|

市场调查报告书

商品编码

1683538

亚太地区工业电脑断层扫描 (CT):市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Asia Pacific Industrial Computed Tomography - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

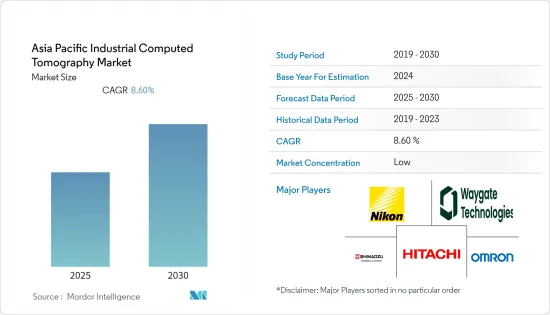

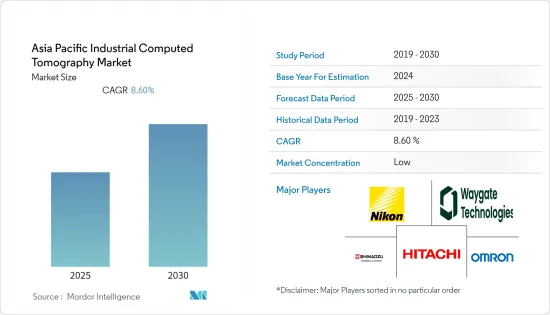

预计预测期内亚太地区工业电脑断层扫描 (CT) 市场复合年增长率将达到 8.6%。

主要亮点

- 新技术的引入,推动了基于3D列印的积层製造技术的飞跃。随着最终用户将 3D 列印融入其製造流程,3D 列印流程已从原型阶段发展到生产阶段。随着积层製造的增加,X射线侦测的需求也随之增加,CT正成为最终用户首选的X射线侦测技术。

- X光电脑断层扫描已被证明是包括汽车工业在内的许多行业必不可少的工具,可确保机器零件、铸造金属、复合材料和塑胶材料等工业零件製造的最高品质。此外,工业CT 扫描仪也用于该地区各种製造和组装作业。

- 该地区的政府也致力于工业 CT 扫描仪的新技术创新。例如,2022年4月,日本政府宣布,计划在国际教育研究中心建设工业产品大型电脑断层扫描(CT)系统进行研发,该中心定于2024年在福岛县全面启用。提案的方法可以拍摄汽车或飞机截面的大尺寸X射线影像,无需拆卸即可重建3D模型。

- 近年来工业CT面临的技术挑战大多与软体有关。目前,CT 走向主流的最大障碍是供应链和大型OEM缺乏确保技术和结果可靠性的要求和标准。

- 该地区受到新冠肺炎疫情、工厂关闭、供应链中断和经济放缓的严重打击。这些方面已经阻碍了当地市场一段时间的成长。然而,在 COVID-19 之后,区域市场的成长可能会受到航太、国防、电子和汽车等各行业中工业 CT 系统在检查和检测目的的使用增加的推动。

亚太地区工业电脑断层扫描 (CT) 市场趋势

该地区汽车产业成长强劲

- 汽车产业整合了一些对品质最为关键的产品,从微型电子感测器到汽车中的全复合零件。大多数公司在设计X射线侦测和CT系统时都会考虑效率和重复性,以确保设备每次都能安全、准确地运作。为了节省时间和成本,汽车製造商选择 CT 机一次性检查涡轮机和活塞引擎等关键零件。

- 随着人口和都市化的发展,该地区每年生产和销售数百万辆汽车。为了保持这种高生产率,整个供应链必须高效,每个合作伙伴都必须按时交付品质和数量的产品。如今,自动化已在全球汽车产业中广泛应用,并采用电脑断层扫描技术来适应机器人生产线,以满足快速、精确和稳健的要求。

- 根据调查,随着我国高铁、大飞机、汽车、火箭、核能等高端装备产业的快速发展,对密钥的高品质保证需求日益增加。这些高端电脑断层扫描的主要特点是尺寸大、品质高、结构复杂、製造技术特殊。

- 如今,许多知名的测试技术被用于汽车领域,以检验製造流程、改善组装、确保可靠性和测量偏差。它们都有其局限性、优点和缺点,而弥补这些缺点的一种新颖的方法是使用X射线CT。它是一种无损检测 (NDT) 技术,可以由工业计量专家、品管或学术研究人员直接或间接执行。在汽车产业,他们可以提升自己的能力。

- 此外, 电脑断层扫描扫描可以让製造商确保在正确的时间输送正确数量的燃料。此外,由于工业电脑断层扫描简化了汽车製造技术,它可能继续成为市场发展的驱动力。然而,扫描仪的前景光明,它必将带来该地区製造业的模式转移。

可携式X 光设备需求不断成长

- 工业射线照相的要求和优势、基本设备的可用性、广泛的工作条件和常用技术包括强伽马辐射源以及该地区用于工业用途的X光设备的日常操作和曝光。

- 如今,高品质的X光影像对于可携式工业X光设备来说已不再是问题。尖端射频技术仅需标准电源连接即可在小尺寸内提供高性能。此外,其轻巧、用户友好的操作以及将X光设备与数位系统结合使用的整合介面使得无损检测行业能够实现广泛的检测方法。

- 此外,许多公司正致力于开发用于各种应用的创新X射线设备。例如,Vision Medicad Equipments Pvt。有限公司提供可携式X射线X光设备可携式X光设备。

- 这些可携式设备使用方便,价格市场领先,有多种型号可供选择,方便移动。该公司的Vision VIXI可携式X射线安全检查设备广泛应用于政府机关、火车站、法院、大使馆等。

- 同样,新加坡的Pacific-Tec公司也提供各种可携式辐射侦测设备,如辐射门式侦测器、辐射检测器、测量仪或盖氏计数器、电子剂量计、笔式剂量计、搜寻仪器、同位素识别器、辐射屏蔽和防护、核子医学校准器和配件、QC测试工具、可携式X射线设备、边境管制装置、饭店安全设备和行李扫描设备。在该地区提供此类设备的公司将进入各种应用市场,包括航太、汽车、石油和天然气。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概况

- 产业相关人员分析

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争强度

- COVID-19 市场影响

第五章 市场动态

- 市场驱动因素

- 可携式X 光设备需求不断成长

- 解析度和影像处理的技术进步

- 市场挑战

- 工业CT系统维护成本高

第六章 市场细分

- 按应用

- 缺陷检测与检验

- 故障分析

- 组装分析

- 其他用途

- 按最终用户产业

- 航太

- 车

- 电子产品

- 石油和天然气

- 其他最终用户产业

第七章 竞争格局

- 公司简介

- Waygate Technologies (Baker Hughes Digital Solutions GmbH)

- Nikon Corporation

- Omron Corporation

- Zeiss International

- Hitachi Ltd.

- Bruker Corporation

- Thermo Fischer Scientific Inc.

- Shimadzu Corporation

- Comet Group Limited

- Shimadzu Corporation

第八章投资分析

第九章:市场的未来

简介目录

Product Code: 92079

The Asia Pacific Industrial Computed Tomography Market is expected to register a CAGR of 8.6% during the forecast period.

Key Highlights

- With the introduction of new technologies, laminated modeling based on 3D printing has dramatically developed. As end-users integrated 3D printing into the manufacturing process, the 3D printing process evolved from the prototype stage to the manufacturing stage. As additive manufacturing increases, the need for radiography increases, and CT is the end user's favorite x-ray inspection technology.

- An increasing number of industries, including automotive, have discovered that X-ray CT scanning is an essential tool for ensuring the highest quality in the production of industrial parts, such as mechanical parts, cast metals and composites, and plastic materials. In addition, industrial CT scanners are used in various region manufacturing processes and assembly operations in the region.

- Governments in the region are also focused on innovating new technologies for industrial computed tomography. For instance, in April 2022, the government of Japan plans to conduct research and development to build a large-scale computer tomography (CT) system for industrial products at the International Education and Research Center, scheduled to be fully opened in Fukushima Prefecture in 2024. The proposed method can take large X-ray images of cross-sections of cars and planes to reproduce 3D models without disassembly.

- Most of the technical challenges of industrial CT over the last few years have been software-related. At this point, the most significant setbacks where CT will become mainstream are supply chains and major OEMs that do not have the requirements and standards that enable confidence in technology and results.

- The region has been hit hard by the COVID-19 pandemic, factory closures, supply chain disruptions, and economic slowdowns. These aspects have hindered the growth of regional markets for some time. However, regional market growth post-COVID-19 is likely due to the increased use of industrial CT systems for testing and inspection purposes in various industries such as aerospace, defense, electronics, and automotive.

APAC Industrial Computed Tomography Market Trends

Automotive to Gain Significant Growth in the Region

- The automotive industry integrates some of the most quality-critical products, from small electronic sensors to fully-compound parts of a vehicle. Most companies have X-ray and CT systems designed with efficiency and reproducibility to ensure that the equipment operates safely and correctly every time. To save time and money, automotive manufacturers choose CT equipment to inspect significant components such as turbines and piston engines in a single pass.

- Every year, millions of cars are manufactured and sold in the region with rising population and urbanization. To maintain this high production rate, the entire supply chain must be efficient, and each subcontractor must provide both quality and quantity on time. Automation is now well implemented worldwide in the automotive industry and is adapting to robotized production lines by using computed tomography as it needs to be fast, accurate, and robust.

- According to a recent study, the rapid development of the high-end equipment industry in high-speed rail, large aircraft, automotive, rockets, and nuclear power in China has increased the demand for high-quality assurance of keys. The main features of these high-end CT scans are large dimensions, high quality, complex structures, and special manufacturing techniques.

- Today, the automotive sector uses many well-known test technologies to verify manufacturing processes, improve assembly, ensure reliability, and measure deviations. They all have limitations, strengths, and weaknesses, and a new and innovative way to complete them is to use XRay CT. It is a non-destructive inspection (NDT) technique that enables industrial measurement professionals, quality managers, or academic researchers to work directly or indirectly. The automotive industry allows them to improve their capabilities.

- Moreover, manufacturers can ensure that the right amount of fuel is delivered at the right time by inspecting the CT scans. Also, industrial CT scans will still drive the market to streamline automotive manufacturing techniques. However, the future of scanners will be bright and bring a paradigm shift to the manufacturing industry in the region.

Rising Demand for Portable Radiography Equipment

- The requirements and benefits of industrial radiography, the availability of critical equipment, a wide range of working conditions, and commonly used techniques involve powerful gamma-ray sources and routine operation and exposure of x-ray equipment used for industrial purposes in the region.

- Today, high-quality x-ray images are no longer a problem for portable industrial x-ray equipment. State-of-the-art high-frequency technology provides high performance in a miniature format with only standard power connections. The lightweight, user-friendly operation and integrated interface for using X-ray equipment in digital systems enable various inspection methods in the NDT industry.

- Further, many companies are focused on developing innovative radiography equipment for various applications. For instance, Vision Medicad Equipments Pvt. Ltd. offers Portable X-ray equipment, including portable X-ray scanners and portable X-ray appliances for welding.

- These portable devices are easy to use and are offered at market-leading prices, and are available in a variety of models that are easy to move around. The company's VisionVIXI portable X-ray security inspection equipment is widely used in government buildings, train stations, courts, and embassies.

- Similarly, Pacific-Tec, Singapore offers a broad spectrum of Portable Radiation Detection Instruments such as Radiation Portal Monitors, Radiation Detectors, Survey Meters or Geiger Counters, Electronic Dosimeters, Pen Dosimeters, Search Instruments, Isotope Identifiers, Radiation Shielding and Protection, Nuclear Medicine Calibrators and accessories, QC test tools or X-ray equipment for Radiology departments or X-Ray Security equipment for border control, embassies, hotel security, and luggage check. Companies offering such equipment in the region will leverage the market in various applications such as aerospace, automotive, oil and gas, and more.

APAC Industrial Computed Tomography Industry Overview

The Asia Pacific computer monitor market is fragmented by the presence of major companies such as Baker Hughes Digital Solutions GmbH, Nikon Corporation, Omron Corporation, and Hitachi Ltd. Key players focus on new product innovation and business growth by collaborating with other market players.

- September 2021 - Shimadzu Corporation has launched its new Xslicer SMX-1010 and Xslicer SMX-1020 microfocus X-ray inspection systems in Japan and other countries. Both X-ray inspection systems are designed for broad market appeal, with a vertical emission X-ray configuration, a 90 kV microfocus X-ray generator, and a high-resolution flat panel detector.

- March 2021 - Nikon Corporation announced the release of a 225kV, microfocus X-ray CT system that is 'XT H 225 ST 2x'. Advanced improvements have been made by the company in its new 'XT H 225 ST 2x'. The product helps both the exterior and interior of a sample to be inspected and measured non-destructively.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definitions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Stakeholder Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Impact of COVID-19 on the market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Rising Demand for Portable Radiography Equipment

- 5.1.2 Technology Advancements in Resolution and Image Processing

- 5.2 Market Challenges

- 5.2.1 High Maintenance Cost of Industrial CT Systems

6 MARKET SEGMENTATION

- 6.1 By Application

- 6.1.1 Flaw Detection and Inspection

- 6.1.2 Failure Analysis

- 6.1.3 Assembly Analysis

- 6.1.4 Other Applications

- 6.2 By End-User Industry

- 6.2.1 Aerospace

- 6.2.2 Automotive

- 6.2.3 Electronics

- 6.2.4 Oil and Gas

- 6.2.5 Other End-User Industries

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1

Waygate Technologies (Baker Hughes Digital Solutions GmbH)

- 7.1.2 Nikon Corporation

- 7.1.3 Omron Corporation

- 7.1.4 Zeiss International

- 7.1.5 Hitachi Ltd.

- 7.1.6 Bruker Corporation

- 7.1.7 Thermo Fischer Scientific Inc.

- 7.1.8 Shimadzu Corporation

- 7.1.9 Comet Group Limited

- 7.1.10 Shimadzu Corporation

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET

02-2729-4219

+886-2-2729-4219