|

市场调查报告书

商品编码

1639413

热喷涂材料:市场占有率分析、行业趋势和统计、成长预测(2025-2030 年)Thermal Spray Materials - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

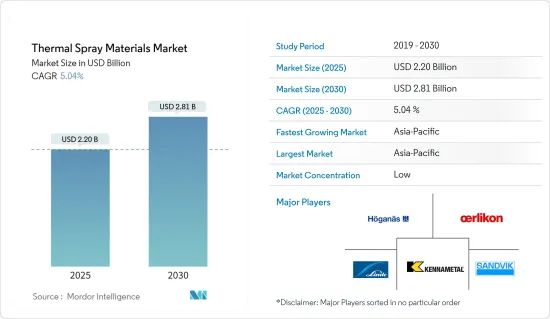

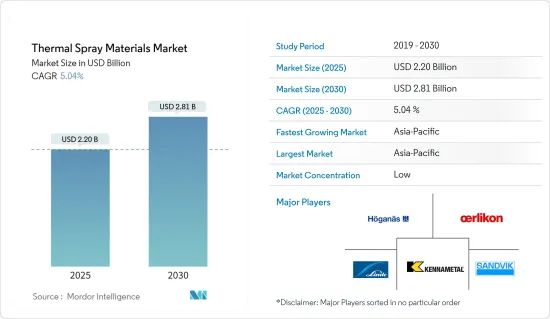

预计2025年热喷涂材料市场规模为22亿美元,预计2030年将达到28.1亿美元,预测期间(2025-2030年)的复合年增长率为5.04%。

新冠疫情对2020年和2021年上半年的市场产生了负面影响。为了遏制病毒传播,所有製造和其他活动都被关闭,这对市场造成了不利影响。然而,疫情过后,由于製造业的成长和目前已几乎全面运作的终端用户产业需求的復苏,预计市场将实现强劲成长。

主要亮点

- 市场发展的驱动因素包括医疗设备製造中热喷涂涂层的使用日益增多、热喷涂陶瓷涂层的日益普及、防腐应用中的广泛使用以及亚太地区风力发电行业的不断发展。

- 然而,替代品的出现预计会阻碍市场的成长。

- 金属陶瓷溶液前驱物等离子喷涂、喷涂材料回收、环境屏障涂层 (EBC) 喷涂粉末工业规模生产以及石油和天然气行业的成长前景等进展,是预计推动市场的关键机会。

- 由于中国和印度等经济的显着增长,预计亚太地区将在预测期内占据市场主导地位。

热喷涂材料的市场趋势

航太工业占市场主导地位

- 热喷涂材料在航太工业中有着广泛的应用。热喷涂材料用于生产飞机内各部件的涂层。这些涂层可延长零件的使用寿命、降低维护成本并提高燃油经济性。

- 氧化锆、铝青铜、钴钼等热喷涂材料分别用于涂层火箭燃烧室、压缩机气封及高压喷嘴。

- 航空发动机容易因磨损、高温腐蚀、微动磨损、颗粒侵蚀等原因而出现各种劣化问题。在较高温度下,这种劣化会加速。热喷涂材料赋予引擎零件所需的表面状况,以延长其使用寿命。

- 全球军事和航太製造市场包括波音、洛克希德和诺斯罗普·格鲁曼等主要企业。国际民航组织发布的报告显示,得益于经济开放,后疫情期间商业航空公司的收益大幅成长。预计 2021 年将达到 4.72 亿美元,到 2022年终将达到 6.58 亿美元,增幅高达 39%。

- 航太领域的成长,特别是新兴国家的民航领域的成长,预计将推动市场成长,这得益于对航太基础设施建设和新计画推出的大量支出。例如,在印度,2021 年 3 月,政府根据民航部的 UDAN-RCS 提交了一份在乌贾因大坝开发水上机场计划的提案。

- 因此,由于上述优点,热喷涂材料的采用预计会增加,从而推动其在航太工业的需求。

亚太地区占市场主导地位

- 热喷涂材料在航太工业中用作保护涂层。中国是最大的飞机製造国之一,也是最大的国内航空旅客市场之一。

- 庞大的市场规模、不断增加的政府支持以及在线预订电动车的能力等因素可能会推动该国对电动车的需求。

- 中国航太业预计将在先前大幅下滑后于2022年恢復获利。此外,中国民航局估计,国内航空运输量将恢復到疫情前的85%左右。

- 此外,中国航空公司计划在未来20年内购买约7,690架新飞机,价值约1.2兆美元,预计将推动热喷涂材料的需求。根据波音公司《2021-2040年商业展望》,到2040年中国将交付约8,700架新飞机,市场服务价值将达到1.8兆美元。

- 截至2021年12月,中国计划在未来15年内建造至少150座新核子反应炉,投资4,400亿美元。中国拥有大量核子反应炉: 19座在建,43座等待核子反应炉,166座已宣布建设。这228台机组的总合装置容量为246GW。

- 印度政府将根据重工业部下属的生产连结奖励计画计划,向汽车及汽车零件产业提供 78 亿美元资金。因此,预计在预测期内,由于汽车产量增加而导致的汽车产业扩张将推动市场成长。

- 由于这些发展,预计亚太地区将在预测期内占据市场主导地位。

热喷涂材料产业概况

从本质上来说,热喷涂材料市场是部分分散的。市场的主要企业(不分先后顺序)包括 Hoganas AB、OC Oerlikon Management AG、Kennametal Inc.、Sandvik AB 和 Linde PLC。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 调查前提条件

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 驱动程式

- 扩大热喷涂涂层在医疗设备製造的应用

- 热喷涂陶瓷涂层的需求不断增加

- 防腐应用中的广泛使用

- 亚太地区风电产业的发展

- 限制因素

- 替代品的出现

- 产业价值链分析

- 波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第 5 章 市场区隔(以金额为准的市场规模)

- 依产品类型

- 涂层材料

- 粉末

- 陶瓷

- 陶瓷氧化物

- 氧化铝

- 二氧化钛

- 锆石

- 氧化铬和其他陶瓷氧化物

- 硬质合金(包括金属陶瓷)

- 碳化铬

- 碳化钨

- 金属

- 纯金属和合金

- 贵金属

- MCrAlY

- 聚合物和其他涂层材料

- 线材/棒材

- 其他涂料(液体)

- 次要材料(辅助材料)

- 涂层材料

- 依工艺类型

- 燃烧

- 电能

- 按最终用户产业

- 航太

- 工业用燃气涡轮机

- 车

- 电子产品

- 石油和天然气

- 医疗设备

- 能源和电力

- 其他最终用户产业

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 东南亚国协

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争格局

- 併购、合资、合作与协议

- 市场排名分析

- 主要企业策略

- 公司简介

- Aisher APM LLC

- Ametek Inc.

- Aimtek Inc.

- C&M Technologies GmbH

- Castolin Eutectic

- CenterLine(Windsor)Limited

- CRS Holdings Inc.

- Fisher Barton

- Global Tungsten & Powders Corp.

- HAI Inc.

- HC Starck GmbH

- Hoganas AB

- Hunter Chemical LLC

- Kennametal Stellite

- Linde PLC

- LSN Diffusion Ltd

- Metallisation Limited

- Metallizing Equipment Co. Pvt. Ltd

- OC Oerlikon Management AG

- Polymet Corporation

- Powder Alloy Corporation

- Saint-Gobain

- Sandvik AB

- Thermion

第七章 市场机会与未来趋势

- 金属陶瓷溶液前驱物等离子体喷涂的最新发展。

- 热喷涂材料的回收利用

- 环境屏障涂层 (EBC) 热喷涂粉末的工业规模生产

- 石油和天然气产业的成长前景

The Thermal Spray Materials Market size is estimated at USD 2.20 billion in 2025, and is expected to reach USD 2.81 billion by 2030, at a CAGR of 5.04% during the forecast period (2025-2030).

COVID-19 negatively impacted the market in 2020 and the first half of 2021. All the manufacturing and other activities were put on hold to curb the spreading of the virus, thereby negatively affecting the market. However, the market is projected to grow steadily post the retraction of the pandemic, owing to increased manufacturing and reinstating demand from the end-user industries, which have become operational at almost full scale.

Key Highlights

- The studied market's significant factors include the increasing usage of thermal spray coating in medical device manufacturing, the rising popularity of thermal spray ceramic coatings, extensive consumption in anti-corrosion applications, and evolution in the Asia-Pacific wind power sector.

- On the other hand, the emergence of alternate substitutes is expected to hinder the market's growth.

- The ongoing progress in solution precursor plasma spraying of cermets, recycling of thermal spray processing materials, industrial-scale production of environmental barrier coatings (EBC) thermal spray powders, and growth prospects in the oil and gas industry are the significant opportunities expected to drive the market in the future.

- Asia-Pacific region is expected to dominate the market in the forecast period because of vastly growing economies such as China and India.

Thermal Spray Materials Market Trends

Aerospace Industry to Dominate the Market

- Thermal spray materials are extensively used in the aerospace sector. They are used in manufacturing coatings, which are applied to various parts throughout the aircraft. These coatings offer component longevity, thus, reducing maintenance costs and increasing fuel efficiency.

- Thermal spray materials, such as zirconium oxide, aluminum bronze, and cobalt-molybdenum, are used for coating purposes in rocket combustion chambers, compressor air seals, and high-pressure nozzles, respectively.

- Various degradation problems exist in aircraft engines due to wear, hot corrosion, fretting, particle erosion, and many more. This degradation is accelerated when high temperatures are involved. Thermal spray material imparts the surface conditions required to increase engine components' service life.

- The global military and aerospace manufacturing market include dominant players such as Boeing, Lockheed, and Northrop Grumman. As per the report published by International Civil Aviation Organisation, commercial airlines' revenue grew significantly during the post-pandemic period because of the opening up of economies. It reached up to USD 472 million in 2021 and is forecasted to gain a whopping 39% standing at USD 658 million by the end of 2022.

- Growth in the aerospace sector, especially in civil aviation in emerging economies, on account of high expenditure on aerospace infrastructural construction and commissioning new projects, is expected to drive the market's growth. For instance, in India, in March 2021, the government submitted a proposal to develop a water aerodrome project at the Ujjain Dam under the Ministry of Civil Aviation's UDAN-RCS.

- Thus, increasing the adoption of thermal spray material due to its advantages mentioned above is expected to boost its demand in the aerospace industry.

Asia-Pacific to Dominate the Market

- Thermal spray materials are used in the aerospace industry as protective coating. China is one of the largest aircraft manufacturers and one of the largest markets for domestic air passengers.

- Factors such as large market size, increasing government support, and the ability to book electric vehicles online are likely to fuel the demand for electric vehicles in the country.

- China's aerospace industry is projected to return to profitability in 2022 after facing a significant decline in the previous years. In addition, the Civil Aviation Administration of China (CAAC) has estimated the aviation sector to recover domestic traffic to around 85% of pre-pandemic levels.

- Moreover, Chinese airline companies are planning to purchase about 7,690 new aircraft in the next 20 years, valued at approximately USD 1.2 trillion, expected to drive the demand for thermal spray materials. According to the Boeing Commercial Outlook 2021-2040, around 8,700 new deliveries will be made in China by 2040, with a market service value of USD 1,800 billion.

- In December 2021, China planned to build at least 150 new nuclear reactors in the next 15 years with an investment of USD 440 billion. The country has 19 reactors under construction, 43 reactors awaiting permits, and a massive 166 reactors that have been announced. The combined capacity of these 228 reactors is 246GW.

- The Government of India has planned to give USD 7.8 billion to the automobile and auto components sector in production-linked incentive schemes under the Department of Heavy Industries. Thus, the expansion of the automotive sector with the growing production of automobiles is anticipated to drive the market's growth over the forecast period.

- Owing to these developments, Asia-Pacific is expected to dominate the market over the forecast period.

Thermal Spray Materials Industry Overview

The thermal spray materials market is partially fragmented in nature. Some of the major players in the market (in no particular order) include Hoganas AB, OC Oerlikon Management AG, Kennametal Inc., Sandvik AB, and Linde PLC.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Usage of Thermal Spray Coating in Medical Device Manufacturing

- 4.1.2 Rising Demand of Thermal Spray Ceramic Coatings

- 4.1.3 Extensive Consumption in Anti-corrosion Applications

- 4.1.4 Evolution in the Asia-Pacific Wind Power Sector

- 4.2 Restraints

- 4.2.1 Emergence of Alternate Substitutes

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Product Type

- 5.1.1 Coating Materials

- 5.1.1.1 Powders

- 5.1.1.1.1 Ceramics

- 5.1.1.1.1.1 Ceramic Oxides

- 5.1.1.1.1.1.1 Alumina

- 5.1.1.1.1.1.2 Titania

- 5.1.1.1.1.1.3 Zirconia

- 5.1.1.1.1.1.4 Chromia and Other Ceramic Oxides

- 5.1.1.1.1.2 Carbides (including Cermets)

- 5.1.1.1.1.2.1 Chromium Carbides

- 5.1.1.1.1.2.2 Tungsten Carbides

- 5.1.1.1.2 Metals

- 5.1.1.1.2.1 Pure Metal and Alloys

- 5.1.1.1.2.2 Precious Metals

- 5.1.1.1.2.3 MCrAlY

- 5.1.1.1.3 Polymer and Other Coating Materials

- 5.1.1.2 Wires/Rods

- 5.1.1.3 Other Coating Materials (Liquid)

- 5.1.2 Supplementary Materials (Auxiliary Materials)

- 5.1.1 Coating Materials

- 5.2 Process Type

- 5.2.1 Combustion

- 5.2.2 Electric Energy

- 5.3 End-user Industry

- 5.3.1 Aerospace

- 5.3.2 Industrial Gas Turbines

- 5.3.3 Automotive

- 5.3.4 Electronics

- 5.3.5 Oil and Gas

- 5.3.6 Medical Devices

- 5.3.7 Energy and Power

- 5.3.8 Other End-user Industries

- 5.4 Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 ASEAN Countries

- 5.4.1.6 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Aisher APM LLC

- 6.4.2 Ametek Inc.

- 6.4.3 Aimtek Inc.

- 6.4.4 C&M Technologies GmbH

- 6.4.5 Castolin Eutectic

- 6.4.6 CenterLine (Windsor) Limited

- 6.4.7 CRS Holdings Inc.

- 6.4.8 Fisher Barton

- 6.4.9 Global Tungsten & Powders Corp.

- 6.4.10 HAI Inc.

- 6.4.11 HC Starck GmbH

- 6.4.12 Hoganas AB

- 6.4.13 Hunter Chemical LLC

- 6.4.14 Kennametal Stellite

- 6.4.15 Linde PLC

- 6.4.16 LSN Diffusion Ltd

- 6.4.17 Metallisation Limited

- 6.4.18 Metallizing Equipment Co. Pvt. Ltd

- 6.4.19 OC Oerlikon Management AG

- 6.4.20 Polymet Corporation

- 6.4.21 Powder Alloy Corporation

- 6.4.22 Saint-Gobain

- 6.4.23 Sandvik AB

- 6.4.24 Thermion

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Current Progress in Solution Precursor Plasma Spraying of Cermets

- 7.2 Recycling of Thermal Spray Processing Materials

- 7.3 Industrial Scale Production of Environmental Barrier Coatings (EBC) Thermal Spray Powders

- 7.4 Growth Prospects in the Oil and Gas Industry