|

市场调查报告书

商品编码

1644353

印度雷射:市场占有率分析、行业趋势和统计、成长预测(2025-2030 年)India Laser - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

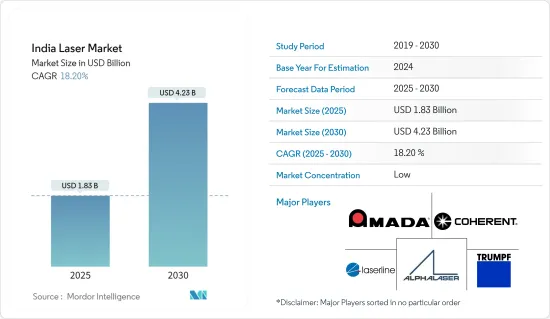

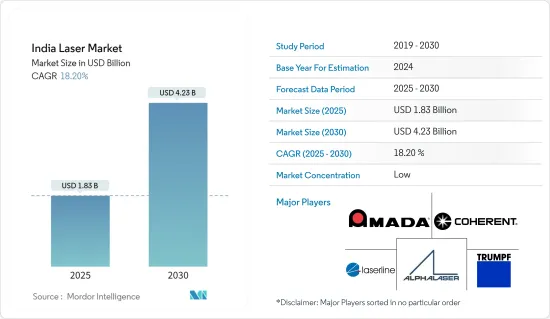

预计 2025 年印度雷射市场规模为 18.3 亿美元,到 2030 年将达到 42.3 亿美元,预测期内(2025-2030 年)的复合年增长率为 18.2%。

市场驱动因素包括汽车、重工业、电子、基础设施、铁路、耐用消费品和其他行业。

主要亮点

- 传统焊接技术在製造业领域已经占有了一席之地。然而,高科技雷射焊接的进步使其在许多工业应用中变得经济高效。一些雷射焊接系统可以进一步配置以执行附加功能,例如切割,钻孔和序列化。在各种应用中,雷射焊接的行进速度比 TIG 焊接快 5 到 10 倍,比 MIG 焊接快 3 到 5 倍。

- 根据印度 Laser Technology Pvt. Ltd (LTPL) 的数据,雷射打标在设备销售方面最为普遍,但雷射切割是 2021 年最大的收益贡献者。雷射切割仍然是印度最受欢迎的雷射应用,预计至少在未来几年仍将保持成长。这主要是由于雷射加工机成本下降以及政府对某些领域的干预,尤其是基础设施和汽车领域。然而,大多数机器都是从中国进口的。该公司预计未来几年雷射切割产业将成长 1.5 倍。

- 然而,监管合规对市场是一个限制因素。雷射技术为固体雷射和光纤雷射提供了应用。这些雷射使用钕、铬、铒和镱等稀土元素,稀土元素的加工和精製可能会对环境造成有害影响。其中一个主要影响是来自泥浆尾矿的放射性污染。

- COVID-19 对市场的影响可能会阻碍所研究市场的预期成长。由于一些製造厂被迫关闭或暂停生产,一些市场相关人员的收益出现下降。然而,预计预测期内市场开发创新将推动医疗保健产业的市场成长。

- 例如,2022 年 7 月,MaxiVision 眼科医院推出了 Technolas Teneo 317 Model 2。德国技术团队研发了最先进的高性能准分子雷射:Teneo M2。我们为各种患者提供个人化的护理,包括患有散光、远视、近视和老花眼的患者。

印度雷射市场趋势

汽车产业经历显着成长

- 印度雷射市场受汽车业推动。这些企业主要位于普纳、班加罗尔、清奈、马内萨尔(靠近德里)和艾哈默德巴德等汽车中心,占据了金属切割雷射加工车间市场的 80% 以上。工具机产业遍布印度各地,但在旁遮普邦、昌迪加尔、卢迪亚纳和哥印拜陀更为盛行。同时,钻石加工雷射主要集中在苏拉特,那里有超过10,000-12,000台雷射正在使用中。

- 汽车业占印度製造业GDP的49%和该国整体GDP的7.1%,而该行业一年多来一直在放缓。然而,新冠疫情爆发后,出现了V型復苏。根据印度品牌股权基金会(IBEF)预测,到2026年,印度汽车产业(包括零件製造)的规模将达到2,514亿至2,828亿美元。预计这将成为一个重要的成长要素。自从新冠疫情爆发以来,人们对个人化、更安全的出行选择的需求以及新车客户数量的增加推动了新车需求的持续增长。预计预测期内汽车产业的成长将推动市场发展。

- 印度政府也制定了电动车(EV)政策、印度第六阶段(BSVI)法规和安全政策。汽车产业需要时间来适应这些变化,因此预计市场将暂时放缓。然而,预计在预测期内它将以前所未有的成长率反弹。

- 此类雷射切割设备的本地生产是不断变化的环境中的关键要素之一。印度已有许多机械製造商生产和整合雷射切割机,包括 SIL Pune、SLTL Ahmedabad、Proteck Chennai 和 Delta Automation。另有十几家公司正在製定在地化设备的策略。印度政府透过「印度製造」计画等措施提供的政府补贴和财政援助成为本土生产的主要动力。根据该计划,印度政府向中小微型企业提供高达 80% 的补贴。

- 此外,Intech Additive Solutions Pvt. Ltd(前身为Intech DMLS Pvt. Ltd)宣布,随着新系列金属3D列印机的推出,它将为印度製造业设计、开发和提供真正的「印度製造」技术解决方案。 iFusion 系列金属 3D 列印机基于选择性雷射熔融技术,旨在以高精度、稳定性、可靠性和更快的建造速度提供无与伦比的性能。

- Intech Additive Solutions 是日本金属增材製造领域的领先公司。该公司为印度汽车行业等各个行业提供从概念设计到功能齐全的生产部件的端到端解决方案。

光纤雷射正在快速发展

- 光纤雷射切割机市场是印度成长最快的雷射市场。光纤雷射具有动态工作功率范围,其中光束焦点及其位置随着雷射功率的变化而保持不变。此外,透过改变光学配置可以实现各种光斑尺寸。这些功能可让您选择适当的功率密度来切割不同的金属,例如碳钢、不銹钢和工具钢。

- 用于工业应用的光纤雷射切割机的销量正在迅速增长。主要是中国机械製造商,例如HSG Laser、Bodor Laser和Han's Laser,透过经销商/经销商进行销售,其中包括Laser Technologies Mumbai、Laser Lab Delhi、Han's Laser和Golden Laser等在印度设有办事处的印度企业,以及其他25-30家销售中国切割机的经销商。

- 印度的钢铁工业正在逐步发展,而钢铁是一种利用率很高的金属。需求的成长可能会极大地有利于主要使用光纤雷射切割机的金属成型产业。此外,根据印度焊接学会(IIW)的统计,印度几乎 90% 的钢材是在焊接过程中消耗的。预计预测期内这将进一步增加对雷射焊接设备的需求。根据世界钢铁协会2022年4月发布的资料,印度是全球十大产钢国中唯一2022年1-3月钢产量年增的国家,产量为3,190万吨,成长5.9%。

- 在需要精密微切割的电气和医疗行业中,光纤雷射正在取代化学分层和固体雷射切割。这些变数以及对窄幅板材切割和精加工设备日益增长的需求将推动该行业在研究期间扩张。

- 由于光纤雷射的功能不断增强,预计其使用量在预测期内将持续成长。 2021 年 1 月,OmniGuide 宣布其 OTO-U CO2 雷射系统光纤已获得 FDA 批准并商业化,用于耳鼻喉和耳部手术。这有助于增强可视性、147 微米的小组织目标尺寸,以及使用其他先进的雷射能量系统和灵活的仪器进行机器人手术。

印度雷射产业概况

印度雷射市场高度分散,进入门槛较低,再加上雷射设备製造商收入的不断增加,导致竞争对手之间的竞争非常激烈。竞争策略主要包括设备和技术创新、产品发布、合作等。主要参与者包括AMADA、Coherent Corporation、Alpha Laser、Trumpf Group、Laserline GmbH 等。

2022 年 6 月,Bharat Fritz Werner Group 在印度推出了首款由 Meltio 驱动的雷射定向能量沉积 (L-DED) 机器:Photon 1000H 和 Photon 1000R。

2022 年 4 月,印度领先的 CNC 和工业 4.0 设备和技术公司 Bharat Fritz Werner Ltd (BFW) 和 m2nxt(BFW 的子公司)推出了 PHOTON 4000G 雷射定向能量沉积 (L-DED) 机器,该机器在印度製造并在全球发售。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 市场概况

- 产业吸引力-波特五力分析

- 产业相关人员分析(OEM| 经销商 | 整合商 | 最终使用者组织)

- 市场驱动因素

- 市场集中度和产品可得性的提高有助于降低成本

- 雷射切割相关应用需求旺盛

- 更换现有设施,印度成为主要製造地点之一(受有利政策变化的支持)

- 市场挑战

- 高度依赖海外供应商来满足需求

- 供应问题

- 缺乏技术专业知识与在地生态系统

- 市场机会

- 雷射打标的可能性

- 预期买家槓桿发展

- 积极的成长前景

- 主要行业标准和法规

- COVID-19对印度雷射产业的影响评估

第五章 技术简介

- 印度雷射光电产业的发展

- 按应用程式映射关键机会和使用案例

- 预计采用的主要世界/队列

第六章 市场细分

- 按类型

- Co2雷射

- 光纤雷射

- Nd:YaG激光

- 其他类型

- 按最终用户

- 车

- 铁路

- 建造

- 农业

- 通讯

- 太阳能产业

- 其他最终用户

第七章 竞争格局

- 公司简介

- Trumf Group

- Amada Co. Limited

- Coherent Inc.

- Alpha Laser

- Laserline

- IPG Photonics

- Max Photonics Co. Limited

- Wuhan Raycus Fiber Laser Technologies Co. Limited

- nLight Inc.

第八章投资分析

第九章 未来市场展望

The India Laser Market size is estimated at USD 1.83 billion in 2025, and is expected to reach USD 4.23 billion by 2030, at a CAGR of 18.2% during the forecast period (2025-2030).

The automotive, heavy industrial, electronics, infrastructure, rail, consumer durables, and other sectors are the main drivers of the market.

Key Highlights

- The conventional techniques of welding have established a niche in the manufacturing sector. However, high-tech laser welding advancements operate economically and efficiently in several industrial applications. Some laser welding systems can be further configured to do additional functions such as cutting, drilling, and serializing. Laser welding offers travel speeds that can be five to ten times faster than TIG welding and three to five times faster than MIG welding in various applications.

- According to Laser Technology Pvt. Ltd (LTPL) India, laser marking is the most popular in terms of equipment sales, although laser cutting was the leading revenue contributor in 2021. In India, laser cutting is still the most popular laser application, and it is anticipated to develop for at least another couple of years. The primary cause is a decline in laser machine prices and government intervention in specific sectors, particularly infrastructure and automotive. Most of the machinery, however, is imported from China. The company anticipates the laser cutting industry to have 1.5X growth in the coming years.

- However, regulatory compliances act as restraints for the market. Laser technology provides the application of solid and fiber lasers. These lasers use rare elements such as neodymium, chromium, erbium, and ytterbium, where the processing and refining these rare earth elements may cause potentially hazardous environmental consequences. One of the significant consequences is radioactive pollution caused by slurry tailings.

- The COVID-19 impact on the market is likely to impede the anticipated growth in the studied market. With several manufacturing units observing shutdowns and temporary halts in production, several market players observed a dip in revenues. However, with innovations in product development, the market is expected to grow in the healthcare sector over the forecast period.

- For instance, in July 2022, MaxiVision Eye Hospital released the Technolas Teneo 317 Model 2. A skilled German technical team created a cutting-edge, high-performance excimer laser, the Teneo M2. It offers individualized care for various patients, including astigmatism, hyperopia, myopia, and presbyopia.

India Laser Market Trends

Automotive Sector to Witness Significant Growth

- The market for lasers in India is driven by the automotive sector; thus, job shops for sheet metal cutting. These are mainly located in automotive hubs such as Pune, Bangalore, Chennai, Manesar (near Delhi), and Ahmedabad, which account for more than 80% of the job shop market for metal-cutting lasers. While the machine tool industry is spread throughout India, it is more prevalent in Punjab, Chandigarh, Ludhiana, and Coimbatore. At the same time, lasers for diamond processing are mainly focused in Surat, with more than 10,000 to 12,000 lasers used.

- The automobile sector, which accounts for 49% of India's manufactured GDP and 7.1% of the country's overall GDP, has been slowing for more than a year. However, post-COVID-19 pandemic, it recovered in a V-shape. According to the India Brand Equity Foundation (IBEF), the Indian automobile sector (including component manufacturing) is predicted to reach USD 251.4-282.8 billion by 2026. It is expected to be a significant growth contributor. Because of the need for individualized, safer transportation and the growing number of new automobile customers, the demand for new cars has been continually on the rise since the COVID-19 pandemic. The growth in the automobile sector will drive the market in the forecast period.

- Also, the government is putting in place a policy for electric vehicles (EVs), Bharat Stage VI (BSVI) norms, and safety regulations. It will take some time for the automotive sector to prepare for these changes, and the market is expected to witness a temporary slowdown in this sector. Nevertheless, it is anticipated to revive with unprecedented growth rates in the forecast period.

- Local production of these laser-cutting devices, which is gaining traction, is one crucial part of a changing environment. Many machine makers in India already manufacture/integrate laser cutting machines, including SIL Pune, SLTL Ahmedabad, Proteck Chennai, Delta Automation, and others. A dozen other companies are developing strategies to incorporate the devices locally. Government subsidies and financial aid provide a primary drive for local manufacturing through initiatives like the 'Make In India' scheme of the Government of India. Under the scheme, the Government of India (GoI) provides up to 80% subsidy to MSMEs.

- Further, Intech Additive Solutions Pvt. Ltd (formerly known as Intech DMLS Pvt. Ltd) announced that it designed, developed, and delivered a true 'Made in India' technological solution to the Indian Manufacturing Industry with the launch of its new range of Metal 3D Printers. The iFusion series of Metal 3D Printers, based on Selective Laser Melting technology, is designed for high precision, stability, and reliability and to deliver unmatched performance with higher build rates.

- Intech Additive Solutions has been a spearhead in Metal Additive Manufacturing in the country. It helps to provide end-to-end solutions starting from concept design to fully functional production parts for various industries, including automotive segments in India.

Fiber Lasers to Grow Significantly

- The fiber laser cutting machine market is India's fastest-growing laser market. Fiber lasers have a dynamic operating power range allowing the beam focus and its position to remain constant even when the laser power is changed. In addition, changing the optics configuration can achieve a wide range of spot sizes. These features enable in to choose an appropriate power density for cutting various metals such as carbon steel, stainless steel, and tool steel.

- The number of fiber laser cutting machines sold to industrial applications is rapidly increasing. It is dominated mainly by Chinese machine manufacturers such as HSG Laser, Bodor Laser, Han's Laser, and many others through their distributors/resellers that include Indian players such as Laser Technologies Mumbai, Laser Lab Delhi, and another 25-30 distributors selling Chinese cutting machines, apart from Han's Laser and Golden Laser, which have their own offices in India.

- As India gradually advances in the steel manufacturing sector, steel is among the highly utilized metal. The increase in demand will significantly benefit the metal forming industry, which primarily uses fiber laser cutting machines. Further, according to the Indian Institute of Welding (IIW), almost 90% of steel is consumed in the country through the welding process. This is further anticipated to boost the demand for laser welding equipment in the forecast period. According to data issued by the World Steel Association in April 2022, India is the only country amongst the top 10 producers of steel in the world to have experienced an increase in steel output from January to March 2022 as compared to the same period previously, producing 31.9 million tonnes of steel, an increase of 5.9%.

- In the electrical and medical industries, where precise micro-cutting is required, fiber lasers are substituting chemical stripping and solids phase laser cutting. Due to these variables and the rising demand for narrow sheet cutting and finishing equipment, the industry will expand during the study period.

- With the increasing capabilities of fiber lasers, their usage is expected to continue to grow over the forecasted period. In Jan 2021, OmniGuide announced the FDA clearance and commercial launch of OTO-U CO2 laser system fiber for use in ENT and otology surgery. It helps provide enhanced visibility, a small 147-micron tissue target size, and the use of other advanced laser energy systems and flexible Instruments for robotic surgery.

India Laser Industry Overview

The Indian laser market is fragmented in nature, where barriers to entry of new players are fairly low, coupled with laser equipment manufacturers witnessing an increase in revenue, by which the competitive rivalry in the studied market is increasing significantly. The competitive strategy is majorly comprised of innovations in equipment and technology, product launches, collaboration, and others. Key players include Amada Co. Ltd, Coherent Inc., Alpha Laser, Trumpf Group, and Laserline GmbH.

In June 2022, Bharat Fritz Werner Group introduced the first Laser-Directed Energy Deposition (L-DED) equipment, the Photon 1000H and Photon 1000R, driven by the Meltio in India, with Hybrid and Robotic versions to be made commercially accessible in India.

In April 2022, Bharat Fritz Werner Ltd (BFW) and m2nxt (a BFW subsidiary), India's top CNC and Industry 4.0 equipment and technologies firms, released the PHOTON 4000G Laser-Directed-Energy-Deposition (L-DED) machine, that is made in India and accessible globally.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3 Industry Stakeholder Analysis (OEM| Distributors| Integrators| End-user Organizations)

- 4.4 Market Drivers

- 4.4.1 Growing Market Concentration Coupled with Increased Availability of Products has Played a Role in Cost Decline

- 4.4.2 High Demand for Laser Cutting Related Applications

- 4.4.3 Replacement of Existing Installations and the Emergence of India as One of the Major Manufacturing Destinations (Driven by Favorable Policy Changes)

- 4.5 Market Challenges

- 4.5.1 High Dependence on International Vendors to Address Demand

- 4.5.2 Supply Related Concerns

- 4.5.3 Lack of Technical Expertise and Local Ecosystem

- 4.6 Market Opportunities

- 4.6.1 Potential for Laser Marking

- 4.6.2 Anticipated Developments in Buyer's Leverage

- 4.6.3 Positive Growth Outlook

- 4.7 Key Industry Standards and Regulations

- 4.8 Assessment of the Impact of COVID-19 on the India Laser Industry

5 TECHNOLOGY SNAPSHOT

- 5.1 Evolution of Laser & Photonics Industry in India

- 5.2 Application-wise Mapping of Key Opportunities and Use-cases

- 5.3 Key Global Cues Expected to Find Adoption

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Co2 Laser

- 6.1.2 Fiber Laser

- 6.1.3 Nd YaG Laser

- 6.1.4 Other Types

- 6.2 By End User

- 6.2.1 Automotive

- 6.2.2 Railways

- 6.2.3 Construction

- 6.2.4 Agriculture

- 6.2.5 Communications

- 6.2.6 Solar Industry

- 6.2.7 Other End Users

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Trumf Group

- 7.1.2 Amada Co. Limited

- 7.1.3 Coherent Inc.

- 7.1.4 Alpha Laser

- 7.1.5 Laserline

- 7.1.6 IPG Photonics

- 7.1.7 Max Photonics Co. Limited

- 7.1.8 Wuhan Raycus Fiber Laser Technologies Co. Limited

- 7.1.9 nLight Inc.