|

市场调查报告书

商品编码

1630310

橡胶输送带:市场占有率分析、产业趋势、成长预测(2025-2030)Rubber Conveyor Belt - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

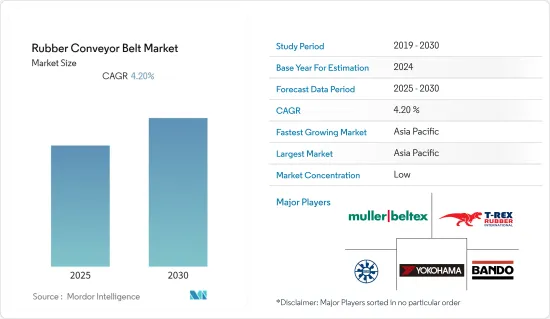

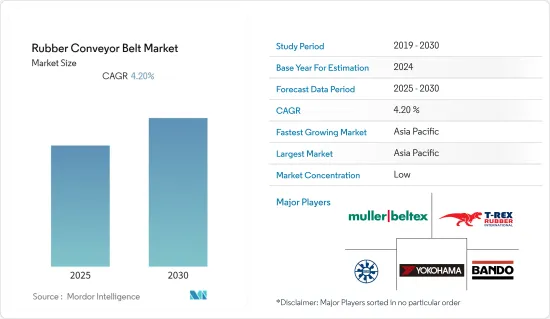

橡胶输送机市场预计在预测期内复合年增长率为 4.2%

主要亮点

- 输送机使用增加的关键驱动因素是电子商务产业的成长。仓库不断激增,增加了物料输送的需求并减少了停机时间。总部位于美国的 SpanTech LLC 提供电子商务输送机,用于自动化电子商务履约流程。

- 输送机因其适应性强、重量轻、性价比高而被广泛应用于各个领域。推动全球输送机市场的关键因素之一是电力、采矿和工业产业需求的不断增长。

- 所有行业的公司,包括製造、采矿、电动车、食品加工、仓储和其他物料输送设施,都在不断寻找改善其流程的方法,这推动了工业设施自动化的需求。输送机系统可能会从职场广泛的自动化中受益匪浅。

- 但市场受原物料价格波动影响较大,对市场成长构成挑战。橡胶价格的上涨和下跌主要受到市场状况的影响,例如全球供需状况、原油价格趋势以及由此对合成替代品价格的影响。

- 由于 COVID-19 对产业的影响,输送机市场正在显着放缓。实施了排除和贸易限制,工厂和工业停止运作。此外,由于供应链限制、人手不足和材料短缺的不确定性,在此期间也没有建造新设施,这直接阻碍了对输送机系统的需求。不过,期内电商的增加部分改善了输送机的需求。

橡胶输送机市场趋势

矿业主导市场

- 采矿业广泛使用输送机带来运输加工所需的材料。 2020 年 9 月,印度煤炭公司对 18 个机组提出了 1,570 亿印度卢比的竞标。这笔投资将用于建造输送机系统,以取代矿井和货车之间的公路运输。投资输送机直接从矿井运输煤炭是避免使用卡车的更便宜、更清洁的方法。它还有助于减少煤炭盗窃和转移并保持品质。

- 拉丁美洲,特别是巴西和智利的采矿业预计将出现大量新投资。 2020年产量约5亿吨,成为全球第二大铁矿石生产国。拉丁美洲也在追随当前的趋势。智利和阿根廷是该地区主要的锂生产国,占全球蕴藏量的60%以上。由于采矿需要大量的物料输送,输送机系统是远距运输最高效、最具成本效益的解决方案。

- 透过 BeltGauge 解决方案,Fenner Dunlop 为其 iBelt 系列输送机技术增加了移动功能,为所有商品和输送机行业应用的客户提供了一种正确监控输送机健康状况的新方法。自 2020 年 9 月推出以来,固定式 BeltGauge 解决方案已在许多地点安装。

- 德国康迪泰克的输送机在牙买加广泛用于运输矾土,每小时可发电 1,300 千瓦,并可返回电网。博茨瓦纳最大的钻石生产商也使用它。

- 针对地下矿井的使用,邓禄输送机输送带製造了耐火输送机。这些皮带根据国家和国际准则获得批准和认证。

亚太地区成长最快

- 由于处理大量货物的电子商务企业的兴起,特别是在中国和印度,该地区对输送机的需求正在增加。

- 该地区市场的扩张很大程度上归功于技术进步以及自动化技术在各个最终用户行业中的日益使用。推动该地区输送机监控需求的其他关键驱动因素包括快速都市化、互补技术改进、有利的政府法规和强劲的外国直接投资流入。

- 在建筑业的大力推动下,亚太地区的工业生产和采矿活动迅速发展,城市基础设施支出也不断增加。因此,该地区对输送机系统的需求不断增加。

- 亚太地区正在大量部署输送机监控解决方案,以协助提高业务效率。该地区最大的采矿国中国和澳洲正在实施即时输送机监控系统,以提高业务效率和生产力。

- 澳洲石油和矿产蕴藏量庞大,市场成长潜力巨大。这些也有助于该国建立强大的采矿业。此外,有利的政府措施和最新状态监测技术的采用预计将在预测期内促进该国的市场成长。对预测性维护技术和工具的需求不断增长,以及远端输送机监控和故障诊断系统的可用性不断提高,正在推动製造商之间的竞争。

橡胶输送机产业概况

越来越多的最终用户行业引入输送机以促进加工,以及企业合併以将创新带入该领域,从而对市场进行了细分。

- 科技公司大陆集团开发了一种用于监控输送机系统的服务解决方案,能够在损坏发生之前及早发现输送机系统的弱点。这项创新技术将视觉和听觉评估结合到一个设备中。

- 设计师表示,输送机技术越来越多地使用复杂的材料。例如,美国的食品製造商可以受益于采用符合 FDA 法规的食品级皮带的「感测器」输送机。这些传送带适合此用途,因为它们具有抗细菌性,并且可以检测微小碎片。

- RFID(无线射频辨识)技术应用于各行业。即时追踪产品和流程(从订购到交付)的能力有可能显着改善物流业务、改善客户体验并改善供应链。 RFID 技术正在整合到自足式的输送机系统中,该系统可以自动做出控制决策并同时执行多个专案的大量任务。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究成果

- 研究场所

- 调查范围

第 2 章执行摘要

第三章市场动态

- 市场概况

- 利用市场促进和市场约束因素

- 市场驱动因素

- 电商产业可望成长

- 提高製造工厂的生产力

- 市场限制因素

- 原物料价格波动

- 价值链分析

- 产业吸引力-波特五力分析

- 新进入者的威胁

- 买家/消费者的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争公司之间敌对关係的强度

第四章市场区隔

- 按类型

- 耐热性

- 耐油性

- 耐火性

- 耐化学性

- 按最终用户产业

- 后勤

- 矿业

- 製造业

- 金属加工

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东/非洲

第五章竞争状况

- 公司简介

- Oxford Rubbers Pvt. Ltd.

- Muller Beltex BV

- T-Rex Rubber International BV

- The Yokohama Rubber Co. Ltd.

- Bando Chemical Industries Ltd.

- Bridgestone Corporation

- Oriental Rubber Industries Pvt. Ltd.

- Fenner Grouo Holdings Ltd.

- Mitsuboshi Belting Ltd/JP

- Wuxi Boton Belt Co. Ltd.

第六章 投资分析

第七章 市场机会及未来趋势

简介目录

Product Code: 67290

The Rubber Conveyor Belt Market is expected to register a CAGR of 4.2% during the forecast period.

Key Highlights

- The main driving factor for the rise of conveyor belt usage is the growth of e-commerce industry. Warehouses are proliferating, due to which there is an increasing need for material handling and reducing downtime. US-based SpanTech LLC offers e-commerce conveyors for the automation of e-commerce fulfillment processes.

- Conveyor belts are widely used in a variety of sectors because of their high adaptability, lightweight, and cost-effectiveness. One of the major factors driving the worldwide conveyor belt market is rising demand from the power, mining, and industrial industries.

- Companies in all industries, including manufacturing, mining, electric vehicles, food processing, warehouses, and other material handling facilities, are continuously seeking ways to improve their processes, which has boosted the demand for industrial facility automation. Conveyor belt systems will benefit greatly from the widespread adoption of automation in the workplace.

- However, the market is largely affected by fluctuations in raw material prices, which act as a challenge for market growth. An increase or decrease in rubber prices is dependant mainly on market conditions such as global supply/demand position, crude oil price movements, and the consequent impact on prices of synthetic substitutes.

- The conveyor belt market is witnessing a significant slowdown due to the impact of COVID-19 on the industries. The imposed lockdown and trade restrictions caused the factories and industries to shut down their operations. Moreover, due to the uncertainty, shortage of manpower, and material caused due to the supply chain restrictions, new facilities were also not built during the period, therefore, directly hampering the demand for conveyor belt systems. However, the rise in e-commerce during the period partially improved the conveyor belt demand.

Rubber Conveyor Belt Market Trends

Mining Industry to Dominate the Market

- The mining industry heavily relies on conveyor belts to transport materials taken up for processing. In September 2020, Coal India floated a 15,700 Crore tender for its 18 sites. This investment will go towards the conveyor belt system to replace road movement between mines and wagons. Investment in conveyor belts to transport coal directly from mines is a cheaper and cleaner way without using trucks. It will also cut down theft as well as diversion of coal and help maintain quality.

- The mining industry in Latin America, particularly in Brazil and Chile, is anticipated to see a rush of new investments. With about half a billion metric tonnes produced in 2020, the country was the world's second-largest iron ore mine producer. The Latin American region has followed the current trends as well. Chile and Argentina are the region's leading lithium producers, with over 60% of global reserves. Because mining necessitates the handling of larger amounts of materials, the conveyor system is the most efficient and cost-effective solution for long distances.

- With the BeltGauge solution, Fenner Dunlop has added mobile functionality to its suite of iBelt conveyor technology, providing a new approach for customers from all commodities and conveyor industry applications to properly monitor conveyor health. Since its launch in September 2020, the fixed BeltGauge solution has been installed at a number of locations.

- Germany-based ContiTech's conveyor belts are extensively being used in Jamaica for the transport of bauxite, generated 1,300 kW per hour, which can be fed back into the grid. They are also being used by Botswana's largest diamond producer.

- For usage in subterranean mines, Dunlop conveyor belting manufactured fire-resistant conveyor belts. These belts have been authorized and accredited according to national and international guidelines.

Asia-Pacific to Witness the Highest Growth

- The increasing demand for conveyor belts in this region is due to the rise in e-commerce operations, especially in China and India, to handle a large volume of goods.

- The market's expansion in this area is mostly due to technical advancements and the increased usage of automation technologies across a variety of end-user industries. Other significant drivers driving the conveyor monitoring demand in the region include rapid urbanization, complementary technical improvements, favorable government regulations, and robust FDI inflows.

- A major boost to the construction sector has resulted in rapid development in Asia Pacific industrial manufacturing and mining activities, as well as increased expenditure on urban infrastructure in the region. Conveyor belt systems are in high demand in the region as a result of this.

- Conveyor monitoring solutions are being deployed in droves in the APAC region to help increase operational efficiency. The biggest mining countries in the region, China and Australia, have been implementing real-time conveyor monitoring systems to boost operational efficiency and productivity.

- Australia is likely to hold a high potential for the market growth owing to the presence of vast reserves of oil and minerals. These have also helped in the establishment of a robust mining sector in the country. Additionally, favorable government policies, coupled with the adoption of the latest technologies in condition monitoring, are expected to augment the market growth in the country over the forecast period. The growing demand for predictive maintenance techniques and tools, along with the rising availability of remote conveyor monitoring and fault diagnosis systems, has resulted in fierce competition among manufacturers.

Rubber Conveyor Belt Industry Overview

The market is fragmented owing to an increasing number of end-user industries deploying conveyor belts for ease in processing and mergers by companies to bring innovation in this domain.

- Continental, a technology business, has developed a service solution for monitoring conveyor belt systems that allow for early detection of weak places along with a belt conveyor system before damage occurs, resulting in unplanned and costly downtimes. The innovative technique combines visual and auditory assessment in one device.

- Conveyor technology is increasingly using sophisticated materials, according to designers. Food manufacturers in the United States, for example, can benefit from "detector" conveyors that employ food-grade belts to stay in line with FDA regulations. Bacteria-resistant and capable of detecting microscopic pieces, these belts are suitable for this purpose.

- RFID (radio-frequency identification) technology is being used in a variety of industries. From the ordering stage until delivery, the ability to track products and processes in real-time may greatly improve logistics operations, increase customer experience, and improve supply chains. RFID technology is being integrated into self-contained conveyor systems that make control decisions automatically and allow numerous operations spanning multiple items to run at the same time.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 EXECUTIVE SUMMARY

3 MARKET DYNAMICS

- 3.1 Market Overview

- 3.2 Introduction to Market Drivers and Restraints

- 3.3 Market Drivers

- 3.3.1 Growth of E-Commerce Industry.

- 3.3.2 Increase in Productivity at Manufacturing Facilities.

- 3.4 Market Restraints

- 3.4.1 Fluctuations in Raw Material Prices

- 3.5 Value Chain Analysis

- 3.6 Industry Attractiveness - Porter's Five Force Analysis

- 3.6.1 Threat of New Entrants

- 3.6.2 Bargaining Power of Buyers/Consumers

- 3.6.3 Bargaining Power of Suppliers

- 3.6.4 Threat of Substitute Products

- 3.6.5 Intensity of Competitive Rivalry

4 MARKET SEGMENTATION

- 4.1 By Type

- 4.1.1 Heat-Resistant

- 4.1.2 Oil-Resistant

- 4.1.3 Fire-Resistant

- 4.1.4 Chemical-Resistant

- 4.2 By End-user Industry

- 4.2.1 Logistics

- 4.2.2 Mining

- 4.2.3 Manufacturing

- 4.2.4 Metal Processing

- 4.3 Geography

- 4.3.1 North America

- 4.3.2 Europe

- 4.3.3 Asia-Pacific

- 4.3.4 Latin America

- 4.3.5 Middle East & Africa

5 COMPETITIVE LANDSCAPE

- 5.1 Company Profiles

- 5.1.1 Oxford Rubbers Pvt. Ltd.

- 5.1.2 Muller Beltex B.V.

- 5.1.3 T-Rex Rubber International B.V.

- 5.1.4 The Yokohama Rubber Co. Ltd.

- 5.1.5 Bando Chemical Industries Ltd.

- 5.1.6 Bridgestone Corporation

- 5.1.7 Oriental Rubber Industries Pvt. Ltd.

- 5.1.8 Fenner Grouo Holdings Ltd.

- 5.1.9 Mitsuboshi Belting Ltd/JP

- 5.1.10 Wuxi Boton Belt Co. Ltd.

6 INVESTMENT ANALYSIS

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

02-2729-4219

+886-2-2729-4219