|

市场调查报告书

商品编码

1549858

全球液体纸板市场:市场占有率分析、产业趋势/统计、成长预测(2024-2029)Liquid Paperboard - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

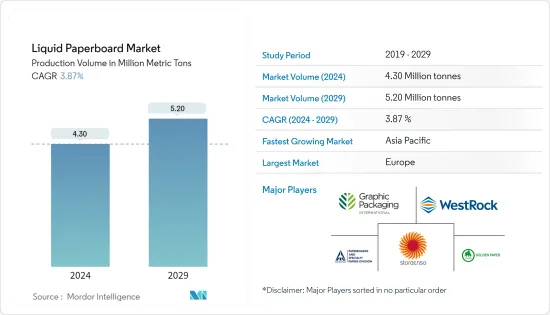

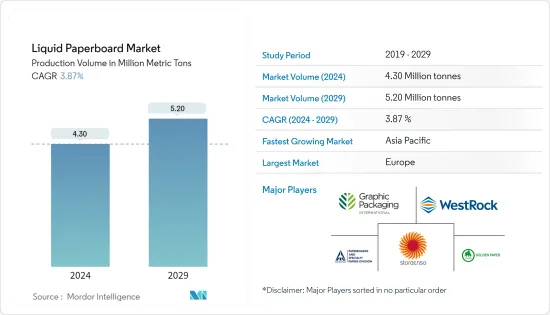

基于产量的全球液体纸板市场规模预计将从2024年的430万吨扩大到2029年的520万吨,预测期间(2024-2029年)复合年增长率为3.87%。

主要亮点

- 液体纸板 (LPB) 是一种多功能且永续的包装材料,主要用于食品和饮料行业。纸板由涂有各种阻隔材料(例如聚乙烯和其他生物聚合物)的层组成,以提供额外的保护。这种多层结构提供了强大的物理保护和有效的防潮、防氧和防光屏障,使其成为包装牛奶、果汁、汤和酱汁等液体产品的理想选择。

- 液体纸板因其永续性和阻隔性而被广泛用于包装液体纸盒。製造商正在采用极简、高设计的方法来生产更小的单份包装,以减少材料的使用和浪费。这些紧凑的设计透过最大限度地减少与包装相关的碳排放,提高了消费者的便利性并促进了环境责任。

- 阻隔涂层的技术进步是液体纸板发展和增强的主要驱动力。正在开发包括生物基和生物分解性材料在内的创新涂层技术,以提高 LPB 性能,同时最大限度地减少对环境的影响。这些涂料不仅可以防止污染和变质,从而提高包装产品的保质期和质量,还可以满足消费者和监管机构对永续包装不断增长的需求。例如,奈米技术的进步使得创建超薄但高效的隔离层成为可能,可涂布LPB 以改善功能,而无需显着增加重量或成本。

- 然而,由于液体纸板是纸板和聚乙烯的复合材料,回收带来了挑战。现有的回收基础设施通常需要协助分离这些层,阻碍了有效的回收过程。这种复杂性需要回收技术和系统的进步,以有效地处理液体纸板并提高永续性。

液体纸板市场趋势

饮料业需求增加将提振市场

- 饮料行业需求的成长正在显着推动液体纸板市场的发展。包装製造商和消费品牌越来越多地转向液体,因为与选择纸板等其他材料相比,它们使用的原材料更少,产生的废弃物更少,并且可以节省成本。液体纸板使公司能够生产更轻、更永续的包装,降低运输成本并最大限度地减少对环境的影响。这种效率在饮料业尤其有利,因为包装体积和重量对整体物流和碳足迹有重大影响。

- 优质液体包装纸板具有成本效益,并提供卓越的产品保护,确保饮料的新鲜度和安全性。这些纸板具有卓越的印刷、加工和填充性能,使品牌能够保持高品质标准和视觉上吸引人的设计。这种功能性和美观性的结合使液体纸板成为果汁、汤、水和优格等饮料行业包装应用的有吸引力的选择。强大的防潮、氧气和光阻隔性能进一步提高了这些产品的保质期和质量,使液体纸板成为製造商的首选材料。

- 为了使液体纸板更加永续性和高效,斯道拉恩索等公司正在大力投资,使废弃饮料纸盒更加循环利用。斯道拉恩索致力于提高材料效率并开发创新解决方案来提高液体纸板的性能。其中一项进步是微纤化纤维素 (MFC) 的使用,它可以增强纸板强度,同时减轻重量。这项改进减少了所需原材料的数量,提高了包装的耐用性和功能性,并提高了其相对于其他形式的竞争力。

- 用于长保质期液体产品(例如乳製品、豆奶、果汁、水果柠檬水和纯净水)的饮料纸盒也采用箔片贴合加工。这种薄薄的铝层可以保护您的饮料免受光和氧气的影响。铝层厚度仅6.5微米,不到人类头髮厚度的四分之一。铝是氧气和光线的绝佳屏障,这些饮料无需防腐剂或冷藏即可保存长达 18 个月。

- 根据芬宝2023年纸板年度报告发布的报告,液体包装纸板的年需求量为500万吨,仅占纸箱纸板总需求量5,900万吨的8.5%。由于耐用性、防潮性和永续性等特殊性能,该行业在液体包装领域很受欢迎,这对于饮料和乳製品等行业至关重要。

欧洲预计将实现显着成长

- 欧洲液体纸板市场正在经历变革,这主要是由于对永续性的日益关注。由于环保意识不断增强,消费者的偏好越来越倾向环保包装。这一趋势极大地推动了对传统塑胶包装更永续的液体纸板替代品的需求。

- 欧盟一次性塑胶指令等欧洲法规也强化了这种转变,该指令强制减少一次性塑胶的使用,并鼓励使用液体纸板等可再生和可回收材料。

- 此外,电子商务的快速发展也对市场产生影响。网路购物的增加增加了对坚固可靠的包装解决方案的需求,这些解决方案可以保护运输途中的产品,同时又环保。液体纸板很好地满足了这项要求,具有耐用性和永续性。这两个优势使得液体纸板对寻求将其营运与永续性目标保持一致并满足消费者对环保包装的期望的零售商和电子商务公司具有吸引力。

- 欧洲液体纸板产业的市场整合也值得注意。市场由少数大型企业主导,导致高度整合。这种整合将有助于对研发进行大量投资,促进创新和提高效率。这些领先的製造商不断寻找透过技术进步来提高液体纸板性能和永续性的方法。

- 数位印刷技术等进步实现了高品质、可自订的包装解决方案,使品牌脱颖而出并吸引消费者。此外,生物分解性和可堆肥涂料的进步使液体纸板更具永续性。这些创新将改善液体纸板的环境足迹,扩大其在各个领域的应用,并进一步推动市场成长。

- 根据联合国粮食及农业组织的资料,德国2024年产能为2,453万吨。另一方面,纸箱纸板产能为174万吨,仅占纸及纸板总产能的7%。纸箱纸板包括折迭式牛奶纸盒和食品服务盒纸板。

液体纸板产业概况

液体纸板市场由斯道拉恩索、ITC、Graphic Packaging、WestRock 和 Golden Paper Group 等主要企业主导。 领先的公司正在透过策略併购来推动这种整合,增加市场占有率并扩大其全球影响力,以满足对永续包装不断增长的需求。

2023 年 6 月:斯道拉恩索和利乐在波兰斯道拉恩索的 Ostroleka 纸板工厂启用了一条新的消费后饮料纸盒回收生产线。两家公司表示,新增产能将使该工厂成为欧洲主要的液体纸板包装回收站。根据斯道拉恩索介绍,新生产线的吞吐能力为每年5万吨。它仅处理饮料纸盒并将纤维与聚合物和铝分离。然后,这些纤维被回收并重新用于纸板製造。 Czech Plastigram Industries 和利乐公司正在工业化一种解决方案,将非纤维「PolyAl」部分回收到新产品中。

2023 年 3 月:Asia Symbol 江苏采用 Teat Every 的製造执行系统 (MES) 来业务并提高其如皋工厂纸箱纸板生产线的业务效率。现代资讯技术、关键业务流程的数位化和自动化提高了生产和营运管理。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业价值链分析

- 产业吸引力-波特五力分析

- 新进入者的威胁

- 买方议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争公司之间的敌对关係

- 液体纸板和液体包装的市场现状

- 技术进步提高了阻隔性并延长了保质期

- 分析导致更小的饮料纸盒包装的极简设计趋势

- 纸板材料进出口的国际贸易政策

- 行业法规

第五章市场动态

- 市场驱动因素

- 对方便易用的包装形式的需求不断增长

- 越来越重视永续和环保的包装解决方案

- 市场挑战

- 替代包装形式的市场成长挑战

第六章 市场细分

- 依材料类型

- 液体包装纸板

- 食品/杯汤

- 按最终用途

- 饮料

- 食品

- 食品补充品

- 家庭和个人护理

- 其他最终用途

- 按地区

- 北美洲

- 欧洲

- 亚洲

- 拉丁美洲

- 中东/非洲

第七章 供应商市场占有率

第八章 竞争格局

- 公司简介

- Stora Enso Oyj

- Graphic Packaging International

- WestRock Company

- ITC Limited

- Golden Paper Company

- Greatview Aseptic Packaging Co. Ltd

- Ningbo Sure Paper Co. Ltd

- Suneja Sons

- Billerud AB

- Asia Symbol Paper Co. Ltd

第九章投资分析

第十章 市场未来展望

The Liquid Paperboard Market size in terms of production volume is expected to grow from 4.30 Million metric tons in 2024 to 5.20 Million metric tons by 2029, at a CAGR of 3.87% during the forecast period (2024-2029).

Key Highlights

- Liquid paperboard (LPB) is a versatile and sustainable packaging material predominantly used in the food and beverage industry. Liquid paperboard consists of layers coated with various barrier materials, typically polyethylene or other biopolymers, to enhance its protective qualities. This multi-layered structure provides robust physical protection and effective barriers against moisture, oxygen, and light, making it ideal for packaging liquid products like milk, juices, soups, and sauces.

- Liquid paperboard is widely used in packaging for liquid cartons due to its sustainability and barrier properties. Manufacturers employ a minimalist, designable approach to create smaller packs that cater to single servings, reducing material usage and waste. These compact designs enhance convenience for consumers and promote environmental responsibility by minimizing the carbon footprint associated with packaging.

- Technological advancements in barrier coating have been a key driver in developing and enhancing liquid paperboard. Innovative coating technologies, such as those involving bio-based and biodegradable materials, are being developed to improve the performance of LPB while minimizing its environmental impact. These coatings not only enhance the shelf life and quality of the packaged products by preventing contamination and spoilage but also align with the growing consumer and regulatory push for sustainable packaging. For instance, advancements in nanotechnology have enabled the creation of ultra-thin yet highly effective barrier layers that can be applied to LPB, improving its functionality without significantly increasing its weight or cost.

- However, recycling liquid paperboard presents challenges because it is a composite material made from paperboard and polyethylene. Existing recycling infrastructure often needs help to separate these layers, hindering the recycling process efficiently. This complexity necessitates advancements in recycling technologies and systems to effectively handle liquid paperboard and improve its sustainability credentials.

Liquid Paperboard Market Trends

Rising Demand from the Beverage Segment Boosts The Market

- The rising demand from the beverage segment is significantly boosting the liquid paper board market. Packaging manufacturers and consumer brands increasingly opt for liquid paperboard because it can use fewer raw materials and create less waste, offering cost savings compared to other materials such as plastic or glass. By utilizing liquid paperboard, companies can produce lighter, more sustainable packaging that reduces transportation costs and minimizes environmental impact. This efficiency is particularly beneficial in the beverage industry, where the volume and weight of packaging can substantially influence overall logistics and carbon footprint.

- Premium liquid packaging boards are cost-effective and deliver exceptional product protection, ensuring the freshness and safety of beverages. These boards offer superior printing, converting, and filling performance, enabling brands to maintain high-quality standards and visually appealing designs. This combination of functionality and aesthetics makes liquid paperboard an attractive choice for packaging applications in the beverage industry, including juice, soups, water, and yogurt. The ability to provide a strong barrier against moisture, oxygen, and light further enhances these products' shelf life and quality, making liquid paperboard a preferred material for manufacturers.

- To further enhance the sustainability and efficiency of liquid paperboard, companies like Stora Enso are making significant investments in boosting the circularity of used beverage cartons. They are focusing on improving material efficiency and developing innovative solutions to enhance the performance of liquid paperboard. One such advancement is incorporating microfibrillated cellulose (MFC), which strengthens the paperboard while reducing its weight. This improvement decreases the amount of raw material needed and enhances the durability and functionality of the packaging, making it more competitive against other formats.

- Beverage cartons for long-life liquid products, like dairy products, soy milk, juices, fruit-based lemonades, and non-carbonated waters, additionally have a foil laminate. This thin aluminum layer protects beverages from light and oxygen. The aluminum layer is just 6.5 micrometers thick, less than a quarter of a hair. Aluminum is an excellent barrier for oxygen and light, and these drinks can last up to 18 months without preservatives or refrigeration.

- According to a report published in the annual report of the Metsa Board in 2023, a liquid packaging board with an annual demand of 5 million tons represents only 8.5% of the total carton board demand, which stands at 59 million tons. This segment is popular for packaging liquids due to specialized properties, such as durability, moisture resistance, and sustainability, making it crucial for sectors like beverages and dairy.

Europe is Set To Witness Significant Growth

- The European liquid paperboard market is experiencing a transformative shift, primarily driven by a heightened focus on sustainability. Consumer preferences increasingly lean toward eco-friendly packaging options due to growing environmental awareness. This trend significantly boosts the demand for liquid paperboard, a more sustainable alternative to traditional plastic packaging.

- The shift is also reinforced by European regulations, such as the EU's single-use plastics directive, which mandates the reduction of single-use plastics and encourages using renewable, recyclable materials like liquid paperboard.

- Additionally, the market is being influenced by the rapid growth of e-commerce. The rise in online shopping has increased the need for robust and reliable packaging solutions that protect goods during transit while being environmentally friendly. Liquid paperboard fits this requirement well, offering both durability and sustainability. This dual benefit makes liquid paperboard attractive for retailers and e-commerce companies looking to align their operations with sustainability goals and meet consumer expectations from green packaging.

- The market consolidation in the European liquid paperboard sector is also noteworthy. A few large players dominate the market, leading to high levels of consolidation. This consolidation enables significant investments in research and development, fostering innovation and efficiency improvements. These large manufacturers are continually exploring ways to enhance the performance and sustainability of liquid paperboard through technological advancements.

- Developments such as digital printing technologies allow for high-quality, customizable packaging solutions that cater to brand differentiation and consumer engagement. Additionally, biodegradable and compostable coating advancements make liquid paperboard even more sustainable. These technological innovations improve the environmental footprint of liquid paperboard and expand its applications across various sectors, further driving market growth.

- According to Food and Agriculture Organization data, Germany has a production capacity of 24.53 million tons in 2024. In contrast, the country has a production capacity of 1.74 million tons for carton boards, which is only 7% of total paper and paperboard production capacity. The carton boards include folding milk cartons and foodservice boxboards.

Liquid Paperboard Industry Overview

The market for liquid paperboard is dominated by key players such as Stora Enso, ITC, Graphic Packaging, WestRock, and Golden Paper Group. Major players are driving this consolidation through strategic mergers and acquisitions, enhancing their market share and expanding their global reach to meet the rising demand for sustainable packaging.

June 2023: Stora Enso and Tetra Pak started a new recycling line for post-consumer beverage cartons at Stora Enso's Ostroleka corrugated packaging plant in Poland. According to the companies, the newly added capacity intends to make the site one of Europe's main recycling hubs for liquid paperboard packaging. Stora Enso reported that the new line has a capacity of 50,000 tonnes a year. It handles only beverage cartons, separating the fibers from polymers and aluminum. The fibers are then recycled and reused for board production. Czech companies Plastigram Industries and Tetra Pak are industrializing a solution to recycle the non-fiber "PolyAl" fraction into new products.

March 2023: Asia Symbol Jiangsu Co. Ltd selected Tietoevry's Manufacturing Execution System (MES) to execute business transformation and increase operational efficiency in their Rugao mill's carton board line. The latest information technologies, digitalization, and automation of key business processes enable production and operations management improvements.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Threat of New Entrants

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Bargaining Power of Suppliers

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Current Market Scenario For Liquid Paperboard and Liquid Cartons

- 4.4.1 Technological Advancements Leading to Better Barrier Properties and Extended Shelf Life

- 4.4.2 Trend Analysis for Minimalist Designs Resulting in Smaller Beverage Carton Packs

- 4.4.3 International Trade Policies on Import and Export of Paperboard Materials

- 4.4.4 Industry Regulations

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Demand for Convenient and Easy-to-Use Packaging Formats

- 5.1.2 Growing Focus on Sustainable and Eco-Friendly Packaging Solutions

- 5.2 Market Challenge

- 5.2.1 Alternative Forms of Packaging is Challenging the Market Growth

6 MARKET SEGMENTATION

- 6.1 By Material Type

- 6.1.1 Liquid Packaging Board

- 6.1.2 Food and Cupstock

- 6.2 By End-Use Application

- 6.2.1 Beverage

- 6.2.2 Food

- 6.2.3 Nutraceuticals

- 6.2.4 Homecare and Personal Care

- 6.2.5 Other End-use Applications

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia

- 6.3.4 Latin America

- 6.3.5 Middle East and Africa

7 VENDOR MARKET SHARE

8 COMPETITIVE LANDSCAPE

- 8.1 Company Profiles

- 8.1.1 Stora Enso Oyj

- 8.1.2 Graphic Packaging International

- 8.1.3 WestRock Company

- 8.1.4 ITC Limited

- 8.1.5 Golden Paper Company

- 8.1.6 Greatview Aseptic Packaging Co. Ltd

- 8.1.7 Ningbo Sure Paper Co. Ltd

- 8.1.8 Suneja Sons

- 8.1.9 Billerud AB

- 8.1.10 Asia Symbol Paper Co. Ltd