|

市场调查报告书

商品编码

1637800

美国泡壳包装:市场占有率分析、行业趋势和成长预测(2025-2030 年)United States Blister Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

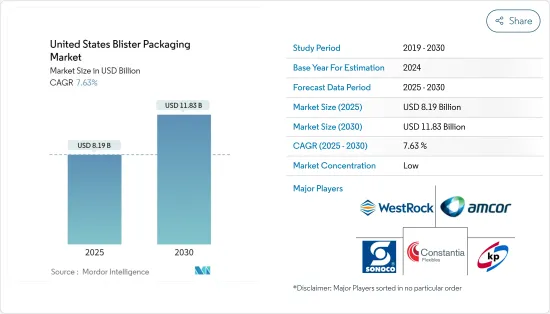

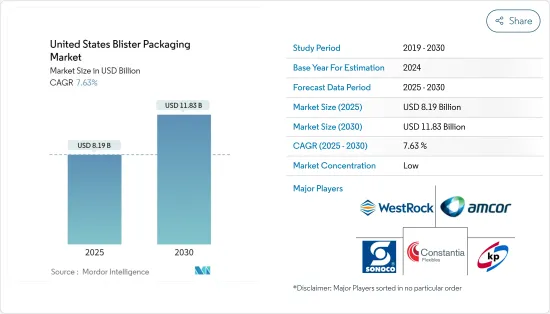

美国泡壳包装市场规模预计在2025年为81.9亿美元,预计到2030年将达到118.3亿美元,预测期内(2025-2030年)的复合年增长率为7.63%。

泡壳包装是用于各种消费品、食品和药品的预成型塑胶包装。这些包装解决方案可保护您的产品免受潮湿和污染等外部因素的影响,确保长期保护。

在泡壳包装中,产品放入预先形成的泡壳或腔体中,并用卡片或垫片固定到位。这种包装方法广泛用于各种消费品,尤其是製药和工业产业。製药业占据泡壳包装市场的主导地位,占有相当大的份额。製药公司更喜欢泡壳包装,因为它提供了额外的产品保护、简化的分销、单位剂量的便利性和清晰的产品标誌。

根据美国商务部的数据,到 2050 年,美国85 岁及以上人口预计将增加两倍。临床医生和公共卫生服务提供者正在为这一人群及其亚群体培养一种富有同情心的文化。随着老化和肥胖人口的增加,骨关节炎、糖尿病和相关行动障碍的盛行率可能会持续上升。所有这些因素预计都将刺激对口服药物的需求,从而推动对药品泡壳包装的需求。

根据美国疾病管制与预防中心 (CDC) 的数据,美国50 岁及以上美国预计将成长,在 2020 年至 2050 年间达到近 6,100 万人。这意味着患有一种或多种慢性病的人数预计将增加近9,900万人,从2020年的7,150万人增加到2050年的1.42亿多人。

随着生活方式的演变,消费者越来越青睐便携式食品包装,并注重便利性和易用性。为了满足这种需求,糖果零食和烘焙製造商越来越多地使用泡壳包装。随着该地区烘焙产品零售额的不断增长,泡壳包装预计将在食品行业中实现显着增长。

泡壳包装引发了严重的环境问题。如果处理不当,它们会对环境造成危害。此外,由塑胶和铝箔成的专用包装也使回收过程变得复杂。药品泡壳包装是最大的固态废弃物来源之一。包装复杂、层次多,回收难度高。

美国泡壳包装市场趋势

製药业可望强劲成长

- 泡壳包装作为一种包装形式变得越来越流行,以满足注重安全的消费者和监管机构的需求。泡壳包装允许追踪和序列化通讯协定,有助于防止假冒。无论产品是非处方止痛药或新型临床试验药物,泡壳包装仍是一种有效的包装形式,可提高患者的依从性。

- 单位剂量包装有助于减少治疗期间的错误并防止错过剂量。这也使得忙碌的人们能够更准确、更方便地管理他们的用药方案。在单位剂量包装中,锭剂或胶囊可分为单位剂量泡壳包装和穿孔包装。

- 根据患者的需求,包装可以客製化为每日或亚每日剂量。它们也可以印在包装上,帮助患者记住何时服用哪种锭剂。单位剂量包装还可以保护每片锭剂直至服用,从而保护产品的功效。它有望挽救因药物过量摄取死亡的生命,并增加对泡壳包装的需求。

- 根据欧洲製药工业和协会联合会(EFPIA)的资料,2017年至2022年美国新药销售份额为64.4%,2018年至2023年将增至67.1%。预计预测期内此类新药在国内销售的成长将进一步推动泡壳包装的需求。

- 在市场上经营的各家公司都在推出新产品作为业务扩展的一部分。例如,2023 年 10 月,全球特种材料市场领导索尔维宣布推出一种具有超高水蒸气阻隔性将减少药品泡壳薄膜的碳足迹。作为一种水分散体,DiofanUltra 736 满足直接药物接触的监管要求,并有助于设计更薄涂层设计中的永续薄膜。该公司投资这项具有挑战性的计划是为了进一步提高医疗保健产业的产品识别要求。

老龄人口增加和疾病流行

- 随着国家人口的增长和疾病发病率的上升,製药公司正在利用这一优势扩大其固态剂量生产设施。根据美国人口普查局的数据,过去十年美国65 岁及以上人口增加了三分之一以上。

- 预计到 2060 年,美国人口将进入老化阶段,约四分之一的美国年龄将超过 65 岁。其中,69%的老年人最终将需要长期照护。预计这些因素将推动市场成长。

- 随着越来越多的消费者过着积极的生活方式,对按需便利的需求也随之增加。对于力量和灵活性较差的老年人来说,撕开泡壳包装底部的小标籤可能是一项挑战。将产品从泡壳包装的铝箔(或冲孔)中推出,迫使产品从泡壳包装的底部出来,使老年患者更容易在旅途中取用药物。

- 老年人口正在增加,预计这一趋势将在整个预测期内持续,从而增加对药品的需求,从而推动市场成长。此外,癌症和感染疾病等慢性病的急剧增加,加上人口老化需要先进且用户友好的包装,可能会增强泡壳包装市场。泡壳包装以其便利性而闻名,尤其适用于固态口服药物。

- 随着人口老化,医疗保健系统面临越来越多的慢性病和不断上涨的处方笺费用。一般来说,老年患者对药物的反应与年轻患者不同。根据美国人口普查局的数据,2016年至2060年间,美国100岁或以上人口数预计将增加。 2016年,美国100岁以上老人数量达82,000人。到2060年,百岁老人的数量预计将达到58.9万人。预计所有这些因素都将支持美国泡壳包装的成长。

美国泡壳包装产业概况

美国泡壳包装市场较为分散。该市场的供应商采用关键伙伴关係、合併和收购作为主要策略来生产满足最终用户需求的产品。包装材料经过严格的品质测试,以确保其不会污染内容物或带来任何健康风险。保持稳定的原料供应是伙伴关係的关键驱动力。美国泡壳包装市场的主要参与者包括 Amcor Ltd、Westrock Company、Sonoco Products Company、Constantia Flexibles Group、Honeywell International Inc. 等。

2023 年 9 月,全球包装领导者 Sonoco 决定收购 Graphic Packaging Corporation 的软包装部门。 Graphic Packaging 被位于科罗拉多戈尔登的 ACX Technologies Inc. 收购。 Sonoco 在软包装领域的立足点被公认为包装行业中一个快速成长的领域。

2023 年 7 月 Constantia Flexibles 推出其在医药包装领域的最新创新 REGULA CIRC。这种尖端的冷成型箔技术重新定义了泡壳包装的永续性标准,使消费者和环境都受益。基于我们对循环社会的承诺,REGULA CIRC 旨在满足即将出台的法规并确保其符合永续包装的基准标准。 REGULA CIRC 代表了设计的重大转变,透过使用聚乙烯 (PE) 密封层代替传统的 PVC,体现了循环经济的原则。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概况

- 产业价值链分析

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场动态

- 市场驱动因素

- 老龄人口增加和疾病流行

- 产品创新,例如尺寸较小、成本相对较低

- 市场限制

- 严格的政府法规

第六章 市场细分

- 按工艺

- 冷成型

- 热成型

- 按材质

- 塑胶

- 纸和纸板

- 铝

- 按最终用户产业

- 消费品

- 药品

- 工业

- 其他最终用户产业

第七章 竞争格局

- 公司简介

- Amcor PLC

- Westrock Company

- Constantia Flexibles GmbH

- Sonoco Products Company

- Klockner Pentaplast Group

- Tekni-Plex Inc.

- Blisterpak Inc.

- Honeywell International Inc.

第八章投资分析

第九章:市场的未来

The United States Blister Packaging Market size is estimated at USD 8.19 billion in 2025, and is expected to reach USD 11.83 billion by 2030, at a CAGR of 7.63% during the forecast period (2025-2030).

Blister packs are pre-formed plastic packaging for various consumer goods, foods, and pharmaceuticals. These packaging solutions safeguard products from external factors like humidity and contamination, ensuring prolonged protection.

Blister packaging involves placing products in pre-formed blisters or cavities secured with cards or pads. This packaging method is widely used for various consumer goods, especially in the pharmaceutical and industrial industries. The pharmaceutical industry dominates the blister packaging market, holding a substantial share. Pharmaceutical companies prefer blister packaging because it offers enhanced product protection, streamlined distribution, unit dosage convenience, and clear product identification.

According to the United States Department of Commerce, the US population aged 85 and over is projected to triple by 2050. Clinicians and public health service providers cultivate a culture of compassion for this population and its subgroups. The prevalence of osteoarthritis and diabetes, as well as related mobility impairments, will continue to rise as people age and become more overweight. All such factors are anticipated to boost the demand for oral medication, thus propelling the demand for blister packaging in pharmaceuticals.

According to the Centers for Disease Control and Prevention (CDC), the number of people over 50 in the United States is expected to increase, reaching almost 61 million between 2020 and 2050. That means the number of people with one or more chronic diseases is expected to go up by nearly 99 million, from 71.5 million in 2020 to over 142 million in 2050.

As lifestyles evolve, consumers favor on-the-go packaging for food products, prioritizing convenience and ease of use. Confectionery and bakery manufacturers are increasingly using blister packaging to meet this demand. With the region experiencing a rise in retail sales of bakery goods, blister packaging is expected to see significant growth in the food industry.

Blister packaging raises significant environmental concerns. If not disposed of correctly, it poses risks to the environment. Additionally, specific packs that combine plastic and foil complicate the recycling process. Pharmaceutical blister packaging is one of the largest sources of solid waste. Recycling is difficult due to the complexity of these packages with multiple layers.

United States Blister Packaging Market Trends

The Pharmaceutical Segment is Expected to Witness Significant Growth

- The blister pack is becoming increasingly popular as a packaging format that meets the needs of security-conscious consumers and regulatory bodies. Blister packaging enables track-and-trace and serialization protocols and helps prevent counterfeiting. The blister pack remains an effective packaging format for enhancing patient compliance, regardless of whether the product is an OTC pain reliever or a novel clinical-trial medication.

- Unit dose packaging helps to reduce errors and prevent missed doses during therapy. It also makes it easier for busy individuals to manage their medication regimens correctly and conveniently. Unit dose packaging allows pills and capsules to be parcelled and perforated in unit dose blister packs.

- Depending on the patient's needs, the packaging can be customized to daily or time-of-day dosage. The packaging can also be printed to help patients remember which pills to take and when. The unit dose packaging also helps protect the product's efficacy by protecting every tablet until it is administered. It is expected to save lives from drug overdoses and boost the demand for blister packaging.

- According to data from the European Federation of Pharmaceutical Industries and Associations (EFPIA), the sales distribution of new drugs in the United States from 2017 to 2022 was 64.4%, and it increased to 67.1% from 2018 to 2023. Such a rise in the sales of new drugs in the country would further drive the demand for blister packs during the forecast period.

- Various companies operating in the market are launching new products as part of their business expansion. For instance, in October 2023, Solvay, one of the global market leaders in specialty materials, introduced DiofanUltra736, a new polyvinylidene chloride (PVDC) coating solution with an ultra-high water vapor barrier that allows carbon footprint decline for pharmaceutical blister films. As an aqueous dispersion, DiofanUltra736 fulfills regulatory needs for direct pharmaceutical contact and helps design sustainable films with thinner coating designs. The company invested in this challenging project to further improve product identification, a requirement in the healthcare industry.

Growing Geriatric Population and Prevalence of Diseases

- As the country's population grows and disease rates rise, pharmaceutical companies are taking advantage of this to expand their manufacturing facilities for solid doses. According to the United States Census Bureau, the number of people aged 65+ in the United States has increased by more than one-third over the past decade.

- The United States population is projected to gray out by 2060, with nearly one-quarter of Americans aged 65+. Of these, 69% of senior adults will need long-term care at some point. Such factors are anticipated to fuel market growth.

- As more and more consumers are engaged in active lifestyles, the demand for on-demand convenience increases. For seniors with reduced physical strength or agility, the small tabs on the bottoms of blister packs can be challenging to peel. Pushing the product through the foil (or punch-out) of a blister pack, which pushes the product out of the base of the blister, makes it easier for elderly patients to access their medications while on the go.

- The senior population is rising, a trend projected to persist throughout the forecast period, fueling a heightened demand for pharmaceuticals and driving market growth. Additionally, the surging prevalence of chronic ailments, including cancer and infectious diseases, coupled with an aging demographic that requires advanced, user-friendly packaging, is set to bolster the blister packaging market. Blister packaging, known for its convenience, is particularly beneficial for solid oral medications.

- As the population ages, the healthcare system faces many chronic diseases and increasing prescription costs. In general, elderly patients respond differently to medications compared to younger patients. According to the United States Census Bureau, the number of people over 100 in the United States is expected to increase between 2016 and 2060. In 2016, the United States had 82,000 people over 100. In 2060, the number of centenarians is expected to reach 589,000. All such factors are expected to support the growth of blister packaging in the United States.

United States Blister Packaging Industry Overview

The blister packaging market in the United States is fragmented. Vendors in the market have been using significant partnerships, mergers, and acquisitions as major strategies to produce products that meet the needs of end users. Packaging materials undergo rigorous quality testing to ensure that they do not contaminate the contents or affect health. Maintaining a steady supply of raw materials is a significant challenge that drives partnerships. Major players in the US blister packaging market include Amcor Ltd, Westrock Company, Sonoco Products Company, Constantia Flexibles Group, and Honeywell International Inc.

September 2023: Sonoco, a global leader in packaging, finalized its acquisition of Graphic Packaging Corporation's flexible packaging division. Graphic Packaging is a wholly owned subsidiary of ACX Technologies Inc., based in Golden, Colorado. In an all-cash deal, Sonoco invested around USD 105 million. Sonoco's foothold in flexible packaging is recognized as the packaging industry's rapidly expanding segment.

July 2023: Constantia Flexibles introduced REGULA CIRC, its latest innovation in pharmaceutical packaging. This state-of-the-art coldform foil technology redefines sustainability standards in blister packaging, benefiting both consumers and the environment. With a commitment to circularity, REGULA CIRC is engineered to align with upcoming regulations, ensuring it meets the standard of sustainable packaging benchmarks. REGULA CIRC introduces significant design changes by replacing traditional PVC with a polyethylene (PE) sealing layer, embracing circular economy principles.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Geriatric Population and Prevalence of Diseases

- 5.1.2 Product Innovations Such as Downsizing Coupled with Relatively Low Costs

- 5.2 Market Restraints

- 5.2.1 Stringent Government Regulations

6 MARKET SEGMENTATION

- 6.1 By Process

- 6.1.1 Coldforming

- 6.1.2 Thermoforming

- 6.2 By Material

- 6.2.1 Plastic

- 6.2.2 Paper and Paperboard

- 6.2.3 Aluminum

- 6.3 By End-user Industry

- 6.3.1 Consumer Goods

- 6.3.2 Pharmaceutical

- 6.3.3 Industrial

- 6.3.4 Other End-user Industries

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Amcor PLC

- 7.1.2 Westrock Company

- 7.1.3 Constantia Flexibles GmbH

- 7.1.4 Sonoco Products Company

- 7.1.5 Klockner Pentaplast Group

- 7.1.6 Tekni-Plex Inc.

- 7.1.7 Blisterpak Inc.

- 7.1.8 Honeywell International Inc.