|

市场调查报告书

商品编码

1440438

碳泡沫:市场占有率分析、产业趋势与统计、成长预测(2024-2029)Carbon Foam - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

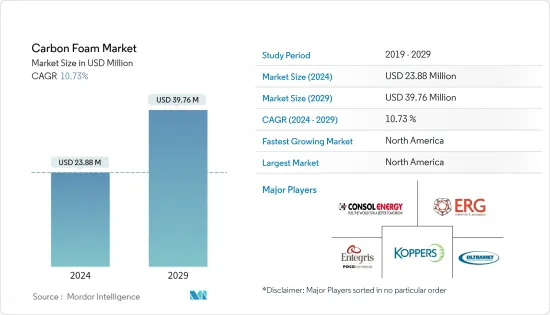

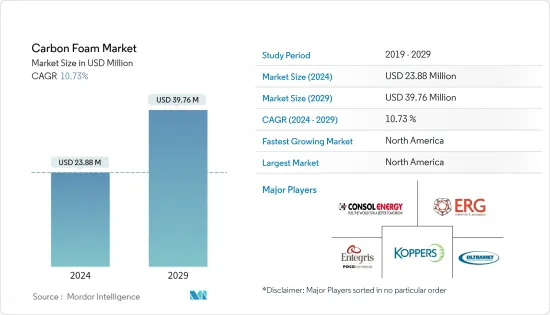

碳泡沫市场规模预计到 2024 年为 2,388 万美元,预计到 2029 年将达到 3,976 万美元,在预测期内(2024-2029 年)复合年增长率为 10.73%。

由于供应炼和市场中断,COVID-19 对 2020 年的市场产生了重大影响。疫情期间,许多负责生产碳泡沫的工厂关闭。然而,市场正在迅速成长,并已达到疫情前的水平。

主要亮点

- 短期内,碳泡沫在航太和国防工业的使用不断增加将是推动市场需求的关键因素。

- 碳泡沫製造过程的高成本阻碍了市场的成长。

- 对低成本碳泡沫开发的日益关注可能会在未来几年创造市场机会。

- 北美地区预计将主导市场,并且在预测期内也可能出现最高的复合年增长率。

碳泡棉市场趋势

越来越多地在航太和国防工业中使用

- 碳泡沫可用于製造各种航太和国防应用的工程材料,包括航太工具、耐火结构产品、吸能结构、防爆系统和高温结构。广泛用于飞机和火箭的隔热。

- 可用于 EMI 屏蔽和雷达吸收应用的热保护系统和结构面板。它还可用于隐形技术,这是即将推出的第五代飞机的重要方面。

- 由于其重量轻、强度大和优良的热性能,也用于恶劣环境下的火箭喷嘴系统。固体火箭马达透过燃烧固体推进剂产生热气体并通过喷嘴排放产生推力。

- 石墨碳泡沫可以防御爆炸性能量、定向能量武器和电磁脉衝威胁。

- 2022年2月,中国动态研究发展中心测试了一种碳泡沫基涂层,以提高高超音速武器的性能。我们发现,基于碳泡沫的涂层可以将衝击波衝击减少 20% 以上,并显着提高动态稳定性。他也表示,碳泡沫作为未来高超音速飞行的涂层材料具有巨大潜力。

- 2021年10月,美国复合材料协会认可了空军研究中心进行的部分研究成果。该实验室开发了碳泡沫技术和相关材料,用于关键系统和复合工具,例如波音 787 梦幻飞机以及空军和 NASA 卫星。

- 根据波音《2022-2041 年商业展望》,到 2041 年,全球新飞机交付总量预计将达到 41,170 架。由于如此巨大的预期交付,预计在预测期内全球对碳泡沫的需求将会增加。

- 此外,根据斯德哥尔摩国际和平研究所(SIPRI)的数据,去年全球军费总额较2020年成长0.7%,达到21,130亿美元。此外,2021年最大的五个支出国是美国、中国、印度、英国和俄罗斯,占支出的62%。因此,军事和国防费用的增加预计将支持国防应用对碳泡沫的需求。

美国将征服北美地区

- 北美地区预计将主导市场。美国是该地区最大、最强大的经济体之一。

- 2021 年 7 月,美国农业部林业局林业产品研究所和Ligsteel LLC 的科学家与Domtar Inc. 合作,从木质素中提取了高价值的碳,木质素是一种在植物细胞壁中发现的物质,可以使碳泡沫变硬。木质素价格低廉且来源广泛,纸浆和造纸工业每年生产 7,000 万吨。

- 美国是仅次于中国的第二大电动车市场。从电动车销量来看,去年国内插电式电动车保有量约65.69万辆,较2020年成长约100%。

- IEA 表示,联邦政府的目标是到 2030 年电动车 (EV) 占美国新小客车和轻型卡车销量的 50%。此外,根据国际清洁交通理事会的数据,2020年,加州政府宣布一项州强制令,要求到2035年在加州销售的所有新车和搭乘用均为零排放车辆,包括纯电动车和插电式混合动力汽车。也宣布了一项行政命令授权

- 此外,根据美国联邦航空管理局(FAA)的数据,该国与前一年同期比较民航机数量为5,882架,年减22.9%。预计到 2041 年,商业船队将增至 8,756 艘船舶,复合年增长率为 2%。预计这将增加航太多种应用的市场需求。

碳泡沫产业概况

目前,碳泡沫市场本质上是整合的,主要企业占据了调查市场的大部分份额。该市场的主要参与者包括(排名不分先后)CONSOL Energy Inc.、Entegris、Koppers Inc.、Ultramet 和 ERG Aerospace。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章 简介

- 调查先决条件

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场动态

- 促进因素

- 越来越多地在航太和国防工业中使用

- 抑制因素

- 泡沫碳製造製程高成本

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 买方议价能力

- 新进入者的威胁

- 替代产品和服务的威胁

- 竞争程度

第五章市场区隔(以金额为准的市场规模)

- 类型

- 石墨

- 非石墨

- 最终用户产业

- 航太和国防

- 建筑与建造

- 车

- 电

- 产业

- 其他最终用户产业

- 地区

- 亚太地区

- 中国

- 印度

- 日本

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 德国

- 英国

- 其他欧洲国家

- 世界其他地区

- 亚太地区

第六章 竞争形势

- 併购、合资、合作与协议

- 市场排名分析

- 主要企业采取的策略

- 公司简介

- American Elements

- Carbon-Core Corporation

- CONSOL Energy Inc.

- ERG Aerospace

- Firefly International Energy

- Koppers Inc.

- Entegris Inc.

- Ultramet

- Xiamen Zopin New Material Limited

第七章市场机会与未来趋势

- 低成本碳泡沫的开发

- 其他机会

The Carbon Foam Market size is estimated at USD 23.88 million in 2024, and is expected to reach USD 39.76 million by 2029, growing at a CAGR of 10.73% during the forecast period (2024-2029).

COVID-19 highly impacted the market in 2020 because of supply chain and market disruption. During the pandemic, many factories responsible for carbon foam production were shut down. However, the market is growing rapidly and has reached pre-pandemic levels.

Key Highlights

- Over the short term, increasing usage of carbon foam in the aerospace and defense industry is a key factor driving market demand.

- The high cost of the production process of carbon foam is hindering the market's growth.

- Increasing focus on developing low-cost carbon foam will likely create opportunities for the market in the coming years.

- The North American region is expected to dominate the market and is also likely to witness the highest CAGR during the forecast period.

Carbon Foam Market Trends

Increasing Usage in the Aerospace and Defense Industry

- Carbon foam can be used to manufacture engineering material for various aerospace and defense applications, including aerospace tooling, fireproof structural products, energy-absorbing structures, blast protection systems, and hot structures. It is widely used to insulate aircraft and rockets.

- It can be used in thermal protection systems and structural panels for EMI shielding and radar-absorbing applications. It can also be used for stealth technology, an essential aspect of the upcoming fifth-generation aircraft.

- Due to its lightweight nature, strength, and excellent thermal properties, it is also used in rocket nozzle systems, even in harsh environments. Solid rocket motors generate their thrust by burning a solid propellant to generate hot gases, which are exhausted through a nozzle.

- Graphitic carbon foam can protect against blast energy, directed energy weapons, and electromagnetic pulse threats.

- In February 2022, the China Aerodynamics Research and Development Centre tested carbon foam-based coatings on hypersonic weapons to enhance their performance. It found that carbon foam-based coatings could reduce the impact of shock waves by more than 20% and dramatically improve aerodynamic stability. It also mentioned that carbon foam has great application potential as a coating material for future hypersonic flight.

- In October 2021, the American Society for Composites acknowledged some of the research work done by the Air Force Research Laboratory. The laboratory developed carbon foam technology and related materials and applied significant systems, such as those in the Boeing 787 Dreamliner and Air Force and NASA satellites, and composite tooling.

- According to the Boeing Commercial Outlook 2022-2041, the total global deliveries of new airplanes are estimated to be 41,170 by 2041. Due to such huge expected deliveries, the demand for carbon foam is expected to rise globally during the forecast period.

- Furthermore, according to the Stockholm International Peace Research Institute (SIPRI), the total global military expenditure increased by 0.7% to USD 2,113 billion last year compared to 2020. Moreover, the five largest spenders in 2021 were the United States, China, India, the United Kingdom, and Russia, accounting for 62% of expenditure. As a result, rising military and defense spending is expected to support the demand for carbon foam for defense applications.

United States to Dominate the North American Region

- The North American region is expected to dominate the market. The United States is one of the region's largest and most powerful economies.

- In July 2021, scientists from the USDA Forest Service's Forest Products Lab and Ligsteel LLC collaborated with Domtar Inc. to produce high-value carbon foam from lignin, a material found in plant cell walls that makes carbon foam hard. Lignin is inexpensive and widely available, with the pulp and paper industry producing 70 million tons per year.

- The United States is the second-largest market for electric vehicles after China. According to the EV volumes, the country's total plug-in electrical vehicles accounted for around 656,900 units last year, registering a growth rate of ~100% compared to 2020.

- According to the IEA, in the United States, the federal aim is for electric vehicles (EVs) to make up 50% of new passenger cars and light trucks sold by 2030. Moreover, as per the International Council on Clean Transportation, in 2020, the California Government announced an executive order which directs the state to require that, by 2035, all new cars and passenger trucks sold in California be zero-emission vehicles, including BEV and PHEV.

- Moreover, according to the Federal Aviation Administration (FAA), the number of aircraft in the country's commercial fleet accounted for 5,882 in 2020, witnessing a decline rate of 22.9% compared to the previous year. The commercial fleet is forecasted to increase to 8,756 in 2041, with an average annual growth rate of 2% per year. This is expected to increase the market demand from multiple applications in the aerospace industry.

Carbon Foam Industry Overview

The carbon foam market is currently consolidated in nature, where the top players hold the majority share of the market studied. Some of the major players in the market include CONSOL Energy Inc., Entegris, Koppers Inc., Ultramet, and ERG Aerospace (not in any particular order).

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Usage in the Aerospace and Defense Industry

- 4.2 Restraints

- 4.2.1 The High Cost of the Production Process of Carbon Foam

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Type

- 5.1.1 Graphitic

- 5.1.2 Non-graphitic

- 5.2 End-user Industry

- 5.2.1 Aerospace and Defense

- 5.2.2 Building and Construction

- 5.2.3 Automotive

- 5.2.4 Electrical

- 5.2.5 Industrial

- 5.2.6 Other End-user Industries

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 Rest of Europe

- 5.3.4 Rest of the World

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 American Elements

- 6.4.2 Carbon-Core Corporation

- 6.4.3 CONSOL Energy Inc.

- 6.4.4 ERG Aerospace

- 6.4.5 Firefly International Energy

- 6.4.6 Koppers Inc.

- 6.4.7 Entegris Inc.

- 6.4.8 Ultramet

- 6.4.9 Xiamen Zopin New Material Limited

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Development of Low-cost Carbon Foam

- 7.2 Other Opportunities