|

市场调查报告书

商品编码

1636457

亚太地区电动汽车电池製造设备:市场占有率分析、产业趋势与成长预测(2025-2030)Asia-Pacific Electric Vehicle Battery Manufacturing Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

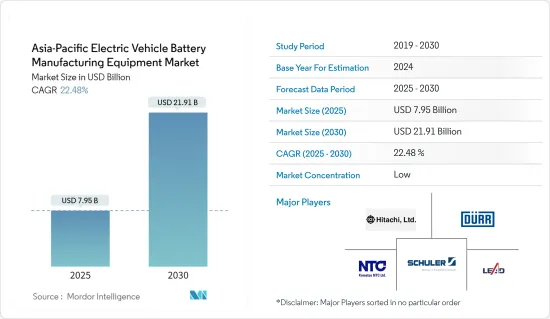

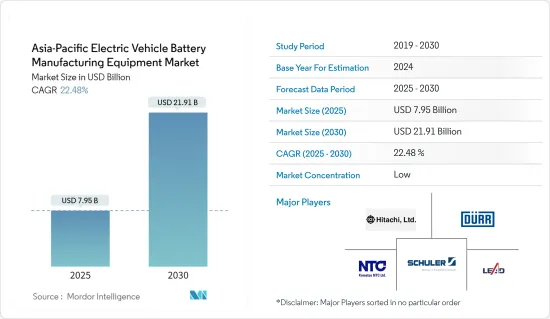

预计2025年亚太地区电动汽车电池製造设备市场规模为79.5亿美元,2030年达219.1亿美元,预测期间(2025-2030年)复合年增长率为22.48%。

主要亮点

- 从中期来看,电动车(EV)普及率的提高以及政府对电动车电池製造的支持措施和投资预计将在预测期内推动亚太电动汽车电池製造设备市场的需求。

- 另一方面,高昂的初始投资和设置成本预计将阻碍预测期内的市场成长。

- 然而,电动车电池本地生产的扩大预计未来将为亚太地区电动汽车电池製造设备市场带来重大商机。

- 在该地区所有国家中,印度预计在预测期内电动车电池製造业将显着成长。

亚太地区电动汽车电池製造设备市场趋势

锂离子电池成长迅速

- 锂离子 (Li-ion) 电池正在彻底改变电动车 (EV) 产业,推动亚太地区电池製造取得重大进步。其高能量密度、长循环寿命和快速充电能力巩固了其在电动车市场的主导地位。

- 锂离子电池的独特之处在于其出色的容量重量比。儘管锂离子电池成本较高,亚太地区主要企业仍在投资研发并增加产量。这种动态运动正在加剧竞争、降低价格并扩大锂离子电池的可用性。

- 2023年,电动车电池组的平均价格降至139美元/kWh时,大幅下降13%。据预测,这种下降势头预计将持续下去,到2025年将达到113美元/千瓦时,并在2030年进一步降至80美元/千瓦时。在技术和製造进步的推动下,价格下降可能会扩大该地区对锂离子电池专业製造设备的需求。

- 亚太国家政府正在积极支持电动车机芯,并透过优惠政策和奖励促进锂离子电池生产。这些倡议的核心是研究和开发,特别是寻找具有成本效益的材料来取代钴等昂贵的零件。这项策略不仅降低了製造成本,还加强了永续供应链并增加了对尖端製造工具的需求。

- 例如,2024 年 5 月,中国宣布巨额投资约 60 亿元人民币(8.45 亿美元),旨在开拓下一代电动车电池技术,包括固态电池。与传统锂离子电池相比,这些创新提高了能量密度和安全性,预计将推动该地区对先进製造设备的需求。

- 此外,2023年12月,韩国财政部决定在未来五年内向锂电池产业注入38兆韩元(约285亿美元)的政策资金,并计画于2024年正式推出。该策略包括1兆韩元(约7.5亿美元)的锂电池产业促进基金、736亿韩元(约5,520万美元)的研发投资,以及重大的矿产资源强化。这些倡议,再加上培育电池再利用和回收生态系统的努力,将为锂离子电池产业乃至电动车电池製造设备市场注入活力。

- 此外,对锂离子电池不断增长的需求导致亚太地区超级工厂的出现。这些大型生产基地在确保电池稳定供应以满足电动车快速增长的需求方面发挥关键作用。该地区的主要企业已经启动了多个计划,并为蓬勃发展的电动车电池市场做好了准备。

- 例如,2024年2月,BMW宣布计画在泰国罗勇兴建电动车电池工厂。随着该工厂为锂离子电池生产设定了积极的目标,该合资企业必将刺激对尖端製造工具的需求。

- 这些进步正在提高锂离子电池的产能,并增加对复杂电动车电池製造工具的需求。生产设施的不断扩张和最尖端科技的采用对于塑造亚太地区电动汽车电池製造设备的未来至关重要。

印度正在经历显着的成长

- 随着环保移动解决方案的推出,印度的电动车 (EV) 电池製造业正在迅速扩张。这一增长是由政府倡议、电动车需求激增以及国内外公司的大量投资所推动的。

- 随着印度转向清洁能源,大力投资电动车已成为许多公司的首要任务。该地区的电动车销量大幅成长。例如,根据国际能源总署(IEA)的报告,2023年印度纯电动车(BEV)销量将达到约82,000辆,与2022年相比成长惊人的70%。如果电动车的普及继续稳定成长,对电动车电池製造的需求预计将迅速增加。此外,印度政府还制定了一个雄心勃勃的目标,即到2030年使新登记的私家车30%、巴士40%、商用车70%、两轮和三轮车80%电动化。这些目标证实了对电池(尤其是锂离子电池)的快速增长的需求,并表明电动车电池製造和相关製造设备的市场蓬勃发展。

- 印度已成为电动车电池製造投资的磁石,吸引了国内外的参与者。此次注资的战略目的是加强该国的电动车基础设施、遏制对石化燃料的依赖并支持永续交通。在政府支持性政策和奖励的支持下,这些投资正在巩固印度在全球电动车领域的地位。

- 例如,Ola Electric于2024年7月宣布将投资1亿美元在印度泰米尔纳德邦建造超级工厂的早期阶段。该工厂将生产国产锂离子电池。 Ola Electric 计划在明年初之前从目前从韩国和中国进口的电池转向生产自己的电动车电池。预计此类发展将在未来几年引发电池生产设备的需求激增。

- 此外,印度政府正在推出一系列倡议,以加速电动车(EV)的普及并促进当地电池製造。这些措施包括对电动车购买者的补贴、对製造商的税收减免以及增加充电基础设施的投资。

- 例如,2023年,印度政府宣布了另一个雄心勃勃的目标:到2030年,30%的私家车、70%的商用车、80%的两轮车和三轮车将是电动的。此外,政府还推出了每千瓦时 10,000 印度卢比(120 美元)至 15,000 印度卢比(180 美元)的补贴奖励措施。这些协调一致的努力不仅将促进电动车的生产和销售,还将增加对电池製造和相关设备的需求。

- 2022年初,产业巨头Ex-Aid Industries宣布计画投资7.18亿美元在卡纳塔克邦建立锂离子电池製造工厂。该工厂启动时产能为6GWh,预计2024年投入营运。

- 2023 年 4 月,电池技术新兴企业Log9 Materials 在班加罗尔贾库尔开设了印度第一家锂离子电池製造工厂。 Log9 的宏伟目标是,从 50MWh 的产能开始,到 2025 年第一季将电池製造产能扩大到 1GWh,电池组产能扩大到 2GWh。这些发展导致印度对电动车电池製造设备的强劲需求。

- 鑑于这些动态,印度很可能在未来几年成为电动车电池製造设备的重要市场。

亚太地区电动汽车电池製造设备产业概况

亚太地区电动汽车电池製造设备市场已缩减一半。市场主要企业包括(排名不分先后)日立、杜尔股份公司、舒勒股份公司、日本小松公司NTC和无锡利德智慧装备。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 调查范围

- 市场定义

- 研究场所

第 2 章执行摘要

第三章调查方法

第四章市场概况

- 介绍

- 2029年之前的市场规模与需求预测(单位:美元)

- 最新趋势和发展

- 政府法规政策

- 市场动态

- 促进因素

- 电动车的扩张

- 政府对电动车电池製造的支持政策与投资

- 抑制因素

- 需要较高的初始投资和推出成本

- 促进因素

- 供应链分析

- 波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争公司之间的敌对关係

- 投资分析

第五章市场区隔

- 按流程

- 混合物

- 涂层

- 日历

- 狭缝/电极加工

- 其他工艺

- 透过电池

- 锂离子电池

- 铅酸电池

- 镍氢电池

- 透过其他电池

- 按地区

- 中国

- 印度

- 日本

- 韩国

- 马来西亚

- 泰国

- 印尼

- 越南

- 其他亚太地区

第六章 竞争状况

- 併购、合资、联盟、协议

- 主要企业策略

- 公司简介

- Duerr AG

- Hitachi Ltd.

- Schuler AG

- Wuxi Lead Intelligent Equipment Co Ltd

- Xiamen Tmax Battery Equipments Limited

- Xiamen TOB New Energy Technology Co., Ltd.

- TC Machinery Co., Ltd.

- Komatsu NTC Ltd.

- Shenzhen Yinghe Technology Co.,Ltd.

- Xiamen Lith Machine Limited

- 其他知名企业名单

- 市场排名分析

第七章 市场机会及未来趋势

- 扩大电动车电池的本地生产

简介目录

Product Code: 50003724

The Asia-Pacific Electric Vehicle Battery Manufacturing Equipment Market size is estimated at USD 7.95 billion in 2025, and is expected to reach USD 21.91 billion by 2030, at a CAGR of 22.48% during the forecast period (2025-2030).

Key Highlights

- Over the medium term, the growing adoption of electric vehicles (EV) and supportive government initiatives and investments towards EV battery manufacturing are expected to drive the demand for the Asia-Pacific electric vehicle battery manufacturing equipment market during the forecast period.

- On the other hand, the requirement of high initial investments and setup costs are expected to hinder the market's growth during the forecast period.

- Nevertheless, the expansion of local EV battery production is expected to create vast opportunities for the Asia-Pacific electric vehicle battery manufacturing equipment market in the future.

- Among all the countries in the region, India is expected to have significant growth in the electric vehicle battery manufacturing industry during the forecast period.

Asia-Pacific Electric Vehicle Battery Manufacturing Equipment Market Trends

Lithium-ion Battery to be the Fastest Growing

- Lithium-ion (Li-ion) batteries have transformed the electric vehicle (EV) industry, spurring notable advancements in battery manufacturing across the Asia-Pacific region. Their high energy density, long cycle life, and rapid charging capabilities have solidified their dominance in the EV market.

- What distinguishes lithium-ion batteries is their superior capacity-to-weight ratio. Even though they come at a premium, top players in the Asia-Pacific are channeling investments into R&D and ramping up production. This surge in activity is intensifying competition and driving prices down, broadening the accessibility of lithium-ion batteries.

- In 2023, the average price of EV battery packs fell to USD 139/kWh, marking a significant 13% drop. Projections indicate this downward momentum will persist, with prices anticipated to reach USD 113/kWh by 2025 and plummet further to USD 80/kWh by 2030. These price reductions, spurred by advancements in technology and manufacturing, are likely to amplify the demand for specialized manufacturing equipment for lithium-ion batteries in the region.

- Asia-Pacific governments are actively championing the electric vehicle movement and bolstering lithium-ion battery production through favorable policies and incentives. Central to these initiatives is R&D, particularly in identifying cost-effective material substitutes for expensive components like cobalt. This strategy not only reduces manufacturing expenses but also strengthens a sustainable supply chain, heightening the demand for cutting-edge manufacturing tools.

- For instance, in May 2024, China announced a substantial investment of approximately CNY 6 billion (USD 845 million) aimed at pioneering next-generation battery technologies for EVs, including solid-state batteries. Given their enhanced energy density and safety over traditional lithium-ion batteries, these innovations are poised to drive up the demand for advanced manufacturing equipment in the region.

- Furthermore, in December 2023, South Korea's Ministry of Finance committed KRW 38 trillion (~USD 28.5 billion) in policy financing to the lithium battery sector over the next five years, with official rollout set for 2024. Their strategy encompasses a KRW 1 trillion (~USD 750 million) promotion fund for the lithium battery industry, a KRW 73.6 billion (~USD 55.2 million) R&D investment, and strengthening critical mineral reserves for local battery production. These moves, alongside efforts to cultivate a battery reuse and recycling ecosystem, are set to energize the lithium-ion battery sector and, consequently, the market for EV battery manufacturing equipment.

- Additionally, the rising appetite for lithium-ion batteries has catalyzed the emergence of Gigafactories throughout the Asia-Pacific. These colossal production hubs play a crucial role in ensuring a steady supply of battery cells to cater to the surging EV demand. Key players in the region are embarking on multiple projects, positioning themselves for a flourishing EV battery market.

- As an illustration, in February 2024, BMW announced its plans for an EV battery factory in Rayong, Thailand, with ambitions to establish the country as a key export center for Asia-Pacific's EV batteries. Given the facility's aggressive targets for lithium-ion battery production, this venture is bound to stimulate demand for state-of-the-art manufacturing tools.

- With these advancements, lithium-ion battery production capacity is on the rise, driving the need for sophisticated EV battery manufacturing tools. The continuous expansion of production facilities and the adoption of cutting-edge technologies are crucial in shaping the future of the Asia-Pacific EV battery manufacturing equipment landscape.

India To Witness Significant Growth

- India's electric vehicle (EV) battery manufacturing industry is rapidly expanding as the nation embraces greener mobility solutions. This growth is fueled by government initiatives, surging demand for electric vehicles, and substantial investments from both domestic and international entities.

- As India pivots towards clean energy, the emphasis on electric vehicles has become paramount for numerous companies. EV sales in the region have surged dramatically. For example, the International Energy Agency (IEA) reported that battery electric vehicle (BEV) sales in India hit approximately 82,000 units in 2023, marking a staggering 70% increase from 2022. With such a robust uptick in EV adoption, the demand for EV battery manufacturing is poised to skyrocket. Furthermore, the Indian Government has set ambitious targets for 2030: aiming for 30% of newly registered private cars, 40% of buses, 70% of commercial vehicles, and a striking 80% of two-wheelers and three-wheelers to be electric. Such targets underscore a burgeoning demand for batteries, especially lithium-ion, and signal a thriving market for EV battery manufacturing and related production equipment.

- India has emerged as a magnet for investments in EV battery manufacturing, attracting both domestic and international players. This capital influx is strategically aimed at strengthening the nation's electric vehicle infrastructure, curbing reliance on fossil fuels, and championing sustainable transportation. Bolstered by supportive government policies and incentives, these investments are cementing India's stature in the global EV arena.

- For instance, in July 2024, Ola Electric unveiled a USD 100 million investment for the initial phase of its gigafactory in Tamil Nadu, India. This facility is set to produce indigenous lithium-ion batteries. Ola Electric plans to transition to its battery cells for its electric vehicles by early next year, moving away from current imports from Korea and China. Such moves are set to catalyze a surge in battery production equipment demand in the coming years.

- Moreover, the Indian government has rolled out a suite of initiatives to amplify electric vehicle (EV) adoption and stimulate local battery manufacturing. These measures encompass subsidies for EV purchasers, tax breaks for manufacturers, and bolstered investments in charging infrastructure.

- As an illustration, in 2023, the Indian government reiterated its ambitious targets: 30% of private cars, 70% of commercial vehicles, and 80% of two and three-wheelers are to be electric by 2030. Additionally, the government has introduced subsidy incentives ranging from INR 10,000 per kWh (USD 120) to INR 15,000 per kWh (USD 180). These concerted efforts are set to not only boost EV production and sales but also amplify the demand for battery manufacturing and related equipment.

- In early 2022, industry giant Exide Industries unveiled plans for a USD 718 million investment to establish a lithium-ion cell manufacturing plant in Karnataka. The facility, starting with a 6 GWh capacity, is slated to commence operations by 2024, with ambitions to double its capacity to 12 GWh in subsequent years.

- In April 2023, Log9 Materials, a battery technology startup, inaugurated India's maiden lithium-ion cell manufacturing facility in Jakkur, Bengaluru. Starting with a 50 MWh capacity, Log9 is eyeing an ambitious expansion to 1 GWh for cell manufacturing and 2 GWh for battery packs by Q1 2025. Such developments are fueling a robust demand for EV battery manufacturing equipment in India.

- Given these dynamics, India is poised to emerge as a significant market for EV battery manufacturing equipment in the coming years.

Asia-Pacific Electric Vehicle Battery Manufacturing Equipment Industry Overview

The Asia-Pacific Electric Vehicle Battery Manufacturing Equipment market is semi-fragmented. Some of the key players in the market (not in any particular order) include Hitachi Ltd., Duerr AG, Schuler AG, Komatsu NTC Ltd., and Wuxi Lead Intelligent Equipment Co Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Growing Adoption of Eelectric Vehicles

- 4.5.1.2 Supportive Government Policies and Investments Towards EV Battery Manufacturing

- 4.5.2 Restraints

- 4.5.2.1 Requirement of High Initial Investments and Setup Costs

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Consumers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes Products and Services

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Process

- 5.1.1 Mixing

- 5.1.2 Coating

- 5.1.3 Calendering

- 5.1.4 Slitting and Electrode Making

- 5.1.5 Other Process

- 5.2 Battery

- 5.2.1 Lithium-ion Battery

- 5.2.2 Lead-acid Battery

- 5.2.3 Nickel Metal Hydride Battery

- 5.2.4 Other Batteries

- 5.3 Geography

- 5.3.1 China

- 5.3.2 India

- 5.3.3 Japan

- 5.3.4 South Korea

- 5.3.5 Malaysia

- 5.3.6 Thailand

- 5.3.7 Indonesia

- 5.3.8 Vietnam

- 5.3.9 Rest of Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 Duerr AG

- 6.3.2 Hitachi Ltd.

- 6.3.3 Schuler AG

- 6.3.4 Wuxi Lead Intelligent Equipment Co Ltd

- 6.3.5 Xiamen Tmax Battery Equipments Limited

- 6.3.6 Xiamen TOB New Energy Technology Co., Ltd.

- 6.3.7 TC Machinery Co., Ltd.

- 6.3.8 Komatsu NTC Ltd.

- 6.3.9 Shenzhen Yinghe Technology Co.,Ltd.

- 6.3.10 Xiamen Lith Machine Limited

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Expansion of Local EV Battery Production

02-2729-4219

+886-2-2729-4219