|

市场调查报告书

商品编码

1630326

过程自动化和仪器:市场占有率分析、行业趋势和统计、成长预测(2025-2030)Process Automation and Instrumentation - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

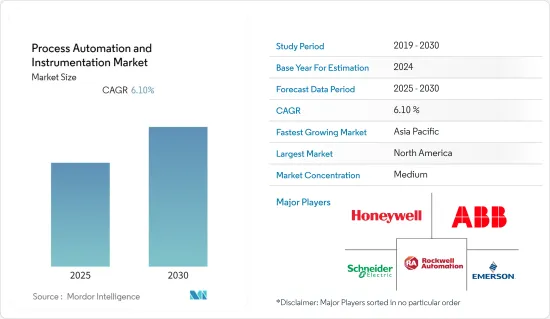

製程自动化和仪器市场预计在预测期内复合年增长率为 6.1%。

主要亮点

- 透过将製造的方面相结合以实现最佳性能,自动化行业正在发生彻底变革。此外,对缩短上市时间和实现零废弃物生产的关注正在加速整个加工行业使用的流程自动化和仪器的市场成长。

- 自动化製造流程具有多种优势,包括更轻鬆的监控、减少废弃物和更快的生产速度。连接工业机械和设备并捕获即时资料在 SCADA、HMI、PLC 系统和提供可视化的软体的采用中发挥关键作用。这使您能够减少产品缺陷、减少停机时间、安排维护,并从被动决策转向预测性和规范性决策。

- Onpassive(一家生产完全自主产品的人工智慧技术公司)对自动化解决方案的采用情况进行了研究,发现大量公司现在正在增加智慧自动化和 RPA 的使用。在调查中,大约 58% 的执行长表示他们已经开始自动化。特别是,大约 35% 的人表示他们正在“试验”,13% 的人正在“部署”,8% 的人“正在进行大规模自动化”。这些趋势正在为所研究市场的成长创造有利的前景。

- 虽然物理控制阀组件等设备多年来基本保持不变,但围绕这些阀门的技术却取得了显着进步。随着我们提高即时收集数位情报的能力,控制阀自动化将不断改进。控制阀自动化与最新的智慧数位控制阀门定位器和最先进的电动阀门致动器相结合,正处于不断上升的浪潮中,预计将使所有现代製程工厂受益。

- 然而,製程自动化成本高昂,因为它需要大量的前期投资来升级整体基础设施,包括机械、IT 等。因此,高初始投资加上高营运和维护成本阻碍了中小型企业采用流程自动化和仪器流程,这是挑战所研究市场成长的关键挑战之一。

- COVID-19 对研究市场的成长产生了重大影响,特别是在初始阶段,由于广泛的封锁,导致工业部门的供应链和营运发生重大中断,导致对研究市场的需求放缓研究市场。然而,这种流行病极大地提高了人们对数位技术好处的认识,预计这将推动对自动化和先进仪器解决方案的投资,为研究市场创造成长机会。

流程自动化和仪器市场趋势

石油和天然气产业占主要市场占有率

- 石油和天然气行业处理各种危险材料,并暴露在恶劣的环境和操作环境中,因此爆炸和灾难可能威胁人类和环境安全。流程自动化和仪器提供必要的监控和控制,以确保人力资源安全并遵守环境法规。当整合到自动化系统中时,智慧控制阀等製程设备可以透过提供有关最终产品品质和製程效率的连续资料来帮助製造商提高生产率和产品一致性。

- 此外,保护加压管道免受腐蚀和洩漏并最大限度地减少停机时间是石油和天然气行业的重要责任。根据 NACE(美国腐蚀工程师协会)统计,石油和天然气产业每年因腐蚀而造成的损失就超过 16 亿美元。气体样品中存在氧气表示加压管路系统有洩漏。透过采用先进的製程控制和自动化设备以及分析仪器,操作员可以显着降低成本。

- 此外,先进的自动化可以显着减少石油和天然气行业所有领域的能源使用,包括製程装置、公共事业和异地装置。对于大多数石油和气体纯化来说,能源是最大的单一可控成本,通常占非原油营运成本的 50% 以上。此外,营运成本的增加促使大多数炼油厂更加密切地关注其能源使用情况,从而为勘探市场创造了成长机会。

- 全球石油和天然气消费量的增加正促使石油生产公司增加产量并增加投资以探索新的油田和开采区。 IEA 预计,2026 年全球石油需求将达到 1.041 亿桶/日,高于 2020 年的 9,100 万桶/日。

预计北美将占据较大市场占有率

- 北美是全球最大的製程自动化和仪器市场之一。美国以其创新能力而闻名,在第四次工业革命新技术的显着发展方面处于领先地位。美国新发现的页岩资源和加拿大不断增加的石油和天然气计划是市场潜力的额外指标。

- 例如,代表加拿大石油和天然气钻探行业的 CAOEC(加拿大能源承包商协会)预计将在 2023 年扩大其活动。该组织预计2023年加拿大将钻探6,409口井,比2022年增加约15%。随着製程自动化和仪器(例如控制阀、PLC 等)广泛应用于上游、下游和中游活动,此类趋势预计将支持研究市场的成长。

- 工业自动化将在北美地区(尤其是美国)呈现强劲成长,因为在与中国持续衝突的情况下,政府最近采取的促进当地工业的倡议预计将有利于该国的製造业成长。对工业机器人和其他自动化技术的投资不断增长就证明了这一点。例如,根据推进自动化协会(A3)统计,2022年1月至9月,北美企业采购了35,804台工业机器人,金额18.75亿美元,与2021年2017年同期相比,订单增长了24%,销售额增长了27%。

- 为了寻求由于流程自动化解决方案的快速采用而带来的成长机会,该地区的公司不断增加其业务并扩大产品系列。例如,2022 年 8 月,数控、机器人和机器人机器供应商FANUC America 宣布进行西园区扩建,将其奥克兰县营运空间扩大至约 200 万平方英尺。据该公司称,扩建计划包括建造一座 655,000 平方英尺的工厂,用于容纳製造、研发和工程计划。

流程自动化和仪器产业概述

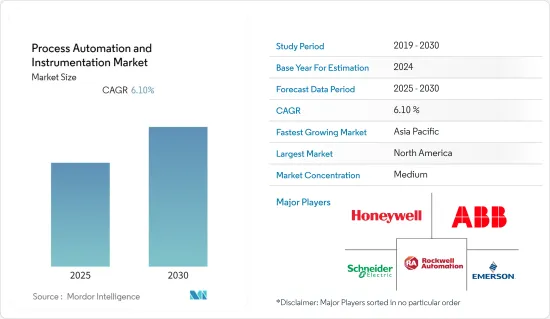

製程自动化和仪器市场适度分散,许多从事该领域业务的主要企业在全球范围内的市场影响大致相似。该市场生态系统还面临高昂的初始成本和来自 ABB、Honeywell和罗克韦尔自动化等现有参与者的激烈竞争,增加了新进入市场的障碍。 2022年11月,ABB测量与分析在印度班加罗尔开设了第一家智慧仪器。据该公司介绍,新工厂将为电力、製药、石油天然气、水务等多个行业生产温度和压力变送器、IP转换器和电磁流量计等现场设备。 2022 年 8 月,OPC 基金会 (OPCF) 和 FieldComm Group (FCG) 宣布合作,促进基于 OPC UA 的仪器和现场级增强功能的多供应商互通性。该开发旨在在 PLC/DCS 和致动器、变送器和仪表等仪器之间提供可互通的介面。

其他好处:

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业价值链分析

- 产业吸引力——波特五力

- 新进入者的威胁

- 买方议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争公司之间敌对关係的强度

- COVID-19 对市场的影响

第五章市场动态

- 市场驱动因素

- 能源效率和降低成本的重要性

- IIoT 解决方案的采用率不断提高

- 市场限制因素

- 实施流程自动化和仪器解决方案的投资和维护成本高

第六章 市场细分

- 仪器

- 现场设备

- 控制阀

- 分析设备

- 按解决方案

- 先进製程控制 (APC)

- 集散控制系统(DCS)

- 人机互动(HMI)

- 製造执行系统(MES)

- 可程式逻辑控制器(PLC)

- 安全自动化

- 监控和资料采集 (SCADA)

- 按最终用户产业

- 石油和天然气

- 饮食

- 製药/生物製药

- 化学/石化

- 其他最终用户产业

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 南美洲

- 中东/非洲

第七章 竞争格局

- 公司简介

- ABB Ltd

- Emerson Electric Co.

- Honeywell International, Inc.

- Mitsubishi Electric

- Rockwell Automation, Inc.

- Schneider Electric SE

- Siemens AG

- Yokogawa Electric Corporation

- General Electric Company

- Eaton Corporation

第八章投资分析

第九章 市场未来展望

The Process Automation and Instrumentation Market is expected to register a CAGR of 6.1% during the forecast period.

Key Highlights

- The automation industry has been revolutionized by combining the digital and physical aspects of manufacturing to deliver optimum performance. Further, the focus on a shorter time to market and achieving zero waste production has augmented the market's growth for process automation and instrumentation used across the processing industries.

- Automation of manufacturing processes has offered various benefits, such as effortless monitoring, waste reduction, and production speed. Connecting the industrial machinery and equipment and obtaining real-time data have played a vital role in the adoption of SCADA, HMI, PLC systems, and software that offer visualization; this enables reducing the faults in the product, reducing downtime, scheduling maintenance, and switching from being in the reactive state to predictive and prescriptive stages for decision-making.

- According to a survey about the adoption of automation solutions by Onpassive, an AI tech company that builds fully autonomous products, it was discovered that a significant number of companies nowadays are boosting their use of intelligent automation and RPA. In responding to the survey, about 58% of CEOs stated that they have started automating. In particular, about 35% reported that they are experimenting, 13% said that they are deploying, and 8% reported that they are automating at scale. Such trends create a favorable scenario for the growth of the studied market.

- While the instruments such as physical control valve assembly have changed little over the years, the technology surrounding these valves has advanced significantly. Increased capabilities to gather digital intelligence in real-time will only continue to enable improvements in control valve automation moving forward. Combined with the newest intelligent digital control valve positioners and cutting-edge electric valve actuators, control valve automation is on an upward wave that is anticipated to benefit all modern process plants.

- However, process automation is costly, as it requires a significant upfront investment to upgrade the overall infrastructure, including machinery, IT, etc. Hence, the high initial investment coupled with high operational and maintenance costs prevents small and medium-sized enterprises from adopting process automation and instrumentation processes, which is among the significant factor challenging the studied market's growth.

- A notable impact of COVID-19 has been observed on the growth of the studied market, as the widespread lockdown imposed, especially during the initial phase, significantly disrupted the supply chain and the operation of the industrial sector, creating a slowdown in demand for the studied market. However, the pandemic has dramatically enhanced awareness about the benefits of digital technologies, which is expected to drive investments in automation, and advanced instrumentation solutions, creating growth opportunities in the studied market.

Process Automation & Instrumentation Market Trends

Oil and Gas Industry to Hold Significant Market Share

- As the oil and gas industries process a variety of hazardous substances that are also exposed to harsh environments and operational environments, any explosions or catastrophic event can endanger the safety of humans and the environment. Process automation and instrumentation provide monitoring and control essential for ensuring human resources' safety and compliance with environmental regulations. When integrated into automation systems, processing instruments, such as smart control valves, also helps manufacturers increase productivity and product consistency by delivering continuous data regarding end-product quality and process efficiency.

- Furthermore, in the oil and gas industry, protecting a pressurized pipeline from corrosion and leaks and minimizing downtime are among the crucial responsibilities of the industry. According to the NACE (National Association for Corrosion Engineers), the oil and gas industry suffers a cost of over USD 1.6 billion per year due to corrosion alone. The presence of oxygen in the gas sample determines that there is a leak in the pressurized pipeline system. The adoption of advanced process control and automation instrumentations, along with analytical instruments, can help the operators significantly reduce this cost.

- Furthermore, advanced automation can significantly reduce energy utilization in all areas of the oil and gas industry, including process units, utilities, and offsite units. Energy is the single largest controllable cost for most oil and gas refineries, often comprising more than 50% of non-crude operating expenses. Further, the increase in operational costs has caused most refineries to look even more closely at their energy utilization, creating growth opportunities for the studied market.

- The increasing global consumption of oil and gases are driving oil-producing companies to increase their production and investment to explore new oil fields and extraction zones which is expected to create a supportive growth environment for the studied market. According to the IEA, the global demand for crude oil is expected to reach 104.1 million barrels per day by 2026, from 91 million barrels per day in 2020.

North America is Expected to hold a Significant Market Share

- North America is one of the largest global markets for process automation and instrumentation. The United States is renowned for its innovation capabilities and is at the forefront of prominent developments surrounding the emerging technologies of the Fourth Industrial Revolution. New-found shale resources in the United States, and an increasing number of oil and gas projects in Canada, are additional indicators of the market potential.

- For instance, the Canadian Association of Energy Contractors (CAOEC) organization, which represents Canada's oil and gas drilling sector, expects more activity in 2023. The organization expects 6,409 wells to be drilled in Canada in 2023, an approximately 15% increase from 2022. As process automation and instrumentations, such as control valves, PLCs, etc., are widely used in upstream, downstream, and midstream activities, such trends are expected to support the studied market's growth.

- Industrial automation in the North American region, especially in the United States, is expected to exhibit strong growth, as the recent government initiatives to push the local industries amid its ongoing disputes with China are expected to favor the growth of the manufacturing sector in the country. This is evident from the growing investment in industrial robots and other automation technologies. For instance, according to the Association for Advancing Automation (A3), during the period January to September 2022, North American companies purchased 35,804 units of industrial robots, valued at USD 1.875 billion, up 24% for ordered units and 27% for revenue over the same period in 2021.

- For seeking the growth opportunity with a rapid increase in the adoption of process automation solutions, companies in the region are continuously expanding their presence and product portfolio for the studied market. For instance, in August 2022, FANUC America, a supplier of CNCs, robotics, and ROBOMACHINEs, announced an expansion of its West Campus that would expand its operational space in Oakland County to nearly about two million square feet. According to the company, the expansion plan involves the construction of a 655,000-square-foot facility to house manufacturing, R&D, and engineering projects.

Process Automation & Instrumentation Industry Overview

The market for process automation and instrumentation is moderately fragmented, with the presence of many key players operating in the segment with almost similar market presence globally. Also, the market ecosystem is subjected to high initial costs and high competition from established players, including ABB, Honeywell, and Rockwell Automation, among others, increasing the barrier for new entrants into the market. In November 2022, ABB Measurement & Analytics opened its first smart instrumentation factory in Bangalore, India. According to the company, the new plant will manufacture field devices such as temperature and pressure transmitters, IP converters, and electromagnetic flowmeters for various industries, including power, pharmaceutical, oil and gas, water, and other segments. In August 2022, the OPC Foundation (OPCF) and the FieldComm Group (FCG) announced a collaboration to drive multi-vendor interoperability of OPC UA-based instrumentation devices and the extensions for the field level, named OPC UA FX (Field eXchange). This development is aimed at providing an interoperable interface between PLC / DCS and instrumentation devices, such as actuators, transmitters, and instruments.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter Five Forces

- 4.3.1 Threat of New Entrants

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Bargaining Power of Suppliers

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Importance of Energy Efficiency and Cost Reduction

- 5.1.2 Increasing Adoption of IIoT Solutions

- 5.2 Market Restraints

- 5.2.1 High Investment for Implementation and Significant Maintenance Cost for Process Automation and Instrumentation Solutions

6 MARKET SEGMENTATION

- 6.1 By Instrument

- 6.1.1 Field Instruments

- 6.1.2 Control Valve

- 6.1.3 Analytical Instruments

- 6.2 By Solution

- 6.2.1 Advanced Process Control (APC)

- 6.2.2 Distributed Control System (DCS)

- 6.2.3 Human Machine Interaction (HMI)

- 6.2.4 Manufacturing Execution System (MES)

- 6.2.5 Programmable Logic Controller (PLC)

- 6.2.6 Safety Automation

- 6.2.7 Supervisory Control and Data Acquisition (SCADA)

- 6.3 By End-user Industry

- 6.3.1 Oil and Gas

- 6.3.2 Food and Beverage

- 6.3.3 Pharmaceutical and Biopharma

- 6.3.4 Chemical and Petrochemical

- 6.3.5 Other End-user Industries

- 6.4 By Geography

- 6.4.1 North America

- 6.4.2 Europe

- 6.4.3 Asia Pacific

- 6.4.4 South America

- 6.4.5 Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 ABB Ltd

- 7.1.2 Emerson Electric Co.

- 7.1.3 Honeywell International, Inc.

- 7.1.4 Mitsubishi Electric

- 7.1.5 Rockwell Automation, Inc.

- 7.1.6 Schneider Electric SE

- 7.1.7 Siemens AG

- 7.1.8 Yokogawa Electric Corporation

- 7.1.9 General Electric Company

- 7.1.10 Eaton Corporation