|

市场调查报告书

商品编码

1438439

混合积层製造机器:市场占有率分析、产业趋势与统计、成长预测(2024-2029)Hybrid Additive Manufacturing Machine - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

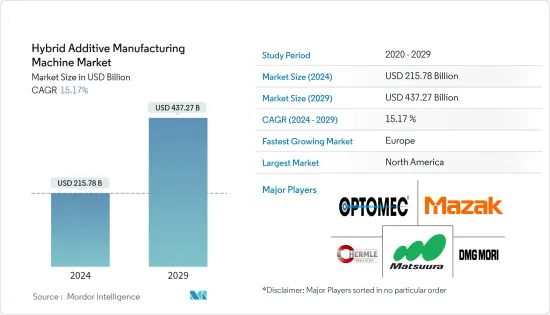

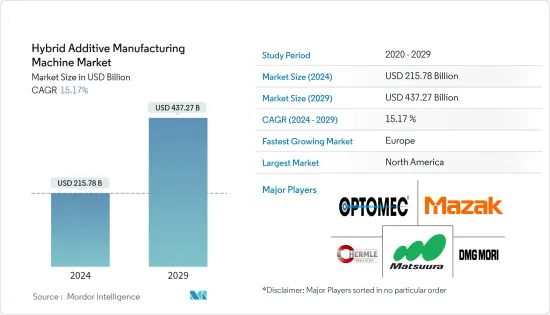

混合积层製造机器市场规模预计到 2024 年为 2,157.8 亿美元,预计到 2029 年将达到 4,372.7 亿美元,在预测期内(2024-2029 年)复合年增长率为 15.17%。

该市场是由航太、国防和汽车行业不断增长的需求所推动的。

混合製造是一种将消减过程製程和添加剂处理结合到一台机器中的製程。市场的主要驱动因素是这两个过程可以在一台机器上执行。对于航太、国防和汽车产业尤其如此。在两种工艺之间即时切换的能力使製造变得更加容易。儘管这项技术与 3D 列印一样相对较新,但混合积层製造的潜在优势让这项技术的采用者对其前景非常乐观。由于冠状病毒感染疾病(COVID-19)的爆发,混合积层製造机械部门的多种产品已停止生产。这主要是由于主要国际市场的封锁延长。这大大减缓了过去几个月混合积层製造设备市场的成长。 COVID-19感染疾病了2020年第一季的设备和机械销售,全年市场成长也受到影响。

混合製造还可以根据需要生产零件,从而无需持有昂贵且占用空间的库存。混合积层製造使製造商能够生产自订材料和快速原型,为新产品和提高效率提供了机会。最近,2023 年 1 月,美国在巴丹号航空母舰上安装了飞利浦的增材混合金属 3D 列印解决方案。该设备还可用于各个行业,减少对环境的负面影响。混合生产过程释放的化学物质和有害污染物较少,并显着减少碳排放。

混合积层製造也透过使用可以沿任意方向移动製造零件的多轴系统来弥补增材製造系统的一些缺点。此外,废弃物减少 95%、效率提高、製程开发和材料表征能力以及材料成本降低等主要优势将进一步推动混合积层製造机器在所有领域的采用。这就是该部门。然而,与这些机器相关的高昂初始投资和安装成本阻碍了市场成长。此外,投资能力较低的中小企业和製造业,由于初期投资成本较高,无法引进机械。

此外,需要熟练且训练有素的工人来操作机器。为了维持设备效能并消除系统损坏问题,公司必须花费大量成本为其员工提供专业培训课程。尼康(Nikon)宣布最近对 Hybrid Manufacturing Technologies Global, Inc. 进行投资。此整合技术可让使用者将附加工具整合到任何平台中,由屡获殊荣的 Hybrid Manufacturing Technologies Global, Inc. (HMT) 成功开发。积层製造 (AM) 领域的产业领导者。这项突破性的解决方案使用户能够透过将多种互补技术组合到一个设定中来充分利用其生产流程。

混合积层製造市场趋势

医疗产业预计将占据较大份额

- 就采用率而言,医疗产业在混合积层製造机器市场中占据了很大份额。混合製造在医疗领域的优势在于可以选择客製化零件,而不是使用现成的钛零件。在医疗产业,混合製造用于製造最终产品,例如手术器械、义肢和植入以及支架。

- 混合积层製造在医疗领域的应用正在增加。其主要原因是越来越多的手术正在进行,越来越多的人开始意识到并利用医疗技术的进步。例如,手术机器人在医疗领域的普及正在推动自动化,这使得医疗领域的混合製造成为必要。

- 此外,与医疗产业的传统製造相比,混合製造的主要优势是缩短产品开发时间、改善患者康復、开发患者或外科医生专用产品、降低製造成本和提高准确性,这是一种进步。

- 医疗领域的积层製造流程传统上也被认为是一种仅用于创建原型或模型的技术。然而,随着先进技术和生物相容性材料的发展,采用混合製造作为主要製程的市场不断成长。

- 此外,数位化正在迅速发展,包括3D列印在内的一切都在网路上完成。 3D 文件可以在线上平台上按需储存和订购,客户和经销商可以随时随地轻鬆存取。从趋势来看,医疗设备的3D列印前景乐观。这些做法预计将进一步增加该行业的市场需求,因为它们有助于医疗保健专业人员重复手术、缩短手术时间并限制决策时间。然而,混合积层製造机器的高成本预计将阻碍市场的发展。

北美占主要份额

- 由于存在多个主要参与者且各行业混合积层製造机器的消耗量相对较高,预计北美地区将在混合增材製造机器市场中占据主要收益份额。

- 然而,医生和患者对新医疗技术的好处越来越了解,加速了这些技术在该地区的采用。

- 北美也是最早采用先进医疗技术的国家之一。此外,不断增加的医疗保健成本、高可支配收入、低製造成本、快速产品开发以及越来越多的外科手术取代医疗旅游正在推动市场相关人员的兴趣。

- 此外,美国航太和汽车工业的持续扩张带动了工业的快速发展。人们对提供高效生产能力的混合製造机械的认识不断提高,正在推动整个产业的需求。

混合积层製造机械产业概述

由于存在提供积层製造中使用的机器和设备的大型供应商,混合混合製造机械市场的竞争形势适度集中,这些供应商占据了大部分市场占有率。提供混合製造机械的公司正在寻求新产品开发、创新、併购、伙伴关係和协作等,以便在竞争激烈的行业中保持竞争力并增强其在全球范围内的混合积层製造机械产品。采用了多种策略。此外,混合製造机械市场的主要企业专注于技术先进且具有成本效益的设备的创新和开发,这使得设备价格实惠,这使得它不仅适合大型工业,而且适合大多数人。到行业。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究成果

- 调查先决条件

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场动态

- 市场概况

- 市场驱动因素与阻碍因素简介

- 市场驱动因素

- 工业4.0集成

- 医疗保健和汽车等行业对病患专用零件的需求越来越大。

- 市场限制因素

- 混合积层製造机器的购买和安装成本通常很高,这可能会阻碍小型製造商和公司采用这项技术。

- 确保混合製造流程中一致的品质和准确性可能具有挑战性,因为它们需要积层和减材阶段之间的紧密整合、精确校准和维护。

- 市场机会

- 航太和国防领域的采用率增加

- 石油和天然气能源产业可以受益于混合积层製造机器,这些机器可以生产具有更高耐腐蚀和结构完整性的复杂零件。

- 产业价值链分析

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买方议价能力

- 新进入者的威胁

- 替代产品的威胁

- 竞争公司之间的敌意强度

- 技术简介

第五章市场区隔

- 按最终用户产业

- 航太和国防

- 能源和电力

- 电子产品

- 医疗保健

- 车

- 其他最终用户产业

- 地区

- 北美洲

- 欧洲

- 亚太地区

- 世界其他地区

第六章 竞争形势

- 公司简介

- Optomec, Inc.

- Mazak Corporation

- DMG MORI

- Matsuura Machinery Ltd.

- Hybrid Manufacturing technologies

- ELB-SCHLIFF Werkzeugmaschinen GmbH

- Mitsui Seiki, Inc.

- Okuma America Corporation

- Diversified Machine Systems

- Fabrisonic*

第七章 投资分析

第八章市场的未来

The Hybrid Additive Manufacturing Machine Market size is estimated at USD 215.78 billion in 2024, and is expected to reach USD 437.27 billion by 2029, growing at a CAGR of 15.17% during the forecast period (2024-2029).

The market is driven by the increasing demand from the aerospace, defense, and automotive industries.

Hybrid manufacturing is the process of putting both subtractive and additive processes into a single machine. The market is mostly driven by the fact that both processes can be done on one machine. This is especially true in the aerospace, defense, and automotive industries. It makes manufacturing effortless with the capability to switch between two processes instantly. Although the technology is relatively new, much like 3D printing, the potential benefits of hybrid additive manufacturing have made the adopters of the technology very optimistic about the technology's prospects. The COVID-19 epidemic halted the production of several items in the hybrid additive manufacturing machine sector, mostly because of the extended lockdown in important international markets. This severely slowed the market growth for hybrid additive manufacturing equipment during the past several months. COVID-19 impacted equipment and machinery sales in the first quarter of 2020, and market growth suffered throughout the year.

Hybrid manufacturing also makes parts as they are needed, so there is no need to keep expensive and space-consuming stock. With hybrid additive manufacturing, manufacturers can produce custom materials and rapid prototypes and provide an opportunity for new products and better efficiency. Recently, in January 2023, the US Navy installed a Phillips additive hybrid metal 3D printing solution on USS Bataan. Also, using this equipment in different industries helps to reduce the bad effects on the environment. The hybrid production processes release fewer chemical and hazardous pollutants and account for a major reduction in the carbon footprint.

Also, hybrid additive manufacturing makes up for some of the flaws of the additive manufacturing system by using multi-axis systems that let the parts being made move in any direction. Also, 95% waste reduction, better efficiency, capabilities for process development and material characterization, and material and material cost savings, etc., are some of the major benefits that are further augmenting the adoption of hybrid additive manufacturing machines across sectors. However, high initial investments and installation costs associated with these machines are hindering market growth. Further, SMEs and manufacturing companies with low investment capabilities are unable to deploy the machinery due to the high initial investment costs.

Additionally, the machines require skilled and well-trained labor to operate them. To maintain equipment performance and eliminate system breakage issues, companies need to incur huge costs to provide professional training sessions for workers. Nikon Corporation (Nikon) has disclosed a recent investment in Hybrid Manufacturing Technologies Global, Inc. An integration technique that enables users to integrate additive tools onto any platform was successfully developed by Hybrid Manufacturing Technologies Global, Inc. (HMT), an award-winning industry leader in additive manufacturing (AM). By combining several complementary technologies in a single setup, this ground-breaking solution enables users to fully use the production process.

Hybrid Additive Manufacturing Machine Market Trends

Medical Sector Expected to Hold a Significant Share

- In terms of rate of deployment, the medical sector holds a significant share of the market for hybrid additive manufacturing machines. The benefits of hybrid manufacturing in the medical sector are due to the option to customize parts rather than using pre-made titanium pieces. In the medical industry, hybrid manufacturing is used to make end products such as surgical equipment, prosthetics and implants, and scaffolds.

- The use of hybrid additive manufacturing in the medical field is growing, mostly because more surgeries are being done and more people are becoming aware of and using advances in medical technology. For example, the widespread use of surgical robots in the medical field is leading to automation, which is why the medical field needs hybrid manufacturing.

- Further, the major benefits of hybrid manufacturing over traditional manufacturing in the medical industry are short product development times, better patient recovery, the development of patient- or surgeon-specific products, low manufacturing costs, and better accuracy.

- Also, traditionally, the additive manufacturing process in the medical field was considered a technique used solely to produce prototypes or models. However, with the development of advanced technologies and biocompatible materials, the market has grown in its adoption of hybrid manufacturing as a major process.

- Also, with a splurge in digitization, everything, including 3D printing, is happening online. 3D files can be kept on an online platform that is easily accessible to clients or distributors everywhere at any time to order on demand. According to the trends, 3D printing for medical devices seems optimistic. Such practices are further expected to augment market demand in the industry because they help medical practitioners repeat the operation, reduce the time of the surgery, and limit the decision-making time. However, the high cost of hybrid additive manufacturing machines is expected to hamper the market.

North America to Hold a Major Share

- The North American region is expected to hold a major share in the hybrid additive manufacturing machines market in terms of revenue, owing to the presence of several major players and the relatively higher consumption of hybrid manufacturing machines across all industry verticals.

- However, doctors and patients are becoming more educated about the benefits of new medical technologies, which is helping to speed up the adoption of these technologies in the region.

- Also, North America has been an early adopter of advanced medical technologies. Moreover, the increasing healthcare expenditure, high disposable incomes, low cost of manufacturing, rapid product development, and a growing number of surgical procedures in lieu of medical tourism have amplified the interest of market players.

- Furthermore, the continuous expansion of the aerospace and automotive industries in the U.S. is driving industry development at a rapid pace. The rising awareness of hybrid manufacturing machines that offer efficient production capabilities is driving overall industry demand.

Hybrid Additive Manufacturing Machine Industry Overview

The competitive landscape of the hybrid additive manufacturing machine market is moderately concentrated due to the presence of major vendors providing the machines and equipment used for hybrid manufacturing, and these vendors hold the majority market share. The companies providing hybrid manufacturing machines adopt various strategies, such as new product development, innovations, mergers and acquisitions, partnerships and collaborations, to sustain in the highly competitive industry and to enhance their hybrid additive-manufacturing machines offerings worldwide. Moreover, major players in the hybrid manufacturing machine market are focusing on innovation and development of technologically advanced and cost-effective equipment so that they are affordable and hence applicable to a majority of industries and not just large industries.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Introduction to Market Drivers and Restraints

- 4.3 Market Drivers

- 4.3.1 Industry 4.0 Integration

- 4.3.2 In industries like healthcare and automotive, there is a growing demand for customized and patient-specific parts.

- 4.4 Market Restraints

- 4.4.1 Hybrid additive manufacturing machines are often expensive to acquire and install, which can deter smaller manufacturers and businesses from adopting this technology.

- 4.4.2 Ensuring consistent quality and precision in hybrid manufacturing processes can be challenging, as it requires tight integration between additive and subtractive stages, precise calibration, and maintenance

- 4.5 Market Opportunities

- 4.5.1 Increased Adoption in Aerospace and Defense

- 4.5.2 The energy sector, including oil and gas, can benefit from hybrid AM machines for producing complex components and parts with improved corrosion resistance and structural integrity

- 4.6 Industry Value Chain Analysis

- 4.7 Industry Attractiveness - Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers/Consumers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitute Products

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Technology Snapshot

5 MARKET SEGMENTATION

- 5.1 By End-user Industry

- 5.1.1 Aerospace & Defense

- 5.1.2 Energy & Power

- 5.1.3 Electronics

- 5.1.4 Medical

- 5.1.5 Automotive

- 5.1.6 Other End-user Industries

- 5.2 Geography

- 5.2.1 North America

- 5.2.2 Europe

- 5.2.3 Asia-Pacific

- 5.2.4 Rest of the World

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Optomec, Inc.

- 6.1.2 Mazak Corporation

- 6.1.3 DMG MORI

- 6.1.4 Matsuura Machinery Ltd.

- 6.1.5 Hybrid Manufacturing technologies

- 6.1.6 ELB-SCHLIFF Werkzeugmaschinen GmbH

- 6.1.7 Mitsui Seiki, Inc.

- 6.1.8 Okuma America Corporation

- 6.1.9 Diversified Machine Systems

- 6.1.10 Fabrisonic*