|

市场调查报告书

商品编码

1690833

欧洲收缩和弹力套筒标籤:市场占有率分析、行业趋势和成长预测(2025-2030)Europe Shrink and Stretch Sleeve Label - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

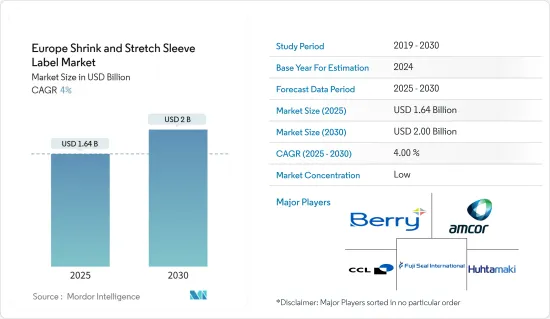

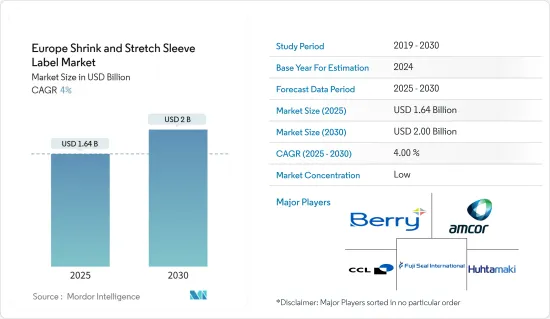

预计 2025 年欧洲收缩和弹力套筒标籤市场规模将达到 16.4 亿美元,预计 2030 年将达到 20 亿美元,预测期内(2025-2030 年)的复合年增长率为 4%。

COVID-19 疫情爆发及由此导致的停工影响了全部区域的工业活动。然而,2020 年前四个月造成的中断预计将导致订单延迟,并且到 2021 年第二季整个套筒标籤供应链的前置作业时间增加。

由于原料供应商效率低下,疫情也为套筒标籤製造商带来了短期供应压力。由于许多国家停工,许多欧洲包装公司无法实现全部生产能力。

关键亮点

- 货架上的产品展示对推动销售起着至关重要的作用,尤其是在零售店和超级市场。此外,包装 3D 建模技术的出现简化了印前流程,使转换器能够在送去印刷之前为品牌模拟成品包装的外观。

- 此外,收缩套筒标籤从上到下覆盖容器,并透过在同一标籤上加入易开或保证密封来防止内容物被篡改,从而为产品公司提供更高的安全性。

- 例如,Brown-Forman Beverages 使用 Eastman Embrace LV 共聚酯製作收缩膜标籤,该标籤覆盖了英国推出的限量版包装 Southern Comfort 的整个 700 毫升瓶子。收缩标籤覆盖瓶颈和瓶盖,起到防篡改密封的作用,给人一种包装好的礼物的感觉。

- PVC 或 PETG 基收缩标籤的密度比水大。这会污染再生 PET 流并劣化再生 PET (rPET) 产品的品质。这导致人们加强开发新的聚烯薄膜结构,这种薄膜在清洗过程中可以漂浮,使标籤和瓶子材料分离。

- 欧盟将于2021年禁止一次性塑胶製品。成员国必须达成2025年宝特瓶回收率达到77%,到2029年达到90%的目标。此外,到2025年宝特瓶必须至少使用25%的再生材料,到2030年必须至少使用30%的再生材料。监管规范的这种动态变化,尤其是塑胶禁令,预计将对该地区的收缩和弹力套筒标籤市场产生负面影响。

欧洲收缩和弹力套筒标籤市场趋势

PE 领域显着成长

- 聚乙烯是最受欢迎的收缩和拉伸包装材料,因为它相对便宜,可以生产出各种密度,并且可以透过添加剂改质以提供多种功能。大部分收缩膜都是LDPE,更复杂的薄膜也会混合LLDPE。也可以添加少量 HDPE。

- 大多数市场相关人员都在推出新标籤,提供多种永续解决方案供选择。例如,2020 年 5 月,芬欧蓝泰标籤推出了 UPM Raflatac Forest Film PE,以补充其永续薄膜标籤解决方案系列。新型 PE 薄膜标籤推动了芬欧蓝泰标籤对超越化石能源的智慧未来的探索,减少了居家医疗和个人护理标籤应用中原始化石基原材料的使用。

- 此外,聚乙烯薄膜製造商和回收商 Barbier Group 全力致力于向更永续的模式转型。透过在生产过程中使用再生聚合物,Barbier 集团减少了原生塑胶(石化燃料)的消费量并减少了其碳排放。每吨再生塑胶取代一吨石油基材料就相当于减少三吨碳排放。

- 然而,PE成长放缓也减缓了新产能的推出。 2020 年计画总合运作710 万吨 PE,其中 270 万吨预计将延后至 2021 年(资料来源:欧盟委员会)。

饮料占很大市场占有率

- 套式标籤在饮料终端用户领域的使用持续成长。这主要是由于消费者认可度的竞争日益激烈。

- 使用宝特瓶和铝罐来包装饮料产品的趋势日益明显。越来越多的人开始在铝罐上使用收缩套标来代替直接印刷。封套上列出了品牌数量和版本灵活性。永续性、货架影响力、功能性和数位印刷预计将在未来几年推动饮料行业标籤使用的创新。

- 为了应对永续性问题,许多公司正在推出采用新材料形式的封套。 Sliver International 最近推出了一款新产品 LDPET,用于更好地回收废弃宝特瓶。

- 2021 年 2 月,CCL Label 推出了其永续拉伸套标「Eco 拉伸」。使用后, 拉伸会在该公司位于奥地利的工厂进行回收,并在完全封闭式的生产循环中返回製造流程。该回收设施将位于 CCL 位于奥地利的 Voelkermarkt 工厂。该工厂是拉伸和收缩套管的生产中心,主要针对乳製品、饮料和居家医疗产业。

- 此外,根据欧洲饮料协会联盟(UNESDA)的数据,2019年,欧盟成员国公民平均每年消费约94.7公升软性饮料。在英国等主要已开发国家,软性饮料消费量远高于欧盟平均。 2010年,欧盟人均非酒精饮料消费量为238.2公升,到2019年将上升至243.9公升。这样的案例可能会带来显着的市场成长。

欧洲收缩和弹力套筒标籤行业概况

欧洲收缩和弹力套筒标籤市场适度细分。创新可改善端到端客户体验并简化部署和使用,是市场参与企业产品创新和策略的关键驱动力。市场参与企业采取了强有力的竞争策略,如产品开发、投资和收购,以维持其在市场中的地位。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概览

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买家/消费者的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争强度

- 产业生态系统分析

第五章市场动态

- 市场驱动因素

- 提高各类产品货架吸引力的需求

- 需要防篡改

- 市场限制

- 由于环境问题日益严重,监管标准不断变化

- COVID-19 市场影响

第六章市场区隔

- 按类型

- 热缩套管

- 拉伸套

- 其他的

- 按材质

- PVC

- PET-G

- PE

- PP

- 其他的

- 按应用

- 饮料

- 食物

- 个人护理

- 其他的

- 按国家

- 德国

- 法国

- 英国

- 义大利

- 俄罗斯

- 波兰

- 荷兰

- 西班牙

- 其他欧洲国家

第七章竞争格局

- 公司简介

- Berry Global Inc.

- CCL Industries Inc.

- Klockner Pentaplast Group

- Fuji Seal International Inc.

- Huhtamaki OYJ

- The Dow Chemical Company

- Amcor PLC

- Clondalkin Group Holdings BV

- Westrock Company

- Decomatic SA

- Oerlemans Plastics

- Maca SRL

第八章 主要机械供应商

第九章投资分析

第十章:投资分析市场的未来

The Europe Shrink and Stretch Sleeve Label Market size is estimated at USD 1.64 billion in 2025, and is expected to reach USD 2.00 billion by 2030, at a CAGR of 4% during the forecast period (2025-2030).

The COVID-19 pandemic and the consequent lockdowns have affected industrial activities across the region. However, the disruptions caused in the first four months of 2020 were expected to result in order delays and increased lead times across the sleeve label supply chain until the second quarter of 2021.

The pandemic has also created a short-term supply pressure on sleeve label players, as raw material suppliers have been functioning at lowered efficiencies. Most packaging companies in Europe were not able to manage full production capacities due to lockdowns in many countries.

Key Highlights

- The shelf appeal of a product plays a crucial role in driving its sales, especially in retail stores, and supermarkets. Moreover, with the advent of the 3D modeling technology for packaging, the streamlining of the pre-press process becomes simpler and allows the converter to simulate the appearance of the finished product packaging to brands before they hit the press.

- Further, shrink sleeve labels offer added security and safety for product companies as they cover the container from top to bottom, and incorporate an easy open or guarantee seal on the same label, thereby protecting the contents from being tampered with.

- For example, Brown-Forman Beverages used the Eastman Embrace LV copolyester for shrink film labels, covering the entire 70 cl bottle of Southern Comfort liquor for a limited edition package, which was launched in the United Kingdom. The shrink label includes the neck and cap, acting as a tamper-evident seal and giving the impression of a wrapped gift.

- Shrink-sleeve labels that are either PVC-based or PETG-based have a density higher than water. Hence, they contaminate the recycled PET stream and deteriorate the quality of recycled PET (rPET) products. This has led to increased efforts for developing new polyolefin film structures that float during washing to enable the separation of the label and bottle materials.

- The European Union banned single-use plastic items in 2021. The member states need to achieve a 77% collection target for plastic bottles by 2025 and 90% by 2029. Also, the law requires plastic bottles to contain at least 25% recycled content by 2025 and 30% recycled content by 2030. Such dynamic changes in regulatory standards, especially the ban on plastic, are expected to have an adverse effect on the shrink and stretch sleeve label market in the region.

Europe Shrink and Stretch Sleeve Label Market Trends

PE Segment to Witness Significant Growth

- Polyethylene is the most commonly used material for shrink and stretch wrapping because it is relatively cheap, and can be produced in a wide range of different densities and modified with additives to perform many functions. The vast majority of shrink film is LDPE, and some of the more sophisticated films have blends of LLDPE as well. Sometimes, a small quantity of HDPE material is also added.

- Most market players are launching new labels that offer a wide variety of sustainable solutions to choose from. For instance, in May 2020, UPM Raflatac launched UPM Raflatac Forest Film PE to complement its range of sustainable film labeling solutions. The new PE film label takes UPM Raflatac forward in its quest for a smarter future beyond fossils, decreasing the use of fossil-based virgin raw materials in home and personal care labeling applications.

- Furthermore, Barbier Group, a producer of polyethylene films and recyclers, is fully committed to transition to a more sustainable model. Using recycled polymers in its production process, Barbier Group reduces its carbon impact by reducing its consumption of virgin plastic (fossil fuels). One ton of recycled plastics, when replacing one ton of material from oil, corresponds to a savings of three tons of carbon.

- However, with the decline in the growth of PE, there is a delay in new capacity start-ups. A total of 7.1 million tons of PE were due on stream in the 2020 year, but 2.7 million tons of this was expected to be shifted to 2021 (source: European Commission).

Beverages to Occupy Significant Market Share

- The use of sleeve-format labels has been growing continuously in the beverage end-user segment. This is primarily driven by the growing competition for consumer acceptance.

- There is a growing trend of use of plastic bottles and aluminum cans for beverage products. Aluminum cans are increasingly using shrink sleeves, replacing direct printing. Sleeves provide the brand volume and versioning flexibility. Sustainability, shelf impact, functionality, and digital printing are expected to drive innovation in the use of labels in the beverage industry in the future.

- In order to address sustainability concerns, many companies are launching sleeves in new material formats. Sleever International recently launched the LDPET, a new product for the better recovery of used PET bottles.

- In February 2021, CCL Label launched EcoStretch, a sustainable stretch sleeve option, which, after use, would be recycled at the company's facility in Austria and returned to the manufacturing process in an entirely closed production loop. The recycling facility would be located at CCL's Voelkermarkt site in Austria, a hub for the production of stretch and shrink sleeves mainly produced for the dairy, beverage, and home care industries.

- Further, according to the Union of European Beverages Associations (UNESDA), in 2019, the average citizen of an EU member state consumed about 94.7 liters of soft drinks annually. Leading industrialized countries, such as the United Kingdom, see a much higher consumption of soft drinks than the EU average. In 2010, 238.2 liters of non-alcoholic drinks were consumed per person in the European Union, which increased to 243.9 liters per person by 2019. Such instances may lead to substantial market growth.

Europe Shrink and Stretch Sleeve Label Industry Overview

The European shrink and stretch sleeve label market is moderately fragmented. Innovation and ease in deployment and usage, which leads to increased end-to-end customer satisfaction, have been the key factors driving the product innovation and strategies among the market players. The market players are are adopting powerful competitive strategies, such as product development, investments, and acquisitions, to remain relevant in the market.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers/Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Ecosystem Analysis

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Demand to Increase On-shelf Appeal of Various Products

- 5.1.2 Need for Tamper-evident Protection

- 5.2 Market Restraints

- 5.2.1 Changes in Regulatory Standards due to Increasing Environmental Concerns

- 5.3 Impact of COVID -19 on the Market

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Heat Shrink Sleeve

- 6.1.2 Stretch Sleeve

- 6.1.3 Other Types

- 6.2 By Material

- 6.2.1 PVC

- 6.2.2 PET-G

- 6.2.3 PE

- 6.2.4 PP

- 6.2.5 Other Materials

- 6.3 By Application

- 6.3.1 Beverage

- 6.3.2 Food

- 6.3.3 Personal Care

- 6.3.4 Other Applications

- 6.4 By Country

- 6.4.1 Germany

- 6.4.2 France

- 6.4.3 United Kingdom

- 6.4.4 Italy

- 6.4.5 Russia

- 6.4.6 Poland

- 6.4.7 Netherlands

- 6.4.8 Spain

- 6.4.9 Rest of Europe

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Berry Global Inc.

- 7.1.2 CCL Industries Inc.

- 7.1.3 Klockner Pentaplast Group

- 7.1.4 Fuji Seal International Inc.

- 7.1.5 Huhtamaki OYJ

- 7.1.6 The Dow Chemical Company

- 7.1.7 Amcor PLC

- 7.1.8 Clondalkin Group Holdings BV

- 7.1.9 Westrock Company

- 7.1.10 Decomatic SA

- 7.1.11 Oerlemans Plastics

- 7.1.12 Maca SRL