|

市场调查报告书

商品编码

1436035

过程分析设备:市场占有率分析、产业趋势与统计、成长预测(2024-2029)Process Analytical Instrumentation - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

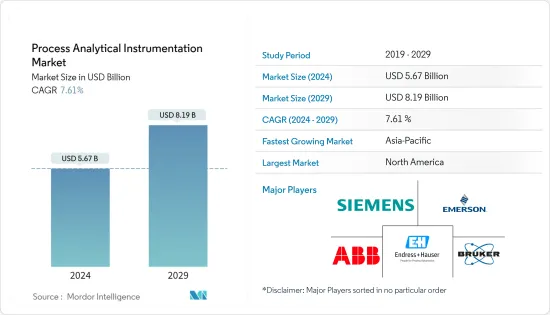

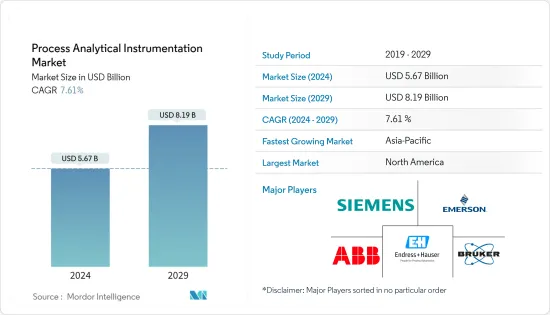

过程分析仪市场规模预计到 2024 年为 56.7 亿美元,预计到 2029 年将达到 81.9 亿美元,在预测期内(2024-2029 年)增长 7.61%。复合年增长率为

主要亮点

- 程式工程中使用最广泛的分析是製程气体层析法。它是最常用的气体分析方法,因为它可以同时分析多种成分。气相层析的停机时间很长,需要仔细监控。气相层析由一系列精选的製程模组化炉组成,可使用单独的模组进行维修和更换。此外,这还可以减少设备停机时间并提高流程生产力。过程气相层析是碳氢化合物和其他复杂气体分析中使用最广泛的分析仪器,但客户发现製程气相层析很困难。

- 製造业自动化的成长推动了所研究市场的发展。由于工业4.0世界的影响,製造业正走向自动化。过程分析设备非常适合这一不断发展的趋势。例如,透过将标准与基本现场汇流排和电子设备说明语言等数位通讯技术整合,可以轻鬆存取设备收集的信息,从而增强流程并实现持续的准确性。

- 近年来,所研究市场的成长是由程式工程中设备使用的增加、全球对药品的高投资、药品安全方面的严格监管、对食品质量的日益重视以及原油的开发等因素推动的。石油. 推广者页岩气生产和质谱技术进步。光谱仪正在环境、石化、食品安全、冶金、地球化学和临床毒理学研究中得到应用。这些产品主要用于中国、印度和拉丁美洲市场,以符合日益严格的国际环境和消费者安全法规。

- 此外,市场的未来也受到以下因素的影响:全球对药品的大量投资、严格的药品安全法规、原油和页岩气产量的扩大以及对食品品质和质谱仪技术进步的日益关注。有重大影响。

- 然而,分析仪器的软体许可必须被视为所研究市场的主要挑战之一,因为许可因公司而异。例如,有些可能允许我们使用其他电脑上的软体来处理资料。有些要求您为此目的购买第二张许可证。因此,此类问题可能会对预测期内所研究市场的成长产生负面影响。

- COVID-19 爆发期间,全球经济面临压力。经过多年的强劲成长,全球贸易放缓,主要是由于欧洲和美国问题的累积。未来新兴国家也可能出现类似的问题。然而,这些短期走势应该揭示全球贸易体系的长期结构性变化,预计这些变化将有利于所研究的市场。

过程分析技术市场趋势

製药和生物技术正在经历显着成长

- 该部门包括从事药品和药品製造的公司。它还包括提供用于治疗和诊断的医疗设备的公司。

- 生物製药製造业依靠分析测试来提高生产力、製程优化和监控、生技药品和生物仿製药表征以及即时产品品管。所有这些对于在生物製造中创建更简化的流程至关重要,从而降低成本、更一致的产品品质以及整体上更有效率的製造。

- 製药业一直在寻求提高产品品质的方法。随着时间的推移,随着设备变得越来越准确,业界也变得更加重视效率。因此,增加对药物研发的投资将为所研究市场的成长创造良好的前景。例如,根据 EvaluatePharma 的数据,预测期内全球药物研发支出预计将达到 2,540 亿美元。

- 此外,层析法和光谱等重要的分析工具正在获得新的地位。 GC 用于后製,因为层析法(GC) 设备可以分析小而轻的化合物。换句话说,GC是品管中的一个标准流程。然而,气相层析在製药业的主要应用是挥发性杂质的鑑定。

- 光谱学有多种技术,每种技术在不同的生产阶段都表现出色。虽然近红外线(NIR) 和傅立叶转换红外线(FTIR) 吸收光谱等一些方法已被广泛接受,但兆赫光谱等新技术的广泛采用也可能有利于药品生产。最近,光谱学也开始关注药物的结构组成和分布。它还在品管方面有其他应用,有助于检验製造过程和最终产品是否符合严格的合规性和监管控制。这些趋势将有利于所研究市场未来的成长。

北美占有很大的市场占有率

- 北美製程分析技术 (PAT) 和设备供应商在过去几年中不断提高其技术的易用性、准确性、可靠性和有效性。该领域的公司引入了技术开发和其他创新,以更好地支援实验室和 QA/QC业务。

- 石油和天然气、金属和采矿以及製药等行业的传统生产方法涉及包括製造最终产品和实验室分析以检验最终成品品质的过程。然而,这些传统方法有几个缺点,包括反覆出现的製造困难、持续的製程优化以及批次失败的可能性。因此,为了克服这些缺陷,FDA(美国食品药物管理局)引入了一种称为PAT的新技术来改变操作模式。

- 美国FDA 发布了实施 PAT 的法规结构概述。透过此框架,FDA 寻求鼓励製药业加强其生产流程。例如,2021年1月,ENVEA推出了一款新型可携式多气体监测仪。它旨在满足监管和定期排放监测的要求,同时节省使用者全天现场时间。 MIR 9000P 符合全球法规和标准,包括美国EPA。它保证了 8 个参数(NOx、SO2、CO、CO2、CH4、N2O、O2 和残余 H2O)的出色精度和宽测量范围。分析仪采用具有气体过滤相关性 (NDIR-GFC) (SRM) 的非色散红外线技术,同时使用内建顺顺磁性感测器测量 O2。

- 由于美国和加拿大的存在,该地区在过程分析设备市场中占据了很大份额,这两个国家在研发方面投入巨资,在生命科学、石油和天然气、材料科学、製药和製药等领域占有重要份额。生物製药行业。马苏。据Pharmaceutical Commerce称,美国药品市场正在成长。到 2023 年,美国人预计将在药品上花费 6,350 亿美元至 6,550 亿美元。与2019年相比,这显示2020年支出稳定成长29.6-33.7%。

- 新药核准的增加将极大地促进药品解决方案的成长,并加强对药品製造过程中分析溶液的化学成分或物理性质的製程分析设备的要求。例如,FDA 药物评估与研究中心 (CDER) 于 2022 年核准了37 种新药和生物製药。此外,2022 年核准的37 种新药中有 20 种(54%)被 CDER 认定为First-in-Class。

流程分析技术产业概况

过程分析设备市场由几家主要公司细分。两家公司继续投资于策略合作伙伴关係和产品开发,以获得市场占有率。该市场的主要参与者包括 ABB Ltd、西门子 AG、布鲁克公司、艾默生电气公司和 Endress &Hauser。市场的最新发展包括:

- 2023 年 4 月 - 印度科学技术部发起倡议,该部将为该部支持下建立的仪器设施 (AIF) 的维护和劣化提供财政支持。政府的设备升级预防性维修和维护支援 (SUPREME) 计划扩大了对维护、维修、劣化或购买额外配件的财政支持,以提高现有分析仪设备的功能能力。

- 2022 年 6 月 - Endress+Hauser AG 推出 LiquilineSystem CA80TN,可提供准确且定期合规的总氮线上测量。 LiquilineSystem CA80TN 比色分析仪提供即时氮值,协助废水处理厂管理者控制流程。 CA80TN 分析仪的钛反应器及其硬涂层滤光片可提供卓越的长期性能。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业价值链分析

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买方议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

- COVID-19 对市场的影响

第五章市场动态

- 市场驱动因素

- 高效率马达简介

- 更多采用电源管理和预测性维护解决方案

- 市场挑战

- 充满活力的全球经济

第六章市场区隔

- 按类型

- 气相层析

- 气体分析仪

- 液体分析仪

- 光谱仪

- 按最终用户产业

- 油和气

- 化学品/石化产品

- 製药/生物技术

- 金属/矿业

- 水/污水

- 其他的

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 世界其他地区

第七章 竞争形势

- 公司简介

- ABB Ltd.

- Siemens AG

- Bruker Corporation

- Emerson Electric Co.

- Endress & Hauser AG

- Extrel CMS LLC

- Focused Photonics Inc.

- Hach Company

- Horiba Ltd

- Mettler Toledo

- MKS Instruments Inc.

- Neo Monitors AS

- Schneider Electric SE

- ServomexGroup Limited

- SICK AG

第八章投资分析

第9章 市场的未来

The Process Analytical Instrumentation Market size is estimated at USD 5.67 billion in 2024, and is expected to reach USD 8.19 billion by 2029, growing at a CAGR of 7.61% during the forecast period (2024-2029).

Key Highlights

- The most vastly used analysis for process engineering is process gas chromatography. It is the most utilized method for gas analysis since it permits multiple components to be analyzed alongside. Gas chromatographs have plenty of downtime and need a lot of supervision. The gas chromatograph consists of a process modular oven choice that another module may fix and replace. Furthermore, this may decrease equipment downtime & improve process productivity. Customers find process gas chromatographs difficult, although they are the most broadly used analyzer for hydrocarbon & other complicated gas analyses.

- The growth of automation in the manufacturing sector has driven the development of the market studied. With the worldwide impact of Industry 4.0, the manufacturing industry is going toward automation. Process analytical instruments are a good fit with this evolving trend. For instance, integrating digital communications technologies & standards like foundation fieldbus & electronic device description language has constructed the information collected by the instruments readily accessible to enhance the process and deliver persistent accuracy.

- In current years, the increase in the market studied has been driven by factors like the growing use of the equipment in process engineering, high investments in pharmaceuticals worldwide, strict regulations on drug safety, growing emphasis on the quality of food products, development of crude and shale gas production, and technological advancements in mass spectrometers. Spectrometers are discovering applications in environmental, petrochemical, food safety, metallurgical, geochemical, & clinical toxicology research. These products are primarily used in markets like China, India, and Latin America to help comply with growing stringent international environmental & consumer safety regulations.

- Furthemore, the future of the market is anticipated to have a greater influence of factors such as a high investments in pharmaceuticals across the globe, stringent safety regulations medicines, the expansion of crude oil and shale gas production, increasing attention to food quality and technological advances in mass spectrometers.

- However, analytical instrumentation's software licensing should be considered among the major challenging factor to the studied market, as different companies have different licenses. For instance, some allow the use of software on other computers for data processing; while others require the purchase of a second license for this purpose. Hence, such issues may negatively impact the growth of the market studied market during the forecast period.

- During COVID-19 global economy was under stress. After many years of strong growth, global trade slowed, mainly due to the accumulation of problems in Europe and the United States. Similar issues might arise in emerging economies in the future. However, these short-term dynamics should clarify the longer-term structural changes in the global trading system which is anticipated to work in favor of the studied market.

Process Analytical Technology Market Trends

Pharmaceutical and Biotechnology is Observing a Significant Growth

- This segment contains firms engaged in manufacturing medicinal & pharmaceutical products. It also contains companies delivering healthcare devices utilized for treatment or diagnosis.

- The biopharmaceutical manufacturing industry relies on analytical testing to help improve productivity, optimize and monitor processes, characterize biologics and biosimilars, and provide real-time product quality control. All these are essential in creating a more streamlined process within biomanufacturing, resulting in lower costs, more consistent product quality, and more efficient manufacturing across the board.

- The pharmaceutical industry has always searched for ways to improve product quality. Over time, as instrument accuracy and precision improved, the industry began focusing more on efficiency. Hence, the growing investment in pharmaceutical research and development will create a favorable outlook for the growth of the studied market. For instance, according to EvaluatePharma, global spending on pharmaceutical research and development is anticipated to reach USD 254 billion during the forecast period.

- Furthermore, crucial analytical tools like chromatography and spectroscopy are gaining new ground. Since chromatography (GC) machines can analyze tiny and light compounds, GC is used in post-production. In other words, GC is a standard process during quality control. However, identifying volatile impurities is the primary use of GC within the pharmaceutical industry.

- There are several optical spectroscopy techniques, and each excels at various manufacturing stages. While some methods enjoy wide acceptance, such as near-infrared (NIR) and Fourier transform infrared (FTIR) absorption spectroscopy, broader adoption of newer techniques, such as terahertz Raman spectroscopy, can also benefit pharmaceutical production. More recently, spectroscopy has also begun to focus on the structural composition and distribution of pharmaceutical products. It has additional applications in quality control, which help validate that the manufacturing process and end products meet strict compliance and regulatory controls. Such trends will favor the growth of the studied market in future.

North America to Hold a Significant Market Share

- Process analytical technology (PAT) and instrument vendors in North America have continually advanced their technology's usability, accuracy, reliability, and efficacy in the past few years. Companies in this sector introduced technological developments and other innovations to better support lab and QA/QC operations.

- The traditional ways of production in the industries, such as oil and gas, metal and mining, and pharmaceuticals, involved processes that included manufacturing of the finished products and laboratory analysis for verifying the quality of the final finished products. However, these traditional methods have some drawbacks as recurring manufacturing difficulties, constant process optimization, and the probability of failed batches. Thus, to overcome these glitches, the new technology known as PAT was introduced by FDA (Food and Drug Administration) to change the mode of operation.

- The US FDA has outlined a regulatory framework for PAT implementation. With this framework, the FDA tries to motivate the pharmaceutical industry to enhance the production process. For instance, in January 2021, the new portable multi-gas monitor was launched by ENVEA, intending to meet the demands of regulatory and routine stack emission monitoring while saving users'' time throughout their on-site day. The MIR 9000P complies with global regulations and standards, including US EPA's. For eight parameters, it ensures great accuracy and wide measuring ranges (NOx, SO2, CO, CO2, CH4, N2O, O2, and residual H2O). The analyzer uses a built-in paramagnetic sensor to measure O2 while using the non-dispersive infrared technique with gas filter correlation (NDIR-GFC) (SRM).

- Owing to the existence of the United States and Canada, which are the countries that spend a substantial amount on research and development and hold a prominent share in life sciences, oil and gas, materials sciences, pharma, and biopharma industries, the region holds a major share of the process analytical instrumentation market. According to Pharmaceutical Commerce, the pharmaceutical market is on the rise in the United States. By 2023, it is expected that Americans will spend USD 635 to USD 655 billion on pharmaceuticals; compared to 2019, this indicated a solid 29.6-33.7% rise in spending in 2020.

- The increase in the approval of new drugs would significantly drive the rise of pharmaceutical solutions, which would enhance the requirement of process analytical instruments to analyze the chemical composition or physical properties of the solution during drug making. For instance, the FDA's Center for Drug Evaluation and Research (CDER) approved 37 new drugs and biological products in 2022. Furthermore, 20 of the 37 novel drugs approved in 2022 (54%) were identified by CDER as first-in-class.

Process Analytical Technology Industry Overview

The process analytical instrumentation market is fragmented, with several major companies. The companies continuously invest in strategic partnerships and product developments to gain market share. Some major players in the market are ABB Ltd, Siemens AG, Bruker Corporation, Emerson Electric Co., and Endress & Hauser. Some of the recent developments in the market are:

- April 2023 - India's Science and Technology Minister launched an initiative under which the ministry will provide financial support for the maintenance and degradation of analytical instrumentation facilities (AIFs) created under the ministry's support. The Support for Up-gradation Preventive Repair and Maintenance of Equipment (SUPREME) program by the government extends financial support for maintenance, repair, degradation, or acquiring additional attachments to increase the functional capabilities of existing analytical instrumentation facilities.

- June 2022 - Endress + Hauser AG launched the LiquilineSystem CA80TN, which provides a precise and regular-compliant online measurement of total nitrogen. The LiquilineSystem CA80TN colorimetric analyzer could deliver real-time nitrogen values, helping wastewater treatment plant managers control their processes. The titanium reactor of the CA80TN analyzer and its hard-coated optical filters could offer superior long-term performance.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitutes

- 4.3.5 Degree of Competition

- 4.4 Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Introduction of High-efficient Motors

- 5.1.2 Increasing Adoption of Power Management and Predictive Maintenance Solutions

- 5.2 Market Challenges

- 5.2.1 Dynamic Global Economy

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Gas Chromatographs

- 6.1.2 Gas Analyzers

- 6.1.3 Liquid Analyzers

- 6.1.4 Spectrometers

- 6.2 By End-user Industry

- 6.2.1 Oil and Gas

- 6.2.2 Chemicals & Petrochemicals

- 6.2.3 Pharmaceutical & Biotechnology

- 6.2.4 Metal & Mining

- 6.2.5 Water & Wastewater

- 6.2.6 Other End-user Industries

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia-Pacific

- 6.3.4 Rest of the World

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 ABB Ltd.

- 7.1.2 Siemens AG

- 7.1.3 Bruker Corporation

- 7.1.4 Emerson Electric Co.

- 7.1.5 Endress & Hauser AG

- 7.1.6 Extrel CMS LLC

- 7.1.7 Focused Photonics Inc.

- 7.1.8 Hach Company

- 7.1.9 Horiba Ltd

- 7.1.10 Mettler Toledo

- 7.1.11 MKS Instruments Inc.

- 7.1.12 Neo Monitors AS

- 7.1.13 Schneider Electric SE

- 7.1.14 ServomexGroup Limited

- 7.1.15 SICK AG