|

市场调查报告书

商品编码

1632051

亚太地区半导体蚀刻设备:市场占有率分析、产业趋势、成长预测(2025-2030)Asia-Pacific Semiconductor Etch Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

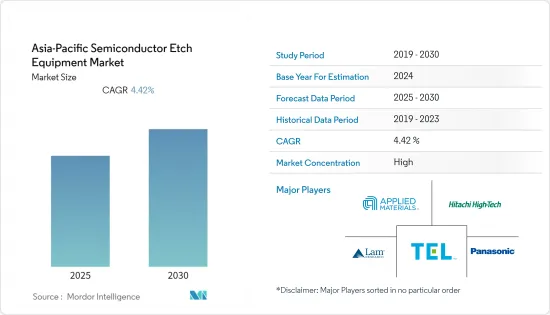

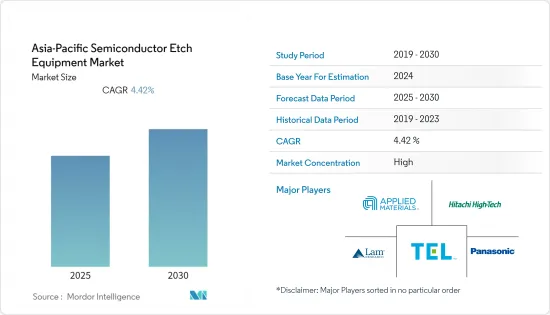

亚太半导体蚀刻设备市场预计在预测期内复合年增长率为4.42%

主要亮点

- 汽车应用以及物联网、人工智慧和跨多种最终用途应用的连网型设备的整合可能会增加对各种类型半导体的需求。该地区是许多拥有最新技术的半导体製造公司的所在地。这使得亚太地区成为全球半导体蚀刻设备的製造强国。例如,中国在 7 奈米晶片生产方面正越来越接近自力更生。据报道,中国在 7 奈米晶片製造流程方面取得了突破,在製造流程的多个环节开发了工具和技术,以减少对外国设备和材料供应商的依赖。

- 该地区各国都致力于透过提供税收优惠、资金、补贴和其他形式援助的政府措施来鼓励半导体蚀刻设备製造。 「中国製造2025」和「印度製造」计画正在促进该地区的製造业和其他高科技业务。例如,印度政府表示,印度半导体产业目前价值 150 亿美元,预计到 2026 年将成长至 630 亿美元。透过政府对半导体製造及週边环节的干预,印度很可能成为全球半导体供应链的主导。政府正在邀请世界各地的公司考虑在该国设立设施。

- 北美和欧洲的新型半导体将在各自地区生产晶片,标誌着亚太地区半导体及相关领域的成长突破。亚太地区作为半导体晶片的主要製造地区和全球供应商,面临业务亏损的挑战。例如,加拿大宣布将禁止中国最大的两家通讯设备製造商华为和中兴参与其5G手机网路。这项业务损失预计将对该地区的半导体蚀刻设备市场产生负面影响。

- COVID-19 对市场产生了负面影响,并导致半导体产业的供应链和生产中断。劳动力短缺对半导体蚀刻设备製造商的影响尤其严重。疫情期间,全球半导体供应链上的多家公司被迫缩减甚至取消营运。该行业的巨额亏损和不断增长的需求造成了供应链的巨大缺口。

亚太半导体蚀刻设备市场趋势

功率元件预计将成长

- 功率元件利用固体电子元件的功能进行功率控制和转换。这些电子元件可直接用于功率处理电路中以控制和转换电能。这些元件主要用作电路和系统中的开关和整流器,是电力电子技术的重要组成部分。

- 由于工业、汽车、资料中心和能源产业等各种电子应用对高功率元件的需求不断增加,功率元件製造业预计将显着成长。

- 例如,2021年3月,东芝电子元件及储存装置株式会社宣布将在日本加贺东芝电子株式会社兴建300毫米晶圆製造厂,以扩大其功率元件产能。

- 同样,2022 年 2 月,德国晶片製造商英飞凌科技宣布计划投资超过 20 亿欧元在马来西亚居林新建一座前端工厂。考虑到需求的成长,该公司增加了投资以扩大其GaN和SiC製造能力,并保持其在整个功率半导体领域的地位。

- 由于蚀刻是功率元件製造过程中的关键步骤,此类案例也为研究市场创造了有利的市场情景。此外,设备製造商增加研发投资以满足客户不断变化的需求也推动了研究市场的创新。

预计中国将占据亚太地区主要市场占有率

- 中国吸引了包括台积电在内的多家公司的多次投资,华为等本土公司也进入了晶片生产领域。

- 2021年5月,台积电将在中国投资28亿美元,以提高汽车晶片的产量,并在供不应求的情况下在南京建造新工厂。虽然华为打算使用其 45 奈米製造製程生产晶片,但该工厂不会成为智慧型手机的解决方案,但可以在 2022 年之前为华为的 5G套件生产网路晶片。

- 电动车需求的不断增长正在推动亚太汽车半导体产业的快速扩张。汽车製造商将继续创新、创造和开发自动驾驶汽车,吸引来自各个主要汽车製造国的客户。

- 全自动驾驶汽车的成长将在很大程度上受到技术进步、消费者接受全自动驾驶汽车的意愿、定价以及供应商和OEM解决关键车辆安全问题的能力的影响。由于这些因素,汽车产业和半导体产业始终专注于增强技术、协商原材料价格,并最终将汽车与可靠的技术结合。

亚太半导体蚀刻设备产业概况

亚太半导体蚀刻设备市场竞争激烈,只有少数几家主要企业占了市场占有率。新进入者很难进入这个市场,因为它需要大量的资金。不同的公司正在探索不同的策略来增强其市场力量,包括产品创新、扩张、新兴市场开发、併购。

- 2022年5月:韩国易恩孚科技在天安工厂投资512亿韩元,准备建立氢氟酸生产设施。氢氟酸是氟化氢的原料药,用于在半导体製造过程中断开电路并去除污染物。三星电子和SK海力士等半导体製造商将其用于晶圆蚀刻和清洗操作。

- 2022年5月:为了因应日益增长的电动产品需求,日立宣布已在宫城第四工厂(宫城县村田市)开始量产电动车逆变器。电动车在全球范围内的需求量很大,因为它们在帮助政府实现碳中和和减少碳排放发挥关键作用。日立将透过提高马达和逆变器等电动车关键零件的产能并扩大产品阵容来应对这一不断增长的需求。

- 2021年1月:日本ULVAC, Inc.宣布推出uGmni系列,这是丛集系统。这使得在同一个传输核心上安装溅镀、蚀刻和CVD等各种製程模组成为可能。我们也开始销售使用这个新平台的生产系统。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究成果

- 研究场所

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场动态

- 市场概况

- 市场驱动因素

- 扩大该地区的智慧电子设备

- 政府主导的该地区国内半导体製造计划

- 市场限制因素

- 新进军欧美半导体市场

- 价值链/供应链分析

- 波特五力分析

- 新进入者的威胁

- 买家/消费者的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争公司之间敌对关係的强度

- COVID-19 对市场的影响

第五章市场区隔

- 依产品类型

- 高密度蚀刻设备

- 低密度蚀刻设备

- 依蚀刻类型

- 导体蚀刻

- 介电蚀刻

- 多晶硅蚀刻

- 按用途

- 逻辑和记忆

- 功率元件

- MEMS

- 按国家/地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

第六章 竞争状况

- 公司简介

- Applied Materials Inc

- Hitachi High Technologies

- Lam Research Corporation

- Tokyo Electron Limited

- Panasonic Corporation

- Plasma-Therm

- Gigalane

- SUZHOU DELPHI LASER CO. LTD

- NAURA Technology Group Co. Ltd

第七章 投资分析

第八章市场的未来

简介目录

Product Code: 90927

The Asia-Pacific Semiconductor Etch Equipment Market is expected to register a CAGR of 4.42% during the forecast period.

Key Highlights

- Automotive applications and the integration of IoT, AI, & connected devices across multiple end-use verticals will likely increase the demand for various types of semiconductors. The region has many semiconductors manufacturing companies with the latest technologies. By this, Asia-Pacific has become a worldwide manufacturing powerhouse for semiconductor Etch Equipment. For instance, China is moving significantly closer to self-reliance in 7nm chip production. China has made breakthroughs in its 7nm chip-making process, reportedly developing tools and know-how for several segments of the manufacturing process amid efforts to reduce reliance on foreign equipment and material vendors.

- Various countries in this region are focused on encouraging semiconductor etch equipment manufacturing through government policies offering tax breaks, money, subsidies, and other forms of assistance. Made in China 2025 and make in India programs promote manufacturing and other high-tech businesses in the region. For instance, according to the government, the Indian semiconductor sector, which is presently valued at USD 15 billion, is predicted to grow to USD 63 billion by 2026. Through governmental intervention in the manufacturing of semiconductors and the peripheral sector, India will become a lead country in global semiconductor supply chains. The government invites companies from all over the world to explore establishing facilities in the country.

- The new semiconductor acts in North America and Europe to manufacture the chips in their regions, creating a break in the growth of the semiconductor and allied sectors in the APAC region. Being a major manufacturing region and a global supplier of semiconductor chips, Asia-Pacific faces challenges in terms of business loss. For instance, Canada has announced that two of China's largest telecom equipment manufacturers, Huawei and ZTE, will be prohibited from working on its 5G phone networks. This business loss will negatively impact the Semiconductor Etch Equipment market in the region.

- COVID-19 has negatively influenced the market, causing supply chain and production disruptions in the semiconductor industry. The impact on semiconductor etch equipment makers was particularly severe because of labor shortages. Several companies in the semiconductor supply chain worldwide were forced to reduce or even discontinue operations during the pandemic. A large supply chain gap resulted from the sector's substantial deficit and rising demand.

APAC Semiconductor Etch Equipment Market Trends

Power devices is expected to grow in the market

- Power devices leverages the features of solid-state electronics for the control and conversion of electric power. These electronic devices can be directly used in the power processing circuits to control or convert electric power. These devices are primarily used as switches or rectifiers in circuits and systems and have become a key component of power electronics technology.

- With the demand for high-power devices increasing in several electronics applications, including the industrial, automotive, data center, and energy industries, the Power devices manufacturing industry is expected to witness significant growth.

- For instance, in March 2021, Toshiba Electronic Devices & Storage Corporation announced the expansion of the production capacity for power devices with the construction of a 300-millimeter wafer fabrication facility at Kaga Toshiba Electronics Corporation in Japan.

- Similarly, in February 2022, German chipmaker Infineon Technologies unveiled its plans to invest more than EUR 2 billion in a new frontend fab in Kulim, Malaysia. Considering the growing demand, the company has been increasing investments in expanding its manufacturing capacity for GaN and SiC to maintain its position across the entire range of power semiconductors.

- Such instances also create a favorable market scenario for the studied market, as etching is a key step in the manufacturing process of power devices. Furthermore, it is also driving innovations in the studied market as the equipment manufacturers are increasing their investments in R&D to meet the evolving demand of their customers.

China is expected to hold the major market share in the APAC region

- China is witnessing multiple investments from various companies, including TSMC, as well as local companies such as Huawei, which are entering into producing their chips as the US embargo has made it significantly difficult for Huawei to buy chips, so it has no other alternative but to develop the capability to manufacture for itself.

- In May 2021, TSMC will invest USD 2.8 billion in China to ramp up auto chip production and build new Nanjing facilities amid severe shortages. Whereas Huawei intends to produce chips based on the 45nm manufacturing process, where the fab will not be a solution for its smartphones, it may make networking chips for Huawei's 5G kit by 2022.

- The rising demand for electric vehicles fuels the rapid expansion of the APAC automotive semiconductor industry. Automobile manufacturers will continue to innovate, create, and develop self-driving cars, attracting various customers in key automotive manufacturing countries.

- The growing fully-autonomous automobiles are heavily influenced by technological advancements, consumer willingness to accept fully-automated vehicles, pricing, and suppliers' and OEMs' capacity to address significant concerns about vehicle safety. According to these factors, the automotive and semiconductor industries are always concentrating on enhancing technologies, negotiating raw material prices, and finally combining cars with reliable technology.

APAC Semiconductor Etch Equipment Industry Overview

The Asia-Pacific semiconductor etch equipment market is very competitive, and only a few key players contribute to the significant market share. Due to the significant capital required to enter this market, it is difficult for new entrants. Various companies are exploring various strategies such as product innovation, expansions, developments, mergers, and acquisitions to enhance their market domination.

- May 2022: ENF Technology, a Korean company, is preparing to establish hydrofluoric acid manufacturing facilities by investing KRW 51.2 billion in its Cheonan factory. Hydrofluoric acid is a raw hydrogen fluoride chemical used to cut circuits and eliminate contaminants during semiconductor manufacturing. Semiconductor manufacturers such as Samsung Electronics and SK Hynix use it in wafers' etching and washing operations.

- May 2022: To address the growing demand for electrification goods, Hitachi announced that mass production of electric car inverters has begun at its Miyagi No.4 Plant in Murata, Miyagi Prefecture. Electric vehicles are in high demand worldwide because of their critical role in helping governments achieve carbon neutrality and reduce carbon emissions. Hitachi has increased its manufacturing capabilities and product line-up of fundamental components for electric vehicles, such as motors and inverters, to address this growing demand by forming manufacturing subsidiaries.

- Jan 2021: ULVAC, Inc., a Japanese company, announced the launch of the uGmni Series cluster system that combines deposition and etch modules. This enables the customers to equip a range of process modules, including sputter, etch, CVD, and others on the same transfer core. The company has also begun to sell production systems using this new platform.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 The growth in adoption of smart electronic devices in the region

- 4.2.2 Government initiative Programs in the region for domestic semiconductor manufacturing

- 4.3 Market Restraints

- 4.3.1 New semiconductor acts in Europe and America

- 4.4 Value Chain / Supply Chain Analysis

- 4.5 Porters 5 Force Analysis

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers/Consumers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Intensity of Competitive Rivalry

- 4.6 COVID-19 Impact on the Market

5 MARKET SEGMENTATION

- 5.1 By Product Type

- 5.1.1 High-density Etch Equipment

- 5.1.2 Low-density Etch Equipment

- 5.2 By Etching Type

- 5.2.1 Conductor Etching

- 5.2.2 Dielectric Etching

- 5.2.3 Polysilicon Etching

- 5.3 By Application

- 5.3.1 Logic and Memory

- 5.3.2 Power Devices

- 5.3.3 MEMS

- 5.4 By Country

- 5.4.1 China

- 5.4.2 India

- 5.4.3 Japan

- 5.4.4 South Korea

- 5.4.5 Rest of Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Applied Materials Inc

- 6.1.2 Hitachi High Technologies

- 6.1.3 Lam Research Corporation

- 6.1.4 Tokyo Electron Limited

- 6.1.5 Panasonic Corporation

- 6.1.6 Plasma-Therm

- 6.1.7 Gigalane

- 6.1.8 SUZHOU DELPHI LASER CO. LTD

- 6.1.9 NAURA Technology Group Co. Ltd

7 Investment Analysis

8 Future of the Market

02-2729-4219

+886-2-2729-4219