|

市场调查报告书

商品编码

1640475

美国工厂自动化与工业控制:市场占有率分析、产业趋势、成长预测(2025-2030 年)United States Factory Automation and Industrial Controls - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

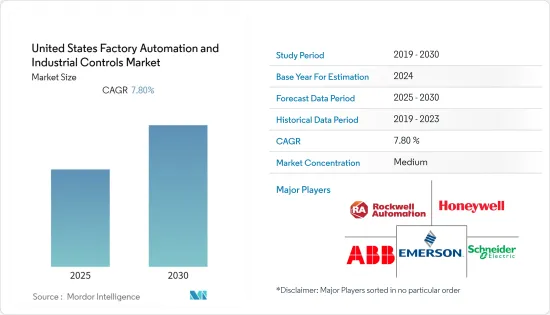

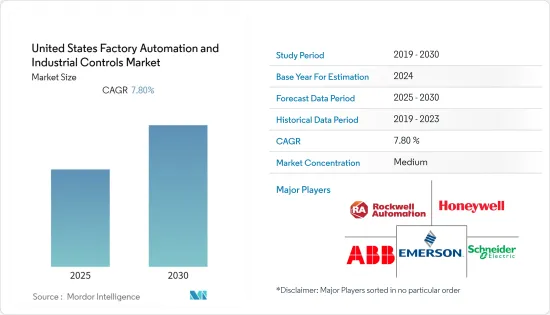

预计预测期内美国工厂自动化和工业控制市场的复合年增长率将达到 7.8%

关键亮点

- 工厂自动化和控制解决方案透过设计和建构完全整合的智慧控制系统(包括感测器、机器人、电脑、工业仪器和先进的资料处理解决方案),促进整个製造/生产设施的自动化。

- 这些解决方案主要用于减少公司对不可靠、容易出错的手动流程的依赖,并用机械化设备执行的逻辑编程命令和命令响应活动取而代之。通用工业製程控制器包括可程式逻辑控制器 (PLC) 和独立 I/O 模组。

- 美国工业领域受到了 COVID-19 的显着影响。工业领域对人力部署有多项限制,对工业部门的成长产生了不利影响。根据美国经济分析局(BEA)的资料,2020 年第一季,该国实际 GDP 折合成年率下降了 4.8%。然而,这场疫情大大提高了人们对自动化、人工智慧和工业物联网等先进技术的使用的认识。预计这些将对美国研究市场的成长产生长期影响。

- 近年来,尤其是疫情发生后,美国政府开始专注于透过「美国製造」等措施促进本土製造业,预计将推动受访市场的成长。例如,美国政府在2022年3月宣布,一款产品要获得联邦采购的「美国製造」认证,其零件价格的60%必须在国内生产。计划到 2024 年这一比例将增至 65%,到 2029 年将增至 75%。

美国工厂自动化和工业控制市场的趋势

分散式控制系统 (DCS) 预计将广泛采用

- DCS 是一个以流程为导向的平台,依靠互连的感测器、控制器、终端和致动器网路作为设施中所有生产业务的集中主控制器。因此,DCS 专注于製程控制和监控,让设备操作员可以单一视图查看所有设备操作。

- DCS 在闭合迴路控制平台上运行,能够实施更先进的製程自动化策略。这使得 DCS 成为控制单一设施或工厂操作的理想选择。此外,DCS 对于提供设施日常营运流程的最大可视性至关重要。

- DCS 系统的一大优点是分散式控制器、工作站和其他运算元素之间的数位通讯遵循P2P存取的原则。石化、核能、石油和天然气等製程工业越来越需要控制器,这些控制器能够在确定的设定点附近提供指定的製程公差,以实现更高的精度和控制。

- 这些需求正在推动 DCS 的采用。这些系统降低了操作复杂性、计划风险,并提供了在严苛的应用中实现敏捷製造的灵活性等功能。 DCS 能够整合各种工厂製程控制(如 PLC、涡轮机械控制、安全系统、第三方控制、热交换器、给水加热器、水质等),进一步推动了 DCS 在能源领域的应用。

- 鑑于人们对 DCS 等工业控制系统的网路安全问题日益担忧,一些组织和 DCS 供应商正在努力使分散式控制系统更加安全。

预计汽车业将大量采用

- 汽车工业是世界自动化製造设施中占有重要地位的主要产业之一。据观察,各汽车製造商的生产设施都已自动化,以保持精度和效率。此外,以电动车取代传统汽车的趋势日益增长,预计将进一步增加汽车产业的需求。

- 汽车业主要关注的问题之一是计划工期。具有快速回报期的计划以及低成本的自动化和创新可以帮助您透过提高效率来提高竞争力。

- 此外,製造过程中自动化程度的提高、数位化和人工智慧的参与是推动汽车领域工业机器人发展的关键因素。随着自动化的使用,汽车组装将大幅增加,代表着全球汽车产量的成长模式,同时节省成本,为该领域的智慧工厂普及铺平道路。

- 对于提供智慧工厂解决方案的供应商来说,美国是最有前景的市场之一。该国正在迅速采用先进的工业技术,并大规模使用资料进行生产,并将其与整个供应链中的各种製造系统结合。预计该市场在预测期内将经历显着的成长机会。

- 美国汽车工业是世界上最大的汽车工业,拥有通用汽车、福特、克莱斯勒等主要汽车製造商。根据 OICA 的数据,2021 年美国汽车产量约为 917 万辆,高于 2020 年的 882 万辆。由于汽车产业正在大量采用自动化技术来提高生产效率,该国提供了庞大的商机。

美国工厂自动化与工业控制产业概况

美国工厂自动化和工业控制市场参与者众多,竞争激烈。参与企业参与产品开发、伙伴关係、合併和收购等策略活动。市场的主要发展包括:

- 2021 年 4 月 - Google Cloud 与西门子合作简化製造流程并提高生产车间的效率。西门子计画将Google云端的顶尖资料云和人工智慧/机器学习(AI/ML)功能整合到其工厂自动化解决方案中,以协助製造商的生产流程。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概况

- 产业价值链分析

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争强度

- COVID-19 工业影响评估

第五章 市场动态

- 市场驱动因素

- 自动化的兴起

- 积极的政府政策和充满活力的新兴企业生态系统

- 市场问题

- 贸易紧张局势与货币政策收紧

- 行业政策法规

- 关键用案例和部署场景

第六章 市场细分

- 按类型

- 工业控制系统

- 分散式控制系统(DCS)

- 可程式逻辑控制器 (PLC)

- 监控、控制和资料采集 (SCADA)

- 产品生命週期管理 (PLM)

- 製造执行系统(MES)

- 人机介面 (HMI)

- 其他工业控制系统

- 现场设备

- 机器视觉

- 工业机器人

- 马达和驱动器

- 安全系统

- 感应器和变送器

- 其他现场设备

- 工业控制系统

- 按最终用户产业

- 石油和天然气

- 化工和石化

- 电力和公共产业

- 饮食

- 汽车与运输

- 药品

- 其他的

第七章 竞争格局

- 公司简介

- Schneider Electric SE

- Rockwell Automation Inc.

- Honeywell International Inc.

- Emerson Electric Company

- ABB Ltd

- Mitsubishi Electric Corporation

- Siemens AG

- Omron Corporation

- Yokogawa Electric Corporation

- Fanuc Corporation

第八章投资分析

第九章:未来展望

简介目录

Product Code: 53448

The United States Factory Automation and Industrial Controls Market is expected to register a CAGR of 7.8% during the forecast period.

Key Highlights

- Factory automation and control solutions facilitate the automation of an entire manufacturing/production facility by designing and constructing a fully integrated and intelligent control system, including sensors, robots, computers, industrial instruments, and advanced data processing solutions.

- These solutions are implemented primarily to reduce companies' reliance on unreliable and error-prone manual processes and replace them with command-response activities executed by logical programming commands and mechanized equipment. Some general-purpose industrial-process controllers include programmable logic controllers (PLCs) and stand-alone I/O modules.

- A notable impact of COVID-19 was observed in the US industrial sector. Due to several restrictions on staffing in industries, the growth of the industrial sector was negatively impacted. According to the Bureau of Economic Analysis (BEA) data, the country's real GDP decreased at an annual rate of 4.8% in the first quarter of 2020. However, the pandemic significantly enhanced awareness about using advanced technologies such as automation, AI, IIoT, etc. These are expected to have a long-term impact on the growth of the market studied in the United States.

- In recent years, especially after the pandemic, the US government started focusing on boosting its local manufacturing industries with initiatives like "Make in America," which is expected to drive the growth of the market studied. For instance, in March 2022, the US government announced that for the products to qualify as Made in America for federal procurement, 60% of the value of their parts should be manufactured in the country, which earlier accounted for 55%. The government plans to enhance it further to 65% in 2024 and 75% in 2029.

US Factory Automation and Industrial Controls Market Trends

Distributed Control Systems (DCS) are Expected to Witness Significant Adoption

- DCS are process-oriented platforms that depend on a network of interconnected sensors, controllers, terminals, and actuators to act as a centralized master controller for all of a facility's production operations. Thus, a DCS focuses on controlling and monitoring processes and allowing facility operators to see all facility operations in one place.

- DCS allows the implementation of more advanced process automation strategies because it operates on a closed-loop control platform. This makes DCS ideal for controlling operations at a single facility or factory. Additionally, a DCS is critical for maximizing the visibility of a facility's day-to-day operational processes.

- One of the significant benefits of DCS systems is that the digital communication between distributed controllers, workstations, and other computing elements follows the peer-to-peer access principle. To achieve greater precision and control in process industries, like the petrochemical, nuclear, and oil and gas industries, there is an increasing demand for controllers which offer specified process tolerance around an identified set point.

- These requirements have driven the adoption of DCS, as these systems provide lower operational complexity, project risk, and functionalities, like flexibility for agile manufacturing in highly-demanding applications. The ability of DCS to integrate PLCs, turbomachinery controls, safety systems, third-party controls, and various other plant process controls for heat exchangers, feedwater heaters, and water quality, among others, further drives the adoption of DCS in the energy sector.

- Considering the growing concern regarding cybersecurity issues with industrial control systems such as DCS, several organizations and DCS providers are taking initiatives to make distributed control systems more secure.

Automotive Industry is Expected to Exhibit Significant Adoption

- The automotive industry is one of the prominent sectors that hold a significant in worldwide automated manufacturing facilities. It is observed that the production facilities of various automakers are automated to maintain accuracy and efficiency. Further, the growing trend of replacing conventional vehicles with EVs is expected to further augment the automotive industry's demand.

- One of the primary concerns of the automotive industry is the duration of a project. Quick return-on-investment projects, along with low-cost automation and cost innovation, help the manufacturers to improve competitiveness through efficiency improvement.

- Moreover, the growing adoption of automation in manufacturing processes and digitization and AI involvement are primary factors driving industrial robots in the automotive sector. It has been identified that auto assembly increased significantly, using automation, showing a growth pattern in the number of cars being produced worldwide while simultaneously cutting costs, paving the way for the growth of smart factory implementation in this sector.

- The United States is among the most promising markets for vendors offering smart factory solutions, owing to its presence in some of the biggest industries. The country is fast adopting advanced industrial technologies, where data is being used on a large scale for production while integrating the data with various manufacturing systems throughout the supply chain. The market studied is expected to receive significant growth opportunities during the forecast period.

- The US automotive industry is among the largest globally and is home to some of the biggest auto manufacturers, such as General Motors, Ford, Chrysler, etc. According to OICA, in 2021, about 9.17 million motor vehicles were manufactured in the United States, compared to 8.82 million in 2020. The country offers a huge opportunity as the automotive sector accounts for the significant adoption of automation technologies to enhance production efficiency.

US Factory Automation and Industrial Controls Industry Overview

The United States factory automation and industrial controls market is competitive due to several players in the market. Players are involved in product development and strategic activities such as partnerships, mergers, and acquisitions. Some of the key developments in the market are:

- April 2021 - Google Cloud and Siemens collaborated to streamline production operations and boost shop floor efficiency. Siemens plans to integrate Google Cloud's top data cloud and artificial intelligence/machine learning (AI/ML) capabilities with its factory automation solutions to assist manufacturers in the manufacturing process.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitutes

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Assessment of COVID -19 impact on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Gaining Prominence for Automation Technologies

- 5.1.2 Proactive Government Policies and a Vibrant Startup Ecosystem

- 5.2 Market Challenges

- 5.2.1 Trade Tensions and Monetary Policy Tightening

- 5.3 Industry Policies and Regulations

- 5.4 Key Case Studies and Implementation Scenarios

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Industrial Control Systems

- 6.1.1.1 Distributed Control System (DCS)

- 6.1.1.2 Programable Logic Controller (PLC)

- 6.1.1.3 Supervisory Control and Data Acquisition (SCADA)

- 6.1.1.4 Product Lifecycle Management (PLM)

- 6.1.1.5 Manufacturing Execution System (MES)

- 6.1.1.6 Human Machine Interface (HMI)

- 6.1.1.7 Other Industrial Control Systems

- 6.1.2 Field Devices

- 6.1.2.1 Machine Vision

- 6.1.2.2 Industrial Robotics

- 6.1.2.3 Motors and Drives

- 6.1.2.4 Safety Systems

- 6.1.2.5 Sensors & Transmitters

- 6.1.2.6 Other Field Devices

- 6.1.1 Industrial Control Systems

- 6.2 By End-user Industry

- 6.2.1 Oil and Gas

- 6.2.2 Chemical and Petrochemical

- 6.2.3 Power and Utilities

- 6.2.4 Food and Beverage

- 6.2.5 Automotive and Transportation

- 6.2.6 Pharmaceutical

- 6.2.7 Other End-user Industries

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Schneider Electric SE

- 7.1.2 Rockwell Automation Inc.

- 7.1.3 Honeywell International Inc.

- 7.1.4 Emerson Electric Company

- 7.1.5 ABB Ltd

- 7.1.6 Mitsubishi Electric Corporation

- 7.1.7 Siemens AG

- 7.1.8 Omron Corporation

- 7.1.9 Yokogawa Electric Corporation

- 7.1.10 Fanuc Corporation

8 INVESTMENT ANALYSIS

9 FUTURE OUTLOOK

02-2729-4219

+886-2-2729-4219