|

市场调查报告书

商品编码

1626299

拉丁美洲危险区域马达:市场占有率分析、产业趋势和成长预测(2025-2030)Latin America Hazardous Location Motors - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

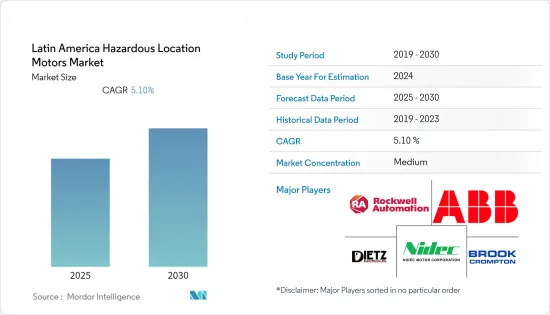

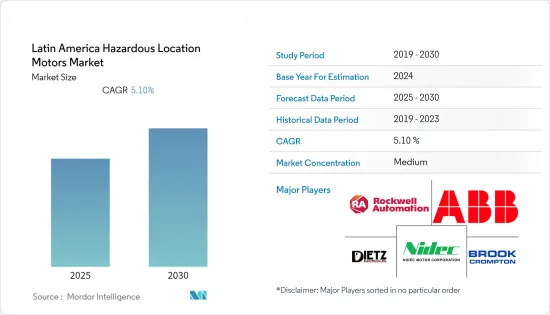

拉丁美洲危险场所马达市场预计在预测期内复合年增长率为 5.1%

主要亮点

- 在危险区域工作时,使用防爆马达对于人员和设备的安全至关重要。防爆马达适用于含有可燃性气体、灰尘和纤维的危险环境。

- 在正常工作条件下,马达会产生热量,如果马达线圈故障,可能会产生火花。在含有某些危险材料的环境中,过高的马达外壳温度或不受控制的火花可能会导致爆炸或火灾。危险区域马达马达内装有防爆装置,以防止产生火花。

- 然而,很难设计和製造完全包含内部爆炸而不使其破裂的马达,或者以将热气体通过称为火焰路径的细长开口排放的方式排放机壳,这是两个。主要挑战。

- 此外,COVID-19 大流行也为所研究的市场带来了一些挑战,例如供应链中断和原材料价格上涨。

拉丁美洲危险区域马达市场趋势

石油和天然气领域预计将占据主要市场占有率

- 石油和天然气行业的工人面临因易燃蒸气和气体点燃而引起火灾和爆炸等风险。卡车、油井、生产设备或储槽和振动筛等地面设备可能会释放蒸气、井气和硫化氢等可燃性气体。点火源包括静电、明火、能源来源、闪电、切割和焊接工具、烟草、热表面和摩擦热。

- 由于表面温度高且可能产生火花,普通马达在含有易燃元素(例如石油和天然气或液体)的情况下使用时容易发生爆炸。其影响范围从轻微的生产中断到严重的伤害甚至死亡。

- 拉丁美洲油气资源生产与消费呈上升趋势。根据贝克休斯统计,截至2021年10月,拉丁美洲共有152座石油和天然气钻井钻机,其中33座为海上钻机。

- 此外,根据美国能源资讯管理局 (EIA) 的数据,2020 年巴西每天生产约 380 万桶原油、天然气工厂液体 (NGPL) 和其他相关液体,使其成为拉丁美洲和加勒比地区最重要的国家)。排名第二的是墨西哥,当年产量为 190 万桶/日。在经历了 COVID-19 大流行造成的低迷之后,该地区的石油和天然气行业正在稳步增长。

- 因此,I 级危险场所马达在存在易燃气体、蒸气或液体的环境中被越来越多地采用,其设计使马达外壳温度不会超过安全温度。

II 级危险场所马达可望推动市场发展

- 甲烷气体和煤尘是煤矿中最常见的两种爆炸危险。当累积的甲烷气体与热源接触并且没有足够的空气将气体稀释到爆炸点以下时,就会发生甲烷爆炸。

- 同样,适当浓度的煤尘细颗粒在接触热源时也会爆炸。由于甲烷和煤尘的结合,也可能发生混合爆炸。

- 谷物和麵粉加工产业是粉尘爆炸的两个最常见原因。麵粉乍看之下似乎无害,但当它在空气中高浓度分布并与火源、密闭空间、扩散和氧气结合时,就会引起爆炸。该地区的麵粉加工活动正在增加,为所研究市场的成长提供了利润丰厚的机会。

- 例如,巴西是拉丁美洲主要的稻米加工国家,根据美国农业部对外农业局的数据,预计 2020 年产量将接近 750 万吨。

- II 级危险区域马达以较低的额定电流运行,以减少热量产生,并防止马达温度过高,使用恆温器等故障安全系统在达到临界温度之前关闭马达。越来越流行。

拉丁美洲危险区域马达产业概况

北美危险场所马达市场需要 Brook Crompton、Stainless Motors, Inc 和 Dietz Electric Co. 等市场参与企业专注于技术创新和策略联盟,以增加市场占有率。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争公司之间的敌对关係

- 技术简介

- COVID-19 影响评估

第五章市场动态

- 市场驱动因素

- 增加安全措施

- 对节能马达的需求不断增长

- 市场限制因素

- 监理与合规

- 与非防爆马达相比,材料和人事费用导致安装成本较高

第六章 市场细分

- 按类型

- 防爆通用马达

- 马达

- 防爆泵马达

- 防爆变频负载马达

- 防爆重载马达

- 按班级

- Ⅰ类

- 二级

- 三级

- 按部分

- 第1节

- 第2节

- 按地区

- 区域0

- 区域1

- 21区

- 22区

- 20区

- 按用途

- 喷漆和精加工区域

- 精製

- 干洗设施

- 天然气厂

- 谷物提昇机和谷物加工设施

- 麵粉厂

- 铝材製造及仓储区

- 火力发电厂和储存设施

- 糖果厂

- 其他的

- 按国家/地区

- 巴西

- 墨西哥

- 其他拉丁美洲

第七章 竞争格局

- 公司简介

- Brook Crompton

- Stainless Motors, Inc.

- Dietz Electric Co., Inc.

- Emerson Electric Co.

- WEG Industries

- Rockwell Automation, Inc.

- Nidec Motor Corporation

- Kollmorgen Corporation

- ABB Ltd

- Heatrex Inc.

第八章投资分析

第9章市场的未来

简介目录

Product Code: 47084

The Latin America Hazardous Location Motors Market is expected to register a CAGR of 5.1% during the forecast period.

Key Highlights

- When operating in a hazardous location, the use of explosion-proof motors is critical for the safety of personnel and equipment. Explosion-proof motors are intended for use in hazardous environments containing flammable gases, dust, or fibers.

- Under normal operating conditions, electric motors generate heat and have the potential to generate a spark if a motor coil fails. Excessive motor case temperatures or an uncontained spark can cause an explosion or ignite a fire in environments containing specific hazardous materials. Hazardous location motors contain an explosion within the motor casing and prevent the occurrence of sparks.

- However, designing and manufacturing motors that completely engulf an internal explosion without rupturing or passing out any hot gases from the enclosure so that they are forced to exit through a long, narrow opening known as flame paths are the two significant challenges faced by hazardous location motors market.

- Further, the Covid-19 pandemic has also posed several challenges to the studied market, like disruption in the supply chain and increased raw materials prices.

Latin America Hazardous Location Motors Market Trends

The Oil and Gas Segment is Expected to Hold a Major Market Share

- The workers in oil and gas industries are exposed to risks like fire and explosion due to the ignition of flammable vapors or gases. Flammable gases, such as vapors, well gases, and hydrogen sulfide, can be released from trucks, wells, production equipment, or surface equipment such as tanks and shale shakers. Ignition sources can include static, open flames, electrical energy sources, lightning, cutting and welding tools, cigarettes, hot surfaces, and frictional heat.

- Regular electric motors are prone to explosions when used in situations containing flammable elements such as oil and gas fumes or liquids, as they could produce high surface temperatures or sparks. The implications could vary from modest production interruptions to serious injury and even death.

- There is an upward trend in the Latin American region's production as well as consumption of oil and gas resources. According to Baker Hughes, the number of oil and gas rigs as of October 2021, Latin America had 152 oil rigs, of which 33 were offshore rigs.

- Further, according to Energy Information Administration (EIA), With almost 3.8 million barrels of crude oil, natural gas plant liquids (NGPL), and other associated liquids produced per day in 2020, Brazil was the most significant petroleum-producing country in Latin America and the Caribbean. Mexico came in second with 1.9 million barrels per day that year. After a downturn due to the COVID-19 pandemic, the oil and gas industry in the region is witnessing steady growth.

- Resultantly, the class-I hazardous location motors, which are designed so that their motor case temperatures do not exceed safe temperatures for environments where combustible gases, vapors, or liquids are present, are increasingly being adopted in the region.

Class II Hazardous Location Motors are Expected to Drive the Market

- Methane and coal dust are two of the most common explosive hazards in coal mines. When a buildup of methane gas comes into contact with a heat source, and there is insufficient air to dilute the gas level below the point of explosion, methane explosions occur.

- Similarly, fine particles of coal dust in the right concentration can be explosive when they come into contact with a source of heat. It is also possible to have hybrid explosions caused by a combination of methane and coal dust.

- The grain and milling industries are two of the most common sources of dust explosions. Flour may appear harmless, but when it is distributed in high concentrations in the air and combined with an ignition source, confined space, dispersion, and oxygen, it causes an explosion. The milling activities in the region are in an upward trend, which provides lucrative opportunities for the growth of the studied market.

- For instance, according to USDA foreign agricultural service, Brazil is a prominent milled rice producer in Latin America, with an estimated output of nearly 7.5 million metric tons in 2020; Peru followed with a production of 2.4 million tons and is expected to rise during the forecast period.

- Class II hazardous location motors, which reduce heat produced by operating at a lower current rating and employ other failsafe methods such as thermostats that disengage the motor power before it reaches critical temperatures to limit an excessive motor case temperature condition, are becoming more popular in the region.

Latin America Hazardous Location Motors Industry Overview

The North America Hazardous Location Motors market is moderately competitive with significant players like Brook Crompton, Stainless Motors, Inc., Dietz Electric Co., Inc., Emerson Electric Co., WEG Industries, etc. The players in the market must focus on technological innovations and strategic collaborations to expand their market share.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Technology Snapshot

- 4.4 Assessment of the Impact of COVID-19

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Safety Measures

- 5.1.2 Increasing Demand for Energy Efficient Motors

- 5.2 Market Restraints

- 5.2.1 Regulations & Compliance

- 5.2.2 High Installation Cost for Material and Labor in Comparison to Non-Explosion Proof Motors

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Explosion-Proof General Purpose Motors

- 6.1.2 Drill Rig Duty Motors

- 6.1.3 Explosion-Proof Pump Motors

- 6.1.4 Explosion-Proof Inverter Duty Motors

- 6.1.5 Explosion-Proof Severe Duty Motors

- 6.2 By Class

- 6.2.1 Class I

- 6.2.2 Class II

- 6.2.3 Class III

- 6.3 By Division

- 6.3.1 Division 1

- 6.3.2 Division 2

- 6.4 By Zone

- 6.4.1 Zone 0

- 6.4.2 Zone 1

- 6.4.3 Zone 21

- 6.4.4 Zone 22

- 6.4.5 Zone 20

- 6.5 By Applications

- 6.5.1 Spray Painting and Finishing Areas

- 6.5.2 Petroleum Refining Plants

- 6.5.3 Dry Cleaning Facilities

- 6.5.4 Utility Gas Plants

- 6.5.5 Grain Elevators and Grain Handling Facilities

- 6.5.6 Flour Mills

- 6.5.7 Aluminum Manufacturing and Storage Areas

- 6.5.8 Fire Work Plants and Storage Areas

- 6.5.9 Confectionary Plants

- 6.5.10 Other Applications

- 6.6 By Country

- 6.6.1 Brazil

- 6.6.2 Mexico

- 6.6.3 Rest of Latin America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Brook Crompton

- 7.1.2 Stainless Motors, Inc.

- 7.1.3 Dietz Electric Co., Inc.

- 7.1.4 Emerson Electric Co.

- 7.1.5 WEG Industries

- 7.1.6 Rockwell Automation, Inc.

- 7.1.7 Nidec Motor Corporation

- 7.1.8 Kollmorgen Corporation

- 7.1.9 ABB Ltd

- 7.1.10 Heatrex Inc.

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET

02-2729-4219

+886-2-2729-4219