|

市场调查报告书

商品编码

1635361

包装器材:市场占有率分析、产业趋势/统计、成长预测(2025-2031)Packaging Machinery - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

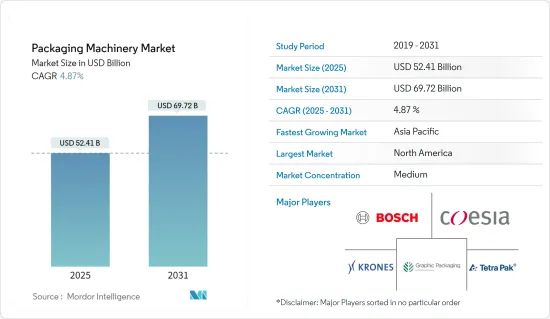

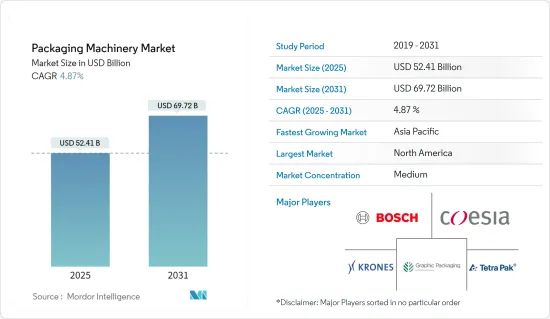

包装器材市场规模预计到2025年为524.1亿美元,预计到2031年将达到697.2亿美元,预测期内(2025-2031年)复合年增长率为4.87%。

全球包装器材市场在食品、饮料、药品、化妆品等各行业中扮演重要角色。包装器材可实现生产流程自动化,确保产品安全并符合严格的监管标准。主要市场驱动因素包括自动化程度的提高、永续性和不断变化的安全要求。食品和製药等行业对于塑造包装技术的需求、推动对创新机械的需求至关重要。此外,自动化显着提高了生产率,减少了人为错误,并提高了工作效率,使包装器材成为现代製造业的重要组成部分。

主要亮点

- 竞争对手和主要企业:Robert Bosch GmbH、Krones Inc. 和 Coesia SpA 等大公司处于行业领先地位,专注于大批量生产线的自动化解决方案。这些公司还优先考虑永续性,并跟上对环保包装解决方案日益增长的需求。儘管 COVID-19 大流行扰乱了供应链并推迟了计划,但它加速了自动化和柔性包装器材的采用,以最少的人为干预来满足不断增长的需求。因此,该行业的长期前景仍然乐观,特别是在以前采用自动化进展缓慢的地区。

技术进步彻底改变了包装解决方案

主要亮点

- 自动化和智慧技术:技术进步,特别是自动化和智慧技术的进步,彻底改变了包装器材产业。自动化包装系统可简化操作、降低人事费用并提高速度和准确性。例如,机械臂和机器视觉系统广泛用于检查、分类和堆迭。这些创新使公司能够灵活地适应各种包装类型和尺寸,而无需进行重大设定变更。

- 包装数位化:包括物联网(IoT)和人工智慧(AI)在内的数位技术在现代包装中发挥关键作用。支援物联网的系统可实现即时机器监控、预测性维护和流程优化。人工智慧主导的见解可帮助製造商预测设备故障、最大限度地减少停机时间并提高效率。此类创新提高了运作性能,同时延长了机器寿命,降低了製造商的长期成本。

- 包装解决方案的永续性:随着业界采用环保实践,永续包装器材正在取得进展。随着旨在减少环境影响的法规不断增加,公司正在设计能够最大限度地减少材料浪费和能源消耗的机器。支持可回收和生物分解的包装材料的环保设备越来越受欢迎。这些解决方案符合全球永续性目标,并鼓励公司减少包装过程中的碳排放和材料使用。

严格安全标准带动市场需求

主要亮点

- 合规性和安全法规:安全标准和法规,尤其是食品、饮料和药品等行业的安全标准和法规,正在推动对先进包装机械的需求。随着世界各地的监管机构制定严格的标准以确保消费者的健康和福祉,该行业拥有确保卫生和安全的包装过程的机械非常重要。

- 包装器材的安全创新:製造商正在将安全功能融入其机器中,例如自动清洗系统、无菌环境和防篡改技术。这些创新帮助公司遵守监管标准,并最大限度地降低与召回和违规相关的风险。此外,安全监控系统变得越来越重要,以确保设备在设定的监管参数内运作并提高操作安全性。

- 国际贸易合规性:国际安全标准和国际贸易法规也推动了对先进包装器材的需求。随着安全法规的发展,製造商需要投资适应性强的机械,以满足不同地区和行业当前和未来的合规标准。随着公司寻求确保合规性和产品完整性的机械,这一趋势预计将支持市场的持续成长。

包装器材市场趋势

食品领域经历显着成长

- 自动化推动包装器材销售:自动化是包装器材市场的关键成长要素。透过整合自动化系统,公司正在提高业务效率、降低人事费用并提高包装过程的准确性。这种趋势在食品和製药等行业尤其明显,这些行业的卫生和精度非常重要。随着这些行业的扩张,对确保更快、更可靠的包装流程的先进包装机械的需求预计将大幅成长。

- 永续性推动市场创新:对永续性的关注正在影响包装器材的发展。製造商正在投资支持可回收和生物分解性材料的技术,同时减少能源消耗。随着环境法规的不断加强,企业正在优先考虑环保包装解决方案,推动市场创新和成长。

- 製药业引领机器成长:由于对安全、防窜改和无菌包装解决方案的需求,製药业对专用包装器材的需求不断增加。这种需求促使製药公司大力投资先进包装技术,以确保产品完整性并符合严格的安全标准。

- 智慧技术提高工作效率:智慧技术在包装器材中的整合正在改变生产过程。物联网和人工智慧系统提供即时洞察,使製造商能够优化效率并减少停机时间。随着越来越多的製造商采用智慧包装解决方案来保持竞争力,这些技术预计将推动成长。

食品领域经历显着成长

- 食品包装器材的需求不断增加:由于加工食品和方便食品的消费不断增加,对食品包装器材机械的需求不断增加。食品安全问题推动了对卫生、高效包装解决方案的需求。製造商正专注于真空密封和无菌包装等创新,以满足消费者对新鲜和安全食品的需求。

- 推动食品包装创新:调气包装(MAP)和智慧包装等新型包装技术在食品领域越来越受欢迎。这些创新有助于延长产品保质期并保持新鲜度,同时满足监管标准。这些技术的日益普及预计将推动市场进一步扩张。

- 自动化正在再形成食品包装流程:自动化正在透过提高生产力和确保安全再形成食品包装产业。工业 4.0 解决方案和 3D 列印等创新正在帮助推进生物分解性和节能的包装解决方案。随着企业寻求提高食品包装的竞争力和效率,预计将持续到自动化的转变。

- 亚太地区引领食品包装成长:由于消费者对包装食品的需求不断增长以及可支配收入的增加,亚太地区正在成为食品包装器材的主要成长地区。中国和印度等国家正在大力投资先进包装技术,使该地区成为全球包装机械市场的主要企业。

亚太地区正在经历显着成长

- 蓬勃发展的製造业推动需求:亚太地区製造业的快速扩张正在推动对包装器材的需求。中国、印度和日本等国家正在投资自动化包装系统,以满足食品、製药和消费品产业日益增长的需求。该地区的工业成长预计将极大地促进市场扩张。

- 永续性措施推动市场扩张:永续性在亚太包装器材市场越来越受到关注。日益严格的环境法规正在推动製造商采用环保的包装解决方案。向永续材料和节能机械的转变预计将在未来几年推动市场成长。

- 技术进步促进成长:智慧技术和自动化的采用是亚太包装器材市场的关键成长要素。支援物联网和人工智慧的机器正在提高生产力和业务效率。对这些先进技术的持续投资预计将支持该地区的市场成长并加强其在全球包装产业的地位。

- 电子商务和消费品推动成长:亚太地区电子商务的兴起正在推动对包装器材的需求。网路购物的趋势,特别是杂货和药品的趋势,正在推动对高效包装解决方案的需求。政府对技术和製造的投资进一步促进了市场扩张,亚太地区在全球包装器材市场上确立了主导地位。

包装器材行业概况

市场适度整合:全球包装器材市场适度整合,罗伯特·博世有限公司、克朗斯公司和 Coesia SpA 等主要企业占据市场主导地位。这些公司为食品、饮料、製药和消费品等行业提供各种机器。利基市场和区域参与者正在透过提供适合当地需求的客製化解决方案来补充市场。

创新和客製化推动竞争:领先的公司都专注于创新,尤其是自动化和永续性。利乐和 Graphic Packaging International 等公司在环保包装技术方面处于领先地位,而克朗斯则透过不断改进饮料包装系统来扩大其全球影响力。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争公司之间敌对关係的强度

- COVID-19 对市场的影响

第五章市场动态

- 市场驱动因素

- 持续的技术开发

- 安全标准和法规的影响

- 新兴市场的主要发展

- 市场限制因素

- 高成本和进口关税对新客户来说是一项挑战

第六章 市场细分

- 依产品类型

- 填充

- 标籤、装饰、编码

- 案件处理

- 瓶装线

- 码垛

- 包装/装订

- 泡壳、贴体、真空包装

- 其他解决方案

- 按最终用户产业

- 食物

- 饮料

- 药品

- 个人护理、化妆品和洗护用品

- 工业/化工

- 其他最终用户产业

- 按地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 西班牙

- 亚洲

- 中国

- 日本

- 印度

- 韩国

- 澳洲/纽西兰

- 拉丁美洲

- 中东/非洲

- 北美洲

第七章 竞争格局

- 公司简介

- Robert Bosch GmbH

- Coesia SpA

- Krones Inc.

- Tetra Pak International SA

- Graphic Packaging International, LLC

- IMA Industria Macchine Automatiche SpA

- MULTIVAC Group

- Ishida Co. Limited

- Sidel SA

- PAC Machinery Group

- Heal Seal LLC

- Ossid LLC

- Marchesini Group SpA

- Ross Industries Inc.

- Starview Packaging Machinery, Inc.

第八章投资分析

第9章市场的未来

The Packaging Machinery Market size is estimated at USD 52.41 billion in 2025, and is expected to reach USD 69.72 billion by 2031, at a CAGR of 4.87% during the forecast period (2025-2031).

The global packaging machinery market plays a critical role across various industries such as food, beverage, pharmaceuticals, and cosmetics. Packaging machinery automates production processes, ensuring product safety and meeting strict regulatory standards. Key market drivers include advancements in automation, sustainability, and evolving safety requirements. Industries like food and pharmaceuticals are pivotal in shaping demand for packaging technologies, fueling the need for innovative machinery. Moreover, automation has significantly enhanced productivity, reduced human error, and boosted operational efficiency, making packaging machinery indispensable in modern manufacturing.

Key Highlights

- Competition and Key Players: Major players such as Robert Bosch GmbH, Krones Inc., and Coesia S.p.A lead the industry, focusing on automated solutions for high-volume production lines. These companies also prioritize sustainability, aligning with the rising need for eco-friendly packaging solutions. The COVID-19 pandemic disrupted supply chains and delayed projects, but it accelerated the adoption of automated and flexible packaging machinery to meet increasing demand with minimal human intervention. As a result, the long-term industry outlook remains positive, particularly in regions previously slow to adopt automation.

Technological Advancements Revolutionize Packaging Solutions

Key Highlights

- Automation and Smart Technologies: Technological advancements, particularly in automation and smart technologies, have revolutionized the packaging machinery industry. Automated packaging systems streamline operations, reduce labor costs, and increase speed and precision. Robotic arms and machine vision systems, for example, are widely used for inspection, sorting, and palletizing. These innovations provide businesses with flexibility, allowing them to handle various packaging types and sizes without significant retooling.

- Digitalization in Packaging: Digital technologies, including the Internet of Things (IoT) and artificial intelligence (AI), play a crucial role in modern packaging. IoT-enabled systems allow real-time monitoring of machinery, predictive maintenance, and process optimization. AI-driven insights help manufacturers predict equipment malfunctions, minimizing downtime and improving efficiency. These innovations enhance operational performance while extending machinery lifespan, reducing long-term costs for manufacturers.

- Sustainability in Packaging Solutions: Sustainable packaging machinery is gaining traction as industries adopt eco-friendly practices. With increasing regulations aimed at reducing environmental impact, companies are designing machines that minimize material waste and energy consumption. Eco-friendly equipment that supports recyclable and biodegradable packaging materials is becoming more popular. These solutions align with global sustainability goals, encouraging companies to reduce carbon emissions and material usage in packaging processes.

Stringent Safety Standards Propel Market Demand

Key Highlights

- Compliance and Safety Regulations: Safety standards and regulations, particularly in sectors like food, beverage, and pharmaceuticals, are driving demand for advanced packaging machinery. Regulatory bodies worldwide enforce stringent standards to ensure consumer health and welfare, making it critical for industries to adopt machinery that guarantees hygienic and safe packaging processes.

- Safety Innovations in Packaging Machinery: Manufacturers are integrating safety features like automated cleaning systems, sterile environments, and tamper-proof technologies into their machinery. These innovations help businesses comply with regulatory standards and minimize risks associated with recalls or non-compliance. Additionally, safety monitoring systems are becoming essential, ensuring that equipment operates within set regulatory parameters and enhancing operational security.

- Global Trade Compliance: International safety norms and regulations for global trade are also propelling demand for sophisticated packaging machinery. As safety regulations evolve, manufacturers need to invest in adaptable machinery that can meet both current and future compliance standards across various regions and sectors. This trend is expected to support sustained market growth as companies look for machinery that ensures regulatory compliance and product integrity.

Packaging Machinery Market Trends

Food Segment to Have a Significant Growth

- Automation Driving Packaging Machinery Sales: Automation is a major growth driver in the packaging machinery market. By integrating automated systems, companies are improving operational efficiency, reducing labor costs, and enhancing accuracy in packaging processes. This trend is especially pronounced in industries like food and pharmaceuticals, where hygiene and precision are critical. As these sectors expand, the demand for advanced machinery that ensures faster, more reliable packaging processes is set to grow significantly.

- Sustainability Pushing Market Innovation: The focus on sustainability is influencing the development of packaging machinery. Manufacturers are investing in technologies that support recyclable and biodegradable materials while reducing energy consumption. With environmental regulations tightening, businesses are prioritizing eco-friendly packaging solutions, driving innovation and growth in the market.

- Pharmaceutical Sector Leading Machinery Growth: The pharmaceutical industry is seeing increased demand for specialized packaging machinery due to the need for secure, tamper-evident, and sterile packaging solutions. This demand is pushing pharmaceutical companies to invest heavily in advanced packaging technologies, ensuring product integrity and compliance with stringent safety standards.

- Smart Technology Enhancing Operational Efficiency: The integration of smart technology in packaging machinery is transforming production processes. IoT and AI-enabled systems provide real-time insights, allowing manufacturers to optimize efficiency and reduce downtime. These technologies are expected to drive growth as more manufacturers adopt smart packaging solutions to remain competitive.

Food Segment to Have Significant Growth

- Rising Demand for Food Packaging Machinery: The demand for food packaging machinery is growing due to the increasing consumption of processed and convenience foods. Food safety concerns are driving the need for hygienic and efficient packaging solutions. Manufacturers are focusing on innovations such as vacuum sealing and aseptic packaging to meet consumer demands for fresh and safe food products.

- Technological Innovations Boosting Food Packaging: New packaging technologies, such as Modified Atmosphere Packaging (MAP) and smart packaging, are gaining traction in the food sector. These innovations help extend product shelf life and maintain freshness, while also complying with regulatory standards. The growing popularity of these technologies is expected to fuel further market expansion.

- Automation Reshaping Food Packaging Processes: Automation is reshaping the food packaging industry by improving productivity and ensuring safety. Innovations such as Industry 4.0 solutions and 3D printing are driving advancements in biodegradable and energy-efficient packaging solutions. This shift towards automation is expected to continue, as companies seek to enhance competitiveness and efficiency in food packaging.

- Asia-Pacific Region Leading Food Packaging Growth: The Asia-Pacific region is emerging as a significant growth area for food packaging machinery, driven by rising consumer demand for packaged foods and increased disposable income. Countries like China and India are investing heavily in advanced packaging technologies, positioning the region as a key player in the global packaging machinery market.

Asia Pacific to Have Significant Growth

- Booming Manufacturing Sector Driving Demand: The rapid expansion of manufacturing sectors in Asia-Pacific is driving demand for packaging machinery. Countries like China, India, and Japan are investing in automated packaging systems to meet rising demand from food, pharmaceutical, and consumer goods industries. The region's industrial growth is expected to fuel market expansion significantly.

- Sustainability Efforts Accelerating Market Expansion: Sustainability is a growing focus in the Asia-Pacific packaging machinery market. With stricter environmental regulations, manufacturers are adopting eco-friendly packaging solutions. This shift towards sustainable materials and energy-efficient machinery is projected to drive market growth in the coming years.

- Technological Advancements Fueling Growth: The adoption of smart technologies and automation is a key growth driver in the Asia-Pacific packaging machinery market. IoT and AI-enabled machinery are improving productivity and operational efficiency. Continued investment in these advanced technologies is expected to bolster the region's market growth and strengthen its position in the global packaging industry.

- E-commerce and Consumer Goods Driving Growth: The rise of e-commerce in Asia-Pacific is fueling demand for packaging machinery. The growing trend of online shopping, especially for groceries and pharmaceuticals, is boosting the need for efficient packaging solutions. Government investments in technology and manufacturing are further contributing to the market's expansion, positioning Asia-Pacific as a leading force in the global packaging machinery market.

Packaging Machinery Industry Overview

Moderately Consolidated Market: The global packaging machinery market is moderately consolidated, with key players like Robert Bosch GmbH, Krones Inc., and Coesia S.p.A dominating the landscape. These companies offer a wide range of machinery catering to industries such as food, beverages, pharmaceuticals, and consumer goods. Niche and regional players complement the market by providing customized solutions tailored to local demands.

Innovation and Customization Driving Competition: Major players are focused on technological innovation, particularly in automation and sustainability. Companies like Tetra Pak and Graphic Packaging International are leading in eco-friendly packaging technologies, while Krones Inc. has strengthened its global presence by continuously enhancing its beverage packaging systems.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Ongoing Technological Developments

- 5.1.2 Impact of Safety Standards & Regulations

- 5.1.3 High Development in the Key End User Market

- 5.2 Market Restraints

- 5.2.1 High Costs and Import Duties Pose a Challenge for New Customers

6 MARKET SEGMENTATION

- 6.1 By Product Type

- 6.1.1 Filling

- 6.1.2 Labelling, Decorating, and Coding

- 6.1.3 Case Handling

- 6.1.4 Bottling Line

- 6.1.5 Palletizing

- 6.1.6 Wrapping and Bundling

- 6.1.7 Blister, Skin/Vacuum Packaging

- 6.1.8 Other Solutions

- 6.2 By End-user Industry

- 6.2.1 Food

- 6.2.2 Beverage

- 6.2.3 Pharmaceutical

- 6.2.4 Personal Care, Cosmetics, and Toiletries

- 6.2.5 Industrial and Chemicals

- 6.2.6 Other End-user Industries

- 6.3 By Geography

- 6.3.1 North America

- 6.3.1.1 United States

- 6.3.1.2 Canada

- 6.3.2 Europe

- 6.3.2.1 United Kingdom

- 6.3.2.2 Germany

- 6.3.2.3 France

- 6.3.2.4 Spain

- 6.3.3 Asia

- 6.3.3.1 China

- 6.3.3.2 Japan

- 6.3.3.3 India

- 6.3.3.4 South Korea

- 6.3.4 Australia and New Zealand

- 6.3.5 Latin America

- 6.3.6 Middle East and Africa

- 6.3.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Robert Bosch GmbH

- 7.1.2 Coesia S.p.A.

- 7.1.3 Krones Inc.

- 7.1.4 Tetra Pak International S.A

- 7.1.5 Graphic Packaging International, LLC

- 7.1.6 I.M.A Industria Macchine Automatiche S.p.A

- 7.1.7 MULTIVAC Group

- 7.1.8 Ishida Co. Limited

- 7.1.9 Sidel S.A.

- 7.1.10 PAC Machinery Group

- 7.1.11 Heal Seal LLC

- 7.1.12 Ossid LLC

- 7.1.13 Marchesini Group S.p.A

- 7.1.14 Ross Industries Inc.

- 7.1.15 Starview Packaging Machinery, Inc.