|

市场调查报告书

商品编码

1892848

冷链监测市场机会、成长驱动因素、产业趋势分析及预测(2026-2035年)Cold Chain Monitoring Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2026 - 2035 |

||||||

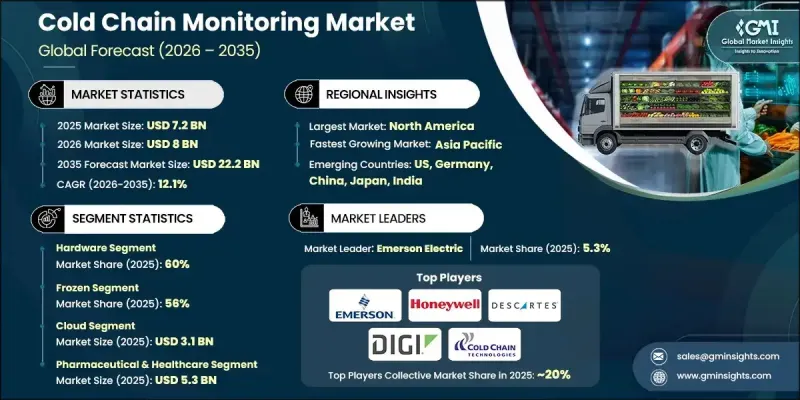

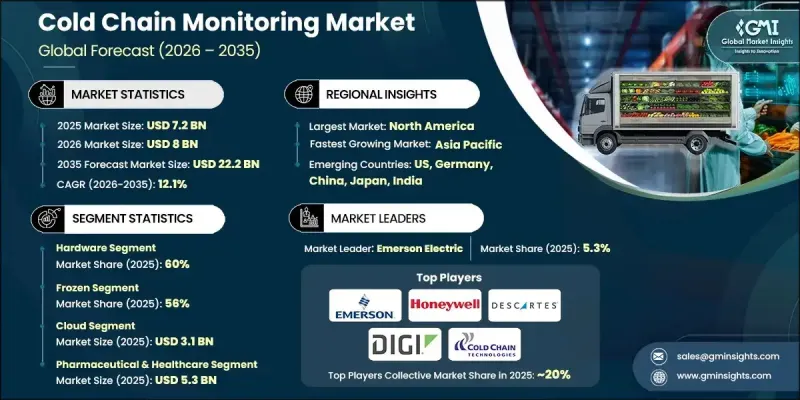

2025 年全球冷链监控市场价值为 72 亿美元,预计到 2035 年将以 12.1% 的复合年增长率成长至 222 亿美元。

易腐食品(包括新鲜农产品、肉类、海鲜、乳製品、冷冻食品和即食食品)的消费量成长,加剧了对整个供应链精准温度控制的需求。随着配送週期缩短和分销网路不断扩展,企业面临越来越大的压力,需要防止产品损坏并维持品质。如今,每批货物的运输都需要完全可追溯性并严格遵守温度控制,尤其是在全球易腐品贸易不断扩张的情况下。冷链监控已成为减少浪费、保持新鲜度以及满足日益增长的安全性和一致性期望的关键。在製药业,精准的温度监管尤其重要,因为生物製剂、疫苗和特殊疗法都依赖严格控制的温度范围。随着温度敏感型疗法的日益普及,製造商和分销商高度依赖能够提供警报和可用于审计资料的即时、经过验证的监控工具。在公共卫生紧急事件期间加速部署数位系统,进一步巩固了即时冷链监管在製药领域的优先地位。

| 市场范围 | |

|---|---|

| 起始年份 | 2025 |

| 预测年份 | 2026-2035 |

| 起始值 | 72亿美元 |

| 预测值 | 222亿美元 |

| 复合年增长率 | 12.1% |

2025年,硬体部分占据了60%的市场份额,预计2026年至2035年将以12.4%的复合年增长率成长。冷链运作依赖大量的实体监控设备,包括温度探头、GPS单元、资料记录器、湿度感测器、远端资讯处理工具和门状态侦测器,这些设备安装在仓库、冷藏运输车辆、货柜和最后一公里配送设备中。由于每个托盘、每批货物和每个存储点都需要持续跟踪,硬体需求增长速度超过了软体采用速度,从而确保了其市场领先地位。

冷冻食品市场在2025年占据了56%的市场份额,预计到2035年将以12.4%的复合年增长率成长。包括某些药品、生物製品和温度敏感食品在内的冷冻产品必须储存在严格控制的环境中。即使是最小的偏差也可能影响产品的安全性和有效性,因此企业需要在整个供应链中投资持续监控、高精度感测器和可靠的即时报告系统。

预计2025年,美国冷链监控市场规模将达23亿美元。美国庞大的冷藏设施网路和温控运输系统促进了监控系统的广泛应用。易腐食品分销规模庞大,加上对新鲜农产品、包装食品、冷冻食品、生物製品和先进药品等产品的严格要求,更凸显了即时可视性的重要性。产品种类繁多、运输距离长以及零售商的高绩效标准,持续推高了对精准冷链追踪技术的需求。

活跃于全球冷链监控市场的公司包括Testo、Controlant、Cold Chain Technologies、Digi International、Sensitech、Zebra Technologies、Descartes Systems、Emerson Electric、Honeywell International和ORBCOMM。这些公司透过拓展硬体产品组合、提升感测器精度以及将先进的连接功能整合到产品线中来巩固其市场地位。许多公司致力于开发即时平台,将温度追踪、地理定位和自动警报功能结合,以支援合规性并降低产品变质风险。与物流供应商和製药厂商的策略合作有助于供应商将监控解决方案更深入地融入供应链。

目录

第一章:方法论与范围

第二章:执行概要

第三章:行业洞察

- 产业生态系分析

- 供应商格局

- 感测器和硬体製造商

- 连接和物联网网路供应商

- 软体/平台供应商

- 冷链包装与保温容器

- 冷冻设备製造商

- 冷库营运商和仓库基础设施

- 成本结构

- 利润率

- 每个阶段的价值增加

- 影响供应链的因素

- 颠覆者

- 供应商格局

- 对力的影响

- 成长驱动因素

- 云端运算和超大规模扩展的快速成长

- 人工智慧、机器学习和高效能运算(HPC)的爆炸性成长

- 各行业资料产生量不断增加

- 边缘运算在低延迟应用中的成长

- 产业陷阱与挑战

- 电力和散热方面的限制制约了高密度伺服器部署。

- 能源成本上涨对总体拥有成本和伺服器更新决策带来压力。

- 供应链波动和半导体短缺导致伺服器出货延迟。

- 市场机会

- 加速采用人工智慧最佳化和GPU加速伺服器

- 边缘运算的成长开启了新的伺服器部署空间

- 过渡到液冷散热会带来硬体升级週期。

- ARM架构伺服器及其他架构的兴起

- 成长驱动因素

- 成长潜力分析

- 监管环境

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 波特的分析

- PESTEL 分析

- 技术趋势与创新生态系统

- 目前技术

- 基于物联网的感测器和无线环境感测器

- 温度和湿度资料记录仪

- 冷藏集装箱/车辆的远端资讯处理集成

- GPS定位/位置追踪结合冷藏货柜监控

- 新兴技术

- 预测分析/人工智慧和机器学习驱动的分析

- 数据驱动型决策平台

- 与更广泛的供应链系统整合

- 边缘运算/本地处理和混合架构

- 目前技术

- 专利分析

- 价格趋势分析

- 按地区

- 副产品

- 生产统计

- 生产中心

- 消费中心

- 进出口

- 成本細項分析

- 风险分析与管理

- 营运风险评估

- 财务风险评估

- 技术与网路安全风险

- 风险缓解策略

- 永续性和环境方面

- 永续实践

- 减少废弃物策略

- 生产中的能源效率

- 环保倡议

- 碳足迹考量

- 用例

- 最佳情况

- 投资报酬率和成本效益分析

- 功能和定价基准分析

- 顾客偏好/购买行为

第四章:竞争格局

- 介绍

- 公司市占率分析

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- MEA

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 战略展望矩阵

- 关键进展

- 併购

- 合作伙伴关係与合作

- 新产品发布

- 扩张计划和资金

第五章:市场估算与预测:依组件划分,2022-2035年

- 硬体

- 感应器

- 射频识别设备

- 车载资讯系统

- 网路装置

- 其他的

- 软体

- 即时监控

- 分析与报告

- 服务

- 专业服务

- 託管服务

第六章:市场估算与预测:依温度划分,2022-2035年

- 冷冻

- 冷藏

第七章:市场估算与预测:依部署方式划分,2022-2035年

- 云

- 现场

- 杂交种

第八章:市场估算与预测:依物流业划分,2022-2035年

- 贮存

- 运输

第九章:市场估算与预测:依最终用途划分,2022-2035年

- 医药与医疗保健

- 餐饮

- 物流与配送

- 化学

- 其他的

第十章:市场估计与预测:依地区划分,2022-2035年

- 北美洲

- 我们

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 北欧

- 比荷卢经济联盟

- 亚太地区

- 中国

- 印度

- 日本

- 澳洲

- 韩国

- 泰国

- 印尼

- 新加坡

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 哥伦比亚

- MEA

- 南非

- 沙乌地阿拉伯

- 阿联酋

第十一章:公司简介

- Global Leaders

- Sensitech (Carrier Global)

- Emerson Electric

- Honeywell International

- Descartes Systems

- Digi International

- Zebra Technologies

- Cold Chain Technologies (CCT)

- ORBCOMM

- Controlant

- Testo

- ELPRO-Buchs

- 区域冠军

- DeltaTrak

- Monnit

- FreshLoc Technologies

- Samsara

- Tive

- Roambee

- Blulog (low-power NFC and wireless data loggers)

- OnAsset Intelligence (air cargo temperature & security tracking)

- Zest Labs

- TagBox

- 新兴参与者

- SenseAnywhere

- Rotronic

- TempGenius

- Zhuhai Rayonics Technology

- Blulog

The Global Cold Chain Monitoring Market was valued at USD 7.2 billion in 2025 and is estimated to grow at a CAGR of 12.1% to reach USD 22.2 billion by 2035.

Rising consumption of perishable foods, including fresh produce, meat, seafood, dairy, frozen meals, and ready-to-eat items, has intensified the demand for precise temperature control throughout supply chains. As delivery cycles become shorter and distribution networks broaden, companies face growing pressure to prevent product damage and maintain quality. Every shipment now requires complete traceability and strict temperature adherence, especially as global trade in perishables expands. Cold-chain monitoring has become essential for reducing waste and preserving freshness while meeting heightened expectations for safety and consistency. The need for accurate temperature oversight is even more critical in the pharmaceutical sector, where biologics, vaccines, and specialized therapies depend on tightly regulated temperature ranges. With the increasing adoption of temperature-sensitive treatments, manufacturers and distributors rely heavily on real-time, validated monitoring tools that offer alerts and audit-ready data. The accelerated deployment of digital systems during public health emergencies has further cemented real-time cold-chain oversight as a priority within the pharmaceutical landscape.

| Market Scope | |

|---|---|

| Start Year | 2025 |

| Forecast Year | 2026-2035 |

| Start Value | $7.2 Billion |

| Forecast Value | $22.2 Billion |

| CAGR | 12.1% |

The hardware segment held a 60% share in 2025 and is expected to grow at a CAGR of 12.4% from 2026 to 2035. Cold-chain operations depend on large quantities of physical monitoring devices, temperature probes, GPS units, data loggers, humidity sensors, telematics tools, and door-status detectors installed across warehouses, refrigerated transport, containers, and last-mile equipment. Because every pallet, shipment, and storage point requires continuous tracking, hardware demand grows faster than software adoption, ensuring its leading market position.

The frozen segment accounted for a 56% share in 2025 and is projected to grow at a 12.4% CAGR through 2035. Products stored at frozen temperatures, including certain pharmaceuticals, biologics, and temperature-sensitive foods, must remain within tightly controlled environments. Even the smallest deviation can compromise safety or effectiveness, prompting companies to invest in continuous monitoring, high-accuracy sensors, and reliable real-time reporting throughout the supply chain.

U.S. Cold Chain Monitoring Market generated USD 2.3 billion in 2025. The country's extensive network of refrigerated storage facilities and temperature-controlled transportation promotes strong adoption of monitoring systems. The scale of perishable food distribution, alongside strict requirements for fresh produce, packaged foods, frozen items, biologics, and advanced pharmaceuticals, reinforces the need for real-time visibility. High product variety, long transport distances, and retailer performance standards consistently elevate demand for accurate cold-chain tracking technologies.

Companies active in the Global Cold Chain Monitoring Market include Testo, Controlant, Cold Chain Technologies, Digi International, Sensitech, Zebra Technologies, Descartes Systems, Emerson Electric, Honeywell International, and ORBCOMM. Companies competing in the Cold Chain Monitoring Market strengthen their position by expanding hardware portfolios, enhancing sensor accuracy, and integrating advanced connectivity features into their product lines. Many firms focus on developing real-time platforms that combine temperature tracking, geolocation, and automated alerts to support regulatory compliance and reduce spoilage risk. Strategic collaborations with logistics providers and pharmaceutical manufacturers help vendors embed monitoring solutions deeper within supply chains.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Component

- 2.2.3 Temperature

- 2.2.4 Deployment

- 2.2.5 Logistics

- 2.2.6 End use

- 2.3 TAM Analysis, 2026-2035

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Key decision points for industry executives

- 2.4.2 Critical success factors for market players

- 2.5 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.1.1 Sensor & hardware manufacturers

- 3.1.1.2 Connectivity & IoT network providers

- 3.1.1.3 Software / platform providers

- 3.1.1.4 Cold chain packaging & insulated containers

- 3.1.1.5 Refrigeration equipment manufacturers

- 3.1.1.6 Cold storage operators & warehouse infrastructure

- 3.1.2 Cost structure

- 3.1.3 Profit margin

- 3.1.4 Value addition at each stage

- 3.1.5 Factors impacting the supply chain

- 3.1.6 Disruptors

- 3.1.1 Supplier landscape

- 3.2 Impact on forces

- 3.2.1 Growth drivers

- 3.2.1.1 Rapid growth of cloud computing & hyperscale expansion

- 3.2.1.2 Explosion of AI, machine learning & high-performance computing (HPC)

- 3.2.1.3 Increasing data generation across industries

- 3.2.1.4 Growth of edge computing for low-latency applications

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 Power & cooling constraints limit high-density server deployments

- 3.2.2.2 Rising energy costs pressure TCO and server refresh decisions

- 3.2.2.3 Supply chain volatility and semiconductor shortages delay server shipments

- 3.2.3 Market opportunities

- 3.2.3.1 Accelerated adoption of AI-optimized and GPU-accelerated servers

- 3.2.3.2 Growth of edge computing opens new server deployment footprints

- 3.2.3.3 Transition to liquid cooling creates hardware upgrade cycles

- 3.2.3.4 Rise of ARM-based servers and alternative architectures

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Technology trends & innovation ecosystem

- 3.7.1 Current technologies

- 3.7.1.1 IoT-based sensors & wireless environmental sensors

- 3.7.1.2 Temperature & humidity data loggers

- 3.7.1.3 Telematics integration for refrigerated containers / vehicles

- 3.7.1.4 GPS / location tracking combined with monitoring for refrigerated containers

- 3.7.2 Emerging technologies

- 3.7.2.1 Predictive analytics / AI and ML-driven analytics

- 3.7.2.2 Data-driven decision-making platforms

- 3.7.2.3 Integration with broader supply-chain systems

- 3.7.2.4 Edge computing / local processing & hybrid architectures

- 3.7.1 Current technologies

- 3.8 Patent analysis

- 3.9 Price trend analysis

- 3.9.1 By region

- 3.9.2 By products

- 3.10 Production statistics

- 3.10.1 Production hubs

- 3.10.2 Consumption hubs

- 3.10.3 Export and import

- 3.11 Cost breakdown analysis

- 3.12 Risk analysis & management

- 3.12.1 Operational risk assessment

- 3.12.2 Financial risk evaluation

- 3.12.3 Technology & cybersecurity risks

- 3.12.4 Risk mitigation strategies

- 3.13 Sustainability and environmental aspects

- 3.13.1 Sustainable practices

- 3.13.2 Waste reduction strategies

- 3.13.3 Energy efficiency in production

- 3.13.4 Eco-friendly initiatives

- 3.13.5 Carbon footprint considerations

- 3.14 Use cases

- 3.15 Best case scenario

- 3.16 ROI & Cost-Benefit Analysis

- 3.17 Feature & pricing benchmarking

- 3.18 Customer preference / buying behavior

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 North America

- 4.2.2 Europe

- 4.2.3 Asia Pacific

- 4.2.4 LATAM

- 4.2.5 MEA

- 4.3 Competitive analysis of major market players

- 4.4 Competitive positioning matrix

- 4.5 Strategic outlook matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans and funding

Chapter 5 Market Estimates & Forecast, By Component, 2022 - 2035 ($Bn, Units)

- 5.1 Key trends

- 5.2 Hardware

- 5.2.1 Sensors

- 5.2.2 RFID devices

- 5.2.3 Telematics

- 5.2.4 Networking devices

- 5.2.5 Others

- 5.3 Software

- 5.3.1 Real-time monitoring

- 5.3.2 Analytics and reporting

- 5.4 Services

- 5.4.1 Professional services

- 5.4.2 Managed services

Chapter 6 Market Estimates & Forecast, By Temperature, 2022 - 2035 ($Bn, Units)

- 6.1 Key trends

- 6.2 Frozen

- 6.3 Chilled

Chapter 7 Market Estimates & Forecast, By Deployment, 2022 - 2035 ($Bn, Units)

- 7.1 Key trends

- 7.2 Cloud

- 7.3 On-premises

- 7.4 Hybrid

Chapter 8 Market Estimates & Forecast, By Logistics, 2022 - 2035 ($Bn, Units)

- 8.1 Key trends

- 8.2 Storage

- 8.3 Transportation

Chapter 9 Market Estimates & Forecast, By End Use, 2022 - 2035 ($Bn, Units)

- 9.1 Key trends

- 9.2 Pharmaceutical & healthcare

- 9.3 Food & beverage

- 9.4 Logistics & distribution

- 9.5 Chemical

- 9.6 Others

Chapter 10 Market Estimates & Forecast, By Region, 2022 - 2035 ($Bn, Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 US

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 Germany

- 10.3.2 UK

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.3.6 Russia

- 10.3.7 Nordics

- 10.3.8 Benelux

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 Australia

- 10.4.5 South Korea

- 10.4.6 Thailand

- 10.4.7 Indonesia

- 10.4.8 Singapore

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.5.3 Argentina

- 10.5.4 Colombia

- 10.6 MEA

- 10.6.1 South Africa

- 10.6.2 Saudi Arabia

- 10.6.3 UAE

Chapter 11 Company Profiles

- 11.1 Global Leaders

- 11.1.1 Sensitech (Carrier Global)

- 11.1.2 Emerson Electric

- 11.1.3 Honeywell International

- 11.1.4 Descartes Systems

- 11.1.5 Digi International

- 11.1.6 Zebra Technologies

- 11.1.7 Cold Chain Technologies (CCT)

- 11.1.8 ORBCOMM

- 11.1.9 Controlant

- 11.1.10 Testo

- 11.1.11 ELPRO-Buchs

- 11.2 Regional Champions

- 11.2.1 DeltaTrak

- 11.2.2 Monnit

- 11.2.3 FreshLoc Technologies

- 11.2.4 Samsara

- 11.2.5 Tive

- 11.2.6 Roambee

- 11.2.7 Blulog (low-power NFC and wireless data loggers)

- 11.2.8 OnAsset Intelligence (air cargo temperature & security tracking)

- 11.2.9 Zest Labs

- 11.2.10 TagBox

- 11.3 Emerging Players

- 11.3.1 SenseAnywhere

- 11.3.2 Rotronic

- 11.3.3 TempGenius

- 11.3.4 Zhuhai Rayonics Technology

- 11.3.5 Blulog