|

市场调查报告书

商品编码

1643047

覆层:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Cladding - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

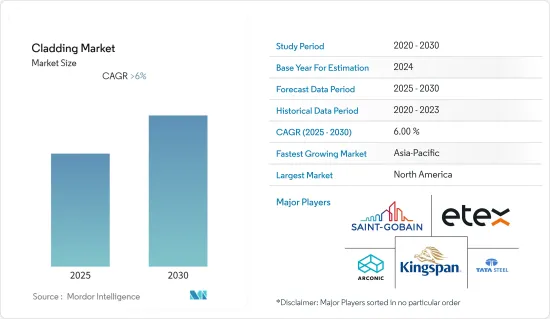

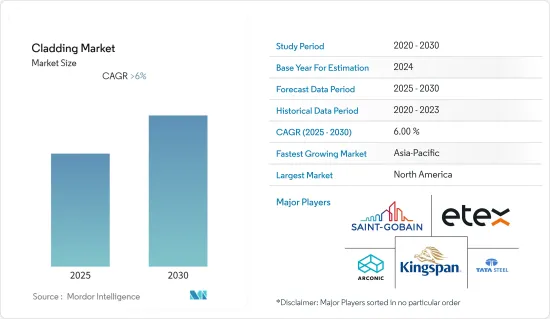

预计预测期内覆层市场复合年增长率将超过 6%。

在材料创新、节能解决方案需求激增以及严格的安全标准的推动下,覆层系统市场正在经历强劲成长。这一势头明显体现在广泛采用尖端覆层材料和技术,支持永续性并提高从住宅到商业等各个领域建筑的性能。

铝复合板(ACP)是一种复合材料,由于其耐用性、重量轻和成本效益而越来越受欢迎。领先製造商 Stakbond 报告称,ACP 的需求激增,尤其是在通风立建筑幕墙。这些建筑幕墙现已成为永续建筑的主要内容,预计到 2024 年 11 月将能源消耗减少高达 30%,提高效率并有助于获得 LEED 等绿色认证。 ACP 的日益普及也反映了其设计的多功能性,使建筑师和建筑商能够实现功能和美学目标。此外,整合智慧覆层系统的趋势也日益增长。

2024 年 7 月,Sto SE & Co. 推出了一款采用奈米技术的自清洁建筑幕墙。建筑幕墙的设计旨在防尘并降低维护成本,符合当代建筑的永续性和美学诉求。这项技术创新不仅降低了营运成本,还延长了覆层系统的使用寿命,使其成为长期投资的理想选择。

人们对消防安全的日益关注推动了对先进覆层系统的需求,特别是在高层住宅维修中。英国格兰菲尔大楼 (Grenfell Tower) 2024 年的维修凸显了防火覆层的迫切需求。这样的维修不仅符合严格的消防规定,也满足了都市区对不燃材料的需求。市场正在转向矿物板和防火铝复合材料等材料,这些材料在不牺牲设计灵活性的情况下提供了更高的安全性。

同时,亚太地区的快速都市化正在推动对经济实惠且耐用的包层材料的需求。作为印度2024年11月宣布的「智慧城市使命」的一部分,新城市发展将采用节能的包层材料,旨在减少能源消耗并增强不断扩张的城市的永续性。该倡议强调,人们越来越重视将先进的覆层系统纳入城市规划,以实现能源效率和环境责任的双重目标。

包层市场趋势

覆层市场对扁平轧延碳钢的需求不断增加

永续性、基础设施扩张和对高性能建筑材料的需求推动了覆层系统中扁钢的需求不断增长。在越来越多的全球建筑项目中,扁轧延碳钢因其耐用性、成本效益和美观性而受到重视。

在新兴市场,尤其是中国,快速的都市化和基础设施发展正在推动需求。在中国,建筑业对钢铁的强劲需求凸显了扁轧延产品作为覆层系统关键组成部分的地位。公共基础设施和住宅开发的持续投资正推动对扁平材的需求大幅成长。根据2024年产业报告,作为钢材主要消费产业的建筑业对扁钢的使用量正在稳步增长。这一成长符合中国雄心勃勃的建设目标,包括大型基础设施计划和城市住宅开发,进一步推动了对扁平材产品的需求。

钢铁製造商正在增加扁钢等高强度钢材的产量,以满足以耐用性为优先考虑的建筑计划的需求。为了满足激增的需求,新日铁正在推出包括 ZAM(R)-EX 在内的专用产品。这种高强度钢专为覆层应用而设计,其耐腐蚀性使其非常适合以长寿命为优先考虑的户外使用。新日铁 ZAM®-EX 将于 2023 年首次亮相,彰显出该产业将转向用于现代覆层系统(尤其是建筑领域)的优质钢铁产品。

此外,钢铁生产技术的进步正在推动对碳钢平板的需求。该行业向永续方法的转变,特别是电弧炉(EAF)的采用,正在加速。与传统製造方法相比,电弧炉技术可以生产出更高品质的钢材,而且对环境的影响更小。这一趋势在覆层系统市场尤为明显,对永续和耐用材料的需求日益增加。根据2024年产业报告,钢铁製造商越来越多地采用EAF製程来遵守监管要求并满足对环保建筑材料日益增长的需求。

配音偏好的兴起

在全球范围内,对耐用且有弹性的外部包层材料的需求正在增加,尤其是在住宅建筑领域。这种增长是由环境问题和对能够承受极端天气、只需极少维护并支持永续建筑实践的材料的需求所推动的。因此,建筑和材料领域的主要企业正在进行创新,以满足人们对更持久、低维护的覆层系统日益增长的偏好。

对永续建筑解决方案的需求不断增加,促使 James Hardie 等行业领导者开发旨在减少碳足迹的产品。例如,James Hardie 在24财年在北美推出了低碳水泥技术。此外,该公司的 Hardie(R) Artisan Lap Siding 于 2024 年 4 月被 Green Builder 评为 2024 年度永续产品,突显了其气候适应力和耐用性。这些措施符合更广泛的产业趋势,即将永续材料纳入住宅建筑,解决环境问题,同时也满足消费者对更环保住宅的期望。

除了永续性之外,纤维水泥包层也因其强度和防火性而越来越受欢迎。 James Hardie 纤维水泥墙板产品在野火多发地区的应用越来越广泛。例如,根据 2024 年 8 月报道,科罗拉多的 Panorama Home计划使用纤维水泥包层来降低发生野火的风险。此外,Ashgrove Cement 正在与 James Hardie 合作试行包层生产的回收解决方案,以减少废弃物并提高产品的永续性。材料科学的这些进步使住宅建筑业能够满足对耐用、易于维护和环保的建筑解决方案日益增长的需求。

覆层行业概况

覆层市场是一个竞争激烈的市场,有多个区域参与者。在全球范围内存在的公司非常少。覆层市场的主要企业包括 Arconic Corporation、Tata Steel Corporation、Etex Group、Compagnie de Saint-Gobain SA 和 Kingspan Group。企业正在开发新型涂层材料以满足市场的各种需求。例如,圣戈班公司正在利用平板玻璃和高性能材料对覆层部分进行创新。室内解决方案包括隔热材料和石膏产品,而室外解决方案包括管道、工业砂浆和外部产品。公司正在采取併购策略来增加市场占有率。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概况

- 市场驱动因素

- 节能建筑解决方案的激增

- 自清洁建筑幕墙系统的需求

- 市场限制

- 先进复合材料的初始成本较高

- 满足法规遵循和消防安全标准的挑战

- 市场机会

- 光伏(PV)系统集成

- 价值链/供应链分析

- 波特五力分析

- 购买者/消费者的议价能力

- 供应商的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争强度

- 深入了解建筑和覆层市场的趋势

- 洞察市场技术颠覆

- 深入了解市场中的政府监管

- 深入了解地缘政治和疫情对市场的影响

第五章 市场区隔

- 按材质

- 金属

- 红陶

- 纤维水泥

- 混凝土的

- 陶瓷製品

- 木头

- 乙烯基塑料

- 其他材料

- 按组件类型

- 墙

- 屋顶

- 门窗

- 其他组件类型

- 按应用

- 住宅

- 非住宅

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 北美其他地区

- 欧洲

- 德国

- 英国

- 法国

- 俄罗斯

- 西班牙

- 其他欧洲国家

- 亚太地区

- 印度

- 中国

- 韩国

- 日本

- 其他亚太地区

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 其他中东和非洲地区

- 北美洲

第六章 竞争格局

- 市场集中度概览

- M&A

- 公司简介

- Arconic

- Tata Steel Ltd

- Compagnie de Saint Gobain SA

- Etex Group

- Kingspan Group

- James Hardie Industries PLC

- Boral Limited

- CSR Building Products

- Nichiha Corporation

- Cembrit Holding AS

- DowDuPont

- 其他公司

第七章 市场机会与未来趋势

第 8 章 附录

The Cladding Market is expected to register a CAGR of greater than 6% during the forecast period.

The cladding systems market is witnessing robust growth, fueled by material innovations, a surge in demand for energy-efficient solutions, and stricter safety standards. This momentum is evident in the broad embrace of cutting-edge cladding materials and technologies, championing sustainability and bolstering building performance across sectors, from residential to commercial.

Aluminum composite panels (ACPs), a type of composite material, are gaining traction for their durability, lightweight nature, and cost efficiency. Leading manufacturer STACBOND reports a surge in demand for its ACPs, particularly in ventilated facades. These facades, now a staple in sustainable construction, promise up to a 30% reduction in energy consumption, boosting efficiency and aiding in green certifications like LEED as of November 2024. The increasing adoption of ACPs is also attributed to their versatility in design, allowing architects and builders to achieve both functional and aesthetic objectives. Furthermore, there's a growing trend towards integrating smart cladding systems.

In July 2024, Sto SE & Co. unveiled a nanotechnology-driven self-cleaning facade, designed to repel dirt and slash maintenance costs, aligning with modern buildings' sustainability and aesthetic aspirations. This innovation not only reduces operational expenses but also enhances the lifespan of the cladding system, making it a preferred choice for long-term investments.

Heightened fire safety concerns are propelling the demand for advanced cladding systems, especially in retrofitting high-rise residential buildings. The 2024 renovation of the Grenfell Tower in the UK highlights the critical need for fire-resistant cladding. Such upgrades not only adhere to stringent fire safety regulations but also address the urban demand for non-combustible materials. The market is witnessing a shift towards materials like mineral-based panels and fire-rated aluminum composites, which offer enhanced safety without compromising on design flexibility.

Meanwhile, in the Asia-Pacific, swift urbanization is spurring a quest for affordable, durable cladding. As part of India's Smart Cities Mission, unveiled in November 2024, new urban developments will feature energy-efficient cladding, targeting reduced energy consumption and bolstered sustainability in expanding cities. This initiative underscores the growing emphasis on integrating advanced cladding systems into urban planning to meet the dual objectives of energy efficiency and environmental responsibility.

Cladding Market Trends

Rising Demand for Flat-Rolled Carbon Steel in the Cladding Market

The rising demand for flat-rolled carbon steel in cladding systems is driven by sustainability, infrastructure expansion, and the need for high-performance construction materials. As global construction grows, flat-rolled carbon steel is valued for its durability, cost-effectiveness, and aesthetics.

Emerging markets, especially China, are fueling demand due to rapid urbanization and infrastructure development. In China, the construction sector's strong steel demand highlights flat-rolled products as key components in cladding systems. Ongoing investments in public infrastructure and residential developments are fueling a significant surge in demand for flat steel. Industry reports from 2024 indicates that the construction sector, a major consumer of steel, is witnessing a steady increase in the use of flat-rolled carbon steel. This growth aligns with China's ambitious construction goals, which include large-scale infrastructure projects and urban housing developments, further driving the demand for flat steel products.

Steelmakers are ramping up their production of high-strength steel products, like flat-rolled carbon steel, to cater to construction projects that prioritize durability. Responding to this surge in demand, Nippon Steel has rolled out specialized offerings, notably ZAM(R)-EX. This high-strength steel, tailored for cladding applications, boasts enhanced corrosion resistance, making it a top choice for outdoor settings where longevity is paramount. Nippon Steel's 2023 debut of ZAM(R)-EX underscores the industry's pivot towards premium steel products, especially for modern cladding systems in construction.

Furthermore, advancements in steel production technology are driving the demand for flat-rolled carbon steel. The industry's transition to sustainable methods, particularly the adoption of electric arc furnaces (EAF), is accelerating. EAF technology enables the production of high-quality steel while reducing environmental impact compared to traditional methods. This trend is particularly significant in the cladding systems market, where demand for sustainable and durable materials is on the rise. As per 2024 industry reports, steel producers are increasingly adopting EAF processes to comply with regulatory requirements and address the growing demand for eco-friendly building materials.

Growing Preferences for Durb

Globally, the demand for durable and resilient wall cladding materials is increasing, particularly in residential construction. This growth is driven by environmental concerns and the need for materials that can withstand extreme weather, require minimal maintenance, and support sustainable building practices. Consequently, major players in the construction and materials sector are innovating to meet the rising preference for long-lasting, low-maintenance cladding systems.

In response to the growing demand for sustainable building solutions, industry leaders like James Hardie are developing products aimed at reducing carbon footprints. For instance, James Hardie introduced its low-carbon cement technology across North America in FY24. Additionally, their Hardie(R) Artisan Lap Siding was named Green Builder's 2024 Sustainable Product of the Year in April 2024, highlighting its climate resilience and durability. These efforts align with a broader industry trend toward incorporating sustainable materials in residential construction, addressing environmental concerns while meeting consumer expectations for eco-friendly housing solutions.

In addition to sustainability, fiber cement cladding is gaining popularity due to its strength and fire resistance. James Hardie's fiber cement siding products have seen increased adoption in wildfire-prone regions. For instance, in FY24, the Panorama Home project in Colorado utilized fiber cement cladding to mitigate wildfire risks, as reported in August 2024. Furthermore, Ash Grove Cement, in collaboration with James Hardie, is piloting recycling solutions for cladding production to reduce waste and enhance product sustainability. These advancements in material science are enabling the residential construction sector to address the growing demand for durable, low-maintenance, and environmentally responsible building solutions.

Cladding Industry Overview

The cladding market is competitive in nature, with various regional players present in the market. Very few companies are present at the global level. Some of the major players in the cladding market are Arconic Inc., Tata Steel Ltd., Etex Group, Compagnie de Saint-Gobain SA., and Kingspan Group, among others. Players are innovating new cladding materials in order to meet the different demands in the market. For instance, Saint-Gobain S.A. is innovating in the cladding material segment with flat glass and high-performance materials. The interior solutions comprise insulation and gypsum products, whereas the exterior solutions consist of pipes, industrial mortars, and exterior products. Companies are adopting acquisition and merger strategies to gain market share.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surge for Energy-Efficient Building Solutions

- 4.2.2 Demand for Self-Cleaning Facade Systems

- 4.3 Market Restraints

- 4.3.1 High Upfront Costs of Advanced Cladding Materials

- 4.3.2 Challenges in Meeting Regulatory Compliance and Fire Safety Standards

- 4.4 Market Opportunities

- 4.4.1 Integration of Photovoltanic (PV) Systems

- 4.5 Value Chain / Supply Chain Analysis

- 4.6 Porter's Five Forces Analysis

- 4.6.1 Bargaining Power of Buyers/Consumers

- 4.6.2 Bargaining Power of Suppliers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitute Products

- 4.6.5 Intensity of Competitive Rivalry

- 4.7 Insights on Trends in the Construction and Cladding Market

- 4.8 Insights on Technological Disruptions in the Market

- 4.9 Insights on Government Regulations in the Market

- 4.10 Insights on Impact of Geopolitics and Pandemic on the Market

5 MARKET SEGMENTATION

- 5.1 By Material

- 5.1.1 Metal

- 5.1.2 Terracotta

- 5.1.3 Fiber Cement

- 5.1.4 Concrete

- 5.1.5 Ceramics

- 5.1.6 Wood

- 5.1.7 Vinyl

- 5.1.8 Other Materials

- 5.2 By Component Type

- 5.2.1 Wall

- 5.2.2 Roofs

- 5.2.3 Windows and Doors

- 5.2.4 Other Component Types

- 5.3 By Application

- 5.3.1 Residential

- 5.3.2 Non-residential

- 5.4 By Geography

- 5.4.1 North America

- 5.4.1.1 United States

- 5.4.1.2 Canada

- 5.4.1.3 Mexico

- 5.4.1.4 Rest of North America

- 5.4.2 Europe

- 5.4.2.1 Germany

- 5.4.2.2 United Kingdom

- 5.4.2.3 France

- 5.4.2.4 Russia

- 5.4.2.5 Spain

- 5.4.2.6 Rest of Europe

- 5.4.3 Asia-Pacific

- 5.4.3.1 India

- 5.4.3.2 China

- 5.4.3.3 South Korea

- 5.4.3.4 Japan

- 5.4.3.5 Rest of Asia-Pacific

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 United Arab Emirates

- 5.4.5.2 Saudi Arabia

- 5.4.5.3 Rest of the Middle-East and Africa

- 5.4.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration Overview

- 6.2 Megers and Acquisitions

- 6.3 Company Profiles

- 6.3.1 Arconic

- 6.3.2 Tata Steel Ltd

- 6.3.3 Compagnie de Saint Gobain SA

- 6.3.4 Etex Group

- 6.3.5 Kingspan Group

- 6.3.6 James Hardie Industries PLC

- 6.3.7 Boral Limited

- 6.3.8 CSR Building Products

- 6.3.9 Nichiha Corporation

- 6.3.10 Cembrit Holding AS

- 6.3.11 DowDuPont*

- 6.4 Other Companies