|

市场调查报告书

商品编码

1637794

压敏黏着剂(PSA):市场占有率分析、产业趋势与成长预测(2025-2030 年)Pressure Sensitive Adhesives (PSA) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

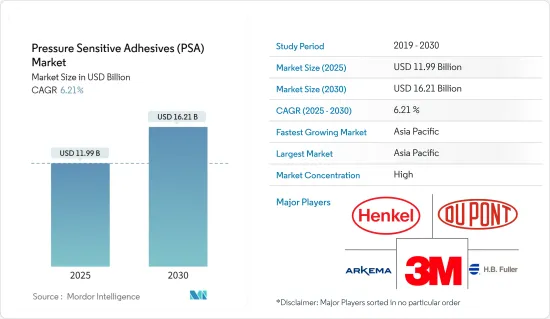

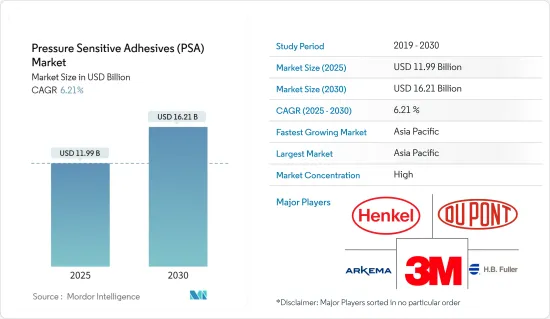

压敏黏着剂(PSA) 市场规模预计在 2025 年为 119.9 亿美元,预计到 2030 年将达到 162.1 亿美元,预测期内(2025-2030 年)的复合年增长率为 6.21%。 据预测。

2020 年,COVID-19 疫情爆发导致全国范围内实施封锁、製造活动和供应链中断以及全球生产停顿,对市场产生了负面影响。然而,2021年情况开始好转,市场恢復成长轨迹。

主要亮点

- 推动市场发展的关键因素是低成本、软包装的不断发展以及固化时间快的压敏黏着剂(PSA)的使用日益增加。

- 然而,有关 VOC排放的严格环境法规以及紫外线固化黏合剂等替代品的持续使用预计会阻碍市场成长。

- 磁带市场占据主导地位,预计在预测期内将会成长。这是由于包装、医疗和运输等终端用户行业的成长。

- 生物基压敏黏着剂的采用和基于奈米技术的功能性PSA的开发很可能是未来的机会。

- 亚太地区占全球市场主导地位,其中中国、印度等国占最大的消费量。

压敏黏着剂(PSA) 市场趋势

包装产业占据市场主导地位

- 这种黏合剂能确保产品包装在到达消费者手中之前保持完好。由于新产品的不断增加和产品种类的爆炸性增长,包装业务需要可靠的黏合剂来满足日益复杂的包装需求。

- 压敏黏着剂(PSA)对包装产业有多种优点:

- 快速返工:返工和重新包装会增加成本。 PSA 提供了一种及时的方法来确保产品合规并上架。压敏黏着剂(PSA)比胶棒更安全,而且比传统胶带更不显眼。与胶棒不同,压敏黏着剂(PSA)不需要加热即可使用。由于没有热量,因此不存在烧烫伤的风险,从而提高了工厂工人的安全性。此外,PSA 可提供您所需的黏合力,而不会干扰您的包装图形或损害您的品牌形象。压敏黏着剂(PSA) 是一种隐藏的包装解决方案,可保留并最大化您的品牌影响力。

- 即时黏合:使用压敏黏着剂(PSA) 可以节省时间,因为无需等待其固化。当使用压敏黏着剂(PSA) 时,它会同时黏合和压缩基材。瞬间黏合可提高加工速度和生产效率。

- 维护品牌形象 品牌形像很大程度上取决于包装的外观。 PSA 提供一种黏合剂,可以干净地去除,而不会损坏包装或在包装上留下任何残留物。维护您的品牌形象将吸引消费者。

- 此外,近年来,随着製造业和工业部门适应软包装,包装产业正经历转型期。

- 包装因其重量轻、易于搬运、节省空间、保质期长、便于运输、抗损坏、印刷性好等优点而受到欢迎。

- 电子商务、电子零售、线上订餐和宅配服务的兴起,增加了对包装材料的需求,尤其是软包装,这很可能在预测期内推动对紫外线固化黏合剂的需求。在德国,2022 年纸包装产业的成长比以往任何时候都要大。

- 据印度包装产业协会(PIAI)称,预测期内印度包装产业预计将成长22%。此外,预计到 2025 年印度包装市场规模将达到 2,048.1 亿美元。

- 软包装用于低收入的南美洲、非洲和亚太国家的食品包装应用。随着经济的持续扩张和食品饮料行业的加速发展,新兴国家对软包装的普及和需求正在增长。

- 由于各终端用户产业对非化石包装的需求不断增加,2022 年德国纸包装产业实现强劲成长。

- 预计这些因素将在预测期内增加对压敏黏着剂(PSA) 市场的需求。

亚太地区可望主导市场

- 亚太地区占全球需求的 40% 以上,是压敏黏着剂(PSA) 最有前景的市场,预计在不久的将来将占据主导地位。这种主导地位归因于该地区对胶带和标籤的需求不断增长。

- 中国、印度、日本和韩国占压敏黏着剂(PSA)需求的80%以上。

- 中国是胶黏产品(胶带、标籤等)主要出口国之一。对于许多客户来说,重要的是产品的品质、供应商提供的产品范围以及减少黏合剂的使用和浪费。因此,中国压敏黏着剂(PSA)市场目前主要由国际企业主导。同样的因素也鼓励本土製造商投资研发,以抢占该国主要市场占有率。

- 受人均收入上升和电子商务巨头崛起的推动,中国是世界上最大的包装消费国。根据印度塑胶工业协会统计,印度包装产业是世界第五大包装产业,每年的成长率约22-25%。高技能劳动力和低廉的人事费用意味着包装和加工食品的成本比欧洲低 40%。人口的成长和包装需求的增加预计将推动市场的发展。

- 此外,随着中国经济的不断发展和购买力增强的中阶的崛起,中国包装产业近年来一直经历着持续的快速成长。食品包装是包装产业的主要企业,占据我国约60%的市场占有率。根据Interpak统计,在中国食品包装类别中,2023年包装总量预计将达到4,470亿个,显示包装产业对压敏黏着剂(PSA)的需求不断增加。

- 印度压敏黏着剂(PSA)市场预计将经历高速成长。其应用范围已逐渐扩大至快速消费品 (FMCG) 製造商的透明和薄膜标籤、收缩包装标籤、柔性标籤和多色环绕标籤。压敏黏着剂(PSA)市场仍处于早期成长阶段,未来具有更高的成长前景。

- 庞大的市场规模加上亚太地区的强劲成长促进了压敏黏着剂(PSA) 市场的扩张。

压敏黏着剂(PSA) 产业概况

压敏黏着剂(PSA)市场正在整合。主要企业合计占近60%。主要企业(不分先后顺序)包括 3M、阿科玛、杜邦、HB Fuller 和汉高股份公司 (Henkel AG &Co.KGaA)。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 调查前提条件

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 驱动程式

- 低成本软质包装日益发展

- 增加固化时间较短的压敏胶的使用

- 其他驱动因素

- 限制因素

- 有关 VOC排放的严格环境法规

- 增加使用紫外线固化黏合剂等替代品

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第 5 章 市场区隔(以金额为准的市场规模)

- 依技术分类

- 水性

- 溶剂型

- 热熔胶

- 辐射

- 按树脂

- 丙烯酸纤维

- 硅胶

- 合成橡胶

- 其他树脂

- 按应用

- 磁带

- 标籤

- 形象的

- 其他用途

- 按最终用户产业

- 包装

- 木製品和配件

- 医疗

- 商业图形

- 运输

- 电子产品

- 其他最终用户产业

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争格局

- 併购、合资、合作、协议

- 市场占有率(%)**/排名分析

- 主要企业策略

- 公司简介

- 3M

- Arkema Group(Bostik SA)

- Ashland Inc.

- Avery Dennison Corp.

- DuPont

- Franklin International

- HB Fuller Co.

- Helmitin Adhesives

- Henkel AG & Co. KGaA

- Huntsman Corporation

- Illinois Tool Works Inc.

- Jowat AG

- Mapei SPA

- Master Bond

- Pidilite Industries Ltd

- Sika AG

- Tesa SE(A Beiersdorf Company)

- Wacker Chemie AG

第七章 市场机会与未来趋势

- 采用生物基压敏黏着剂(PSA)

- 基于奈米技术的功能性压敏胶(PSA)的开发

The Pressure Sensitive Adhesives Market size is estimated at USD 11.99 billion in 2025, and is expected to reach USD 16.21 billion by 2030, at a CAGR of 6.21% during the forecast period (2025-2030).

Due to the COVID-19 outbreak, nationwide lockdowns worldwide, disruption in manufacturing activities and supply chains, and production halts negatively impacted the market in 2020. However, the conditions started recovering in 2021, restoring the market's growth trajectory.

Key Highlights

- The major factor driving the market studied is the increasing development of low-cost, flexible packaging and increasing usage of pressure-sensitive adhesives because of lesser curing time.

- On the flip side, stringent environmental regulations regarding VOC emissions and increasing usage of substitutes like UV-cured adhesives are expected to hinder the studied market's growth.

- The tapes segment dominated the market and is expected to grow during the forecast period. It is owing to the growing end-user industries, such as packaging, medical, and transportation.

- Adopting bio-based pressure-sensitive adhesives and developing nanotechnology-based functional pressure-sensitive adhesives is likely an opportunity in the future.

- Asia-Pacific dominated the global market, with the largest consumption from countries such as China and India.

Pressure Sensitive Adhesives Market Trends

Packaging Industry to Dominate the Market

- Adhesives ensure the product packaging remains intact until it reaches the consumer. Packaging operations require a reliable adhesive to meet the increasingly complex packaging demands as there is an increase in several new products and product proliferation.

- Pressure-sensitive adhesives (PSAs) specifically offer several advantages for the packaging industry:

- Quick reworks: Reworking or repackaging increases costs. PSAs offer a timely way to make products compliant and shelf-ready. Pressure-sensitive adhesives are safer than glue sticks and more discrete than traditional tape. Unlike glue sticks, pressure-sensitive adhesives do not require heat during application. The absence of heat eliminates burns and increases safety among plant workers. Additionally, PSAs are less intrusive on packaging graphics, providing the required adhesion without sacrificing the brand image. Pressure-sensitive adhesives are less visible packaging solutions that preserve and maximize the brand's impact.

- Instant bond: Applying pressure-sensitive adhesives is time-saving, as waiting until they cure is unnecessary. When applied, they compress the substrate right when adhesion occurs. Instant bonding increases the processing speed, as well as improves production.

- Maintaining brand image: Brand image relies heavily on the packaging appearance. PSAs provide a bond that removes cleanly without damaging the packaging or leaving behind residue. Preserving brand image adds to your consumer appeal.

- Furthermore, in the last few years, the packaging industry is experiencing a transition where the manufacturing and industrial sector is adapting to flexible packaging.

- The benefits, such as being lightweight, easy to handle, less space-consuming, longer shelf life, easy transit, damage resistance, and better printability, made packaging popular.

- With the growing trend of e-commerce, e-retail, and online food orders and delivery services, the demand for packaging materials, especially flexible packaging, is increasing, likely to drive the demand for UV-curable adhesives during the forecast period. In Germany, the paper packaging industry grew significantly in 2022 compared to previous years.

- According to the Packaging Industry Association of India (PIAI), the Indian packaging industry is expected to grow at 22% during the forecast period. Moreover, the Indian packaging market is expected to reach USD 204.81 billion by 2025.

- Flexible packaging is used in food packaging applications in low-income South America, Africa, and Asia-Pacific countries. The popularity and demand for flexible packaging are rising in emerging economies, and the demand is supported by continued economic expansion and an acceleration in the food and beverage industry.

- The paper packaging industry grew significantly in Germany in 2022 because of the increasing demand for non-fossil-based packaging for different end-user industries.

- Such factors will likely increase the demand for the pressure-sensitive adhesives market over the forecast period.

Asia-Pacific Region is Expected to Dominate the Market

- With over 40% of the global demand, Asia-Pacific is the most promising market for pressure-sensitive adhesives, which will likely dominate soon. This domination can be attributed to the region's growing demand for tapes and labels.

- China, India, Japan, and South Korea account for over 80% of the demand for pressure-sensitive adhesives.

- China is one of the major exporters of adhesive products (tapes, labels, etc.). The factors concerning most of its customers are the product quality, the product range offered by the vendor, and reducing the dosage and wastage of adhesives. Therefore, international players currently dominate the Chinese market for pressure-sensitive adhesives. The same factor encourages local producers to invest in R&D to acquire a major national market share.

- China is the world's largest packaging consumer globally, owing to growing per capita income and rising e-commerce giants. India's packaging industry is the fifth-largest globally, growing at about 22-25% per year, according to the Plastics Industry Association of India. Packaging and processing food costs can be 40% lower than in Europe because of highly skilled labor and cheap labor costs. The growing population and increasing demand for packaging are expected to drive the market.

- Furthermore, the Chinese packaging industry grew rapidly and consistently in recent years, owing to the expanding economy and rising middle class with greater purchasing power. Food packaging is a major player in the packaging industry, accounting for roughly 60% of the total market share in China. According to Interpak, in China, in the foodstuff packaging category, total packaging is expected to reach 447 billion units in 2023, indicating an increased demand for pressure-sensitive adhesives from the packaging industry.

- The pressure-sensitive adhesives market in India is expected to grow at a higher rate. Its usage increased with transparent and film labels, shrink-wrap labels for fast-moving consumer goods (FMCG) manufacturers, flexible labels, and multicolor wrap-around labels. The pressure-sensitive adhesives market is still in its early growth stage, with a higher scope of growth in the future.

- The large market size, coupled with the huge growth of Asia-Pacific, is instrumental in expanding the pressure-sensitive adhesives market.

Pressure Sensitive Adhesives Industry Overview

The pressure-sensitive adhesives market is consolidated. The top seven players account for almost 60%. The major companies (not in any particular order) include 3M, Arkema, DuPont, HB Fuller, and Henkel AG & Co. KGaA.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Development of Low-cost Flexible Packaging

- 4.1.2 Increasing Usage of PSA Because of Lesser Curing Time

- 4.1.3 Other Drivers

- 4.2 Restraints

- 4.2.1 Stringent Environmental Regulations Regarding VOC Emissions

- 4.2.2 Increasing Usage of Subsitutes like UV Cured Adhesives

- 4.3 Industry Value-Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Technology

- 5.1.1 Water-based

- 5.1.2 Solvent-based

- 5.1.3 Hot Melt

- 5.1.4 Radiation

- 5.2 Resin

- 5.2.1 Acrylics

- 5.2.2 Silicones

- 5.2.3 Elastomers

- 5.2.4 Other Resins

- 5.3 Application

- 5.3.1 Tapes

- 5.3.2 Labels

- 5.3.3 Graphics

- 5.3.4 Other Applications

- 5.4 End-user Industry

- 5.4.1 Packaging

- 5.4.2 Woodworking and Joinery

- 5.4.3 Medical

- 5.4.4 Commercial Graphics

- 5.4.5 Transportation

- 5.4.6 Electronics

- 5.4.7 Other End-user Industries

- 5.5 Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 Italy

- 5.5.3.4 France

- 5.5.3.5 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle-East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle-East and Africa

- 5.5.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share(%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 3M

- 6.4.2 Arkema Group (Bostik SA)

- 6.4.3 Ashland Inc.

- 6.4.4 Avery Dennison Corp.

- 6.4.5 DuPont

- 6.4.6 Franklin International

- 6.4.7 H.B. Fuller Co.

- 6.4.8 Helmitin Adhesives

- 6.4.9 Henkel AG & Co. KGaA

- 6.4.10 Huntsman Corporation

- 6.4.11 Illinois Tool Works Inc.

- 6.4.12 Jowat AG

- 6.4.13 Mapei SPA

- 6.4.14 Master Bond

- 6.4.15 Pidilite Industries Ltd

- 6.4.16 Sika AG

- 6.4.17 Tesa SE (A Beiersdorf Company)

- 6.4.18 Wacker Chemie AG

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Adoption of Bio-based Pressure Sensitive Adhesives

- 7.2 Development of Nanotechnology based Functional Pressure Sensitive Adhesives