|

市场调查报告书

商品编码

1643157

亚洲工业 4.0:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Asia Industry 4.0 - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

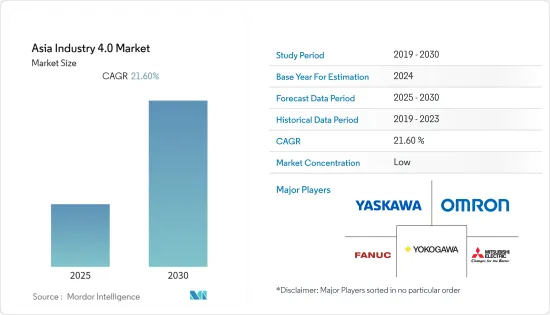

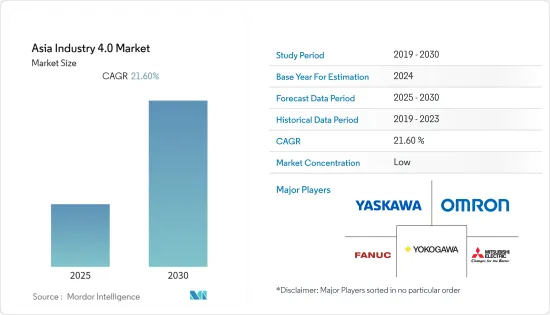

预计预测期内亚洲工业 4.0 市场复合年增长率将达到 21.6%。

主要亮点

- 亚洲是最早采用科技进步的地区之一。这些新兴市场在工业自动化应用方面具有关键优势,因为它们没有重建传统自动化系统或投资机械的负担。

- 机器人技术对于中国的智慧製造目标和综合产业政策至关重要。虽然政府机构的组成略有不同(工信部再次掌舵),但《智慧製造发展规划》的发布包括在2022年发布机器人产业相关的五年发展规划。以5G为代表的工业革命4.0已快速启动,中国已取得良好开端。

- 华为表示,其工业级基于无线专网的关键通讯解决方案为工业 4.0使用案例提供了难以想像的可能性,从机器远程操作到云机器人、流程自动化、预测性资产维护、辅助/自动驾驶汽车、CCTV监控以及任务关键型一键通话和一键视频,全部通过单一网络基础设施实现。

- 过去十年的技术变革彻底改变了工业生产的组织方式,影响了生产流程和供应链。工业4.0(以下简称工业4.0)将人工智慧、物联网、机器学习、云端运算、分析等新技术融入製造业生产营运与流程,推动智慧製造新时代的到来。製造业的数位技术将推动自动化和自我优化,使该地区整个价值链的运作更加高效。

- 工业革命 4.0 将由四个关键因素推动:超高效处理技术(晶片)、广泛的网路应用、机器学习和人工智慧。上一次工业革命所伴随的自动化浪潮普及了大规模同质生产系统,而工业 4.0 则推动了更客製化的工业生产。随着工业 4.0 的出现,一种新的生产模式正在出现,其中 3D 列印机、自动化系统、机器人、资料交换和资料传输在智慧工厂环境中得到有效利用。这使得生产过程精益而灵活,并确保资源的最佳利用。

- 由于新兴国家疫情期间亚洲国家实施了严格的停工措施,工业4.0的发展受到了长达六到八个月的影响。工厂关闭和投资转移是主要因素。多家工厂自动化解决方案供应商已关闭其工厂,以遏制病毒传播。人工智慧、大规模自动化、工业通讯、巨量资料、机器人和3D列印等颠覆性技术正在重塑该地区疫情后的製造业格局。

亚洲工业 4.0 市场趋势

製造业占很大市场占有率

- 製造业是亚太地区经济的主要贡献者,目前正在经历快速的技术和数位转型。由于可以获得廉价劳动力,製造公司越来越多地将业务迁往东南亚以削减成本。

- 工业IoT(IIoT) 正在整个製造业中广泛应用。此外,云端处理、行动行动运算等电脑和网路技术也被引入这些系统,预计将推动该国采用先进技术。

- 根据 MOSPI,2022 年 1 月,21 财年全印度製造业工业生产指数为 116.9。在印度,製造业已逐渐成为高成长产业之一。 「印度製造」计画使印度成为全球製造业中心,并获得了国际社会对印度经济的认可。此外,通用电气、西门子、HTC、东芝和波音等製造业巨头都已在印度建立或正在建立製造厂。这些趋势预计将推动未来工厂采用工业 4.0。

- 三菱公司投资超过300亿日圆增加工厂自动化系统产品的产量以满足日益增长的需求,也推动了这一趋势。此外,为提高产能,该公司计划在爱知县现有工厂附近建立新工厂,取代名古屋现有的工厂。预计类似的措施将推动该地区製造业对工业 4.0 技术的应用。

日本取得显着成长

- 日本是亚太地区转型为自动化工业经济和采用工业4.0成长最快的经济体之一。日本正成为向亚太地区区域市场供应自动化产品的製造地。

- 众多汽车製造商、食品工业和电子製造业的存在使日本成为该地区的重要市场。凭藉高度发展的自动化和机器人产业,该国可被视为生产过程自动化和机器人技术采用的全球领导者。

- 日本製造业贡献了日本名目国内生产总值(GDP)的约20%。据国际货币基金组织(IMF)称,日本的製造业自综合税(ITC)出台以来取得了长足的发展。日本的工业4.0带动了协作机器人、人工智慧机器人等尖端技术的发展。透过在各个流程中实施这些措施,公司能够提高效率并减少错误。预计职场安全法规的不断加强和生产能力的不断提高将推动对机器人系统的需求。

- 该国日益增多的数位化倡议和工业 4.0 的兴起预计将为市场提供良好的机会。儘管影响该国经济的因素多种多样,但该国经济仍保持稳定成长。此外,电子和汽车产业是日本生产率最高的製造业产业,日常工作严重依赖自动化。这一因素可能会推动各种商品製造过程的数位转型和自动化。

亚洲工业 4.0 产业概况

亚洲工业4.0市场竞争激烈。由于大大小小的参与者众多,市场集中度很高。市场的主要参与者包括三菱电机、OMRON、横河电机、FANUC、安川电机、罗伯特博世有限公司和通用电气公司。

2022 年 2 月,三菱电机亚洲工厂自动化与工业部门以二级成员身分加入新加坡 ARTC。为响应新加坡智慧工业就绪指数,先进再製造技术中心(ARTC)是一个透过强大的官民合作关係关係建立的现代化平台,它正在扩大其在工业物联网(IIoT)服务领域的立足点,为製造业开发整合解决方案,以加速其数位转型并增加对工业4.0技术的采用。

2022 年 2 月,日本製造集团三菱电机携手同国 NTT Docomo 加入其在泰国的新工业 4.0 联盟,提供私人 5G 以及其他合作伙伴的智慧製造解决方案。三菱电机称这案例泰国首次采用日本製造的5G设备。两家公司计划于夏季末在泰国建设一个新的私人 5G 设施,作为政府泰国 4.0计划的战略定位。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

- COVID-19 市场影响

第五章 市场动态

- 市场驱动因素

- 该地区积极的政府措施和相关人员的合作

- 工业机器人需求不断成长

- 中小企业如何因应数位转型

- 市场挑战

- 采用工业 4.0 的投资报酬率缺乏认识

- 需要大量投资才能实现利润

- 劳动力和标准化挑战

第六章 市场细分

- 依技术类型

- 工业机器人

- IIoT

- 人工智慧和机器学习

- 区块链

- 扩增实境

- 数位双胞胎

- 3D 列印

- 其他技术

- 按最终用户产业

- 製造业

- 车

- 石油和天然气

- 能源与公共产业

- 电子/铸造厂

- 饮食

- 航太和国防

- 其他最终用户产业

- 按国家

- 中国

- 韩国

- 日本

- 印度

- 印尼

- 亚洲其他地区

第七章 竞争格局

- 公司简介

- Mitsubishi Electric

- Omron Corporation

- Yokogawa Electric Corporation

- Fanuc Corporation

- Yaskawa Electric Corporation

- Robert Bosch GmbH

- General Electric Company

- ABB Ltd

- Cisco Systems Inc.

- Intel Corporation

- IBM Corporation

- Denso Corporation

第八章投资分析

第九章:市场的未来

The Asia Industry 4.0 Market is expected to register a CAGR of 21.6% during the forecast period.

Key Highlights

- Asia has been an early adopter of technological advancements. The market in these developing economies poses a key advantage in implementing industrial automation since they are not tormented by rebuilding legacy automation systems and machine investments.

- Robotics is crucial to China's smart manufacturing ambitions and comprehensive industrial policy. A slightly different variation in the configuration of the government agencies (with MIIT again at the helm) announced a related 5-year development plan for the robotics industry in 2022 as the release of the smart manufacturing development plan. The fast pace toward the 5G-powered industry revolution 4.0 is on, and China has a strong head start.

- According to Huawei, critical communications solutions based on industrial-grade private wireless offer unimaginable possibilities to the power Industry 4.0 use cases, from machine remote control to cloud robotics, process automation, predictive asset maintenance, assisted/autonomous vehicles, CCTV monitoring, and mission-critical push-to-talk and push-to-video, all on a single network infrastructure.

- Technological changes in the last decade revolutionized the organization of industrial production, influencing production processes and supply chains. Industry 4.0, hereafter, has integrated new technologies such as AI, IoT, ML, cloud computing, and analytics into manufacturing production operations and processes, propelling a new era of smart manufacturing. Digital technologies in manufacturing promote automation and self-optimization, leading to the efficiency of operations across the value chain in the region.

- Industry revolution 4.0 is fuelled by four significant components: hyper-efficient processing technology (chips), widespread internet penetration, machine learning, and artificial intelligence. While the waves of automation due to past industrial revolutions popularised the mass-homogeneous production systems, Industry 4.0 brings more customized industrial production to the fore. With Industry 4.0, new production models are emerging where 3-D printers, automated systems, robots, data exchanges, and data exchanges are used effectively in an environment of smart factories. This will make the production processes lean and flexible, enabling optimum resource utilization.

- As Asian countries experienced strict lockdowns during the COVID-19 pandemic, the developments concerning Industry 4.0 were impacted for 6-8 months. Factory closures and shifts in investments were primary factors for the same. Multiple vendors of factory automation solutions shut their facilities in the wake of curbing the spread of the virus. Innovative technologies, such as artificial intelligence (AI), mass automation, industrial communications, big data, robotics, and 3D printing, are transforming the regional manufacturing landscape post-pandemic.

Asia Industry 4.0 Market Trends

Manufacturing Industry to Hold Significant Market Share

- The manufacturing industry is a key contributor to the economy of the Asia-Pacific region and is presently undergoing a rapid technological digital transformation. Manufacturing firms are increasingly moving their operations to Southeast Asia to cut costs due to inexpensive workforce availability.

- Industrial IoT (IIoT) is being adopted significantly in the region of the manufacturing industry. Further, computer and network technologies, such as cloud computing and mobile computing, are also being implemented in these systems, which is expected to boost the adoption of advanced technologies in the country.

- According to MOSPI, in January 2022, the index of industrial production for the manufacturing sector across India in the financial year of 2021 stood at 116.9. In India, the manufacturing industry has gradually emerged as one of the high-growth sectors. The 'Make in India' program places India on the global map as the manufacturing hub provides international recognition to the Indian economy. Moreover, manufacturing giants such as GE, Siemens, HTC, Toshiba, and Boeing, have either set up or are setting up manufacturing plants in India. These trends are expected to boost the adoption of Industry 4.0 in their plants in the future.

- The trend is also augmented by Mitsubishi's investment of more than JPY 30 billion to increase the output of its factory automation system products to meet growing demand. Further, the company plans to establish a new plant near its existing facility in Aichi Prefecture and rebuild an existing plant in Nagoya to bolster production capacity. Similar initiatives are expected to boost the adoption of Industry 4.0 technologies across the region's manufacturing industry.

Japan to Witness Significant Growth

- Japan has been transforming into an automated industrial economy and adopting Industry 4.0 faster in the Asia-Pacific region. The government of Japan has been emerging as a manufacturing hub for automation products and supplies to the regional markets in the Asia-Pacific region.

- The presence of multiple automobile manufacturers, the food processing industry, and the electronic product manufacturing industry makes Japan an essential market in the region. The country with highly-developed automation technologies and a robotic sector can be regarded as the global leader in the automation of production processes and employment of robotics.

- The manufacturing industry in Japan contributes around 20% to the country's nominal Gross Domestic Product (GDP). According to the International Monetary Fund, the country's manufacturing sector gained significant ground by implementing the Integrated Manufacturing Tax (ITC). Industry 4.0 in Japan has led to the development of advanced technologies, such as collaborative and AI-enabled robots. These have allowed companies to improve their efficiency and reduce errors by implementing them in various processes. Increasing workplace safety regulations and improving production capabilities are expected to drive demand for robotic systems.

- The increasing number of digitization initiatives in the country and the emergence of Industry 4.0 are expected to provide promising opportunities for the market. Even with the presence of various factors that have affected the country's economy, it has still managed to grow steadily. Moreover, the electronics and automotive sectors are Japan's most productive manufacturing sectors, which rely heavily on automation daily. This factor is likely to drive digital transformation and automation in the manufacturing processes of various goods.

Asia Industry 4.0 Industry Overview

The Asian Industry 4.0 market is very competitive. The market is highly concentrated due to the presence of various small and large players. Some of the significant players in the market are Mitsubishi Electric, Omron Corporation, Yokogawa Electric Corporation, Fanuc Corporation, Yaskawa Electric Corporation, Robert Bosch GmbH General Electric Company, and many more.

In February 2022, Mitsubishi Electric Asia's Factory Automation & Industrial Division joined Singapore's ARTC as a Tier 2 Member. The Advanced Remanufacturing and Technology Centre (ARTC), a contemporary platform built upon solid public-private partnerships company, is expanding its foothold around the Industrial Internet of Things (IIoT) services by developing integrated solutions for manufacturing companies to accelerate digital transformation and scaling up its adoption of Industry 4.0 technologies in response to Singapore's Smart Industry Readiness Index.

In February 2022, the Japanese manufacturing group Mitsubishi Electric inducted the country mate NTT Docomo into its new Industry 4.0 alliance in Thailand to offer private 5G with smart manufacturing solutions from other partners. Mitsubishi Electric called it the first case of 5G with Japanese equipment in Thailand. The companies will build a new private 5G set up in the country by the end of the summer, strategically located for the government's Thailand 4.0 project.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Favorable Governmental Initiatives and Collaborations Between Stakeholders in the Region

- 5.1.2 Growth in Demand for Industrial Robotics

- 5.1.3 Digital Transformation Initiatives Undertaken by SMEs

- 5.2 Market Challenges

- 5.2.1 Relative Lack of Awareness on the ROI Related to Adoption of Industry 4.0

- 5.2.2 Need For Significant Investments to Realize Benefits

- 5.2.3 Workforce and Standardization Related Challenges

6 MARKET SEGMENTATION

- 6.1 By Technology Type

- 6.1.1 Industrial Robotics

- 6.1.2 IIoT

- 6.1.3 AI and ML

- 6.1.4 Blockchain

- 6.1.5 Extended Reality

- 6.1.6 Digital Twin

- 6.1.7 3D Printing

- 6.1.8 Other Technology Types

- 6.2 By End-user Industry

- 6.2.1 Manufacturing

- 6.2.2 Automotive

- 6.2.3 Oil and Gas

- 6.2.4 Energy and Utilities

- 6.2.5 Electronics and Foundry

- 6.2.6 Food and Beverage

- 6.2.7 Aerospace and Defense

- 6.2.8 Other End-user Industries

- 6.3 By Country

- 6.3.1 China

- 6.3.2 South Korea

- 6.3.3 Japan

- 6.3.4 India

- 6.3.5 Indonesia

- 6.3.6 Rest of Asia

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Mitsubishi Electric

- 7.1.2 Omron Corporation

- 7.1.3 Yokogawa Electric Corporation

- 7.1.4 Fanuc Corporation

- 7.1.5 Yaskawa Electric Corporation

- 7.1.6 Robert Bosch GmbH

- 7.1.7 General Electric Company

- 7.1.8 ABB Ltd

- 7.1.9 Cisco Systems Inc.

- 7.1.10 Intel Corporation

- 7.1.11 IBM Corporation

- 7.1.12 Denso Corporation