|

市场调查报告书

商品编码

1686593

智慧工厂:市场占有率分析、产业趋势与统计、成长预测(2025-2030)Smart Factory - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

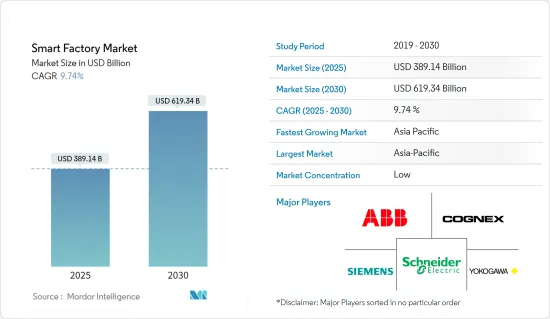

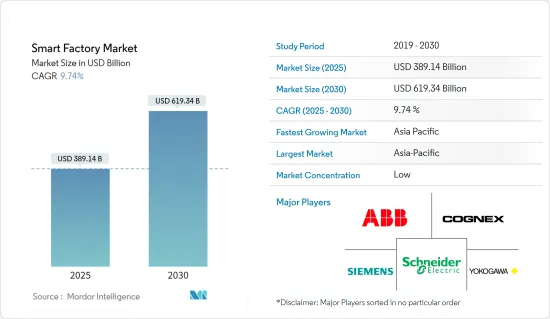

预计2025年智慧工厂市场规模为3,891.4亿美元,到2030年预计将达到6,193.4亿美元,预测期内(2025-2030年)的复合年增长率为9.74%。

主要亮点

- 由于核准工业 4.0 和物联网而导致的製造业重大转变,要求企业必须灵活并采用更具创新性和创造性的方式,利用技术来推动生产,透过自动化补充和增强人力,并减少因工艺故障而导致的工业事故。随着连网设备和感测器的采用率不断提高,促进了 M2M通讯,我们看到製造业开发的资料点呈爆炸式增长。

- 根据 Zebra 的製造业愿景研究,基于物联网和 RFID 的智慧资产追踪解决方案将在 2022 年取代传统的电子表格为基础的方法。根据玛丽维尔大学的计算,到 2025 年,全球预计每年将产生超过 180 兆 GB 的资料。支持 IIoT 的行业可能会产生其中的大部分数据。此外,工业IoT(IIoT) 公司微软公司的一项调查发现,85% 的公司至少有一个正在进行的 IIoT 用例计划。这一数字有所增加,因为大约 95% 的受访者将在 2022 年前製定 IIoT 策略。

- 预计技术进步加上製造设施的持续发展将影响预测期内的市场成长率。例如,英特尔最近与义大利电信和硬体製造商 Exor International 合作开发使用人工智慧 (AI) 和 5G 网路的智慧製造设施。

- 此外,人工智慧和机器学习 (ML) 技术的市场渗透率不断提高,可能会提高资料分析的准确性和速度,从而带来显着的市场进步。此外,现场设备市场、机器人和感测器的进步可能会进一步扩大市场范围。根据思科的预测,到2022年,支援物联网应用的机器对机器(M2M)连线可能占全球285亿台连网装置的50%以上。许多政府也鼓励製造业投资物联网技术来实现智慧工厂。

- 然而,高昂的安装成本对市场成长是一项挑战。此外,需要高技能劳动力来操作和维护自动化基础设施,进一步增加了整体成本,阻碍了大规模采用,特别是在中小型企业中。

- 此外,近期经济不稳定,特别是受美国贸易争端、俄乌战争等地缘政治问题影响,也导致各地商业环境不确定,影响到各地区工业部门的供应链和製成品需求,为市场成长创造了不利的环境。

智慧工厂市场趋势

半导体产业可望推动市场成长

- 半导体製造商依靠智慧製造流程来提高产量比率和利润。透过推进半导体创新并鼓励更多采用先进晶片的创新技术,製造商可以确保生产能够满足工厂日益复杂和互联所带来的日益增长的需求。

- 半导体製造工厂(或称晶圆厂)的建造和维护耗资数十亿美元。这些成本都是在设备上产生的,维护对于设备的持续运作至关重要。透过使用创新製造技术来监控设备健康状况并执行预测性维护,工厂可以显着减少计划外维护时间。

- 全球范围内半导体製造工厂的数量正在增加。半导体行业协会也报告称,新半导体设备的支出增加。这些因素也可能推动半导体产业采用智慧工厂。根据半导体产业协会(SIA)预测,2022年全球半导体销售额将达5,801.3亿美元。半导体是电子设备的关键零件,产业竞争激烈。 2022与前一年同期比较年增率达4.4%。此外,2022 年 3 月欧洲半导体销售额为 46.3 亿美元,略高于上个月的 45.1 亿美元。

- 此外,该地区各国都致力于透过提供税收减免、资金、补贴和其他形式援助的政府政策来鼓励半导体製造业。例如,据政府称,印度半导体产业在 2020 年的价值为 150 亿美元,预计到 2026 年将成长到 630 亿美元(资料来源:电子和资讯技术部)。随着政府对半导体製造和相关产业的干预,印度有望成为全球半导体供应链的主要参与者之一。

- 此外,2022 年 9 月,矿业集团韦丹塔和台湾电子製造巨头富士康进行了有史以来最大的投资之一,投资额为 18.6 亿美元,在古吉拉突邦建立了印度第一家半导体工厂。此类投资可能会在研究市场中产生更大的需求。

- 此外,半导体产业正在不断发展,以满足人工智慧主导的电子设备和自动驾驶汽车和物联网等项目对半导体材料日益增长的需求。汽车导航、安全性和资讯娱乐解决方案中使用的电子元件的消费量不断增加将再次促进半导体产业的成长。

亚太地区市场成长显着

- 亚太地区是研究市场投资的热点。世界各国政府正持续采取倡议加强智慧製造和技术应用。此外,印度政府的国家製造业政策旨在2025年将製造业在GDP中的比重提高到25%。此外,印度政府的「印度製造」计画预计将增加当地製造业对机械和工具的需求和消费。

- 此外,2022 年 1 月,Reliance 向 Addverb Technologies 投资 1.32 亿美元,获得 54% 的股份。预计此类市场投资将推动製造业采用自动化,在预测期内推动智慧工厂市场的发展。

- 中国是亚洲转向智慧应用的重要组成部分。中国政府正加紧智慧製造布局,进行各类规划、标准体系建设示范。中国计画在2025年实现40项製造业创新,重点在于自动化工具机及机器人、高新技术、航太航太装备、船舶装备、现代轨道交通设备、高技术船舶、新能源汽车及设备、电力设备、农业设备、新材料、生物製药及先进医疗产品等领域。

- 此外,2022年1月,自动化专家ABB与中国最重要的汽车零件供应商华域汽车宣布成立合资企业,推动中国汽车产业下一代智慧生产。在两家公司成功伙伴关係的基础上,合资公司将为华域汽车中国业务在灵活、永续的汽车零件製造方面取得重要发展。

- 而且,日本正快速迈向“社会5.0”,开启人类在这个全新超智能社会中发展四大阶段的第五篇章。透过物联网技术,万物互联,各项技术融合,极大改善生活品质。此外,日本政府响应德国政府的“工业4.0”计划,宣布实施“互联工业”,为新一轮製造业革命注入动力。

- 此外,韩国商业和公共部门已同意增加该地区的智慧工厂数量,目标是到 2022 年拥有超过 30,000 家运作的工厂,所有工厂都配备最新的数位和分析技术。韩国贸易、工业和能源部(MOTIE)重申政府愿意帮助中小企业采用和扩展智慧製造技术。中小企业占韩国所有企业的 99% 以上,政府资料显示,中小企业的出口正在成长。

智慧工厂产业概览

智慧工厂市场较为分散,主要企业包括 ABB 有限公司、康耐视公司、西门子股份公司、施耐德电气公司和横河电机公司。市场参与者正在采用创新、伙伴关係、合併和收购等策略来改善其产品供应并获得永续的竞争优势。

2023年3月,工业自动化和能源管理数位转型解决方案供应商施耐德电机在匈牙利破土动工建造新的智慧工厂。该工厂投资额为 4,000 万欧元(4,300 万美元),用地面积25,000平方公尺,僱用员工约 500 人。

2023年3月,领先的消费性电子产品製造商三星电子宣布计画扩大投资,在其位于诺伊达的行动电话製造工厂建立智慧製造能力。该公司还宣布计划扩大在该国的研发设施,以实现具有竞争力的本地製造。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概览

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争激烈程度

- 产业价值链分析

- 评估宏观经济趋势对市场的影响

第五章市场动态

- 市场驱动因素

- 物联网 (IoT) 技术在整个价值链中的应用日益广泛

- 对能源效率的需求不断增加

- 市场限制

- 转型需要庞大资金投入

- 易受网路攻击

第六章市场区隔

- 依产品类型

- 机器视觉系统

- 相机

- 处理器

- 软体

- 外壳

- 影像撷取器

- 整合服务

- 照明

- 工业机器人

- 关节机器人

- 笛卡儿机器人

- 圆柱形机器人

- SCARA机器人

- 并联机器人

- 协作工业机器人

- 控制设备

- 继电器和开关

- 伺服马达和驱动器

- 感应器

- 通讯科技

- 有线

- 无线的

- 其他产品类型

- 机器视觉系统

- 依技术

- 产品生命週期管理 (PLM)

- 人机介面(HMI)

- 企业资源规划(ERP)

- 製造执行系统(MES)

- 分散式控制系统(DCS)

- 监控和资料采集(SCADA)

- 可程式逻辑控制器(PLC)

- 其他技术

- 按最终用户产业

- 车

- 半导体

- 石油和天然气

- 化工和石化

- 製药

- 航太与国防

- 饮食

- 矿业

- 其他的

- 按地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 亚洲

- 中国

- 印度

- 日本

- 澳洲和纽西兰

- 拉丁美洲

- 巴西

- 阿根廷

- 墨西哥

- 中东和非洲

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 南非

- 北美洲

第七章竞争格局

- 公司简介

- ABB Ltd

- Cognex Corporation

- Siemens AG

- Schneider Electric SE

- Yokogawa Electric Corporation

- KUKA AG

- Rockwell Automation Inc.

- Honeywell International Inc.

- Robert Bosch GmbH

- Mitsubishi Electric Corporation

- Fanuc Corporation

- Emerson Electric Co.

- FLIR Systems Inc.(Teledyne Technologies Incorporated)

第八章投资分析

第九章:市场的未来

The Smart Factory Market size is estimated at USD 389.14 billion in 2025, and is expected to reach USD 619.34 billion by 2030, at a CAGR of 9.74% during the forecast period (2025-2030).

Key Highlights

- Tremendous shifts in manufacturing due to Industry 4.0 and the approval of IoT require enterprises to adopt agile, more innovative, and creative ways to advance production with technologies that complement and augment human labor with automation and reduce industrial accidents caused by process failure. With the increased rate of adoption of connected devices and sensors and the fostering of M2M communication, a surge in the data points that are developed in the manufacturing industry is being observed.

- According to Zebra's Manufacturing Vision Study, smart asset-tracking solutions based on IoT and RFID overtook traditional, spreadsheet-based methods in 2022. Maryville University calculates that by 2025, more than 180 trillion gigabytes of data are anticipated to be created worldwide yearly. IIoT-enabled industries will generate a large portion of this. In addition, an Industrial IoT (IIoT) company Microsoft Corporation survey found that 85 percent of companies have at least one IIoT use case project. This number increased, as approx 95 percent of respondents implemented IIoT strategies in 2022.

- Incremental advancement in technology, coupled with a sustained increase in the development of manufacturing facilities, is expected to impact the market growth rate during the forecast period. For instance, Intel has recently partnered with Telecom Italia and hardware manufacturer Exor International to develop a smart manufacturing facility that uses artificial intelligence (AI) and 5G networking.

- Furthermore, the glowing market penetration of AI and machine learning (ML) technologies may enhance the accuracy and speed of data analysis, thereby significantly driving the market forward. Moreover, the advancement in the field devices market, robots, and sensors may further expand the scope of the studied market. According to Cisco projections, by 2022, machine-to-machine (M2M) connections that support IoT applications may have accounted for more than 50 percent of the world's 28.5 billion connected devices. Many governments also motivate manufacturing companies to invest in IoT technologies for smart factory adoption, which creates a favorable outlook for the growth of the studied market.

- However, a high installation cost is the primary factor challenging the market's growth. Additionally, the requirement of a highly skilled workforce to operate and maintain the automation infrastructure further adds to the overall cost, restraining mass adoption, especially in small and medium-scale industries.

- Additionally, the recent economic instability, especially as an outcome of the pandemic and geo-political issues such as the US-China trade dispute and the Russia-Ukraine war, is also challenging the studied market's growth as it has not only led to an uncertain business environment across various regions but are also impacting the supply chain of industrial sectors and demand for manufactured products across various region, leading to an unfavorable environment for the studied market's growth.

Smart Factory Market Trends

Semiconductor Sector is Expected to Drive the Market Growth

- Semiconductor manufacturers rely on smart manufacturing processes to produce higher yields and margins. By advancing semiconductor innovation and encouraging the further implementation of innovative technologies powered by advanced chips, manufacturers can ensure that production keeps pace with rising demand as factories become more complex and connected.

- Semiconductor fabrication plants, or fabs, cost billions of dollars to build and maintain. The cost goes on equipment, the maintenance of which is vital to ongoing operation. By using innovative manufacturing technologies to observe equipment health and execute predictive maintenance, fabs can decrease unplanned maintenance time significantly.

- The semiconductor fabrication plants globally are on the rise. Also, the Semiconductor Industry Association reported increased spending on new semiconductor equipment. These factors will also drive the adoption of smart factories in the semiconductor industry. According to the Semiconductor Industry Association (SIA), in 2022, semiconductor sales reached USD 580.13 billion worldwide. Semiconductors are crucial components of electronic devices, and the industry is highly competitive. The year-on-year growth rate in 2022 reached 4.4 percent. Additionally, semiconductor sales in Europe in March 2022 were USD 4.63 billion, up slightly from last month's figures, which recorded USD 4.51 billion.

- Moreover, various countries in this region are focused on encouraging semiconductor manufacturing through government policies offering tax breaks, money, subsidies, and other forms of assistance. For instance, according to the government, the Indian semiconductor sector was valued at USD 15 billion in 2020 and is anticipated to grow to USD 63 billion by 2026 (Source: Ministry of Electronics & IT). Through governmental intervention in the manufacturing of semiconductors and the peripheral sector, India is expected to become one of the leading countries in global semiconductor supply chains.

- In addition, in September 2022, mining conglomerate Vedanta and Taiwanese electronics manufacturing giant Foxconn made one of the largest ever investments of USD 1,860 million to set up India's first semiconductor plant in Gujarat. Such investment may further create significant demand in the studied Market.

- Besides, the semiconductor industry is growing to accommodate the rising demand for semiconductor materials in AI-driven electronics and programs such as autonomous vehicles and IoT. The growth in the consumption of electronic components utilized in the navigation of automobiles, safety, and infotainment solutions intention again contribute to the semiconductor industry's growth.

Asia-Pacific to Experience Significant Market Growth

- Asia-Pacific significantly invests in the studied Market. Governments continuously take the initiative to enhance smart manufacturing and technology adoptions in various countries. In addition, the National Manufacturing Policy of the Government of India aims to improve the share of manufacturing in GDP to 25 percent by 2025. Also, the "Make in India" policy of the Government of India is anticipated to increase the demand and consumption of machinery and tools by the local manufacturing industry.

- Moreover, in January 2022, Reliance invested USD 132 million in Addverb Technologies to acquire a 54 percent stake. Such investments in the Market are expected to fuel the adoption of automation in the manufacturing industry, thereby fueling the smart factory market during the forecast period.

- China is an integral part of Asia's rising shift to intelligent applications. The Chinese government has strengthened the design of smart manufacturing by implementing various schemes and demonstrations in developing standard systems. China aims to create 40 manufacturing innovations by 2025. The focus areas include automated machine tools and robotics, new advanced information technology, aerospace and aeronautical equipment, marine equipment, modern rail transport equipment, high-tech shipping, new-energy vehicles and equipment, power equipment, agricultural equipment, new materials, biopharma, and advanced medical products.

- Further, in January 2022, ABB, an automation expert, and HASCO, China's most significant automotive components supplier, announced the construction of a joint venture to push China's automotive industry's next generation of smart production. The joint venture will build on the two businesses' successful partnership, resulting in the vital development of highly flexible and sustainable car parts production within HASCO's China operations.

- Furthermore, Japan is rapidly moving toward "Society 5.0", thus introducing the fifth chapter to the four major stages of human development in this new ultra-smart society. All things are connected through IoT technology, and all technologies are getting integrated, dramatically improving the quality of life. Further, the Japanese government announced connected industries in response to the German government's "Industry 4.0" program, and the momentum for a new manufacturing revolution is rising.

- Further, Korea's commercial and public sectors have agreed to boost the number of local smart factories, intending to have more than 30,000 of them working with the newest digital and analytical technology by 2022. Korea's Ministry of Trade, Industry, and Energy (MOTIE) has reaffirmed the government's ambitions to assist small and medium-sized businesses in adopting and expanding smart manufacturing technology. Small and medium-sized firms (SMEs) account for more than 99 percent of all companies in Korea, and government data suggests that SMEs' exports are growing.

Smart Factory Industry Overview

The smart factory market is fragmented, with significant players like ABB Ltd, Cognex Corporation, Siemens AG, Schneider Electric SE, and Yokogawa Electric Corporation. Players in the market are adopting strategies such as innovations, partnerships, mergers, and acquisitions to improve their product offerings and achieve sustainable competitive advantage.

In March 2023, Schneider Electric, a solution provider for the digital transformation of industrial automation and energy management, broke ground on its new smart factory in Hungary. With an expected investment of EUR 40 million (USD 43 million), the new site will span 25,000 m2 with a headcount of about 500 employees.

In March 2023, Samsung Electronics, a leading consumer electronic device manufacturer, announced its plans to increase investment in setting up smart manufacturing capabilities at its mobile phone manufacturing plant in Noida. The company also announced its plans to expand its research and development facility in the country to make production more competitive and localized.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competition

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of Impact of Macroeconomic Trends on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Adoption of Internet of Things (IoT) Technologies Across the Value Chain

- 5.1.2 Rising Demand for Energy Efficiency

- 5.2 Market Restraints

- 5.2.1 Huge Capital Investments for Transformations

- 5.2.2 Vulnerable to Cyberattacks

6 MARKET SEGMENTATION

- 6.1 By Product Type

- 6.1.1 Machine Vision Systems

- 6.1.1.1 Cameras

- 6.1.1.2 Processors

- 6.1.1.3 Software

- 6.1.1.4 Enclosures

- 6.1.1.5 Frame Grabbers

- 6.1.1.6 Integration Services

- 6.1.1.7 Lighting

- 6.1.2 Industrial Robotics

- 6.1.2.1 Articulated Robots

- 6.1.2.2 Cartesian Robots

- 6.1.2.3 Cylindrical Robots

- 6.1.2.4 SCARA Robots

- 6.1.2.5 Parallel Robots

- 6.1.2.6 Collaborative Industry Robots

- 6.1.3 Control Devices

- 6.1.3.1 Relays and Switches

- 6.1.3.2 Servo Motors and Drives

- 6.1.4 Sensors

- 6.1.5 Communication Technologies

- 6.1.5.1 Wired

- 6.1.5.2 Wireless

- 6.1.6 Other Product Types

- 6.1.1 Machine Vision Systems

- 6.2 By Technology

- 6.2.1 Product Lifecycle Management (PLM)

- 6.2.2 Human Machine Interface (HMI)

- 6.2.3 Enterprise Resource and Planning (ERP)

- 6.2.4 Manufacturing Execution System (MES)

- 6.2.5 Distributed Control System (DCS)

- 6.2.6 Supervisory Controller and Data Acquisition (SCADA)

- 6.2.7 Programmable Logic Controller (PLC)

- 6.2.8 Other Technologies

- 6.3 By End-user Industry

- 6.3.1 Automotive

- 6.3.2 Semiconductors

- 6.3.3 Oil and Gas

- 6.3.4 Chemical and Petrochemical

- 6.3.5 Pharmaceutical

- 6.3.6 Aerospace and Defense

- 6.3.7 Food and Beverage

- 6.3.8 Mining

- 6.3.9 Other End-user Industries

- 6.4 By Geography

- 6.4.1 North America

- 6.4.1.1 United States

- 6.4.1.2 Canada

- 6.4.2 Europe

- 6.4.2.1 United Kingdom

- 6.4.2.2 Germany

- 6.4.2.3 France

- 6.4.3 Asia

- 6.4.3.1 China

- 6.4.3.2 India

- 6.4.3.3 Japan

- 6.4.3.4 Australia and New Zealand

- 6.4.4 Latin America

- 6.4.4.1 Brazil

- 6.4.4.2 Argentina

- 6.4.4.3 Mexico

- 6.4.5 Middle East and Africa

- 6.4.5.1 United Arab Emirates

- 6.4.5.2 Saudi Arabia

- 6.4.5.3 South Africa

- 6.4.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 ABB Ltd

- 7.1.2 Cognex Corporation

- 7.1.3 Siemens AG

- 7.1.4 Schneider Electric SE

- 7.1.5 Yokogawa Electric Corporation

- 7.1.6 KUKA AG

- 7.1.7 Rockwell Automation Inc.

- 7.1.8 Honeywell International Inc.

- 7.1.9 Robert Bosch GmbH

- 7.1.10 Mitsubishi Electric Corporation

- 7.1.11 Fanuc Corporation

- 7.1.12 Emerson Electric Co.

- 7.1.13 FLIR Systems Inc. (Teledyne Technologies Incorporated)