|

市场调查报告书

商品编码

1636466

印度电动汽车电池製造:市场占有率分析、产业趋势/统计、成长预测(2025-2030)India Electric Vehicle Battery Manufacturing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

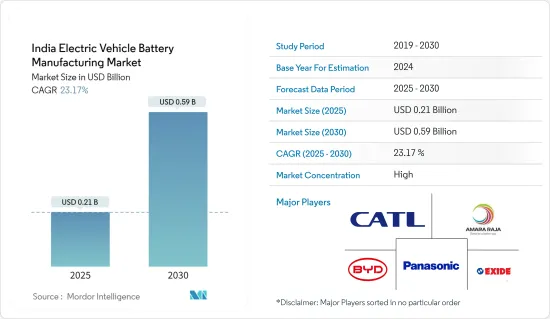

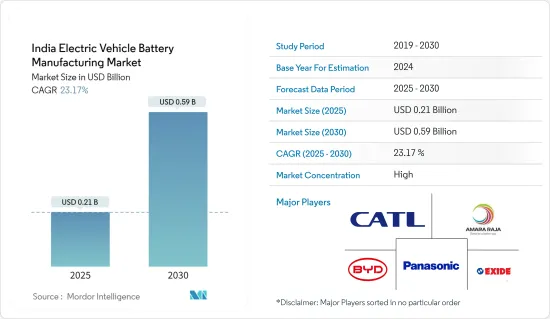

印度电动车电池製造市场规模预计到 2025 年为 2.1 亿美元,到 2030 年将达到 5.9 亿美元,预测期内(2025-2030 年)复合年增长率为 23.17%。

主要亮点

- 从长远来看,增加电池产能的投资和电池原材料成本下降等因素预计将成为预测期内印度电动车电池製造市场的最大驱动力之一。

- 另一方面,与原材料供应链相关的挑战预计将阻碍预测期内的市场成长。

- 电动车的长期雄心壮志预计将为未来的市场带来机会。

印度电动车电池製造市场趋势

锂离子电池类型主导市场

- 印度电动车(EV)电池製造市场预计将大幅成长,这主要得益于锂离子(Li-ion)电池的主导地位。锂离子电池以其高能量密度、长寿命週期和高性能而闻名,使其成为专注于提供可靠、高效车辆的电动车製造商的最佳选择。

- 印度政府正在推出一系列倡议,以促进电动车的采用并提高电动车电池的本地生产。混合动力汽车和电动车的快速采用和製造 (FAME) 计划列出了针对电动车製造商和购买者的经济奖励。补充性的 PLI(生产挂钩激励)计划针对先进化学电池(ACC)蓄电池,旨在在该国培育强大的製造生态系统。

- 印度对电动车的推动与减少碳排放和部署永续能源的更广泛努力产生了共鸣。严格的政府排放法规和政策提倡从内燃机汽车过渡到电动车。在印度这个全球最大的电动车潜在市场,由于都市化、燃油价格飙升和环保意识不断增强,对电动车的需求正在迅速增加。这种不断增长的需求强调了对国产电池的需求并推动市场向前发展。

- 2024年7月,电池储存巨头Exide Industries宣布,其雄心勃勃的位于班加罗尔的12吉瓦锂离子电池製造工厂的第一阶段预计将在本财年结束时完工。同时,位于加尔各答的 Exide 子公司 Exide Energy Solutions (EESL) 的锂离子电池製造计划即将完成。认识到印度电动车市场的快速扩张,EESL已与汽车巨头现代和起亚汽车签署非约束性谅解备忘录(MOU),形成战略合作关係。

- 为了鼓励电动车的普及,全国各地正在大力投资充电基础设施的建设。蓬勃发展的基础设施不仅将支持电动车的普及,还将增加对国产电池的需求。印度企业正在加大研发投入,旨在提高电池技术并降低成本。与国际技术供应商和研究机构的合作是电池製造创新的催化剂。

- 2024 年 7 月,LICO 宣布扩张,在班加罗尔建造最先进的设施,使其成为印度最大的锂离子电池回收工厂之一。 LICO 的工厂将于 2024 年 10 月投入运营,到 2026 年产能将达到每年 25,000 吨。策略上,我们将采取轴辐式营运模式,强调区域加工,降低运输风险和成本。随着电动车采用的加速,印度正准备有效管理废弃电池并确保其基础设施面向未来。

- 印度的锂离子电池(LiB)製造业正在崛起,领先企业对新设备进行策略性投资,以满足快速成长的电动车市场的需求。根据 PLI 计划,Ola Electric、Reliance 和 Rajesh Export 等工业巨头已获得电池製造激励,并计划在 2024 年进行生产。此外,许多公司正在有计划地扩建锂电池工厂,并正在建立能够应对国内外市场的系统。

- 由于这些发展,预计该地区电动车电池的产量将迅速增加,从而导致未来几年对锂离子电池的需求相应增加。

投资增加电池产能

- 印度正在提高其电池製造能力,以满足快速成长的电动车(EV)需求。透过先进化学电池(ACC)电池的生产挂钩激励(PLI)计划等倡议,政府正在寻求吸引投资并加强本地生产。这项战略措施对于遏制进口依赖和培育强大的国内电池製造环境至关重要。

- 印度各地涌现新的电池生产工厂,以满足快速成长的电动车市场的需求。 Exide Industries、Amara Raja 和 Tata Chemicals 等工业巨头正在投资购买最先进的设备。这些工厂在满足国内需求、促进创新、创造就业、推动印度电动车电池製造业的成长方面发挥关键作用。

- 为了增强其电池製造雄心,印度正在举行先进设备竞标,其中包括浆料搅拌机,这对于製造顶级锂离子电池至关重要。这些竞标针对的是提高效率和产量的最尖端科技。透过实现製造流程现代化,我们的目标是提高印度电动车电池生产的竞争基准化分析和质量,并使其与全球基准保持一致。

- 例如,2024 年 7 月,电动两轮车和智慧运输领域的知名企业台湾 Ahamani EV Technology 将大力投资印度的电动车领域。该公司计划在印度建立兆瓦级电池製造工厂,并正在寻求与印度领先汽车相关企业的战略技术转移合作伙伴关係。与三到四家主要电动车公司的谈判已经在进行中。政府的支持措施和消费者对环保交通日益增长的需求正在推动印度对电动车的关注。计划在现场建设的电池设施不仅旨在提高印度在电动车价值链中的自给自足,而且有望创造就业机会并重振经济。

- 印度政府正在透过各种措施积极支持电动车产业,包括税收优惠、对製造商和消费者的补贴以及对充电基础设施的投资。这些措施旨在提高电动车的可负担性和便利性,提高采用率,并最终增加对电池材料的需求。电池技术的创新也正在影响市场动态。例如,比亚迪正在开创磷酸锂铁(LFP)电池等新型电池化学材料,这种电池安全且具有成本效益,但能量密度比传统锂离子电池略低。此类突破对于让更多人使用电动车发挥关键作用。

- 2024 年 8 月,Amara Raja Advanced Cell Technologies (ARACT) 与比亚乔汽车私人有限公司签署了一份谅解备忘录,以在印度推广电动车技术。该合作伙伴关係将专注于为比亚乔的电动三轮车和即将推出的两轮车製造和供应锂离子电池、电池组和充电器。

- 根据全球趋势,印度设定了 2029 年电动车 (EV) 的雄心勃勃的销售目标。政府正在重点关注国内生产,尤其是电池生产,以推动印度的电动车雄心。根据30@30倡议和其他大胆预测,印度到2023年将需要42.5GWh的累积电池产能,到2029年将跃升至577.8GWh。这一激增意味着印度每年的电池需求量可能占全球产量的 17% 至 26%。此外,扩大生产不仅对于满足这一需求至关重要,而且对于降低成本并增加电动车的市场竞争也至关重要。建立稳固的国内生产基地将为日本带来显着的经济效益。

- 总之,这些措施和投资将显着提高印度的电池产能。

印度电动车电池製造业概况

印度的电动车电池製造市场是半集中的。该市场的主要企业(排名不分先后)包括比亚迪、宁德时代新能源科技有限公司、松下公司、Exide Industries 和 Amara Raja Batteries Ltd。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 调查范围

- 市场定义

- 研究场所

第 2 章执行摘要

第三章调查方法

第四章市场概况

- 介绍

- 2029年之前的市场规模与需求预测(单位:美元)

- 最新趋势和发展

- 政府法规和措施

- 市场动态

- 促进因素

- 投资增加电池产能

- 电池原物料成本下降

- 抑制因素

- 原料蕴藏量不足

- 促进因素

- 供应链分析

- PESTLE分析

- 投资分析

第五章市场区隔

- 电池

- 锂离子

- 铅酸

- 镍氢电池

- 其他的

- 电池形式

- 方形

- 袋型

- 圆柱形

- 车辆

- 客车

- 商用车

- 其他的

- 晋升

- 电池电动车

- 油电混合车

- 插电式混合动力电动车

第六章 竞争状况

- 併购、合资、联盟、协议

- 主要企业策略

- 公司简介

- BYD Co. Ltd

- Contemporary Amperex Technology Co. Limited

- EnerSys

- GS Yuasa Corporation

- LG Chem Ltd

- Exide Industries

- Panasonic Corporation

- Amara Raja Batteries Ltd.

- Tata Chemicals

- HBL Power Systems Ltd.

- 其他知名公司名单

- 市场排名分析

第七章 市场机会及未来趋势

- 电动车的长期目标

简介目录

Product Code: 50003733

The India Electric Vehicle Battery Manufacturing Market size is estimated at USD 0.21 billion in 2025, and is expected to reach USD 0.59 billion by 2030, at a CAGR of 23.17% during the forecast period (2025-2030).

Key Highlights

- Over the long term, factors such as Investments to enhance battery production capacity and the decline in the cost of battery raw materials are expected to be among the most significant drivers for the India Electric Vehicle Battery Manufacturing Market during the forecast period.

- On the other hand, challenges associated with the raw material supply chain are expected to hinder market growth during the forecast period.

- Nevertheless, long-term ambitious targets for electric vehicles are expected to create opportunities for the market in the future.

India Electric Vehicle Battery Manufacturing Market Trends

Lithium-ion Battery Type to Dominate the Market

- India's electric vehicle (EV) battery manufacturing market is set for substantial growth, primarily fueled by the supremacy of lithium-ion (Li-ion) batteries. Li-ion batteries, known for their superior energy density, extended life cycles, and enhanced performance, have become the go-to choice for EV manufacturers focused on delivering reliable and efficient vehicles.

- To bolster EV adoption and stimulate local EV battery manufacturing, the Indian government has rolled out a series of initiatives. The Faster Adoption and Manufacturing of Hybrid and Electric Vehicles (FAME) scheme offers financial incentives to both EV manufacturers and buyers. Complementing this, the Production Linked Incentive (PLI) scheme targets advanced chemistry cell (ACC) battery storage, aiming to cultivate a robust manufacturing ecosystem within the country.

- India's push for EVs resonates with its broader commitment to curbing carbon emissions and embracing sustainable energy. The government's stringent emission norms and policies advocate a transition from internal combustion engines to electric vehicles. As the world's largest potential EV market, India's demand for EVs is surging, driven by urbanization, escalating fuel prices, and heightened environmental consciousness. This burgeoning demand underscores the necessity for domestically produced batteries, propelling the market forward.

- In July 2024, Exide Industries, a leading storage battery firm, announced that the first phase of its ambitious 12-gigawatt lithium-ion cell manufacturing plant in Bengaluru is on track for completion by the financial year's end. Meanwhile, Exide's Kolkata-based subsidiary, Exide Energy Solutions (EESL), is nearing the finish line with its lithium-ion cell manufacturing project. Recognizing the rapid expansion of India's EV market, EESL has inked a non-binding memorandum of understanding (MOU) with automotive giants Hyundai Motor and Kia Corporation, signaling a strategic collaboration.

- Massive investments are being funneled into the development of charging infrastructure nationwide, a move that bolsters EV adoption. This burgeoning infrastructure not only supports the widespread use of electric vehicles but also amplifies the demand for locally produced batteries. Indian firms are ramping up investments in research and development, aiming to refine battery technologies and curtail costs. Collaborations with international tech providers and research institutions are catalyzing innovations in battery manufacturing.

- In July 2024, LICO announced its operational expansion with a state-of-the-art facility in Bangalore, poised to be one of India's largest lithium-ion battery recyclers. Set to commence operations by October 2024, LICO's facility aims for an ambitious processing capacity of 25,000 tonnes annually by 2026. Strategically, the plant will emphasize regional processing to mitigate transportation risks and costs, adopting a hub-and-spoke operational model. As EV adoption accelerates, India is gearing up to efficiently manage end-of-life batteries, ensuring a future-ready infrastructure.

- India's Lithium-ion Battery (LiB) manufacturing sector is on an upward trajectory, with major players making strategic investments in new facilities to cater to the burgeoning EV market. Under the PLI scheme, industry stalwarts like Ola Electric, Reliance, and Rajesh Export have secured incentives for cell manufacturing, with production slated for 2024. In addition, numerous companies are methodically scaling up their LiB battery plants, positioning themselves to cater to both domestic and international markets.

- Given these developments, the region is poised for a surge in EV battery production, with a corresponding uptick in demand for lithium-ion batteries in the coming years.

Investments to Enhance the Battery Production Capacity

- India is ramping up its battery manufacturing capabilities to satisfy the surging demand for electric vehicles (EVs). Through initiatives like the Production Linked Incentive (PLI) scheme for advanced chemistry cell (ACC) battery storage, the government seeks to draw in investments and bolster local production. This strategic move is pivotal for curbing import reliance and nurturing a robust domestic battery manufacturing landscape.

- New battery production plants are emerging across India, catering to the burgeoning EV market. Industry giants such as Exide Industries, Amara Raja, and Tata Chemicals are channeling investments into cutting-edge facilities. These plants play a crucial role in satiating domestic demand, spurring innovation, and generating employment, thus propelling the growth of India's EV battery manufacturing sector.

- To bolster its battery manufacturing ambitions, India is issuing tenders for advanced equipment, including slurry mixers, vital for producing top-tier lithium-ion batteries. These tenders target state-of-the-art technology to boost efficiency and output. By modernizing its manufacturing processes, India aims to elevate the competitiveness and quality of its EV battery production, aligning it with global benchmarks.

- For example, in July 2024, Ahamani EV Technology Co., Ltd., a prominent Taiwanese player in electric two-wheelers and smart mobility, is set to make a substantial investment in India's EV landscape. The firm plans to set up a megawatt-scale battery manufacturing unit in India and is on the lookout for strategic technology transfer collaborations with major Indian automotive entities. Talks are already in progress with 3-4 leading EV firms. Given India's heightened emphasis on electric mobility, bolstered by supportive government policies and a surge in consumer demand for eco-friendly transport, Ahamani sees a golden opportunity. The envisioned local battery facility not only aims to bolster India's self-sufficiency in the EV value chain but also promises job creation and economic stimulation.

- India's government is actively backing the EV sector through a range of initiatives, including tax breaks, subsidies for manufacturers and consumers alike, and investments in charging infrastructure. These measures aim to enhance the affordability and convenience of EVs, driving up adoption rates and, in turn, boosting the demand for battery materials. Battery technology innovations are also influencing the market dynamics. For instance, BYD is pioneering new battery chemistries, like lithium iron phosphate (LFP) batteries, which, while being safer and more cost-effective, have a marginally lower energy density compared to conventional lithium-ion batteries. Such breakthroughs are instrumental in making EVs more accessible to the broader public.

- In August 2024, Amara Raja Advanced Cell Technologies (ARACT) inked a Memorandum of Understanding (MoU) with Piaggio Vehicles Private Limited, aiming to propel EV technology in India. This collaboration centers on crafting and supplying lithium-ion cells, battery packs, and chargers tailored for Piaggio's electric three-wheelers and upcoming two-wheelers.

- India is setting its sights on ambitious electric vehicle (EV) sales targets by 2029, in line with global trends. The government is emphasizing domestic manufacturing, especially in battery production, to fuel India's EV aspirations. Under the "30@30" initiative and other bold projections, India needed a cumulative battery capacity of 42.5 GWh in 2023, with expectations to skyrocket to 577.8 GWh by 2029. This surge means India's annual battery requirements could represent 17% to 26% of global production. Moreover, ramping up production is crucial not only to meet these demands but also to drive down costs, enhancing the market competitiveness of EVs. Establishing a solid domestic manufacturing foundation promises substantial economic advantages for the country.

- In conclusion, these initiatives and investments are set to significantly bolster India's battery production capabilities.

India Electric Vehicle Battery Manufacturing Industry Overview

The India Electric Vehicle Battery Manufacturing Market is semi-concentrated. Some of the key players in this market (in no particular order) are BYD Co. Ltd., Contemporary Amperex Technology Co. Limited, Panasonic Corporation, Exide Industries, and Amara Raja Batteries Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Investments to Enhance the battery production capacity

- 4.5.1.2 Decline in cost of battery raw materials

- 4.5.2 Restraints

- 4.5.2.1 Lack of Raw Material Reserves

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 PESTLE ANALYSIS

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Battery

- 5.1.1 Lithium-ion

- 5.1.2 Lead-Acid

- 5.1.3 Nickel Metal Hydride Battery

- 5.1.4 Others

- 5.2 Battery Form

- 5.2.1 Prismatic

- 5.2.2 Pouch

- 5.2.3 Cylindrical

- 5.3 Vehicle

- 5.3.1 Passenger Cars

- 5.3.2 Commercial Vehicles

- 5.3.3 Others

- 5.4 Propulsion

- 5.4.1 Battery Electric Vehicle

- 5.4.2 Hybrid Electric Vehicle

- 5.4.3 Plug-in Hybrid Electric Vehicle

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 BYD Co. Ltd

- 6.3.2 Contemporary Amperex Technology Co. Limited

- 6.3.3 EnerSys

- 6.3.4 GS Yuasa Corporation

- 6.3.5 LG Chem Ltd

- 6.3.6 Exide Industries

- 6.3.7 Panasonic Corporation

- 6.3.8 Amara Raja Batteries Ltd.

- 6.3.9 Tata Chemicals

- 6.3.10 HBL Power Systems Ltd.

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Long-term ambitious targets for electric vehicles

02-2729-4219

+886-2-2729-4219