|

市场调查报告书

商品编码

1913441

醋酸乙烯单体市场机会、成长要素、产业趋势分析及2026年至2035年预测Vinyl Acetate Monomer (VAM) Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2026 - 2035 |

||||||

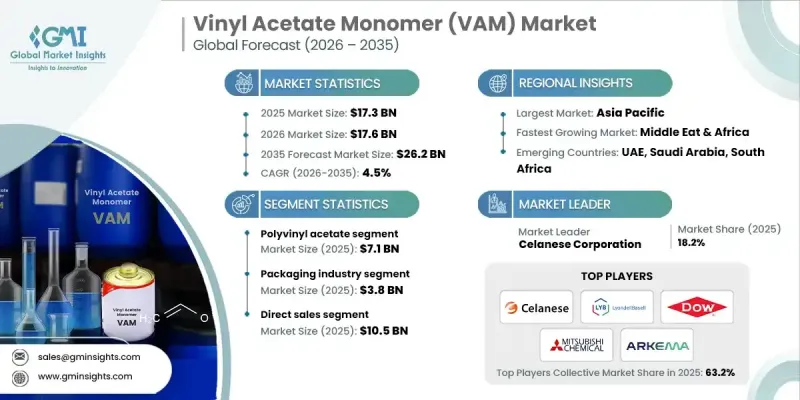

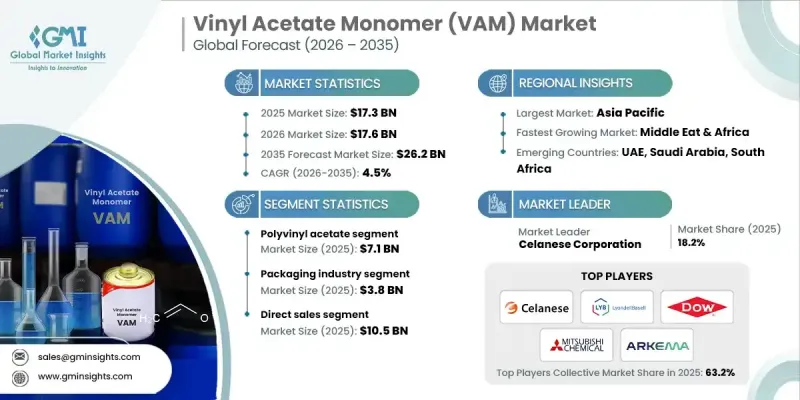

全球醋酸乙烯单体(VAM)市场预计到 2025 年将达到 173 亿美元,到 2035 年将达到 262 亿美元,年复合成长率为 4.5%。

该市场的成长主要受高性能、永续包装解决方案需求的不断增长以及聚醋酸乙烯酯(VAM)衍生聚合物(如聚醋酸乙烯酯、乙烯-醋酸乙烯酯共聚物和聚乙烯醇)应用范围的扩大所驱动。这些聚合物因其优异的黏合性、防水性和多功能性,成为包装薄膜和柔性复合材料的理想选择。此外,消费品和工业包装消费量的成长,以及建筑、汽车和工业涂料行业的成长,也推动了市场需求。都市化加快、基础设施建设和维修活动也促进了基于VAM树脂的黏合剂、密封剂、涂料和复合材料的使用。鼓励使用低VOC和水性配方的环保法规,正推动某些应用领域从传统的溶剂型材料转向水性材料。先进的生产技术和优化的製造流程提高了效率,确保了供应的可靠性,并增强了其在全球市场的竞争力。

| 市场覆盖范围 | |

|---|---|

| 开始年份 | 2025 |

| 预测年份 | 2026-2035 |

| 起始值 | 173亿美元 |

| 预测金额 | 262亿美元 |

| 复合年增长率 | 4.5% |

聚醋酸乙烯酯(VAM)市场预计到2025年将达到71亿美元,这主要得益于其在黏合剂、涂料、涂层和建筑材料等领域的广泛应用。 VAM优异的黏合性能、易于配製以及与水性材料的相容性使其成为包装、木工和纸製品等行业的重要原料。此外,市场对环保型和低VOC黏合剂的需求不断增长,也进一步巩固了VAM在全球市场中的重要性。

包装产业是积层製造材料(VAM)消费量的最大领域,预计2025年将达到38亿美元。 VAM衍生的聚合物,例如聚乙烯醇(PVA)、聚乙烯醇缩丁醛(PVB)和乙烯-乙烯醇共聚物(EVOH),具有优异的黏合性、透明度和阻隔性,是製造防潮和防氧包装所必需的。电子商务的成长、快速消费品(FMCG)分销网络的扩张以及对轻质可回收包装材料的偏好,都在推动这一领域的需求。

预计到2025年,北美醋酸乙烯单体(VAM)市场规模将达45亿美元。该地区占据26%的市场份额,这得益于其完善的石化基础设施、丰富的乙烯和醋酸等原材料供应,以及成熟的下游市场,例如黏合剂、水性涂料、包装薄膜和建筑聚合物。强大的产业基础确保了VAM稳定的消费量和市场成长。

目录

第一章调查方法和范围

第二章执行摘要

第三章业界考察

- 生态系分析

- 供应商情况

- 利润率

- 每个阶段的附加价值

- 影响价值链的因素

- 中断

- 产业影响因素

- 司机

- 对水性黏合剂和涂料的需求不断增长

- 包装行业的扩张

- 从溶剂型体系转向水性体系

- 产业潜在风险与挑战

- 原物料价格波动

- 严格的挥发性有机化合物(VOC)排放法规

- 市场机会

- 用于食品包装的高阻隔EVOH薄膜

- 用于药物输送系统的医用级EVA

- 司机

- 成长潜力分析

- 监管环境

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 波特五力分析

- PESTEL 分析

- 价格趋势

- 按地区

- 透过使用

- 未来市场趋势

- 科技与创新趋势

- 当前技术趋势

- 新兴技术

- 专利状态

- 贸易统计(HS编码)(註:仅提供主要国家的贸易统计)

- 主要进口国

- 主要出口国

- 永续性和环境方面

- 永续努力

- 减少废弃物策略

- 生产中的能源效率

- 环保倡议

- 碳足迹考量

第四章 竞争情势

- 介绍

- 公司市占率分析

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 按地区

- 企业矩阵分析

- 主要市场公司的竞争分析

- 竞争定位矩阵

- 重大进展

- 併购

- 伙伴关係与合作

- 新产品发布

- 扩张计划

第五章 依应用领域分類的市场估算与预测,2022-2035年

- 聚乙酸乙烯酯

- 聚乙烯醇

- 聚乙烯丁醛

- 乙烯 - 乙烯醇

- 氯乙烯-醋酸乙烯酯共聚物

- 聚乙烯醇缩甲醛

- 其他的

6. 2022-2035年按最终用途产业分類的市场估算与预测

- 聚乙酸乙烯酯(PVAc)

- 乳化聚合物

- 黏合剂

- 油漆和黏合剂

- 乙烯-醋酸乙烯酯共聚物(EVA)

- 电影

- 发泡体

- 黏合剂

- 太阳能电池封装

- 聚乙烯醇(PVOH)

- 纤维

- 纸张涂布剂

- 油漆和涂料

- 建筑涂料

- 工业涂料

- 纺织化学品

- 上浆剂

- 整理加工剂

- 造纸化学品

- 活页夹

- 层压板

- 其他的

7. 2022-2035年按分销管道分類的市场估算与预测

- 直销

- 经销商

- 公司

- 线上销售

第八章 2022-2035年各地区市场估算与预测

- 北美洲

- 美国

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 西班牙

- 义大利

- 其他欧洲地区

- 亚太地区

- 中国

- 印度

- 日本

- 澳洲

- 韩国

- 亚太其他地区

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 其他拉丁美洲地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 阿拉伯聯合大公国

- 其他中东和非洲地区

第九章:公司简介

- Celanese Corporation

- LyondellBasell Industries

- Dow

- Mitsubishi Chemical Corporation

- Arkema

- Wacker Chemie AG

- Henan GP Chemicals Co., Ltd.

- Suneco Chem

- Meru Chem Pvt.Ltd.

- Tiankai Chemical

- Gantrade Corporation

- Opes International

- Jubilant Ingrevia

- Vinipul Chemicals

The Global Vinyl Acetate Monomer (VAM) Market was valued at USD 17.3 billion in 2025 and is estimated to grow at a CAGR of 4.5% to reach USD 26.2 billion by 2035.

The market is propelled by the rising demand for high-performance, sustainable packaging solutions and the expanding use of VAM-derived polymers such as polyvinyl acetate, ethylene-vinyl acetate, and polyvinyl alcohol. These polymers are favored in packaging films and flexible laminates due to their excellent bonding, waterproofing, and versatility. The demand is further fueled by increased consumption of consumer goods, industrial packaging, and growth across the construction, automotive, and industrial coatings sectors. Rising urbanization, infrastructure development, and renovation activities are increasing the use of adhesives, sealants, coatings, and composites based on VAM resins. Environmental regulations promoting low-VOC and water-based formulations are shifting some applications from traditional solvent-based materials. Advanced production technologies and optimized manufacturing processes are enhancing efficiency, ensuring supply reliability, and strengthening competitive positions in the global market.

| Market Scope | |

|---|---|

| Start Year | 2025 |

| Forecast Year | 2026-2035 |

| Start Value | $17.3 Billion |

| Forecast Value | $26.2 Billion |

| CAGR | 4.5% |

The polyvinyl acetate segment generated USD 7.1 billion in 2025, driven by its widespread use in adhesives, paints, coatings, and construction materials. Its superior bonding, easy formulation, and compatibility with water-based applications make it a key ingredient in packaging, woodworking, and paper applications. The growing preference for environmentally friendly, low-VOC adhesives continues to reinforce its importance in the global VAM landscape.

The packaging industry reached USD 3.8 billion in 2025, accounting for the highest consumption of VAM. Polymers such as PVA, PVB, and EVOH, derived from VAM, provide exceptional adhesion, clarity, and barrier properties essential for moisture- and oxygen-resistant packaging. Growth in e-commerce, FMCG distribution networks, and the shift toward lightweight, recyclable packaging materials drives demand in this segment.

North America Vinyl Acetate Monomer (VAM) Market accounted for USD 4.5 billion in 2025. The region holds a 26% share due to its integrated petrochemical infrastructure, abundant supply of feedstocks like ethylene and acetic acid, and a mature downstream market for adhesives, water-based coatings, packaging films, and construction polymers. This strong industrial base ensures consistent high-volume VAM consumption and stable market growth.

Major players operating in the Global Vinyl Acetate Monomer (VAM) Market include Celanese Corporation, LyondellBasell Industries, Dow, Mitsubishi Chemical Corporation, Arkema, Wacker Chemie AG, Henan GP Chemicals Co., Ltd., Suneco Chem, Meru Chem Pvt. Ltd., Tiankai Chemical, Gantrade Corporation, Opes International, Jubilant Ingrevia, and Vinipul Chemicals. Companies in the Vinyl Acetate Monomer (VAM) Market strengthen their foothold by investing heavily in research and development to improve product performance, sustainability, and application versatility. They expand manufacturing capacities and establish integrated production facilities to secure reliable supply chains and reduce costs. Strategic partnerships, collaborations with downstream polymer producers, and geographic market expansion help target high-growth regions. Firms also adopt environmentally compliant production processes and low-VOC formulations to meet regulatory standards and attract eco-conscious clients.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Usage

- 2.2.3 End use industry

- 2.2.4 Distribution

- 2.3 TAM Analysis, 2026-2035

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Growing demand for waterborne adhesives & coatings

- 3.2.1.2 Expansion of packaging industry

- 3.2.1.3 Shift from solvent-based to water-based formulations

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 Raw material price volatility

- 3.2.2.2 Stringent VOC emission regulations

- 3.2.3 Market opportunities

- 3.2.3.1 High-barrier EVOH films for food packaging

- 3.2.3.2 Medical-grade EVA for pharmaceutical delivery systems

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By Usage

- 3.8 Future market trends

- 3.9 Technology and innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (HS code) (Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly initiatives

- 3.13 Carbon footprint considerations

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates and Forecast, By Usage, 2022 - 2035 (USD Billion) (Kilo Tons)

- 5.1 Key trends

- 5.2 Polyvinyl acetate

- 5.3 Polyvinyl alcohol

- 5.4 Polyvinyl butyral

- 5.5 Ethylene vinyl alcohol

- 5.6 Vinyl chloride-vinyl acetate copolymer

- 5.7 Polyvinyl formal

- 5.8 Others

Chapter 6 Market Estimates and Forecast, By End Use Industry, 2022 - 2035 (USD Billion) (Kilo Tons)

- 6.1 Key trends

- 6.2 Polyvinyl acetate (PVAc)

- 6.2.1 Emulsion polymers

- 6.2.2 Adhesives

- 6.2.3 Paints & binders

- 6.3 Ethylene vinyl acetate (EVA)

- 6.3.1 Films

- 6.3.2 Foams

- 6.3.3 Hot-melt adhesives

- 6.3.4 Solar encapsulants

- 6.4 Polyvinyl alcohol (PVOH)

- 6.4.1 Fibers

- 6.4.2 Paper coatings

- 6.5 Coatings & paints

- 6.5.1 Architectural coatings

- 6.5.2 Industrial coatings

- 6.6 Textile chemicals

- 6.6.1 Sizing agents

- 6.6.2 Finishing agents

- 6.7 Paper Chemicals

- 6.7.1 Paper binders

- 6.7.2 Laminates

- 6.8 Others

Chapter 7 Market Estimates and Forecast, By Distribution Channel, 2022 - 2035 (USD Billion) (Kilo Tons)

- 7.1 Key trends

- 7.2 Direct sales

- 7.3 Distributors

- 7.4 Merchant traders

- 7.5 Online sales

Chapter 8 Market Estimates and Forecast, By Region, 2022 - 2035 (USD Billion) (Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Rest of Europe

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.4.6 Rest of Asia Pacific

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.5.4 Rest of Latin America

- 8.6 Middle East and Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

- 8.6.4 Rest of Middle East and Africa

Chapter 9 Company Profiles

- 9.1 Celanese Corporation

- 9.2 LyondellBasell Industries

- 9.3 Dow

- 9.4 Mitsubishi Chemical Corporation

- 9.5 Arkema

- 9.6 Wacker Chemie AG

- 9.7 Henan GP Chemicals Co., Ltd.

- 9.8 Suneco Chem

- 9.9 Meru Chem Pvt.Ltd.

- 9.10 Tiankai Chemical

- 9.11 Gantrade Corporation

- 9.12 Opes International

- 9.13 Jubilant Ingrevia

- 9.14 Vinipul Chemicals