|

市场调查报告书

商品编码

1441624

半导体产业 - 市场占有率分析、产业趋势与统计、成长预测(2024 - 2029)Semiconductor Industry - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

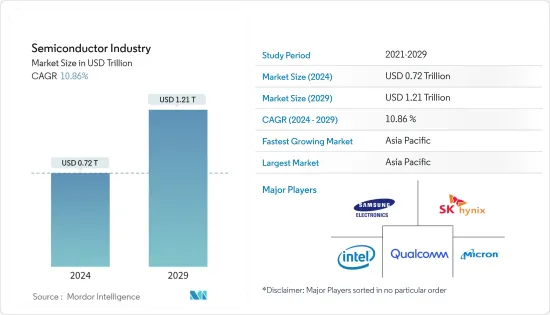

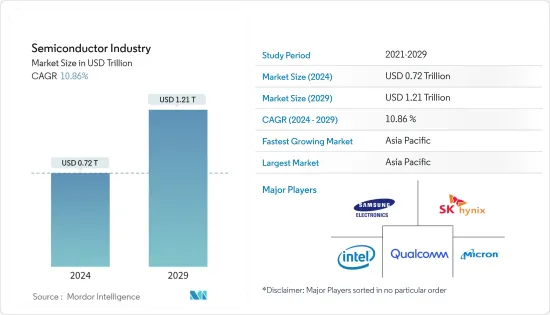

半导体产业预计将从 2024 年的 0.72 兆美元成长到 2029 年的 1.21 兆美元,预测期内(2024-2029 年)CAGR为 10.86%。

主要亮点

- 随着半导体成为当代技术的基本组成部分,半导体产业正在经历迅速扩张。这个行业的进步和突破,直接影响着后续的所有技术。

- 半导体装置是以半导体材料为基础的电子元件。这种材料可用于生产电晶体、二极体和积体电路 (IC) 中的其他基本功能单元。这些设备的特点是既不能很好地导电,也不能充当有效的绝缘体。半导体装置的优点包括其经济性、可靠性和紧凑的尺寸。在过去的几十年里,这些设备在各种电子产品生产中的使用越来越受欢迎,预计在未来几年将继续保持成长势头。

- 半导体产业预计在可预见的未来将出现强劲成长,因为它满足了人工智慧 (AI)、自动驾驶、物联网和 5G 等新兴技术对半导体材料不断增长的需求。这种成长是由主要参与者之间的激烈竞争以及对研发 (R&D) 的持续投资所推动的。因此,供应商不断被推动创新并在市场上获得竞争优势。

- 由于企业广泛采用电气化和自动化,对半导体设备的市场需求预计将增加。电动车正在引领永续未来的运动,其中电子和半导体是关键零件。全球各国政府都为其交通部门的电气化製定了雄心勃勃的目标,促使领先的汽车製造商在电动车研发方面进行大量投资。半导体正在成为电动车的中央处理单元,使它们能够提供最佳性能。因此,电动车投资的不断增长预计将刺激半导体市场的需求。

- 半导体行业需要更多熟练工人。到 2030 年,可能需要增加超过 100 万名技术工人才能满足该行业的需求。此外,半导体产业的特征是交货时间长和资本投资高。製造能力的限制和需求的变化导致供应链短缺。预计这些因素将挑战市场的成长。

- 由于 COVID-19,该行业发生了重大变化,影响了客户行为、业务收入和公司营运。此外,疫情也暴露了供应方面以前未被注意到的风险,可能导致重要零件的短缺。因此,半导体企业正在积极重组供应链以增强弹性,而这些调整可能会在后疫情时代持续下去。

半导体市场趋势

分立半导体将在半导体装置领域占据重要市场份额

- 对高能源和高能效设备的需求不断增长,无线和便携式电子产品的日益普及,加上由于向电气化的转变而在汽车行业中使用这些设备的增加,是推动增长的一些关键因素该段的。

- 分立半导体的重要趋势之一是高效率的电源管理。新的系统架构正在提高交流-直流电源适配器的效率,同时减少尺寸和组件数量。乙太网路供电 (PoE) 的新标准允许更高的功率传输,从而支援新型设备的开发,例如互联照明。

- MOSFET在电信领域一直扮演着重要的角色,因为开关电源是功率MOSFET最普遍的应用,它也常用于MOS射频功率放大器,使行动网路从类比转向数位。根据爱立信的数据,2022年第一季5G用户数增加了7,000万,达到约6.2亿。到2022年底,这一数字预计将达到10亿。这些原因将刺激对功率半导体的需求,从而增加对MOSFET的需求,并导致电信领域的多项突破。

- 此外,各种分立半导体对IGBT的需求不断增长,并广泛应用于低功率转换器。汽车、其他马达驱动和再生能源系统中用于功率转换的最受欢迎的半导体开关是分离式 IGBT。主要驱动力还在于绝缘栅双极电晶体 (IGBT) 装置在汽车、消费性电子、工业、IT 和通讯、医疗保健、航空航太和国防等各个领域的使用不断增加。

- 大多数分立 IGBT 应用包括逆变器、空调和洗衣机等各种消费品、开关模式电源 (SMPS)(个人电脑、焊接设备以及微波炉、电锅、电磁炉等感应加热设备中使用的组件)。炉灶等用于软开关和频闪控制。对 UPS、功率调节器、空调等消费性电子设备的需求不断增长,这些电子设备使用分离式 IGBT 类型进行低电流应用,这被认为推动了分离式 IGBT 市场的成长。人们发现分立式 IGBT 在消费品中具有最低的功率损耗,预计这将成为影响该细分市场市场成长的关键因素。

製造将在半导体材料领域占据重要市场份额

- 半导体製造材料是消费性电子、高阶资料中心、汽车应用、医疗设备、物联网设备、电力电子等领域先进微电子的重要组成部分。该部门涵盖製程化学品、光掩模、电子气体、光阻辅助材料、溅镀靶材、硅和其他材料等材料。

- 推动半导体製造材料需求的主要因素之一是数位整合 IC 在电气、电子、汽车和电信行业中的使用不断增加。此外,由于半导体在太阳能电池板、风力和水轮机驱动器和泵浦以及能量转换中的保护电路中的广泛应用,预计能源领域投资的增加也将对该领域的成长做出积极贡献。确保效率和最小的功率损耗。例如,根据IEA的预测,2022年全球能源投资将成长8%,达到2.4兆美元。此外,根据 IRENA 的数据,再生能源支出预计将稳定成长,从而提振市场。

- 虽然多种材料都可以表现出半导体特性,但某些材料由于其特定的特性而更常用于电子设备的製造。两种最受欢迎的半导体材料是硅和砷化镓。硅是应用最广泛的半导体材料,主要是因为其储量丰富、成本低廉且在高温下性能相对稳定。硅的电导率约为1000S/m。此外,硅拥有完善的製造基础设施,使其成为製造商有吸引力的选择。然而,硅确实有一些缺点,例如与其他材料相比电子迁移率较低,这可能会限制高速元件的性能。

- 砷化镓是另一种流行的半导体材料,因其较高的电子迁移率和直接带隙而受到重视。这些特性使其非常适合光电应用,例如雷射和太阳能电池。然而,砷化镓比硅更昂贵且储量更少,这可能限制其广泛采用。砷化镓的另一个缺点是它本质上是一种半绝缘体,而不是电导率为 0.000001 S/m 的半导体。

- 除了硅和砷化镓之外,研究人员也不断探索具有前景半导体特性的新材料。这些材料包括氮化铝、碳奈米管和许多其他有潜力彻底改变产业的材料。随着对这些新兴材料的了解不断加深,它们可能会在未来的半导体製造中发挥越来越重要的作用。

- 此外,由于低成本方法和半导体领域内部效率的应用,预计製程化学品市场将稳定成长。半导体加工化学品的消耗是由已安装製造能力的成长和新技术消耗的昂贵化学品以及加工的硅晶圆表面积所推动的。

半导体产业概况

半导体产业的主要参与者包括英特尔公司、三星电子、高通、美光科技公司和SK海力士公司,有助于其半整合性质。市场参与者正在积极利用合作伙伴关係和收购等策略来增强其产品组合併确保持久的竞争优势。

2023 年 10 月,美光透过推出 16Gb DDR5 记忆体显着扩展了其 1β 製程节点技术。这款新产品以高达 7,200 MT/s 的速度对系统内功能进行了严格测试和验证,现已交付给美光的资料中心和 PC 客户。美光基于 1β 的 DDR5 记忆体将先进的高 k CMOS 装置技术、4 相时脉系统和时脉同步 1 相结合,效能大幅提升高达 50%,单位效能提升 33%。与上一代相比。

2023 年 9 月,英特尔代工服务 (IFS) 与着名模拟半导体解决方案供应商 Tower Semiconductor 宣布合作。英特尔将扩大其代工服务和 300 毫米製造能力,以协助 Tower 满足其全球客户的需求。作为协议的一部分,Tower 将利用英特尔位于新墨西哥州的先进製造工厂来满足其营运需求。

额外的好处:

- Excel 格式的市场估算 (ME) 表

- 3 个月的分析师支持

目录

第 1 章:简介

- 研究假设和市场定义

- 研究范围

第 2 章:研究方法

第 3 章:执行摘要

第 4 章:市场洞察

- 市场概况

- 科技趋势

- 产业价值链/供应链分析

- COVID-19、宏观经济趋势和地缘政治情景的影响

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争激烈程度

第 5 章:市场动态

- 市场驱动因素

- 消费性电子设备需求的成长推动製造业前景

- 人工智慧、物联网和互联设备在各个行业中的激增

- 半导体在汽车领域的应用不断增加

- 5G部署增加,5G智慧型手机需求上升

- 市场挑战/限制

- 供应链中断导致半导体晶片短缺

- 技术的动态本质要求製造设备发生一些变化

- 垂直整合是OSAT厂商最关心的问题之一

第 6 章:市场细分

- 按下半导体装置

- 分离式半导体

- 光电

- 感应器

- 积体电路

- 按下半导体设备

- 前端装置

- 后端设备

- 依半导体材料

- 製造

- 包装

- 以半导体代工市场划分

- 按外包半导体组装测试服务 (OSAT) 市场划分

第 7 章:竞争格局

- 公司简介

- Intel Corporation

- Samsung Electronics Co. Ltd

- Qualcomm Incorporated

- Micron Technology Inc.

- SK Hynix Inc.

- Texas Instruments Incorporated

- Broadcom Inc.

- Mediatek Inc.

- Applied Materials Inc.

- ASML Holding NV

- Tokyo Electron Limited

- Lam Research Corporation

- KLA Corporation

- Advantest Corporation

- Screen Holdings Co. Ltd

- Teradyne Inc.

- BASF SE

- LG Chem Ltd

- Indium Corporation

- Resonac Holding Corporation

- Kyocera Corporation

- Henkel AG & Co. KGaA

- Sumitomo Chemical Co. Ltd

- Dow Chemical Co. (Dow Inc.)

- Taiwan Semiconductor Manufacturing Company (TSMC) Limited

- Samsung Foundry (Samsung Electronics Co. Ltd)

- United Microelectronics Corporation (UMC)

- GlobalFoundries Inc.

- Semiconductor Manufacturing International Corporation (SMIC)

- Hua Hong Semiconductor Limited

- Powerchip Technology Corporation

- ASE Technology Holding Co.Ltd

- Amkor Technology Inc.

- Jiangsu Changjiang Electronics Technology Co. Ltd

- Powertech Technology Inc.

- Tongfu Microelectronics Co. Ltd

- Tianshui Huatian Technology Co. Ltd

- King Yuan Electronics Co. Ltd

- 供应商市占率

- 供应商市场占有率 - 半导体元件市场

- 供应商市场占有率 - 半导体设备市场

- 供应商市场占有率 - 半导体代工市场

- 供应商市场占有率 - OSAT 市场

第 8 章:投资分析

第 9 章:市场的未来前景

The Semiconductor Industry is expected to grow from USD 0.72 trillion in 2024 to USD 1.21 trillion by 2029, at a CAGR of 10.86% during the forecast period (2024-2029).

Key Highlights

- The semiconductor sector is experiencing a swift expansion as semiconductors are becoming the fundamental components of contemporary technology. The progress and breakthroughs in this industry are directly influencing all subsequent technologies.

- Semiconductor devices are electronic components that use semiconducting material as their foundation. This material produces transistors, diodes, and other fundamental functional units found in integrated circuits (ICs). These devices are characterized by their ability to neither conduct electricity well nor act as effective insulators. The benefits of semiconductor devices encompass their affordability, dependability, and compact size. Over the past few decades, the utilization of these devices in the production of diverse electronics has surged in popularity, and it is projected to continue gaining momentum in the forthcoming years.

- The semiconductor industry is projected to experience strong growth in the foreseeable future as it caters to the rising need for semiconductor materials in emerging technologies like artificial intelligence (AI), autonomous driving, the Internet of Things, and 5G. This growth is fueled by intense competition among key players and consistent investment in research and development (R&D). As a result, vendors are constantly driven to innovate and gain a competitive advantage in the market.

- The market demand for semiconductor devices is projected to rise due to businesses' widespread adoption of electrification and autonomy. Electric vehicles are spearheading the movement toward a sustainable future, with electronics and semiconductors serving as crucial components. Governments across the globe are setting ambitious goals for the electrification of their transportation sectors, prompting leading automakers to make substantial investments in electric vehicle research and development. Semiconductors are emerging as the central processing units of EVs, empowering them to deliver optimal performance. Consequently, the growing investments in electric vehicles are anticipated to fuel the demand for the semiconductor market.

- The semiconductor industry needs more skilled workers. By the year 2030, more than one million additional skilled workers are likely to be needed to meet the industry's demand. Further, the semiconductor industry is characterized by long lead times and high capital investments. Manufacturing capacity constraints and changes in demand have led to shortages in the supply chain. These factors are expected to challenge the market's growth.

- The sector has undergone substantial changes due to COVID-19, impacting customer behavior, business revenues, and corporate operations. Additionally, the pandemic has revealed previously unnoticed risks on the supply side, potentially resulting in shortages of essential parts and components. Consequently, semiconductor companies are proactively restructuring their supply chains to enhance resilience, and these adjustments may persist in the post-pandemic era.

Semiconductor Market Trends

Discrete Semiconductors to Hold Significant Market Share in the Semiconductor Devices Segment

- The rising demand for high-energy and power-efficient devices, the increasing prevalence of wireless and portable electronic products, coupled with the increased use of these devices in the automotive industry due to the shift towards electrification are some of the key factors driving the growth of the segment.

- One of the significant trends in discrete semiconductors is efficient power management. New system architectures are improving the efficiency of AC-DC power adapters while simultaneously reducing the size and component count. New standards for Power-over-Ethernet (PoE) allow higher power transfer, which enables the development of new classes of devices, like connected lighting.

- MOSFET has always played an important part in the telecom sector, as switching power supply is the most prevalent application for power MOSFETs, which are also commonly utilized for MOS RF power amplifiers, allowing mobile networks to move from analog to digital. According to Ericsson, the number of 5G subscriptions increased by 70 million during the first quarter of 2022, reaching about 620 million. By the end of 2022, the number is predicted to reach 1 billion. Such reasons will spur the demand for power semiconductors, which will increase the demand for MOSFETs and lead to several breakthroughs in the telecom sector.

- Further, the demand for IGBT among various discrete semiconductors has been gaining traction and is widely used in low-power converters. The most popular semiconductor switches for power conversion in automotive, other motor drives, and renewable energy systems are discrete IGBTs. The main driving force is also the growing use of Insulated Gate Bipolar Transistor (IGBT) devices across a variety of sectors, including automotive, consumer electronics, industrial, IT and communications, healthcare, aerospace and defense, and others.

- The majority of discrete IGBT applications include inverters, various consumer goods like air conditioners and washing machines, switching-mode power supplies (SMPS), which are components used in personal computers, welding equipment, and induction heating devices like microwaves, electric cookers, induction stoves, etc. for soft switching and strobe flash control. The increasing demand for consumer electronic appliances like UPSs, power conditioners, air conditioners, etc., which use discrete IGBT types for lower-current applications, is credited with driving the growth of the discrete IGBT market. Discrete IGBTs have been found to have the lowest power losses in consumer goods, which is anticipated to be a key factor influencing the segment's growth in the market.

Fabrication to Hold Significant Market Share in Semiconductor Materials Segment

- Semiconductor fabrication materials form a crucial building block for the advanced microelectronics found in consumer electronics, high-end data centers, automotive applications, medical devices, IoT devices, power electronics, and more. The segment covers materials like process chemicals, photomasks, electronic gases, photoresist ancillaries, sputtering targets, silicon, and other materials.

- One of the primary factors driving the demand for semiconductor fabrication materials is the increasing use of digitally integrated ICs in the electrical, electronics, automotive, and telecommunication industries. Additionally, the rising investments in the energy sector are also expected to contribute positively to the growth of this segment, owing to the widespread application of semiconductors in solar panels, drives, and pumps in wind and water turbines, and protection circuits in energy conversion to ensure efficiency and minimal power loss. For instance, as per IEA, global energy investment will increase by 8% in 2022 to reach USD 2.4 trillion. Furthermore, according to IRENA, the spending on renewable energy is expected to grow steadily, boosting the market.

- While a wide range of materials can exhibit semiconductor properties, some materials are more commonly used in the fabrication of electronic devices due to their specific characteristics. Two of the most prevalent semiconductor materials are silicon and gallium arsenide. Silicon is the most widely used semiconductor material, primarily due to its abundance, low cost, and relatively stable properties at high temperatures. The electric conductivity of silicon is around 1000 S/m. Additionally, silicon has a well-established fabrication infrastructure, making it an attractive choice for manufacturers. However, silicon does have some drawbacks, such as lower electron mobility compared to other materials, which can limit the performance of high-speed devices.

- Gallium arsenide is another popular semiconductor material, valued for its higher electron mobility and direct bandgap. These properties make it well-suited for optoelectronic applications, such as lasers and solar cells. However, gallium arsenide is more expensive and less abundant than silicon, which can limit its widespread adoption. Another drawback of gallium arsenide is that it exists intrinsically as a semi-insulator rather than a semiconductor with an electrical conductivity of 0.000001 S/m.

- Aside from silicon and gallium arsenide, researchers are continually exploring new materials with promising semiconductor properties. These materials include aluminum nitride, carbon nanotubes, and many other materials that have the potential to revolutionize the industry. As the understanding of these emerging materials grows, they will likely play an increasingly important role in the future of semiconductor fabrication.

- Moreover, the market for process chemicals is expected to grow steadily due to the low-cost method and the applications for internal efficiency in the semiconductor sector. The consumption of semiconductor process chemicals is fueled by growth in installed fabrication capacity and expensive chemicals consumed by new technology, as well as processed silicon wafer surface area.

Semiconductor Industry Overview

The semiconductor industry features major players like Intel Corporation, Samsung Electronics Co. Ltd, Qualcomm Incorporated, Micron Technology Inc., and SK Hynix Inc., contributing to its semi-consolidated nature. Market participants are actively leveraging strategies such as partnerships and acquisitions to bolster their product portfolios and secure enduring competitive advantages.

In October 2023, Micron significantly expanded its 1β process node technology by introducing the 16Gb DDR5 memory. Rigorously tested and validated for in-system functionality at speeds of up to 7,200 MT/s, this new product is now being shipped to Micron's data center and PC clientele. The incorporation of advanced high-k CMOS device technology, a 4-phase clocking system, and clock-sync 1 in Micron's 1β-based DDR5 memory yield a substantial performance enhancement of up to 50%, accompanied by a 33% improvement in performance per watt compared to the prior generation.

September 2023 witnessed Intel Foundry Services (IFS) and Tower Semiconductor, a notable provider of analog semiconductor solutions, announcing a collaboration. Intel will extend its foundry services and 300mm manufacturing capacity to assist Tower in catering to its global clientele. Tower, as part of the agreement, will leverage Intel's advanced manufacturing facility in New Mexico to fulfill its operational needs.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Technological Trends

- 4.3 Industry Value Chain/Supply Chain Analysis

- 4.4 Impact of COVID-19, Macro Economic Trends, and Geopolitical Scenarios

- 4.5 Industry Attractiveness - Porter's Five Forces Analysis

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Intensity of Competitive Rivalry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Needs of Consumer Electronic Devices Boosting the Manufacturing Prospects

- 5.1.2 Proliferation of AI, IoT, and Connected Devices Across Industry Verticals

- 5.1.3 Increased Applications of Semiconductors in Automotive

- 5.1.4 Increased Deployment of 5G and Rising Demand for 5G Smartphones

- 5.2 Market Challenges/Restraints

- 5.2.1 Supply Chain Disruptions Resulting in Semiconductor Chip Shortage

- 5.2.2 Dynamic Nature of Technologies Requires Several Changes in Manufacturing Equipment

- 5.2.3 Vertical Integration is One of the Significant Concerns of OSAT Players

6 MARKET SEGMENTATION

- 6.1 By Semiconductor Devices

- 6.1.1 Discrete Semiconductors

- 6.1.2 Optoelectronics

- 6.1.3 Sensors

- 6.1.4 Integrated Circuits

- 6.2 By Semiconductor Equipment

- 6.2.1 Front-end Equipment

- 6.2.2 Back-end Equipment

- 6.3 By Semiconductors Materials

- 6.3.1 Fabrication

- 6.3.2 Pacakging

- 6.4 By Semiconductor Foundry Market

- 6.5 By Outsourced Semiconductor Assembly Test Services (OSAT) Market

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles*

- 7.1.1 Intel Corporation

- 7.1.2 Samsung Electronics Co. Ltd

- 7.1.3 Qualcomm Incorporated

- 7.1.4 Micron Technology Inc.

- 7.1.5 SK Hynix Inc.

- 7.1.6 Texas Instruments Incorporated

- 7.1.7 Broadcom Inc.

- 7.1.8 Mediatek Inc.

- 7.1.9 Applied Materials Inc.

- 7.1.10 ASML Holding NV

- 7.1.11 Tokyo Electron Limited

- 7.1.12 Lam Research Corporation

- 7.1.13 KLA Corporation

- 7.1.14 Advantest Corporation

- 7.1.15 Screen Holdings Co. Ltd

- 7.1.16 Teradyne Inc.

- 7.1.17 BASF SE

- 7.1.18 LG Chem Ltd

- 7.1.19 Indium Corporation

- 7.1.20 Resonac Holding Corporation

- 7.1.21 Kyocera Corporation

- 7.1.22 Henkel AG & Co. KGaA

- 7.1.23 Sumitomo Chemical Co. Ltd

- 7.1.24 Dow Chemical Co. (Dow Inc.)

- 7.1.25 Taiwan Semiconductor Manufacturing Company (TSMC) Limited

- 7.1.26 Samsung Foundry (Samsung Electronics Co. Ltd)

- 7.1.27 United Microelectronics Corporation (UMC)

- 7.1.28 GlobalFoundries Inc.

- 7.1.29 Semiconductor Manufacturing International Corporation (SMIC)

- 7.1.30 Hua Hong Semiconductor Limited

- 7.1.31 Powerchip Technology Corporation

- 7.1.32 ASE Technology Holding Co.Ltd

- 7.1.33 Amkor Technology Inc.

- 7.1.34 Jiangsu Changjiang Electronics Technology Co. Ltd

- 7.1.35 Powertech Technology Inc.

- 7.1.36 Tongfu Microelectronics Co. Ltd

- 7.1.37 Tianshui Huatian Technology Co. Ltd

- 7.1.38 King Yuan Electronics Co. Ltd

- 7.2 Vendor Market Share

- 7.2.1 Vendor Market Share - Semiconductor Devices Market

- 7.2.2 Vendor Market Share - Semiconductor Equipment Market

- 7.2.3 Vendor Market Share - Semiconductor Foundry Market

- 7.2.4 Vendor Market Share - OSAT Market