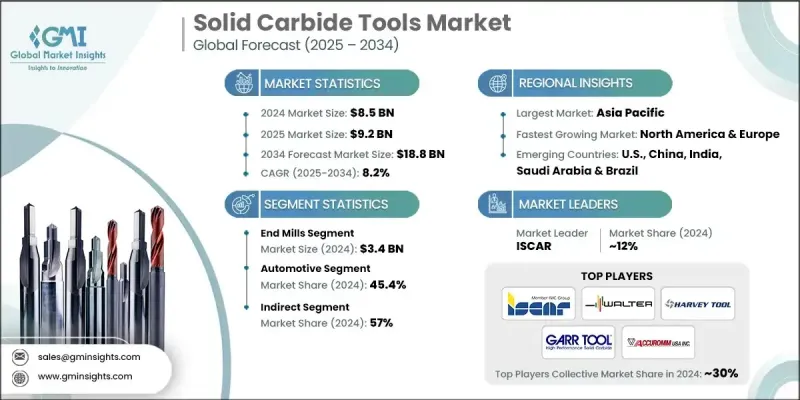

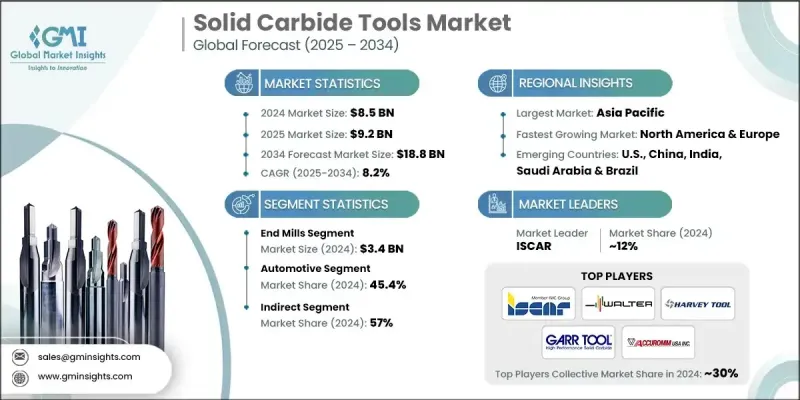

2024 年全球整体硬质合金刀具市场价值为 85 亿美元,预计到 2034 年将以 8.2% 的复合年增长率增长至 188 亿美元。

汽车和电动车 (EV) 製造领域日益增长的需求是推动市场成长的主要动力。随着汽车製造商致力于减轻车身重量并提高性能效率,对高性能材料和精密零件的需求也日益增长,这反过来又提升了对先进切削刀具的需求。整体硬质合金刀具具有无与伦比的硬度、耐热性和耐用性,使其成为加工铝、复合材料和先进合金的理想选择。自动化、数控加工和智慧製造技术的应用进一步推动了市场需求。高速工具机和机器人系统需要能够在极端条件下保持精度的刀具。整体硬质合金刀具通常采用先进涂层和优化几何形状,专为应对这些严苛的製造环境而设计,同时确保加工结果的一致性和高品质。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 85亿美元 |

| 预测值 | 188亿美元 |

| 复合年增长率 | 8.2% |

2024年,立铣刀市场规模达34亿美元,预计2025年至2034年将以8.7%的复合年增长率成长。立铣刀在轮廓加工、开槽、成型和复杂表面精加工等操作中至关重要。电动车产量的成长和轻量化趋势推动了对加工铝、钛和复合材料等先进材料的需求,这些材料需要具有卓越硬度和耐磨性的刀具。整体硬质合金立铣刀能够很好地满足这些严苛的要求,尤其是在汽车、航太和电子製造领域。

汽车产业占据45.4%的市场份额,预计到2034年将以8.6%的复合年增长率成长。电动车的生产提高了对轻质零件(如铝、镁合金和复合材料)加工的需求,而这些零件都需要耐用且耐磨的整体硬质合金刀具。汽车製造商正越来越多地采用高速数控加工和自动化技术来缩短加工週期并满足严格的品质标准,这进一步推动了对精密刀具解决方案的需求。

2024年美国整体硬质合金刀具市场规模达20亿美元,预计2034年将以8.5%的复合年增长率成长。美国的汽车和航太工业是精密刀具的主要消费产业,这主要得益于铝、钛和复合材料等轻质材料的加工。此外,工业4.0技术的广泛应用,包括自动化、数控系统和智慧工厂解决方案,也增加了对高精度、高耐用性整体硬质合金刀具的需求。

全球整体硬质合金刀具市场的主要参与者包括 Accuromm、Accusharp、Birla Precision Technologies、DIC Tools、Fullerton Tool、Garr Tool、Hannibal Carbide Tool、Harvey Tool、ISCAR、Johnson Carbide、Mitsubishi、Orient Tools、Samtec Tools、ISCARB、Tixna Tools。这些公司正透过专注于产品创新来巩固其市场地位,例如采用先进涂层、优化几何形状以及开髮用于轻质和复合材料的专用刀具。许多公司正在投资开发自动化相容解决方案和数控刀具,以满足高速製造环境日益增长的需求。与汽车、航太和电子製造商的策略合作有助于扩大市场覆盖范围,并确保为复杂的加工需求提供客製化解决方案。

目录

第一章:方法论与范围

第二章:执行概要

第三章:行业洞察

- 产业生态系分析

- 供应商格局

- 利润率

- 每个阶段的价值增加

- 影响价值链的因素

- 产业影响因素

- 成长驱动因素

- 汽车和电动车製造需求不断成长

- 采用自动化/数控加工/智慧製造技术

- 日益关註生产力和成本效益

- 产业陷阱与挑战

- 原料和生产成本高昂

- 供应链中断与复杂性

- 成长驱动因素

- 成长潜力分析

- 未来市场趋势

- 技术与创新格局

- 当前技术趋势

- 新兴技术

- 价格趋势

- 按地区

- 依产品类型

- 监管环境

- 标准和合规要求

- 区域监理框架

- 认证标准

- 贸易统计

- 主要进口国

- 主要出口国

- 波特的分析

- PESTEL 分析

- 消费者行为分析

- 购买模式

- 偏好分析

- 消费者行为的区域差异

- 电子商务对购买决策的影响

第四章:竞争格局

- 介绍

- 公司市占率分析

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 按地区

- 公司矩阵分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 关键进展

- 併购

- 合作伙伴关係与合作

- 新产品发布

- 扩张计划

第五章:市场估算与预测:依产品类型划分,2021-2034年

- 主要趋势

- 立铣刀

- 球头立铣刀

- 方头铣刀

- 圆角立铣刀

- 演习

- 麻花钻

- 阶梯训练

- 微型钻头

- 枪炮演习

- 扩孔器

- 直槽铰刀

- 螺旋槽铰刀

- 可调式铰刀

- 水龙头

- 插入件

- 其他(无聊的酒吧等)

第六章:市场估算与预测:依涂料类型划分,2021-2034年

- 主要趋势

- 氮化钛(TiN)

- TiCN(碳氮化钛)

- TiAlN(氮化钛铝)

- AlCrN(氮化铝铬)

- 钻石涂层

- 未涂层硬质合金

- 标准等级

- 微晶粒级

- 奈米晶粒级

第七章:市场估计与预测:依应用领域划分,2021-2034年

- 主要趋势

- 铣削

- 钻孔

- 扩孔

- 螺纹

- 转弯

- 其他(雕刻等)

第八章:市场估算与预测:依最终用途产业划分,2021-2034年

- 主要趋势

- 航太

- 汽车

- 医疗器材

- 电子与半导体

- 通用工程

- 其他的

第九章:市场估算与预测:依配销通路划分,2021-2034年

- 主要趋势

- 直销

- 间接销售

第十章:市场估计与预测:依地区划分,2021-2034年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲

- 印尼

- 马来西亚

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- MEA

- 沙乌地阿拉伯

- 阿联酋

- 南非

第十一章:公司简介

- Accuromm

- Accusharp

- Birla Precision Technologies

- DIC Tools

- Fullerton Tool

- Garr Tool

- Hannibal Carbide Tool

- Harvey Tool

- ISCAR

- Johnson Carbide

- Mitsubishi

- Orient Tools

- Samtec Tools

- SwiftCARB

- Tixna Tools

- Walter Tools

The Global Solid Carbide Tools Market was valued at USD 8.5 billion in 2024 and is estimated to grow at a CAGR of 8.2% to reach USD 18.8 billion by 2034.

The market growth is driven by increasing demand in automotive and electric vehicle (EV) manufacturing. As automakers focus on reducing vehicle weight and improving performance efficiency, there is a growing preference for high-performance materials and precision components, which in turn elevates the need for advanced cutting tools. Solid carbide tools offer unmatched hardness, heat resistance, and durability, making them ideal for machining aluminum, composites, and advanced alloys. The adoption of automation, CNC machining, and smart manufacturing technologies is further propelling market demand. High-speed machines and robotic systems require tools capable of maintaining precision under extreme conditions. Solid carbide tools, often enhanced with advanced coatings and optimized geometries, are specifically designed to sustain these demanding manufacturing environments while delivering consistent, high-quality results.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $8.5 Billion |

| Forecast Value | $18.8 Billion |

| CAGR | 8.2% |

The end mills segment generated USD 3.4 billion in 2024 and is expected to grow at a CAGR of 8.7% from 2025 to 2034. End mills are critical for operations such as profiling, slotting, contouring, and finishing complex surfaces. Rising EV production and lightweighting trends are driving demand for machining advanced materials such as aluminum, titanium, and composites, which require tools with superior hardness and wear resistance. Solid carbide end mills excel in meeting these demanding requirements, particularly in automotive, aerospace, and electronics manufacturing.

The automotive sector held a 45.4% share and is projected to grow at a CAGR of 8.6% through 2034. The production of electric vehicles has heightened the need for machining lightweight components like aluminum, magnesium alloys, and composites, all of which demand durability and wear resistance of solid carbide tools. Automotive manufacturers are increasingly deploying high-speed CNC machining and automation to reduce cycle times and meet stringent quality standards, further boosting demand for precision-tooling solutions.

U.S. Solid Carbide Tools Market generated USD 2 billion in 2024 and is expected to grow at a CAGR of 8.5% through 2034. The country's automotive and aerospace industries are major consumers of precision tools, driven by the machining of lightweight materials such as aluminum, titanium, and composites. Additionally, the widespread adoption of Industry 4.0 practices, including automation, CNC systems, and smart factory solutions, has increased reliance on high-precision and durable solid carbide tools.

Key players in the Global Solid Carbide Tools Market include Accuromm, Accusharp, Birla Precision Technologies, DIC Tools, Fullerton Tool, Garr Tool, Hannibal Carbide Tool, Harvey Tool, ISCAR, Johnson Carbide, Mitsubishi, Orient Tools, Samtec Tools, SwiftCARB, Tixna Tools, and Walter Tools. Companies in the Solid Carbide Tools Market are strengthening their presence by focusing on product innovation, such as advanced coatings, optimized geometries, and specialized tools for lightweight and composite materials. Many firms are investing in automation-compatible solutions and CNC-ready tools to serve the growing demand from high-speed manufacturing environments. Strategic collaborations with automotive, aerospace, and electronics manufacturers help expand market reach and ensure tailored solutions for complex machining requirements.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Product type

- 2.2.3 Coating type

- 2.2.4 Application

- 2.2.5 End use industry

- 2.2.6 Distribution channel

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Increasing demand in automotive & EV manufacturing

- 3.2.1.2 Adoption of automation / CNC machining / smart manufacturing

- 3.2.1.3 Rising focus on productivity & cost efficiency

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High raw material & production costs

- 3.2.2.2 Supply chain disruptions & complexity

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By product type

- 3.7 Regulatory landscape

- 3.7.1 Standards and compliance requirements

- 3.7.2 Regional regulatory frameworks

- 3.7.3 Certification standards

- 3.8 Trade statistics

- 3.8.1 Major importing countries

- 3.8.2 Major exporting countries

- 3.9 Porter's analysis

- 3.10 PESTEL analysis

- 3.11 Consumer behavior analysis

- 3.11.1 Purchasing patterns

- 3.11.2 Preference analysis

- 3.11.3 Regional variations in consumer behavior

- 3.11.4 Impact of e-commerce on buying decisions

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By Region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East & Africa

- 4.2.1 By Region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates & Forecast, By Product Type, 2021 - 2034, (USD Billion) (Million Units)

- 5.1 Key trends

- 5.2 End mills

- 5.2.1 Ball nose end mills

- 5.2.2 Square end mills

- 5.2.3 Corner radius end mills

- 5.3 Drills

- 5.3.1 Twist drills

- 5.3.2 Step drills

- 5.3.3 Micro drills

- 5.3.4 Gun drills

- 5.4 Reamers

- 5.4.1 Straight flute reamers

- 5.4.2 Spiral flute reamers

- 5.4.3 Adjustable reamers

- 5.5 Taps

- 5.6 Inserts

- 5.7 Others (boring bars etc.)

Chapter 6 Market Estimates & Forecast, By Coating Type, 2021 - 2034, (USD Billion) (Million Units)

- 6.1 Key trends

- 6.2 TiN (Titanium nitride)

- 6.3 TiCN (Titanium carbonitride)

- 6.4 TiAlN (Titanium aluminum nitride)

- 6.5 AlCrN (Aluminum chromium nitride)

- 6.6 Diamond coatings

- 6.7 Uncoated carbide

- 6.7.1 Standard grades

- 6.7.2 Micro-grain grades

- 6.7.3 Nano-grain grades

Chapter 7 Market Estimates & Forecast, By Application, 2021 - 2034, (USD Billion) (Million Units)

- 7.1 Key trends

- 7.2 Milling

- 7.3 Drilling

- 7.4 Reaming

- 7.5 Threading

- 7.6 Turning

- 7.7 Others (engraving etc.)

Chapter 8 Market Estimates & Forecast, By End Use Industry, 2021 - 2034, (USD Billion) (Million Units)

- 8.1 Key trends

- 8.2 Aerospace

- 8.3 Automotive

- 8.4 Medical devices

- 8.5 Electronics & semiconductors

- 8.6 General engineering

- 8.7 Others

Chapter 9 Market Estimates & Forecast, By Distribution Channel, 2021 - 2034, (USD Billion) (Million Units)

- 9.1 Key trends

- 9.2 Direct sales

- 9.3 Indirect sales

Chapter 10 Market Estimates & Forecast, By Region, 2021 - 2034, (USD Billion) (Million Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 Germany

- 10.3.2 UK

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 South Korea

- 10.4.5 Australia

- 10.4.6 Indonesia

- 10.4.7 Malaysia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.5.3 Argentina

- 10.6 MEA

- 10.6.1 Saudi Arabia

- 10.6.2 UAE

- 10.6.3 South Africa

Chapter 11 Company Profiles

- 11.1 Accuromm

- 11.2 Accusharp

- 11.3 Birla Precision Technologies

- 11.4 DIC Tools

- 11.5 Fullerton Tool

- 11.6 Garr Tool

- 11.7 Hannibal Carbide Tool

- 11.8 Harvey Tool

- 11.9 ISCAR

- 11.10 Johnson Carbide

- 11.11 Mitsubishi

- 11.12 Orient Tools

- 11.13 Samtec Tools

- 11.14 SwiftCARB

- 11.15 Tixna Tools

- 11.16 Walter Tools