|

市场调查报告书

商品编码

1630428

糖包装:市场占有率分析、产业趋势与统计、成长预测(2025-2030)Sugar Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

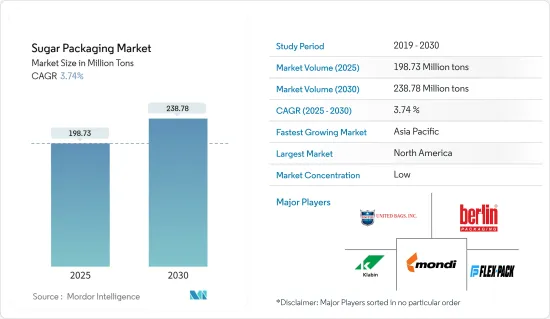

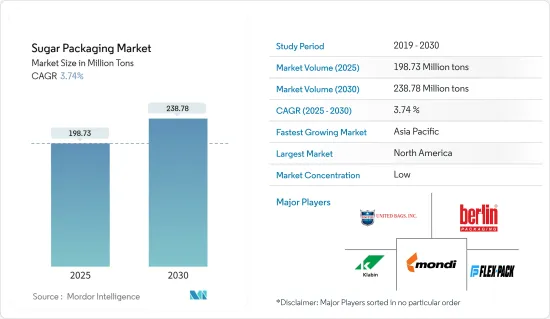

预计2025年食糖包装市场规模为19,873万吨,预估至2030年将达2,3,878万吨,预测期间(2025-2030年)复合年增长率为3.74%。

主要亮点

- 市场正在见证向软包装的显着转变,因为糖被以各种形式包装用于散装和零售目的。由于活性包装和智慧包装等包装技术的创新,糖的软包装不仅成为可能,还可以延长保质期。

- 随着有机和特殊糖的需求增加,对特殊包装的需求也随之增加。这确保了这些高价值产品在运输和储存过程中得到保护。此外,随着贸易变得更加全球化,迫切需要标准化的包装解决方案来满足不同国家和地区的多样化需求。

- 据美国农业部称,澳洲食糖产量将缓慢成长,2022年和2023年将达到440万吨。 2022/23 年甘蔗产量预计为 3,300 万吨。产量的增加与收穫面积的扩大有关,收穫面积增加了 5,000 公顷,达到 35 万公顷。

- 在健康意识日益增强的市场中,糖行销克服了主要障碍。儘管消费者可能在不知不觉中选择含糖量高的产品,但他们在购买原糖时会考虑多种因素。因此,糖袋市场正在大力投资创新包装解决方案,以增强糖的吸引力并确保易用性。

- 纸是纸袋的主要材料,价格实惠且容易取得。然而,纸袋里的糖很容易损坏。然而,纸袋装的糖容易腐烂,且运输方便快速。其防水防潮性能是其一大优势。此外,纸袋简化了销售、储存和消费。此外,纸袋具有高度可降解性,有助于最大限度地减少生态足迹。

- 彩色铁皮是铁盒包装材料的首选。这些盒子有圆柱形、矩形、椭圆形和五边形等形状,以其耐用性、安全密封和抗破损性而闻名。铁盒包装亮丽的外观、鲜艳的色彩,不仅增强了糖的吸引力,还强调了它的坚固性。除了糖之外,铁盒也经常被用来包装糖果零食,许多主要的包装、礼品和糖果零食製造商都使用铁盒来展示其产品的品质。

- 塑胶袋在糖包装中占据主导地位,是最常用的选择。因其防潮、防水、性价比高而广受欢迎。糖生产商经常选择这些袋子,它们有透明和彩色两种。尤其是彩色包装可以增强糖的视觉吸引力,这是老牌和新兴糖果糖果零食糖果零食。然而,重大问题迫在眉睫。这些塑胶袋正在加剧日益严重的塑胶污染。这款糖包装机具有出色的多功能性,可以熟练地处理塑胶袋和纸袋,最新的技术确保了性能的一致性。

食糖包装市场趋势

塑胶材质占较大市场占有率

- Nichrome Packaging Solutions 表示,塑胶包装因其无与伦比的功能而拥有很大的市场占有率。在塑胶解决方案中,软质塑胶包装的特点是比硬质塑胶包装使用的原料少70%。

- 根据反馈组织 2023 年 4 月报道,超级市场作为主要的食糖分销商主导英国市场。这些零售商曾声称他们只是回应消费者的需求,但后来放弃了这个立场。研究一直强调超级市场的「零售商力量」。超级市场是食品生产者和消费者之间的仲介业者。它的主导地位限制了供应商和消费者,缩小了他们购买和销售食品的选择范围。光是五家超级市场就控制了75%以上的零售市场占有率,这一事实证明了这种影响力。超级市场利用其「买方力量」向供应商规定条款并影响库存选择、品质、数量、包装和定价。这种动态也适用于宝洁、雀巢和联合利华等产业巨头。随着超级市场糖销量的增加,对糖包装的需求也随之增加,特别是小袋和小袋等软包装。快餐店和咖啡店的成长进一步增加了对糖袋的需求。

- 用软塑胶袋包装糖的趋势日益明显,这种塑胶袋因其防潮性、成本效益以及透过颜色和透明度打造品牌的潜力而受到糖製造商的青睐。

- 儘管如此,市场相关人员对塑胶包装的替代品很感兴趣。生质塑胶的日益普及对传统塑胶包装提出了重大挑战。在预测期内,可回收和可再生材料可能会取代塑胶包装。

- Logistex Ltd. 强调,巴西货柜食糖出口将在因「货柜 Ergedon」运动而经历了两年的平静期后于 2023 年恢復。出货量的增加与巴西食糖产量的增加和海运费的下降同时发生。此外,世界其他主要食糖生产国面临的挑战进一步巩固了巴西的市场领导地位。

- 相反,印度面临作物挑战,对于重新进入食糖出口市场犹豫不决,尤其是在转向乙醇生产的情况下。这为巴西确立其主导地位铺平了道路。国内生产商更喜欢散货运输,但货柜运输对于出口仍然至关重要,通常涉及复杂的谈判和高附加价值。

- 海事机构威廉斯指出,2023年,巴西货柜糖出口量达294万吨。占巴西总出口量的9.4%,与前一年同期比较大幅成长90.1%。这一数字与2017年高峰298万吨持平,占总出货量的10.7%。在装入容器之前,这些糖通常包装在由黄麻或编织塑胶等天然材料製成的软袋或麻袋中,通常带有塑胶衬里。

亚太地区将经历最高的成长

- 亚太地区凭藉食品包装和品牌的重大创新引领成长。此外,该地区的消费者非常重视糖果零食的奢华体验。

- 人口成长、收入水准提高、生活方式不断变化、媒体影响力不断增强以及经济强劲,正在推动对包装的需求。该部门是该地区最重要且发展迅速的部门之一。值得注意的是,印度领先的评级机构 Care Ratings 强调,印度超过 49% 的纸张生产专用于包装。

- 亚太地区的包装产业监督多项法规,特别是食品和饮料产业。主要法规包括 1956 年《防止食品掺假法》、2011 年《塑胶废弃物(管理和处理)条例》和 2011 年《食品安全标准(包装和标籤)条例》。

- 预期有关食品业纸张和纸浆使用的法规将提振市场。例如,印度食品安全和标准局推出了新的包装法规,旨在加强纸张在食品包装中的作用。此外,BIS 标准 IS 4664:1986 允许在食品包装中使用再生纸浆,这将增加印度糖包装中纸张的使用。

- 据美国对外农业服务局称,2023/2024 年周期印度食糖产量约 3,400 万吨。儘管多年来印度的食糖产量起伏不定,但印度仍自豪地成为仅次于巴西的世界第二大食糖生产国。印度内阁经济事务委员会 (CCEA) 已核准2023-2024 年週期的新标准,强调黄麻包装。具体来说,2023-24 年黄麻年标准要求 100% 的食品谷物包装和 20% 的糖包装使用黄麻袋。

糖包装行业概况

这项研究根据材料类型和产品类型考察了全球食糖生产。糖的包装形式多种多样,包括散装和零售,因此向软包装的转变是显而易见的。活性包装等新技术不仅加速了这一趋势,而且还延长了糖的保质期。塑胶因其无与伦比的功能而在包装市场占据主导地位。软质塑胶包装在塑胶解决方案中脱颖而出,比硬质包装使用的原料少 70%。

糖包装市场适度分散。市场参与者正在提供广泛的产品客製化,以扩大他们的份额并增加收益。主要参与者包括 Mondi Group、United Bags Inc、FlexPack、Klabin SA 和 Berlin Packaging。由于需求不断增长,公司正在透过该市场的创新获得永续的竞争优势。

其他好处:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 竞争公司之间的敌对关係

- 替代品的威胁

- 产业价值链分析

第五章市场动态

- 市场驱动因素

- 印度、中国、欧盟地区等主要国家食糖消费量稳定成长

- 对客製化包装形式和永续材料的需求不断增长

- 市场限制因素

- 製造商面临的营运和监管问题

第六章 市场细分

- 依产品类型

- 软包装

- 袋子和小袋

- 香囊

- 包包

- 其他软包装

- 硬包装

- 瓶子和容器

- 软包装

- 按材质

- 塑胶

- 纸

- 其他材料

- 按地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 义大利

- 亚洲

- 印度

- 中国

- 日本

- 泰国

- 拉丁美洲

- 中东/非洲

- 北美洲

第七章 竞争格局

- 公司简介

- Mondi Group

- United Bags Inc.

- FLexPack

- Berlin Packaging

- Grupo Bio Pappel

- Swiss Pack Limited

- Packman Industries

- TedPack Company Limited

- Klabin SA

- Shri Salasar Plastics

第八章投资分析

第9章市场的未来

The Sugar Packaging Market size is estimated at 198.73 million tons in 2025, and is expected to reach 238.78 million tons by 2030, at a CAGR of 3.74% during the forecast period (2025-2030).

Key Highlights

- The market is witnessing a notable shift towards flexible packaging, especially as sugar is being packaged in various formats for both bulk and retail purposes. Thanks to innovations in packaging technologies, such as active and smart packaging, flexible packaging for sugar is not only feasible but also extends its shelf life.

- With the rising demand for organic and specialty sugars, there's an increasing need for specialized packaging. This ensures the protection of these high-value products during transportation and storage. Moreover, as trade becomes more globalized, there's a pressing need for standardized packaging solutions that meet the varied requirements of different countries and regions.

- According to USDA, Australia's sugar production is set to see a modest rise, reaching 4.4 million tons for the years 2022 and 2023. In the 2022/23 cycle, sugarcane production is estimated at 33.0 million tons. This increase in output is linked to an expansion in the harvested area, which has grown by 5,000 hectares to reach 350,000 hectares.

- In a market increasingly focused on health, sugar marketing is navigating significant hurdles. While consumers might unknowingly choose products high in sugar, they consider multiple factors when purchasing unprocessed sugar. As a result, the sugar bag market is heavily investing in innovative packaging solutions to boost sugar's appeal and ensure user-friendliness.

- Paper, the go-to material for paper bags, is both affordable and easily sourced. Yet, sugar in paper bags is more prone to damage. Despite this vulnerability, paper bags enable quick and convenient transportation. Their waterproof and moisture-proof qualities stand out as significant advantages. Moreover, paper bags simplify selling, storage, and consumption. An added environmental perk of using paper for bags is its degradability, leading to a minimal ecological footprint.

- Tinted tin iron is the favored material for packaging in iron boxes. These boxes, available in shapes like cylinders, rectangles, ovals, and pentagons, are celebrated for their durability, secure sealing, and damage resistance. The bright appearance and vibrant colors of iron box packaging not only enhance sugar's appeal but also underscore its robustness. Beyond sugar, these iron boxes are a go-to for candy packaging, with many leading packaging, gift, and candy producers leveraging them to signify product quality.

- Plastic bags reign supreme in sugar packaging, being the most commonly used option. Their moisture-proof and waterproof nature, combined with cost-effectiveness, makes them a favorite. Sugar producers often opt for these bags, available in both transparent and colored variants. Colorful wraps, especially, can elevate sugar's visual allure, a strategy embraced by both established and budding confectionery makers. Yet, a major concern looms: these plastic bags contribute to the growing issue of plastic pollution. Versatility shines through as sugar packing machines adeptly handle both plastic and paper bags, and with modern technology, they promise consistent performance.

Sugar Packaging Market Trends

Plastic Material to Hold Significant Market Share

- According to Nichrome Packaging Solutions, plastic packaging holds a significant market share due to its unparalleled functionality. Among plastic solutions, flexible plastic packaging is notable for using 70% less raw material than its rigid counterpart.

- As reported by Feedback Organization in April 2023, supermarkets dominate the UK market as primary sugar sellers. While these retailers once claimed to merely respond to consumer demand, they've since abandoned this stance. Research has consistently spotlighted the 'retailer power' of supermarkets. Acting as intermediaries, they bridge food producers and consumers. Their dominance restricts both suppliers and customers, curtailing choices in buying and selling food. This influence is evident as just five supermarkets control over 75% of the retail market share. Leveraging their 'buyer power', supermarkets dictate terms to suppliers, influencing stock selection, quality, quantity, packaging, and pricing decisions. This dynamic holds even for industry giants like Procter & Gamble, Nestle, and Unilever. With supermarkets bolstering sugar sales, they're simultaneously driving up demand for sugar packaging, especially in flexible formats like pouches and sachets. The growth of quick-service restaurants and coffee shops has further amplified the demand for sugar sachets.

- There's a growing trend of packaging sugar in flexible plastic bags, favored by sugar manufacturers for their moisture resistance, cost-effectiveness, and branding potential through color or transparency.

- Despite this, market players are gravitating towards alternatives to plastic packaging. The rising adoption of bioplastics poses a significant challenge to traditional plastic packaging in the industry. Over the forecast period, recyclable and renewable materials are poised to potentially replace plastic packaging.

- Logistex Ltd. highlights a rebound in Brazilian sugar exports via containers in 2023, after a two-year lull, influenced by the "containergeddon" movement. This increase in shipments coincided with a rise in Brazil's sugar production and a decline in seafreight rates. Additionally, challenges faced by other major global sugar producers further cemented Brazil's market leadership.

- Conversely, India faced harvest challenges and was hesitant to re-enter the sugar export market, especially with its shift towards ethanol production. This opened the door for Brazil to assert its dominance. While national producers favored bulk shipping, container shipments remained vital for exports, often involving intricate negotiations and higher value additions.

- In 2023, Brazil's containerized sugar exports reached 2.94 million tons, as noted by maritime agency Williams. This constituted 9.4% of Brazil's total exports and marked a remarkable 90.1% increase from previous years. The figure was on the verge of matching the 2017 peak of 2.98 million tons, which represented 10.7% of total shipments. Before container loading, these sugars are typically packaged in flexible bags or sacks made from woven natural materials like jute or woven plastic, frequently featuring a plastic inner lining.

Asia-Pacific to Witness Highest Growth

- The Asia-Pacific region leads in growth, driven by notable innovations in food packaging and branding. Additionally, consumers in this region place a high value on the indulgent experience of sugar confectionery.

- Rising population, increasing income levels, evolving lifestyles, heightened media influence, and a robust economy are fueling the demand for packaging. This sector stands out as one of the most vital and rapidly expanding in the region. Notably, Care Ratings, a leading credit rating agency in India, highlights that over 49% of the country's paper production is dedicated to packaging.

- Several regulations oversee the packaging industry in the Asia-Pacific, particularly in the food and beverage sectors. Key regulations include the Prevention of Food Adulteration Act of 1956, the Plastic Waste (Management and Handling) Rules of 2011, and the Food Safety and Standards (Packaging and Labelling) Regulations of 2011.

- Anticipated regulations on paper and pulp usage in the food sector are poised to boost the market. For example, India's Food Safety and Standards Authority has rolled out new packaging regulations, aiming to bolster paper's role in food packaging. Furthermore, the BIS standard IS 4664: 1986, which allows recycled pulp in food packaging, is set to enhance paper's prominence in India's sugar packaging.

- As per the USDA Foreign Agricultural Service, India produced around 34 million metric tons of sugar in the 2023/2024 cycle. While sugar production in India has seen its ups and downs over the years, the nation proudly stands as the world's second-largest sugar producer, trailing only Brazil. In the 2023-2024 cycle, India's Cabinet Committee on Economic Affairs (CCEA) approved new norms emphasizing jute packaging. Specifically, the 2023-24 Jute Year norms mandate that jute bags must be used for 100% of food grains and 20% of sugar packaging.

Sugar Packaging Industry Overview

The study considers sugar production globally based on material type and product type. As sugar is packaged in various formats for both bulk and retail, there's been a notable shift towards flexible packaging. New technologies, like active packaging, not only facilitate this trend but also extend the shelf life of sugar. Plastic dominates the packaging market due to its unmatched functionality. Flexible plastic packaging stands out among plastic solutions, utilizing 70% less raw material than its rigid counterpart.

The sugar packaging market is moderately fragmented. Players in the market are offering extensive product customization to increase their share and augment their revenue. Some of the key players are Mondi Group, United Bags Inc, FlexPack, Klabin S.A., Berlin Packaging and more. The companies have a sustainable competitive advantage through innovations in this market, owing to the growing need.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Intensity of Competitive Rivalry

- 4.2.5 Threat of Substitute Products

- 4.3 Industry Value Chain Analysis

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Steady Increase in the Consumption of Sugar in Major Countries such as India, China and EU Regions

- 5.1.2 Rising Demand for Customized Packaging Formats and Sustainable Materials

- 5.2 Market Restraints

- 5.2.1 Operational and Regulatory Concerns Faced by the Manufacturers

6 MARKET SEGMENTATION

- 6.1 By Product Type

- 6.1.1 Flexible Packaging

- 6.1.1.1 Bags and Pouches

- 6.1.1.2 Sachets

- 6.1.1.3 Sacks

- 6.1.1.4 Other Flexible Packaging Types

- 6.1.2 Rigid Packaging

- 6.1.2.1 Jars and Containers

- 6.1.1 Flexible Packaging

- 6.2 By Material Type

- 6.2.1 Platsic

- 6.2.2 Paper

- 6.2.3 Other Material Type

- 6.3 Geography

- 6.3.1 North America

- 6.3.1.1 United States

- 6.3.1.2 Canada

- 6.3.2 Europe

- 6.3.2.1 United Kingdom

- 6.3.2.2 Germany

- 6.3.2.3 France

- 6.3.2.4 Italy

- 6.3.3 Asia

- 6.3.3.1 India

- 6.3.3.2 China

- 6.3.3.3 Japan

- 6.3.3.4 Thailand

- 6.3.4 Latin America

- 6.3.5 Middle East and Africa

- 6.3.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Mondi Group

- 7.1.2 United Bags Inc.

- 7.1.3 FLexPack

- 7.1.4 Berlin Packaging

- 7.1.5 Grupo Bio Pappel

- 7.1.6 Swiss Pack Limited

- 7.1.7 Packman Industries

- 7.1.8 TedPack Company Limited

- 7.1.9 Klabin S.A.

- 7.1.10 Shri Salasar Plastics