|

市场调查报告书

商品编码

1690758

光纤布拉格光栅感测器-市场占有率分析、产业趋势与统计、成长预测(2025-2030)Fiber Bragg Grating Sensor - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

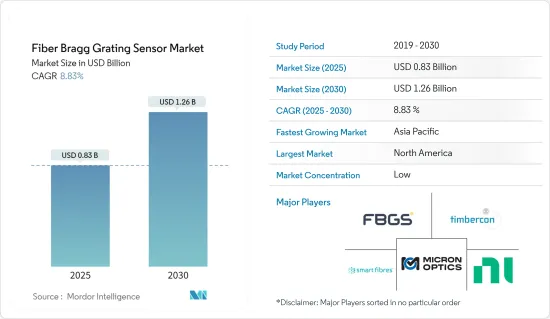

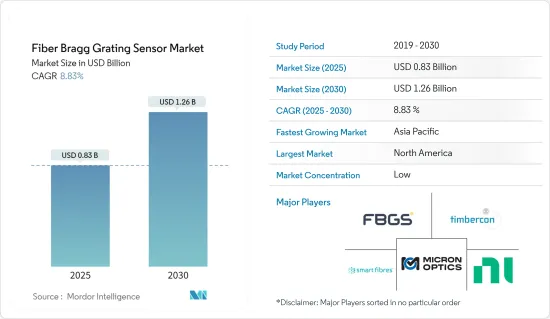

光纤布拉格光栅感测器市场规模预计在 2025 年为 8.3 亿美元,预计到 2030 年将达到 12.6 亿美元,预测期内(2025-2030 年)的复合年增长率为 8.83%。

关键亮点

- 光纤布拉格光栅 (FBG) 技术由于其易于製造、反射讯号强度相对较强以及操作灵活,已成为一种流行的温度和应变测量光纤感测器。

- 光纤布拉格光栅感测器是透过沿着光纤长度週期性地调变光纤芯的屈光而形成的。透过仔细确定结构,可以为光纤添加各种感测功能。输出的波长编码特性透过将每个感测器分配到可用光源频谱的不同波长范围,可以使用分波多工(WDM) 技术。这种能力有利于市场成长,因为校准用于确定物理量和波长之间的对应关係,并且是影响感测器性能的关键因素之一。

- 此外,与其他感测器相比,它们更长的使用寿命也是支持市场成长的主要因素。根据同行评审开放获取科学期刊出版商 Hindawi 称,寿命预测模型显示,在无应力条件下,光纤布拉格光栅 (FBG) 感测器的基本估计监测寿命约为 56 年,而在工作场所受到应力条件下,光纤布拉格光栅 (FBG) 基钢绞线的寿命为 27 年。

- FBG 具有透过单一光纤测量应变、压力和温度等各种参数的固有能力,这增加了其在各个终端用户行业的需求。此外,由大量相对低成本的FBG组成的多点感测阵列具有很高的设计弹性,使其成为各种感测应用的理想设备。

- 光纤布拉格光栅感测器在建筑和航空领域比传统的结构监测设备具有许多优势。然而,某些使用案例的成本和技术限制对采用和成长构成了重大挑战。

- 在受调查的市场中,新冠疫情的影响显而易见。最初,严格的封锁措施使得原材料/零件的供应变得困难,从而扰乱了全球供应链。然而,随着疫情情势恢復正常以及主要终端用户产业进一步扩大业务,预计后疫情时代对这些感测器的需求将会成长。

光纤布拉格光栅感测器市场趋势

航太是 FBG 感测器成长最快的终端用户

- 事实证明,光纤布拉格光栅感测器是需要高精度、遥感探测和轻型感测器的航太应用的理想选择。该技术有多种应用,包括高压感测、地面气动测试设施、衝击压力感测、太空船监测和飞机复合材料的结构健康监测。

- 它们在航太工业的许多应用中也发挥着重要作用,主要是监测飞机机翼和机身疲劳。它也用于製造飞机和空间结构的智慧复合材料。此外,恶劣而复杂的操作环境是航太工业的特点,选择能够承受这种外部环境的极端影响并具有所需准确度、可靠性、精确度和重复性的合适感测器对于行业参与企业来说至关重要。

- 多家飞机製造商已成功应用了这项技术。例如,瑞典航太公司 SAAB 使用一种称为过热检测系统 (OHDS) 的光纤感测器系统即时监控引气管路,以侦测热空气洩漏。据该公司介绍,FBG感测器技术描述了实际的温度测量,具有设定警报阈值、追踪趋势和实现智慧警报功能等特性。

- 此外,预计预测期内飞机製造的成长将推动市场成长。例如,根据日本航空飞机发展公司(JADC)的数据,空中巴士是最大的民航机製造商之一,去年交付了611 架飞机。预计在预测期内它将保持其成长轨迹。波音公司的主要竞争对手去年在全球持有中增加了 340 架喷射机。如此大规模的飞机製造将推动光纤布拉格光栅感测器市场的需求。

- 此外,各地区飞机持有的增加也有望推动航太工业对光纤布拉格光栅感测器市场的需求。例如,根据波音公司预测,到 2041 年,北美地区将以约 10,810 架飞机的数量位居世界最大飞机队之列。

亚太地区预计将创下最快成长

- 预测期内,中国、印度、日本和韩国等新兴经济体的快速工业化将推动亚洲对光纤布拉格光栅感测器的需求。基于光纤布拉格光栅的温度、压力、应变等感测器广泛应用于水处理服务、石油和天然气、采矿和发电等製程控制产业。

- 中国、印度和印尼等国家的政府已采取倡议支持製造业成长,为市场成长创造了进一步的机会。例如,中国于2022年10月宣布了多项措施,以促进外商对製造业的投资。中国政府表示将为外国製造企业进出口提供便利,并在贸易和通关方面提供协助。根据国家统计局数据显示,2022年9月份,中国规模工业增加价值年增6.3%。

- 该地区也是世界最大发电国的所在地,包括日本、印度和中国。例如,印度已于2022年成为世界第三大发电国。 (资料来源:世界人口评论)。根据IBEF预测,到2022财年,印度的发电能力将增加至近400吉瓦。

- 此外,由于光纤布拉格光栅感测器广泛应用于飞机,印度民航业的成长也有望推动市场成长。根据印度品牌资产基金会 (IBEF) 的数据,国内航班约占南亚空中交通的 69%。预计到2023年,印度机场容量将达到每年10亿个航班。印度目前是世界第七大民航市场,预计未来十年内将成为第三大民航市场。

光纤布拉格光栅感知器产业概况

光纤布拉格光栅感测器市场呈现多元化特点,拥有 FBGS International NV、Smart Fibres Ltd、Micron Optics(Luna Innovations)、Timbercon Inc. 和 National Instruments Corporation 等知名参与企业。

2023 年 1 月,Technica Optical Components 成功製造出第一百万个 FBG 感测器,取得了重要的里程碑。该公司提供广泛的 FBG 产品,包括 FBG 感测器、FBG 阵列、电缆和 FBG 封装感测器,使其成为光纤布拉格光栅感测器的领先供应商。

2022 年 12 月,Technica Optical Components 宣布推出一系列基于光纤布拉格光栅的温度感测器,专为在低温环境中运作而设计。这些感测器采用先进的一体式微结构设计,并针对极寒环境下的精确温度测量进行了最佳化。该技术采用高精度、先进的低温额定材料,并将 Technica 製造的 FBG 嵌入光纤芯中,从而形成具有卓越精度、分辨率和可重复性的换能器配置。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概览

- 产业吸引力-波特五力分析

- 新进入者的威胁

- 买家的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争强度

- 产业价值链分析

- COVID-19 对产业的影响

第五章市场动态

- 市场驱动因素

- 飞机上使用率增加

- 内建校准工件并延长使用寿命

- 市场限制

- 热和横向应变敏感性

第六章市场区隔

- 按类型

- 温度感测器

- 应变感测器

- 压力感测器

- 其他的

- 按最终用户产业

- 通讯

- 航太

- 建筑基础设施

- 能源动力

- 矿业

- 其他的

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 其他的

第七章竞争格局

- 公司简介

- FBGS International NV

- Smart Fibres Ltd

- Micron Optics(Luna Innovations)

- Timbercon Inc.

- National Instruments Corporation

- HBM Inc.(An HBK Company)

- Broptics Technology Inc.

- ITF Technologies

- Advanced Optics Solutions(AOS)GmbH

- Technica Optical Components LLC

第八章投资分析

第九章 市场机会与未来趋势

The Fiber Bragg Grating Sensor Market size is estimated at USD 0.83 billion in 2025, and is expected to reach USD 1.26 billion by 2030, at a CAGR of 8.83% during the forecast period (2025-2030).

Key Highlights

- Fiber Bragg grating (FBG) technology is becoming a popular choice for optical fiber sensors for temperature or strain measurements because of their simple manufacture, relatively strong reflected signal strength, and operational flexibilities.

- A periodic modulation of the refractive index of the fiber core along the longitudinal direction forms fiber Bragg grating sensors. Various sensing functionalities can be added to the optical fiber by carefully determining the structure. The wavelength-encoded nature of the output allows the use of the wavelength division multiplexing (WDM) technique by assigning each sensor to a different wavelength range of the available light source spectrum. As calibration is used to determine the mapping relationship between the physical quantity and wavelength and is one of the critical factors affecting the sensor's performance, such a feature favors the market's growth.

- Furthermore, a longer lifetime than other sensors is another major factor supporting the market's growth. According to Hindawi, a publisher of peer-reviewed, open-access scientific journals, the life-prediction model indicates that the estimated monitoring life of an FBG sensor in an unstressed condition is about 56 and 27 years under the stressful situations that fiber Bragg grating (FBG)-based steel strands are subjected to in their working environment.

- Owing to their intrinsic capability to measure a variety of parameters, such as strain, pressure, temperature, and many others, along a single fiber, their demand has been increasing across various end-user industries. Additionally, these multi-point sensing arrays of many relatively low-cost FBGs also provide great flexibility of design, making them ideal devices to be adopted for a multitude of different sensing applications.

- Fiber Bragg grating sensors have many advantages over traditional and structural monitoring devices in the building and aviation sectors. However, cost and technological limitations in some use cases are among the significant factors challenging their widespread adoption and growth.

- A notable impact of the COVID-19 pandemic was observed in the market studied. During the initial phase, the manufacturers faced difficulties in securing the supply of raw materials/components due to stringent lockdown measures, which disrupted the supply chain globally. However, with the condition normalizing and major end-user industries expanding their operations further, the demand for these sensors is expected to grow during the post-COVID period.

Fiber Bragg Grating Sensor Market Trends

Aerospace to be Among the Fastest Growing End User for FBG Sensors

- Fiber Bragg grating sensors have proven ideal options in aerospace engineering-related applications requiring high precision, remote sensing, and lightweight sensors. This technology is used in a variety of applications, including high-pressure sensing, ground-based aerodynamic test facilities, shock pressure sensing, spacecraft monitoring, and structural health monitoring of aircraft composites.

- It also has significant uses in the aerospace industry, mainly for airplane wing monitoring, fuselage fatigue, and many others. Also, they have been used in smart composite manufacturing for aircraft and space structures. Furthermore, a harsh and complex operating environment characterizes the aerospace industry, and choosing a suitable sensor to withstand such external environment extremities and perform at the desired accuracy, reliability, precision, and repeatability is of prime importance for the players in the industry.

- Several aircraft-making companies are successfully using this technology. For instance, SAAB, a Swedish aerospace company, uses a Fiber Optic Sensor System Overheat Detection System (OHDS) for real-time monitoring of bleed air piping to detect hot air leakage. According to the company, FBG sensor technology provides actual temperature measurements with the ability to set alarm thresholds, trace trends, and introduce smart alarm functions.

- Furthermore, a rise in aircraft construction is expected to bolster the market's growth during the forecast period. For instance, according to Japan Aircraft Development Corporation (JADC), Airbus is one of the largest commercial aircraft manufacturers, delivering 611 jets last year. It is expected to maintain its growth trajectory during the forecast period. Boeing's main competitor added 340 jets to the global aircraft fleet last year. Such massive aircraft manufacturing will drive the demand for the Fiber Bragg Grating sensor market.

- The growing aircraft fleet size across various regions is also anticipated to drive the demand for the fiber Bragg grating sensors market in the aerospace industry. For instance, according to Boeing, the North American region is anticipated to lead the charts of the largest aircraft fleets in the world, with about 10,810 aircraft in its fleet by 2041.

Asia Pacific is Expected to Register Fastest Growth

- The demand for fiber Bragg grating sensors in Asia will increase over the forecast period due to rapid industrialization in emerging countries, such as China, India, Japan, and South Korea. Fiber Bragg grating-based sensors, such as temperature, pressure, strain, and others, are widely used in process control industries such as water treatment and services, oil and gas, mining, and power generation.

- The governments in countries such as China, India, and Indonesia, among others, are taking the initiative to support the manufacturing industry's growth, further creating growth opportunities for the market. For instance, in October 2022, China announced several measures to enable foreign investment in the manufacturing industry. The Chinese government stated that it would facilitate imports and exports of foreign-invested manufacturing firms and provide assistance regarding trade and customs clearance. According to the National Bureau of Statistics, China's industrial output increased by 6.3% year-on-year in September 2022.

- The region is also home to some of the largest power-generating countries in the world, like Japan, India, and China. For instance, India emerged as the third-largest electricity-generating country in the world in 2022. (Source: World Population Review). As per IBEF, in the financial year 2022, India's power generation capacity rose to nearly 400 gigawatts.

- Furthermore, the growing civil aviation industry in India will also fuel the market growth as fiber Bragg grating sensors are widely used in aircraft. According to the India Brand Equity Foundation (IBEF), domestic traffic contributes around 69% of the total airline traffic in South Asia. India's airport capacity is expected to handle 1 billion trips annually in 2023. India is currently the 7th largest civil aviation market in the world and is expected to become the third-largest civil aviation market within the next 10 years.

Fiber Bragg Grating Sensor Industry Overview

The Fiber Bragg grating sensor market is characterized by a diverse landscape, featuring prominent players such as FBGS International NV, Smart Fibres Ltd, Micron Optics (Luna Innovations), Timbercon Inc., and National Instruments Corporation. Market participants are strategically employing tactics like partnerships and acquisitions to bolster their product portfolios and establish a sustainable competitive edge.

In January 2023, Technica Optical Components marked a significant achievement by successfully manufacturing their one millionth FBG sensor. The company offers an extensive range of FBG products, encompassing FBG sensors, FBG arrays and cables, as well as FBG packaged sensors, positioning the company as a leading provider of fiber Bragg grating sensors.

In December 2022, Technica Optical Components introduced a new line of Fiber Bragg Grating-based Temperature Sensors engineered for operation in cryogenic environments. These sensors feature an advanced unibody micro-structured design, specifically optimized for precise temperature measurements in ultra-low temperature settings. The technology leverages high-precision, advanced cryogenic-rated materials and incorporates Technica-manufactured FBGs within the fiber cores to deliver a transducer configuration characterized by exceptional precision, resolution, and repeatability.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Threat of New Entrants

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Bargaining Power of Suppliers

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Impact of COVID-19 on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Usage in the Aircraft

- 5.1.2 Built-in Calibration Artifacts and Longer Lifetime

- 5.2 Market Restraints

- 5.2.1 Thermal and Transverse Strain Sensitivity

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Temperature Sensor

- 6.1.2 Strain Sensor

- 6.1.3 Pressure Sensor

- 6.1.4 Other Types

- 6.2 By End-user Industry

- 6.2.1 Telecommunication

- 6.2.2 Aerospace

- 6.2.3 Construction and Infrastructure

- 6.2.4 Energy and Power

- 6.2.5 Mining

- 6.2.6 Other End-user Industries

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia-Pacific

- 6.3.4 Rest of the World

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 FBGS International NV

- 7.1.2 Smart Fibres Ltd

- 7.1.3 Micron Optics (Luna Innovations)

- 7.1.4 Timbercon Inc.

- 7.1.5 National Instruments Corporation

- 7.1.6 HBM Inc. (An HBK Company)

- 7.1.7 Broptics Technology Inc.

- 7.1.8 ITF Technologies

- 7.1.9 Advanced Optics Solutions (AOS) GmbH

- 7.1.10 Technica Optical Components LLC