|

市场调查报告书

商品编码

1689737

成形充填密封(FFS) 包装机:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Form-Fill-Seal (FFS) Packaging Machine - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

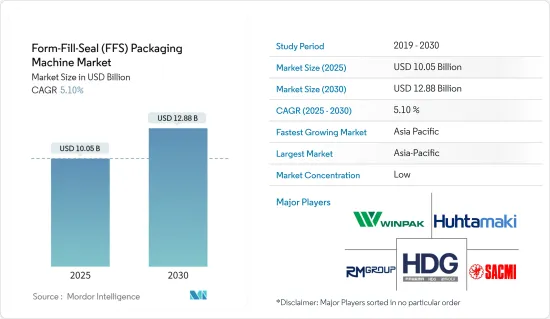

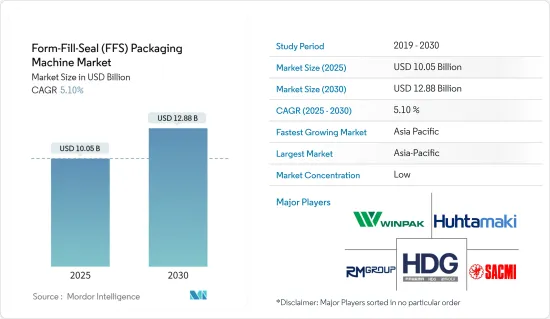

成形充填密封(FFS) 包装机市场规模预计在 2025 年为 100.5 亿美元,预计到 2030 年将达到 128.8 亿美元,预测期内(2025-2030 年)的复合年增长率为 5.1%。

主要亮点

- 成形充填密封(FFS) 机器利用电脑控制的自动化技术来生产弹性至刚性的包装,同时降低污染风险。在包装机中,连续自动成形充填密封(FFS)机由于其速度和效率而成为比传统独立成型、填充和密封机器更受欢迎的选择。

- 成形充填密封膜是一种用途广泛、经济高效且环保的包装选择。非常适合消费品和食品的自动包装,提供最高等级的防潮、防氧和防紫外线保护。这些薄膜用于包装袋、小袋和袋子中,易于使用且耐用,可实现清洁、高效的分配。相容于水平和垂直成形充填密封机,非常适合大规模生产。透过采用FSS薄膜,企业可以提高生产力并同时降低包装成本。

- 由于消费品製造商难以找到工人,因此对协助转换和故障排除的机器的需求日益增长。 FFS 包装机现在配备了运动控制和人机介面 (HMI),使流程更易于运作。

- FFS 袋包装机快速、准确、经济高效,已证明是一种可自动提高效率和盈利的多功能解决方案。然而,以中速包装麵粉、爽身粉、乳清粉等低密度物料是不经济的。 FFS包装就面临这样的包装格式的障碍。

- 随着全球持续遭受新冠肺炎疫情的衝击,包装卫生和安全成为消费者和企业关注的问题。疫情的蔓延表明,它很容易透过人与人之间的接触和交叉污染传播。许多政府都颁布了严格的法规,以确保食品的安全生产、包装和分销。

成形充填密封(FFS) 包装机的市场趋势

卧式成形充填密封机:预计市场将高速成长

- 水平成形充填密封(HFFS) 机器(通常称为 FFS 机器)是大批量生产工厂内包装系统的重要组成部分。这些机器简化了食品的包装、密封和运输过程。

- 选择HFFS机器不仅可以提高工作效率,还可以提高成本效率。这些机器专为速度和精度而设计,其性能优于手动操作和手工包裹等传统方法。 HFFS 擅长快速包装和真空密封产品以确保产品的耐用性。特别值得注意的是这个包,它的最大容量为 2.2 磅。

- 有些 HFFS 机器甚至有两个成型站和两个密封站,可以自动更改包装尺寸而无需停机。此功能对于频繁转换的工厂非常有用。有一些常规设定步骤可确保您的 HFFS 机器生产出高品质、形状良好的冰球。

- 包装食品的需求不断增长,加上软包装的成本效益,预计将推动对包装袋的需求。由软包装公司委託的哈里斯民意调查显示,83% 的品牌所有者已经在使用某种形式的软包装。这种强劲的采用支持了袋装包装市场的扩张并刺激了对水平 FFS 机器的需求。

- 整合技术的进步增强了这些 HFFS 机器的功能,使它们能够快速适应外部变数。例如,Loesch Verpackungstechnik 提供适用于巧克力、格兰诺拉麦片和蛋白质棒的初级包装的水平成形充填密封机。由于人们对包装食品的偏好日益增长以及软包装的成本效益,对包装袋的需求正在增加。

亚太地区市场预计将实现高成长

- 在中国,人口成长、可支配收入提高以及食品饮料行业的扩张正在推动市场成长。该地区生活方式的改变和跨国食品店的进入也将促进包装市场的成长,从而增加成形充填密封机的使用。

- 人们对优质水的需求不断增长以及注重健康的饮水习惯预计将增加瓶装水的消费量,这可能会影响该地区的包装行业。

- 日本是亚洲的主要製造地,拥有高品质的产品和最佳的製造实践。日本是世界製造业领导者。日本除了拥有无可挑剔的电子工业和庞大的汽车工业外,还是世界领先的化妆品生产国和最大的包装器材消费国之一。

- 根据国际货币基金组织的数据,2021年印度人口约13.9亿人。预测表明,到 2026 年,这一数字将上升到 14.6 亿。凭藉如此庞大的人口规模,印度有望成为一个重要的消费市场,大大推动对 FFS包装器材的需求。

- 韩国、澳洲、台湾、泰国、印尼和马来西亚等其他国家也显示出获得显着市场占有率的巨大潜力。这些国家由于政府推出了支持经济成长、增加投资和扩大市场的优惠政策,已成为主要企业。这些市场的多样性和动态性为企业提供了大量机会来建立强大的影响力并实现显着成长。

成形充填密封(FFS) 包装机械产业概览

成形充填密封(FFS)包装机市场较为分散,大型製造商面临小型企业的激烈竞争。市场上的公司在价格、分销网络、创新和品牌声誉方面竞争。併购、伙伴关係和技术创新是这些公司为确保长期成长所采取的一些关键策略。主要参与者包括 Winpak Ltd 和 HDG Verpackungsmaschinen GmbH。

- 2024 年 4 月 Rovema 以其永续包装解决方案而闻名,注重高生产率和灵活性,该公司宣布计划在 2024 年华沙包装展上推出一款突破性产品:带有按钮阀的完全可回收咖啡袋。这项创新与现有的 BVC 机器无缝相容,凸显了 Robema 对创新和永续性的承诺。此次发表会的核心产品是 Robema BVC260 垂直成形充填密封机。这台机器可确保快速、一致的咖啡包装,即使使用替代包装材料也能保持高生产水准。

- 2024 年 5 月,ProMach 品牌旗下 Matrix 宣布计划在墨西哥城举行的 Expo Pack Mexico 2024 的 1702 展位上展示其垂直成形充填密封机 MVI-280E 和预製袋填充/封口机 Pacraft TT-8D-N。 MVI-280E 是 Matrix 经济、多功能垂直成型-填充-封口机。适合宽度为 2-11 英吋、长度为 2-15 英吋的袋子。适用于直径最大为 14 英吋、宽度最大为 23 英吋的捲。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 新进入者的威胁

- 消费者议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争强度

- 产业价值链分析

- 微观经济因素如何影响市场

第五章 市场动态

- 市场驱动因素

- 无菌包装产业需求不断成长

- 宠物食品包装需求不断增加

- 市场限制

- 对于低密度产品来说不经济

第六章 市场细分

- 依设备类型

- 立式成形充填密封机

- 饮食

- 药品

- 个人护理

- 其他最终用户

- 卧式成形充填密封机

- 饮食

- 药品

- 个人护理

- 其他最终用户

- 立式成形充填密封机

- 按地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 其他欧洲国家

- 亚太地区

- 中国

- 日本

- 印度

- 其他亚太地区

- 拉丁美洲

- 中东和非洲

- 北美洲

第七章 竞争格局

- 公司简介

- Winpak Ltd

- HDG Verpackungsmaschinen GmbH

- Huhtamaki Oyj

- REES MACHINERY GROUP LIMITED

- SACMI Imola SC

- HAVER Continental Ltd

- Mega Plast GmbH

- Duravant LLC

- MDC Engineering Inc.

- Busch Machinery

- Rovema GmbH

- Fres-co System USA Inc.

- ProMach Inc.(Matrix Packaging Machinery LLC)

- PFM Group

- Viking Masek Global Packaging Technologies

- Nichrome Packaging Solutions

- Triangle Package Machinery Company

- Scholle IPN

- Bosch Rexroth AG

第八章投资分析

第九章:市场的未来

The Form-Fill-Seal Packaging Machine Market size is estimated at USD 10.05 billion in 2025, and is expected to reach USD 12.88 billion by 2030, at a CAGR of 5.1% during the forecast period (2025-2030).

Key Highlights

- Form-fill-seal (FFS) machines leverage automated computer-controlled technology to craft packages, spanning from flexible to rigid, while mitigating contamination risks. Among packaging machines, the continuous automatic form-fill-seal (FFS) machine stands out as a prevalent choice, prized for its swiftness and efficiency, outpacing traditional standalone machines for forming, filling, and sealing.

- Form-fill-seal films stand out as a versatile, cost-effective, and eco-friendly packaging choice. They excel in automatically packaging consumer goods and food, providing top-tier protection against moisture, oxygen, and UV rays. These films, used in creating pouches, sachets, and bags, are user-friendly and durable and facilitate clean and efficient distribution. Their compatibility with horizontal and vertical form-fill-seal machines makes them ideal for large-scale production. By adopting FSS films, businesses can boost productivity and simultaneously cut packaging expenses.

- Since consumer-packaged goods companies struggle with employee retention, the need for machinery that helps with changeovers and troubleshooting problems is on the rise. FFS packaging machines now come with motion control and human-machine interfaces (HMIs), making executing the process easier.

- FFS pouch packing machines have been demonstrated to be quick, accurate, cost-effective, and versatile solutions that enhance efficiency and profitability automatically. However, packing low-density items such as wheat flour, talcum powder, and whey powder at medium speeds is uneconomical. FFS packaging has a hurdle with this form of packaging.

- Packaging hygiene and safety are a concern for consumers and businesses as the world continues to suffer due to the COVID-19 pandemic. The pandemic's spread has demonstrated how easily it may be disseminated through human contact and cross-contamination. Many governments have enacted strict regulations to ensure that food is produced, packed, and distributed safely.

Form-Fill-Seal (FFS) Packaging Machine Market Trends

Horizontal Form-fill-seal Equipment Expected to Register High Market Growth

- Horizontal form-fill-seal (HFFS) machines, commonly referred to as FFS machines, are pivotal in packaging systems within high-production manufacturing facilities. These machines streamline the process of packing, sealing, and shipping food products.

- Opting for HFFS machines not only enhances operational efficiency but also proves cost-effective. These machines, tailored for speed and precision, outpace traditional methods like manual or hand packaging. They excel in swiftly packaging and vacuum-sealing products, ensuring durability. Notably, the bags they create boast a capacity of up to 2.2 pounds.

- Some HFFS machines are equipped with two molding stations and two sealing stations, allowing for automatic changes from one pack size to another with no downtime. This feature is useful in factories where switching is frequent. There are general setup steps to ensure that the HFFS machine produces high-quality and well-shaped packs.

- The growing demand for packaged foods, coupled with the cost efficiency of flexible packaging, is expected to boost the demand for pouches. A Harris Poll, commissioned by Flexible Packaging, reveals that a significant 83% of brand owners are already leveraging some form of flexible packaging. This robust adoption underpins the expansion of the pouch packaging market, subsequently fueling the need for horizontal FFS machines.

- Advancements in integrated technology are enhancing the capabilities of these HFFS machines, allowing for swift adjustments to external variables. For example, Loesch Verpackungstechnik offers a horizontal form-fill-seal machine tailored for the primary packaging of chocolate, granola, and protein bars. The demand for pouches is on the rise, driven by a growing preference for packaged foods and the cost-efficiency of flexible packaging.

Asia-Pacific is Expected to Witness High Market Growth

- The growing population, rising disposable income, and expanding the food and beverage industry in China contribute to market growth. Changing lifestyles and the development of multi-national food shops in the region also contribute to the growth of the packaging market, leading to the increased use of form-fill-seal machines.

- The increasing need for quality water and health-conscious drinking habits are expected to increase the consumption of bottled water, which is likely to influence the region's packaging industry.

- Japan is Asia's major manufacturing hub, with high-quality products and best manufacturing practices. The country is a world leader in terms of manufacturing. Apart from its impeccable electronics and huge automobile industry, Japan is also a global producer of cosmetics and one of the biggest consumers of packaging machinery.

- India boasted a population of around 1.39 billion in 2021, as per the IMF. Projections indicate that this figure will climb to 1.46 billion by 2026. With such vast demographics, India is expected to emerge as a significant consumer market, driving substantial demand for FFS packaging machinery.

- Other countries such as South Korea, Australia, Taiwan, Thailand, Indonesia, and Malaysia also exhibit significant potential to capture a notable market share. These countries are emerging as key players due to their growing economies, increasing investments, and favorable government policies that support market expansion. The diverse and dynamic nature of these markets presents numerous opportunities for businesses to establish a strong presence and achieve substantial growth.

Form-Fill-Seal (FFS) Packaging Machine Industry Overview

The form-fill-seal (FFS) packaging machine market is fragmented as major manufacturers face stiff competition from smaller players. Companies in the market compete in price, distribution network, innovation, and brand reputation. Mergers and acquisitions, partnerships, and technological innovations are some of the primary strategies adopted by these companies to ensure long-term growth. Key players are Winpak Ltd and HDG Verpackungsmaschinen GmbH, among others.

- April 2024: Rovema, renowned for its sustainable packaging solutions emphasizing high output and flexibility, announced its plans to unveil a groundbreaking product at Warsaw Pack 2024, which is a fully recyclable coffee bag featuring a button valve. The innovation is seamlessly compatible with existing BVC machines, underlining Rovema's commitment to innovation and sustainability. At the heart of this launch is the Rovema BVC 260 vertical form-fill-seal machine. This equipment ensures swift and consistent coffee packaging and can maintain high output levels even when utilizing alternative packaging materials.

- May 2024: Matrix, a ProMach brand, announced its plans to showcase its MVI-280E vertical form-fill-seal machine and the Pacraft TT-8D-N pre-made pouch filler/sealer at booth 1702 during Expo Pack Mexico 2024 in Mexico City. The MVI-280E, an economical offering from Matrix, is a versatile vertical form, fill, and seal machine. It is designed to handle bags ranging from 2 to 11 inches in width and 2 to 15 inches in length. It can accommodate rolls up to 14 inches in diameter and 23 inches in width.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Maret Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Threat of New Entrants

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Bargaining Power of Suppliers

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Impact of Microeconomic Factors on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Demand from Aseptic Packaging Industry

- 5.1.2 Rising Demand for Pet Food Packaging

- 5.2 Market Restraints

- 5.2.1 Uneconomical for Low-density Products

6 MARKET SEGMENTATION

- 6.1 By Equipment Type

- 6.1.1 Vertical Form-fill-seal Equipment

- 6.1.1.1 Food and Beverage

- 6.1.1.2 Pharmaceuticals

- 6.1.1.3 Personal and Household Care

- 6.1.1.4 Other End Users

- 6.1.2 Horizontal Form-fill-seal Equipment

- 6.1.2.1 Food and Beverage

- 6.1.2.2 Pharmaceuticals

- 6.1.2.3 Personal and Household Care

- 6.1.2.4 Other End Users

- 6.1.1 Vertical Form-fill-seal Equipment

- 6.2 By Geography

- 6.2.1 North America

- 6.2.1.1 United States

- 6.2.1.2 Canada

- 6.2.2 Europe

- 6.2.2.1 United Kingdom

- 6.2.2.2 Germany

- 6.2.2.3 France

- 6.2.2.4 Rest of Europe

- 6.2.3 Asia-Pacific

- 6.2.3.1 China

- 6.2.3.2 Japan

- 6.2.3.3 India

- 6.2.3.4 Rest of Asia-Pacific

- 6.2.4 Latin America

- 6.2.5 Middle East and Africa

- 6.2.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Winpak Ltd

- 7.1.2 HDG Verpackungsmaschinen GmbH

- 7.1.3 Huhtamaki Oyj

- 7.1.4 REES MACHINERY GROUP LIMITED

- 7.1.5 SACMI Imola SC

- 7.1.6 HAVER Continental Ltd

- 7.1.7 Mega Plast GmbH

- 7.1.8 Duravant LLC

- 7.1.9 MDC Engineering Inc.

- 7.1.10 Busch Machinery

- 7.1.11 Rovema GmbH

- 7.1.12 Fres-co System USA Inc.

- 7.1.13 ProMach Inc. (Matrix Packaging Machinery LLC)

- 7.1.14 PFM Group

- 7.1.15 Viking Masek Global Packaging Technologies

- 7.1.16 Nichrome Packaging Solutions

- 7.1.17 Triangle Package Machinery Company

- 7.1.18 Scholle IPN

- 7.1.19 Bosch Rexroth AG